Mayonnaise is one of the most consumed condiments worldwide, with the global market expected to reach $16.51 billion by 2030. Yet, its shelf life remains a constant concern for both producers and consumers. Factors such as ingredients, processing equipment, packaging, and storage conditions all influence how long mayo stays safe and appetizing. Understanding these variables is key to balancing quality and safety.

In this article, we’ll break down the main factors that affect the shelf life of mayonnaise, including differences between unopened, opened, and homemade jars. You’ll also learn how raw materials, packaging, machines, temperature, and air exposure all play a role, along with clear signs of spoilage that consumers and manufacturers should watch for.

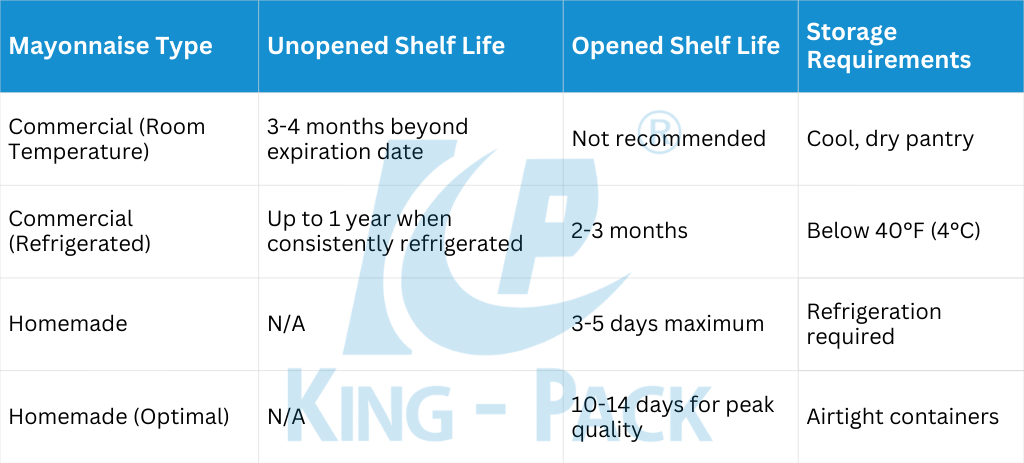

Detailed Breakdown of Shelf Life of Mayonnaise in Different Conditions

Differences Between Unopened, Opened, and Homemade Mayonnaise

Commercial mayonnaise exhibits dramatically different shelf life characteristics depending on its state and production method. Homemade mayonnaise lasts 1–2 weeks when refrigerated, while commercial varieties can last 6–12 months unopened and 2–3 months when refrigerated after opening.

The pasteurization process and preservatives in commercial products create this significant difference in longevity. Modern specialist mixers and technological advancements allow mayonnaise to achieve shelf lives of 9 to 12 months, especially when adding preservatives to high-fat varieties using specialized equipment.

Homemade versions lack these preservation advantages, making them more susceptible to bacterial growth and emulsion breakdown over shorter periods. Understanding specific timeframes helps consumers make informed storage decisions and reduces food waste while maintaining safety standards.

The following table shows main differences between unopened, opened, and homemade mayonnaise:

Opened mayonnaise can last 1 to 2 months at room temperature (68°F to 72°F), but refrigeration is crucial to slow down the spoilage process. This extended room temperature tolerance applies only to commercial products with proper preservatives.

