Mixing is a core step in many manufacturing processes, and planetary mixers have earned a reputation for delivering consistent results. Their dual motion—rotation and orbit—ensures every part of the mixture is worked evenly. Whether it’s mayonnaise in a food plant or ointments in a pharmaceutical setting, these machines are valued for their versatility and efficiency.

In this article, we’ll explore what a planetary mixer is, how it works, and why it stands out compared to other types of mixers. You’ll also learn about its construction, benefits, applications across industries, and key factors to consider before choosing one for your production line.

What Is a Planetary Mixer? Definition and Origin

“Planetary” in the context of mixers refers to the movement pattern: the mixing blade rotates (spin) while the entire assembly rotates (orbit).

- The term likely comes from how the blade “orbits” around the bowl’s center like a planet around the sun, while simultaneously spinning on its own axis.

- This setup helps reach regions in the mixing vessel that a simple stirrer would not.

Studies in chemical and food engineering highlight that integrated mixer lines can reduce overall processing time by 20–35% compared to stand-alone mixing units. Similarly, pharmaceutical research has shown that linking vacuum planetary mixers with automated filling equipment minimizes contamination risks while cutting batch cycle times by 25% or more.

Recommended Reading: Emulsifying Mixer Machine: Factors Affecting The Emulsification Result – King Pack Machinery

How Planetary Mixers Work

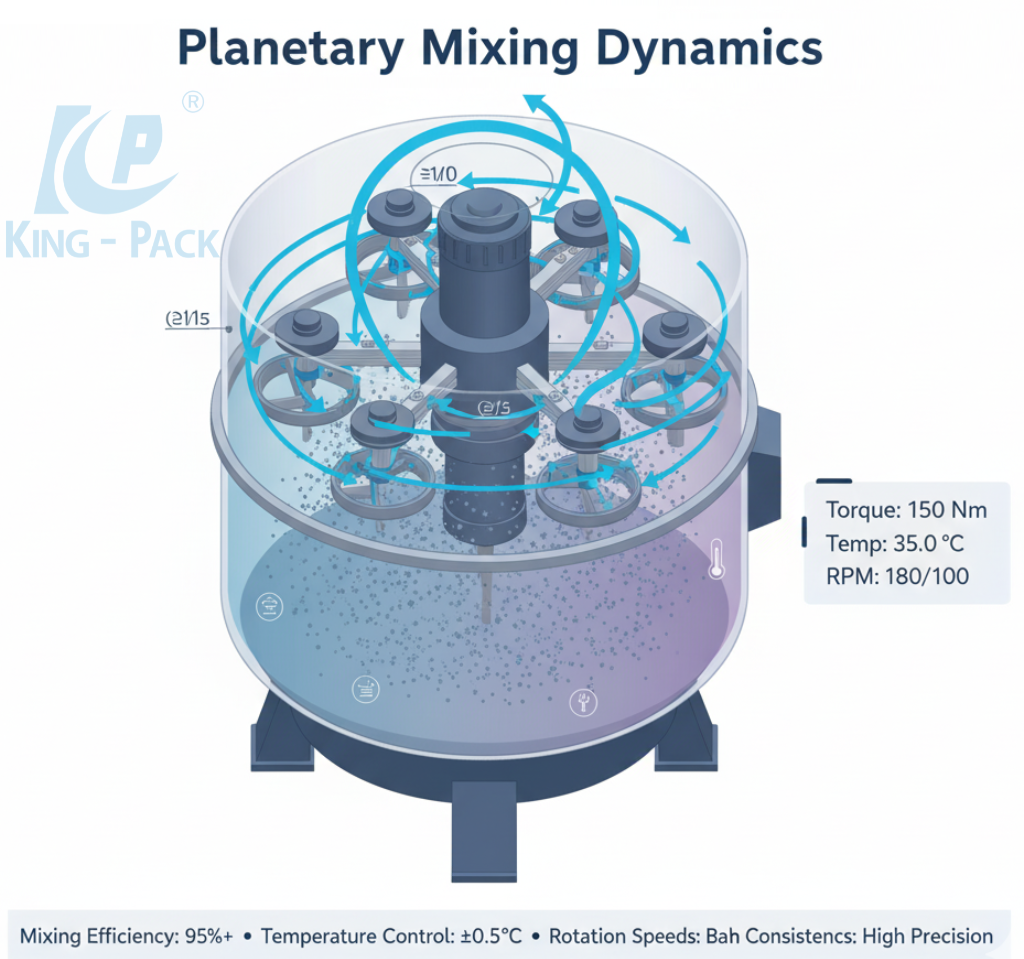

Planetary mixers work by homogenizing mixtures loaded into the bowl, with beater motion allowing material to be mixed faster and better within shorter periods. Industrial studies based on discrete element simulations revealed that planetary mixers sweep the whole bowl in just 30 seconds, ensuring thorough and homogeneous results. The process begins with material loading into the stationary mixing bowl or vessel.