Recommended Reading: How Are Ketchup Packets Made – King Pack Machinery

Factors Affecting Mayonnaise’s Shelf Life

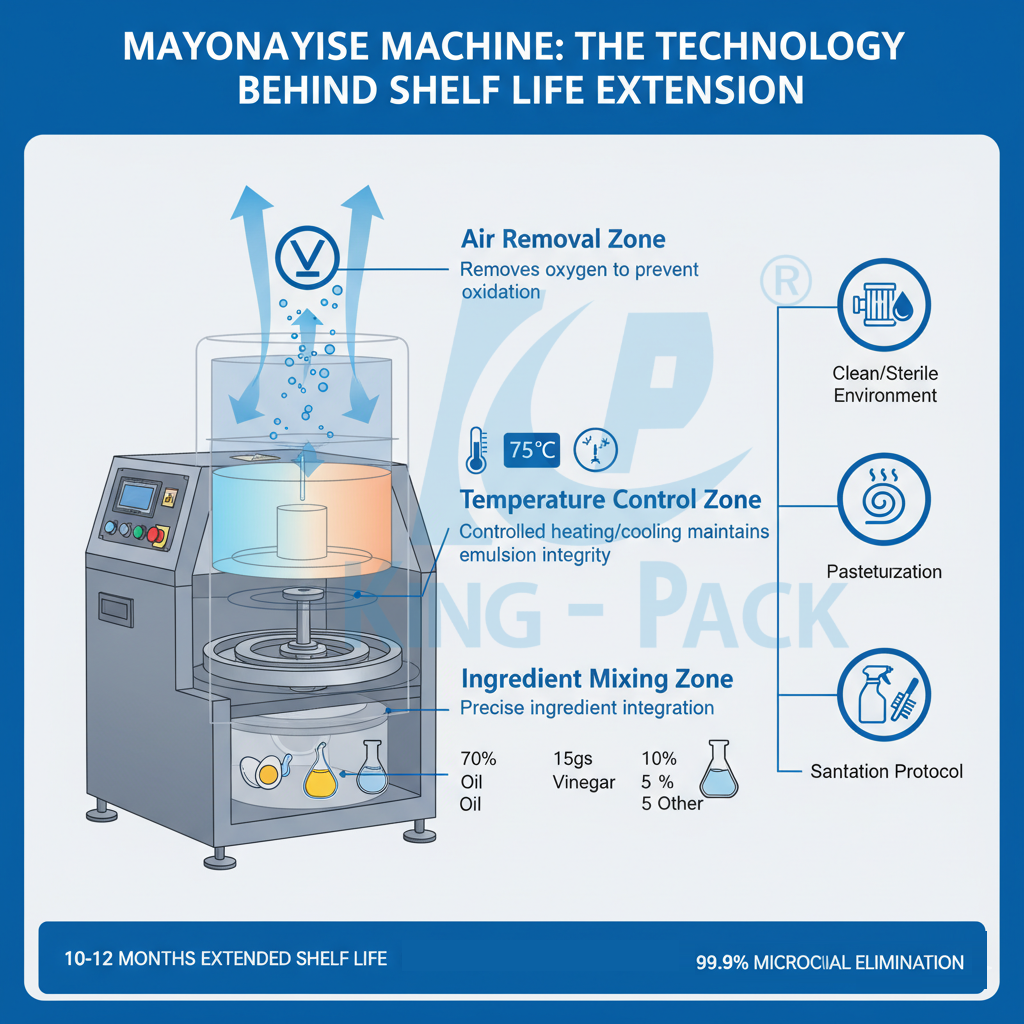

Factor 1: Mayonnaise Machine

Modern production equipment plays a crucial role in extending mayonnaise shelf life through precise control of manufacturing conditions. Vacuum Homogenizers and Emulsifying Mixers remove air that could accelerate oxidation and spoilage while creating stable emulsions that resist separation over time. Using stainless steel 304 construction ensures hygienic contact surfaces and supports compliance with GMP requirements and CE GMP ISO9001 standards.

Specialist Mayonnaise Makers and liquid paste filling machines enable production of mayonnaise with fat content ranging from 10% to higher levels. Integrated piston fillers or plunger pumps allow precise dosing of ingredients, including preservatives, which supports consistent product quality and longevity. This technological precision directly impacts emulsion stability, texture, and flavor retention.

Horizontal packing machines and high-speed capping machines complete the process, sealing jars and bottles to minimize air exposure. Combined with controlled pasteurization and cooling cycles, these systems maintain microbial safety and protect emulsion integrity, ensuring extended shelf life for commercial mayonnaise production.

King Pack’s vacuum emulsifier machines incorporate advanced temperature control and mixing precision that supports optimal shelf life by creating stable emulsions with minimal air incorporation.