The mixing sequence involves careful control of rotation speeds, direction changes, and processing time to optimize material characteristics. Temperature control systems maintain optimal processing conditions while preventing ingredient degradation during extended mixing cycles.

Modern planetary mixers incorporate advanced control systems that monitor torque, temperature, and mixing parameters to maintain consistent results across production batches

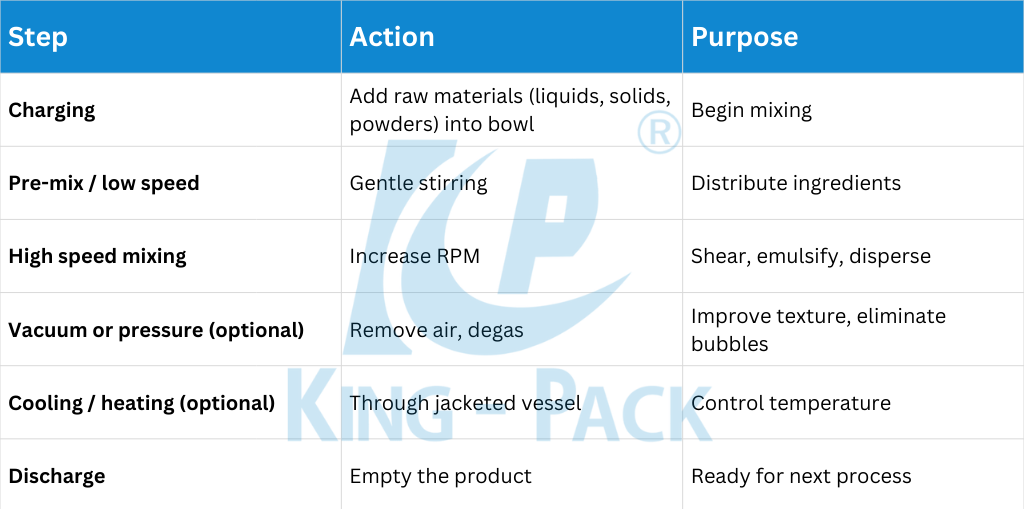

Typical steps in a mixing cycle include:

Key goals a planetary mixer often achieves:

- Homogeneous blend

- Breakup of lumps / agglomerates

- Degassing / bubble removal

- Controlled temperature during mixing

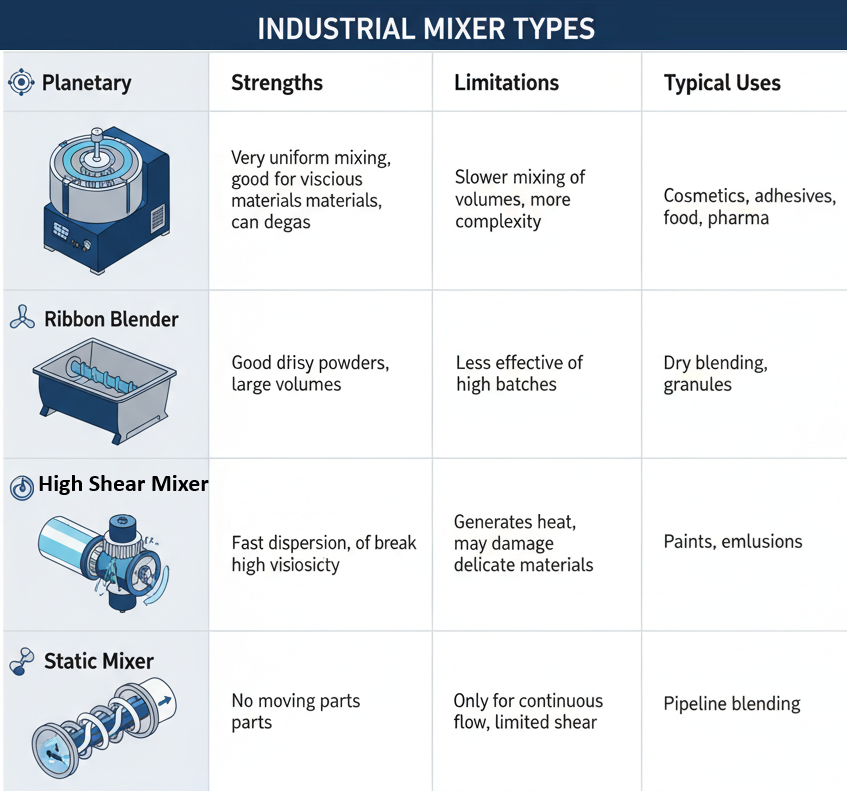

Planetary vs Other Mixers: Where It Stands

Understanding the advantages of planetary mixers requires comparison with alternative mixing technologies used in industrial applications:

Planetary mixers excel when working with high-viscosity emulsions or dense doughs that challenge traditional mixers. Their unique dual-motion system allows dough hooks or mixing paddles to rotate on their own axis while revolving around the stainless steel bowl, applying consistent force across the entire batch.

One major advantage is their ability to deliver uniform mixing, even near the walls of the mix vessel, where ingredients often remain unmixed in other systems. The planetary motion prevents dead zones, ensuring every portion of the batch achieves the same texture and consistency.

Flexibility is another key strength. Stand mixers and commercial mixers can handle kneading, emulsifying, or whipping functions with the right attachments, such as wire whips or attachment hubs. Many models also feature ten speeds and smooth gear-driven transmission, allowing operators to control mixing intensity precisely. Some units even support vacuum or pressure-assisted mixing, which helps reduce air incorporation, improve product stability, and enhance texture.

This adaptability allows foodservice operations and large batch producers to rely on a single planetary mixer for multiple applications, reducing the need for multiple machines and optimizing production efficiency.

Recommended Reading: Emulsifier Machine: Types of Vacuum Emulsifying Mixers & Applications – King Pack Machinery

Construction and Key Components of a Planetary Mixer

A quality planetary mixer includes:

- Mixing bowl / vessel: often stainless steel, sometimes jacketed for temperature control

- Mixing shaft / agitator: can be single or multiple arms, paddles, blades

- Drive system: gearing or motor that provides both spin and orbital motion

- Vacuum or pressure system: to evacuate air or pressurize (for vacuum planetary mixers)

- Seals and shaft bearings: to maintain integrity under vacuum/pressure

- Control panel / PLC: to set speed, time, vacuum, cycles

- Safety and discharge mechanisms: doors, baffles, removable parts

Materials and construction quality matter to resist wear, corrosion, and maintain inertness (for sensitive products).

Recommended Reading: How Does an Emulsifying Machine Work? – King Pack Machinery

Examples of Applications Planetary Mixer

Cosmetics: Creams, Lotions, and Gels

In the cosmetics industry, commercial mixers and stand mixers are used to produce smooth and uniform face creams, body lotions, and styling gels. Mixing paddles and wire whips help prevent clumping of powders while ensuring even distribution of oils, waxes, and active ingredients. Integrated electronic transmission and digital control panels allow operators to maintain precise speeds and monitor temperature, protecting sensitive vitamins and plant extracts from degradation.

Pharmaceuticals: Ointments, Gels, and Suspensions

Pharmaceutical manufacturers rely on planetary mixers for high-viscosity ointments, medicinal gels, and suspensions. Bowl capacity and heavy-duty construction allow these machines to process large batches consistently. Vacuum-assisted mixing removes trapped air, ensuring stable textures and improving dosage uniformity across production runs.

Food: Sauces, Chocolate, and Pastes

In food processing, commercial food mixers and double planetary mixers handle applications such as mayonnaise, tomato paste, chocolate, and specialty sauces. Precise control of mixing speeds, along with stainless steel bowls, ensures consistent textures and reduces air incorporation, which preserves shelf life. Some mixers feature bowl lift and safety guards, making them suitable for high-capacity foodservice operations and industrial kitchens.

Adhesives, Sealants, and Silicone

Dense products like adhesives, sealants, and silicone require high torque and heavy-duty floor models. Gear-driven transmissions provide the strength necessary to blend thick materials efficiently. These mixers also disperse fillers and additives evenly, producing reliable and uniform end products.