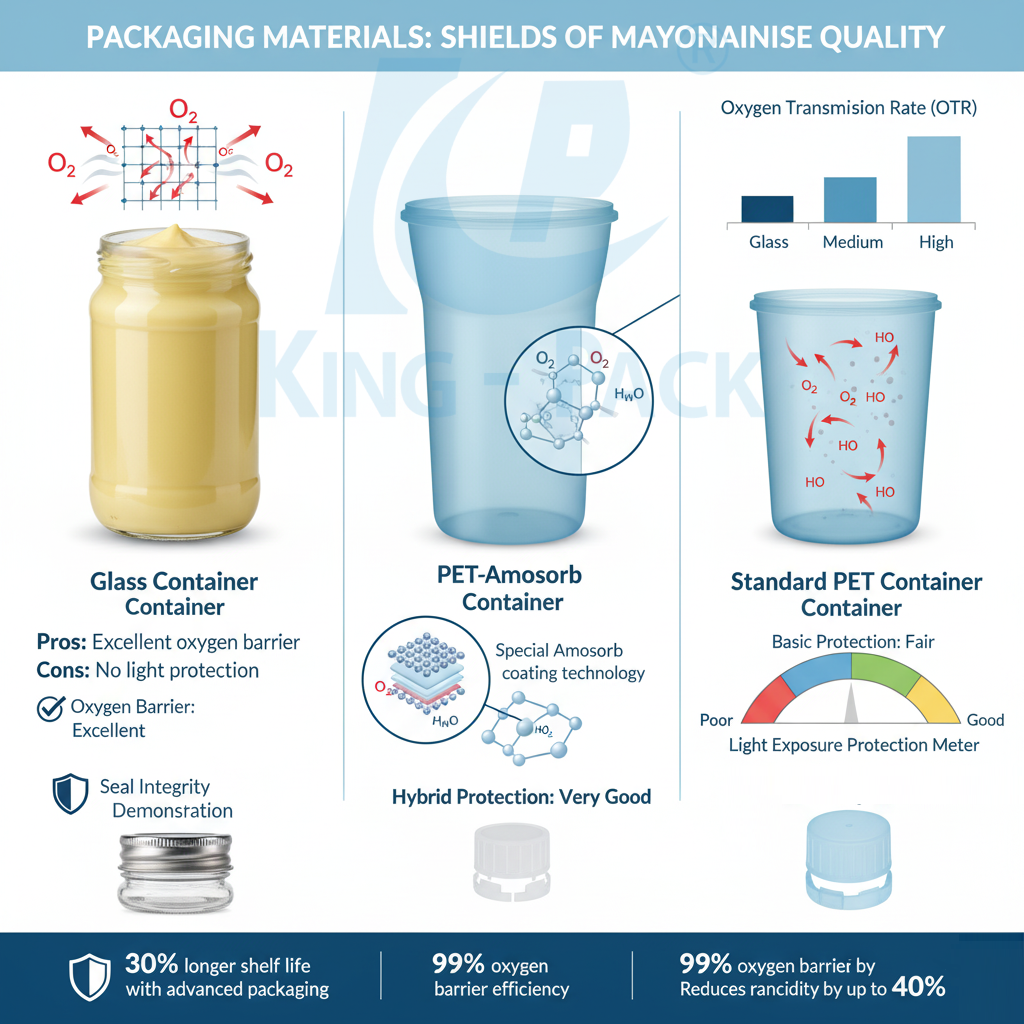

Factor 2: Packaging Material

Packaging material selection significantly influences mayonnaise shelf life through barrier properties that protect against oxygen, light, and moisture infiltration. Using Mayonnaise Pouch Packing Machines or airless package systems can further reduce oxygen exposure, preserving emulsion stability and flavor. Research comparing packaging materials shows that glass and PET-Amosorb containers provide superior oxidative stability compared to standard PET coatings.

Glass containers offer the best protection against oxygen transmission and maintain product quality longest. However, they provide no protection against light exposure, which can accelerate oxidation and flavor degradation in oil-based products.

Plastic containers with oxygen-absorbing properties or specialized barrier coatings extend shelf life by reducing oxygen exposure that causes rancidity. The seal integrity of container closures prevents contamination and maintains the sterile environment needed for extended storage.

The following table shows packaging material comparison:

| Material Type | Oxygen Barrier | Light Protection | Shelf Life Impact | Cost Factor |

| Glass | Excellent | Poor | Best stability | Moderate |

| PET with Amosorb | Very Good | Good | Extended stability | Higher |

| Standard PET | Fair | Good | Moderate stability | Lower |

| Aluminum tubes | Excellent | Excellent | Maximum protection | Highest |

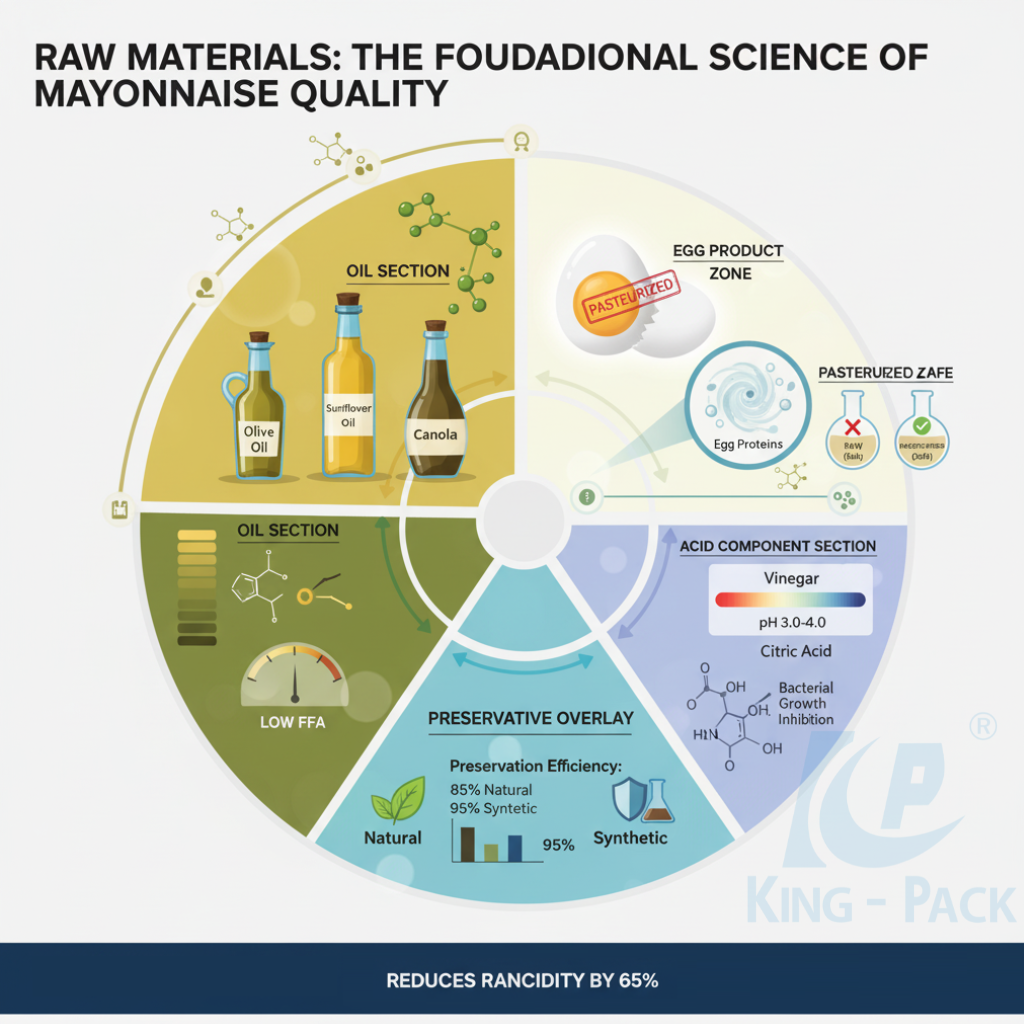

Factor 3: Raw Materials

The foundation ingredients determine mayonnaise shelf life potential before production even begins. Fresh, high-quality oils with low free fatty acid content resist rancidity development and maintain flavor integrity throughout storage periods.

Pasteurized egg products eliminate the primary microbiological risk in mayonnaise while providing consistent emulsification properties. The acidity from vinegar and added preservatives work together to inhibit bacterial growth and lengthen storage life.

Oil selection impacts both flavor stability and nutritional value retention. Oils with natural antioxidants or added stabilizers maintain quality longer, while refined oils may require additional preservatives for comparable shelf life.

Critical raw material factors include:

- Oil freshness and free fatty acid levels

- Pasteurized vs. raw egg yolk selection

- Acidity levels from vinegar or citric acid

- Natural and synthetic preservative content

- Emulsifier quality and concentration

- Salt content for preservation effects

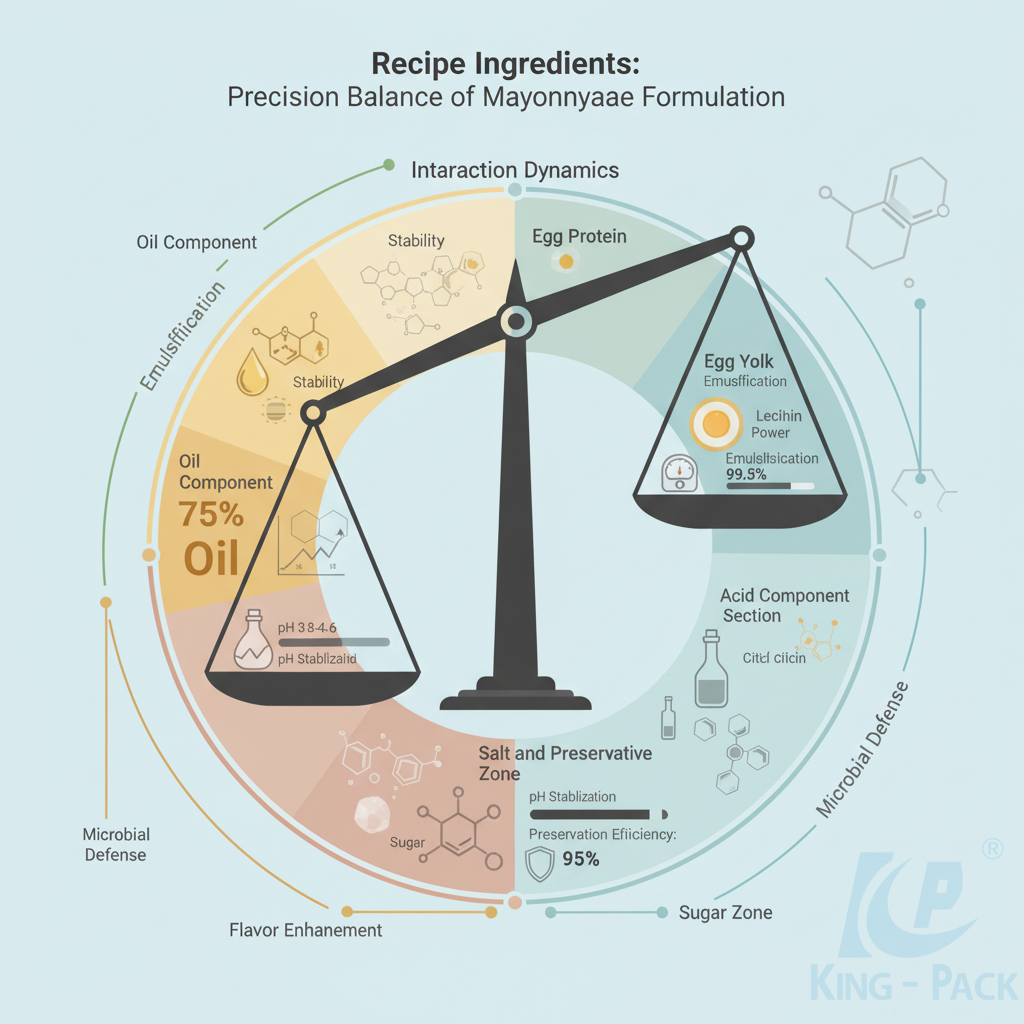

Factor 4: Recipe Ingredients

Recipe formulation directly affects both initial product quality and long-term stability. Salt and vinegar in mayonnaise provide preservation effects that may slow down spoilage, while refrigerated storage significantly reduces oil oxidation rates.

The oil-to-egg ratio determines emulsion stability, with properly balanced formulations resisting separation that can compromise both appearance and safety. Higher egg content provides more lecithin for emulsification but also increases protein levels that can support bacterial growth.

Acidity levels from vinegar or citric acid create environments hostile to pathogenic bacteria while enhancing flavor profiles. The optimal pH range balances preservation with taste preferences and regulatory requirements.

Recipe variables affecting shelf life include:

- Oil percentage (typically 70-80% for stability)

- Egg yolk ratio for optimal emulsification

- Acid content (vinegar/citric acid) for pH control

- Salt concentration for preservation

- Emulsifier additions for stability

- Sugar content in flavored varieties

Recommended Reading: Cream Tube Filling Machine: The Ultimate Guide – King Pack Machinery

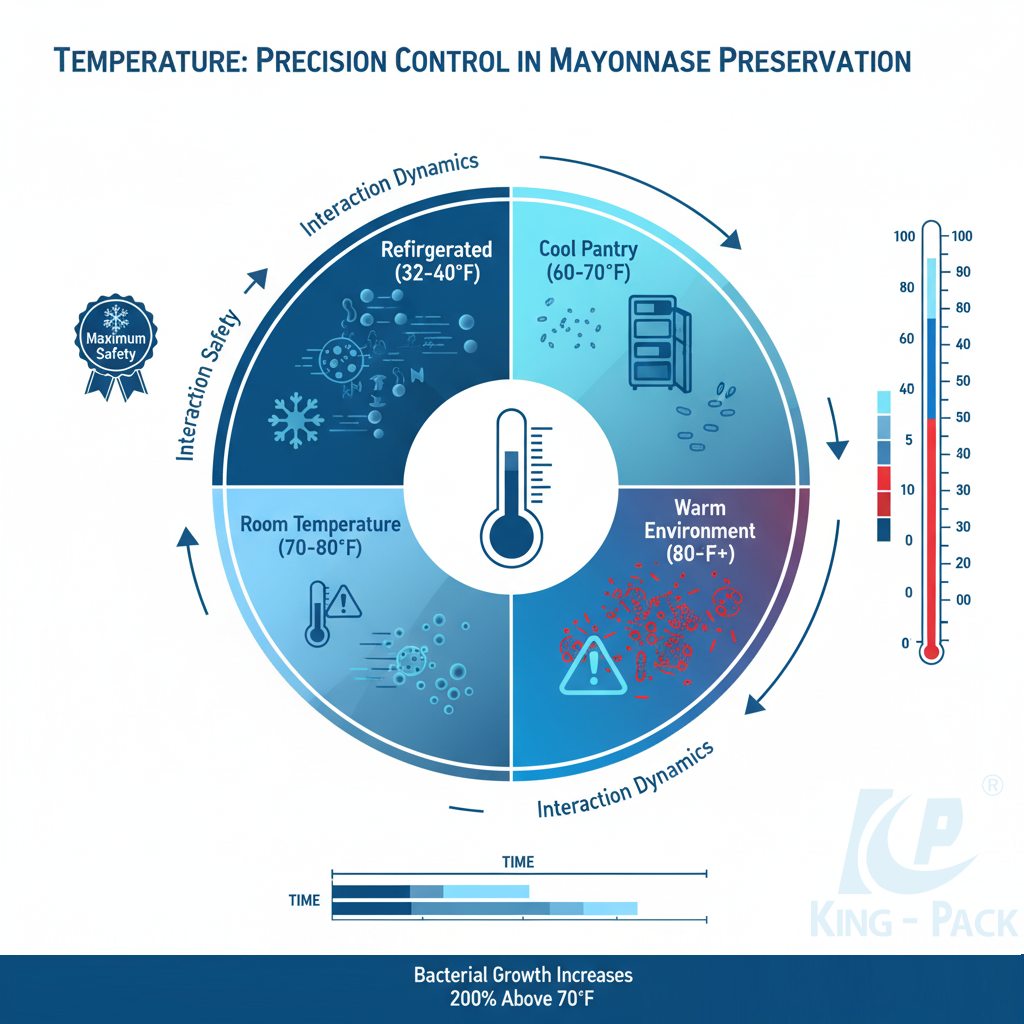

Factor 5: Temperature

Temperature control represents the most critical factor in mayonnaise preservation after production. Mayonnaise should be stored at consistent temperatures below 40°F (4°C), as higher temperatures cause faster spoilage.

Storing mayonnaise at or below 40°F prevents bacterial growth territory that raises foodborne illness risks. Temperature fluctuations stress the emulsion and accelerate chemical reactions that degrade quality and safety.

Commercial products demonstrate remarkable temperature tolerance before opening, but this resistance diminishes once air exposure begins. Heat exposure accelerates oil oxidation and emulsion breakdown while providing favorable conditions for bacterial multiplication.

The following table shows temperature storage guidelines:

| Storage Condition | Temperature Range | Shelf Life Impact | Safety Considerations |

| Refrigerated | 32-40°F (0-4°C) | Maximum shelf life | Safest storage method |

| Cool Pantry | 60-70°F (15-21°C) | Reduced shelf life | Unopened products only |

| Room Temperature | 70-80°F (21-27°C) | Significant reduction | Limited time exposure |

| Warm Environment | Above 80°F (27°C) | Rapid spoilage | Not recommended |

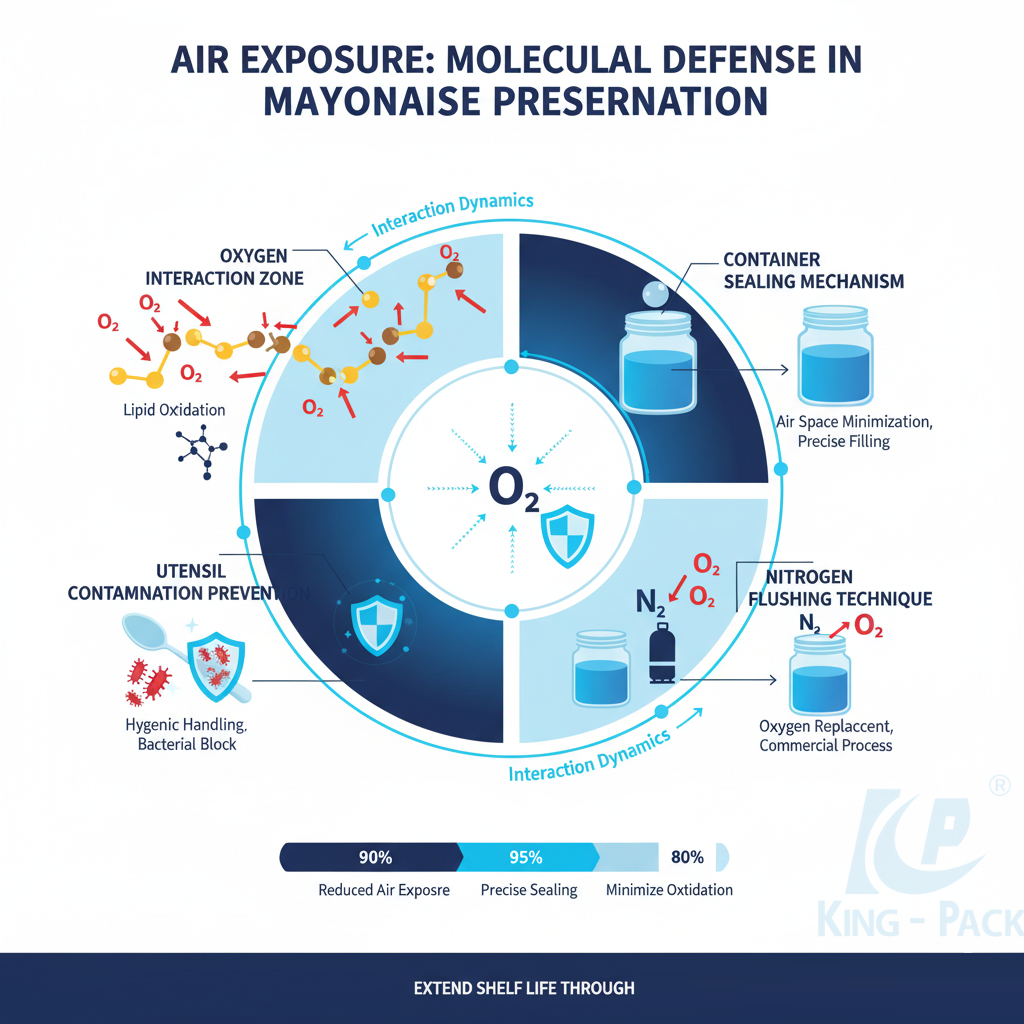

Factor 6: Air Exposure

Air exposure initiates multiple degradation processes that compromise mayonnaise quality and safety. Oxygen contact promotes lipid oxidation that creates off-flavors and reduces nutritional value while providing pathways for airborne contaminant introduction.

Filling jars to the brim reduces air contact, and using clean, dry utensils each time prevents contamination while maintaining product integrity. This practice minimizes the air space that could harbor bacteria or promote oxidation reactions.

Proper sealing after each use maintains the protective atmosphere while preventing moisture loss that could affect texture. Container design features like wide mouths facilitate complete emptying while narrow openings reduce air exposure during storage.

Air exposure control methods include:

- Fill containers completely to minimize air space

- Use clean utensils for each serving

- Replace lids immediately after use

- Store inverted to create air barrier

- Consider nitrogen flushing for commercial products

- Monitor seal integrity regularly

King Pack’s filling and capping machines provide precise fill levels and consistent sealing that minimizes air exposure throughout the packaging process, supporting optimal shelf life achievement.

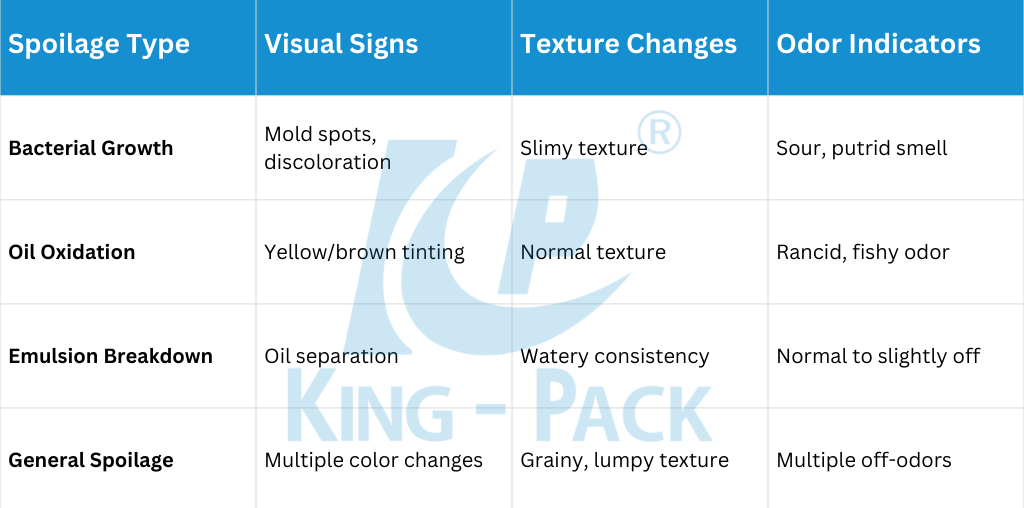

What are Mayonnaise Spoil Indications Signs?

Recognizing mayonnaise spoilage signs prevents consumption of unsafe products and reduces health risks. Visual changes often appear first, with color shifts from creamy white to yellow, brown, or gray indicating oxidation or bacterial activity.

Texture changes include separation where oil layers become visible, unusual thickness or thinning, and grainy or lumpy consistency that indicates emulsion breakdown. These changes signal quality degradation even if the product remains technically safe for consumption.

Odor changes provide the most reliable spoilage indicators. Fresh mayonnaise has a mild, pleasant aroma, while spoiled products develop sour, rancid, or putrid smells that indicate bacterial growth or oil oxidation.

The following table shows spoilage indicator checklist:

What to Do When Spoilage is Suspected

Recommended Reading: How Vial Filling Machines Improve Efficiency and Accuracy in Liquid Filling – King Pack Machinery

KP Filling Machine Solutions for Mayonnaise Production

1. Vacuum Emulsifier Mixers

KP Filling Machine offers Mayonnaise filling machines like vacuum emulsifier mixers designed to remove excess air from the mixture. This reduces oxidation, improves emulsion stability, and extends the freshness of mayonnaise. These mixers allow precise temperature control during production and maintain a consistent emulsion of oil for smooth, stable mayonnaise.

Ideal for viscous liquid food products, they support both large-scale and small-batch production while meeting GMP standards. Features like sweep wall stirrers and 304 stainless steel construction ensure durability and easy cleaning.

Image: KPZ-500L Vacuum homogenizing emulsifier – King Pack Machinery

2. Filling and Capping Machines

Accurate filling and reliable sealing are critical for protecting mayonnaise from air exposure and contamination. KP’s filling and capping machines ensure jars and bottles are filled consistently and sealed tightly. Options with pneumatic components and PLC touch screens enable precise dosing and control for different batch sizes. Automatic packing and tamper-proof closures maintain product quality, hygiene, and shelf life.

Image: Three-in-One Liquid Filling and Capping Machine – King Pack Machinery

3. Automatic Packaging Lines

For large-scale operations, automatic packaging machines streamline the production process. These systems combine filling packaging machines, Jar filling machines, and horizontal or vertical packing machines to handle filling, sealing, and labeling in a controlled environment. Minimal human contact preserves hygiene, reduces contamination risks, and improves production efficiency, ensuring longer product stability on store shelves.

Image: Special-shaped packing machine – King Pack Machinery

4. Customizable Production Systems

KP Filling Machine provides tailor-made solutions to meet unique production needs. Whether it’s adjusting for batch size, recipe requirements, or packaging formats, their Mayonnaise machines support low-fat or high-fat formulations, flavored variants, and preservative-enhanced recipes—all while maintaining emulsion integrity and compliance with food safety standards.

5. Clean-in-Place (CIP) Technology

Hygiene is non-negotiable in mayonnaise production. KP’s equipment supports CIP (Clean-in-Place) systems, making it simple to clean stainless steel tanks, filling nozzles, and product pathways between batches. This reduces bacterial contamination, ensures consistent product quality, and maintains compliance with food product safety regulations.

Conclusion: Managing Mayonnaise Shelf Life Effectively

The shelf life of mayonnaise is shaped by a combination of factors—ingredients, recipes, processing machines, packaging choices, and storage conditions. Homemade versions, while fresh and flavorful, spoil quickly, whereas commercial mayonnaise benefits from pasteurization, preservatives, and barrier packaging that extend its usability for months.

For food manufacturers aiming to meet strict safety standards and deliver long-lasting products, investing in reliable equipment makes all the difference. KP Filling Machine provides advanced emulsifiers and filling solutions that help extend shelf life and maintain consistency. Reach out today and discover how the right machines can upgrade your production line.