Paints, Coatings, and Pigments

Industries producing paints, coatings, and pigments use industrial mixers with heat-treated steel alloy gears to ensure uniform distribution of colorants and binders. Vacuum-capable models prevent bubbles and maintain the quality of the final surface finishes. Hybrid belt systems and bowl trucks support large batch processing while keeping operations safe and efficient.

Recommended Reading: The Differences Between Homogenization and Emulsification – King Pack Machinery

What to Consider When Buying a Planetary Mixer

Before selecting a mixer, evaluate:

- Batch volume: small lab scale vs industrial batches

- Viscosity of product: adhesives or gels need stronger motors

- Vacuum / pressure capability: needed for degassing or inert atmosphere

- Temperature control: is heating or cooling required (jacketed bowl)?

- Material compatibility: stainless steel grade, coatings

- Ease of cleaning & maintenance: CIP (clean-in-place) or disassembly

- Control system features: programmable cycles, speed ranges

- Reliability, after-sales support, spare parts

If you choose the model wrongly, you may underperform in mixing or face mechanical failures.

Click Here to Check Our Products

KPPM-100 Vacuum Planetary Mixer from KP Filling Machine

King Pack’s KPPM-100 Vacuum Planetary Mixer demonstrates the advanced capabilities available in modern planetary mixing technology. This specific model incorporates vacuum resistance, allowing operation under reduced pressure conditions that are essential for specialized applications.

The KPPM-100 is engineered as a high-efficiency, multi-functional system designed to meet demanding production requirements while maintaining superior product quality. Its vacuum capability makes it particularly valuable for processes where air entrainment must be minimized or eliminated entirely.

Key features of the KPPM-100 include:

- Vacuum-resistant design for safe operation under reduced pressure

- High-efficiency mixing with consistent results across batches

- Multi-functional performance: kneading, dispersing, emulsifying

- Effective at minimizing air entrainment and oxidation

- Suitable for small to medium batch production

Because this model has vacuum capability, it is well suited for applications in cosmetics, pharmaceuticals, adhesives, or any process where air bubbles or oxidation would damage product quality.

Types of Planetary Mixers & Their Use Cases

Planetary mixers are designed in several configurations, each tailored to specific production needs. While all share the same core mixing principle, the variations determine how efficiently they handle viscosity, batch size, and product sensitivity.

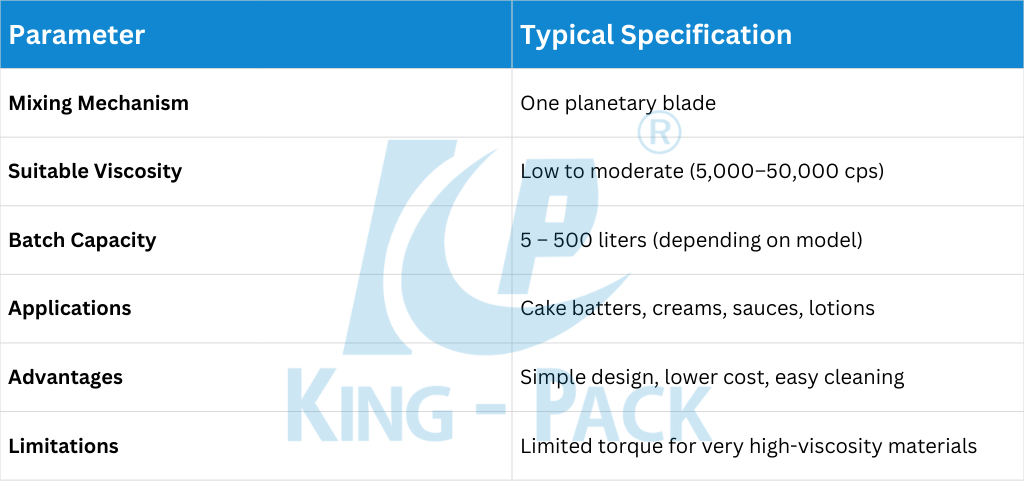

1. Single Planetary Mixer

This is the most common design, featuring a single blade that revolves around the mixing bowl. It works well for moderate-viscosity materials such as cake batters, creams, and sauces. Its straightforward design makes it a reliable choice for general food and cosmetic applications.

The following table shows the technical specifications of this type:

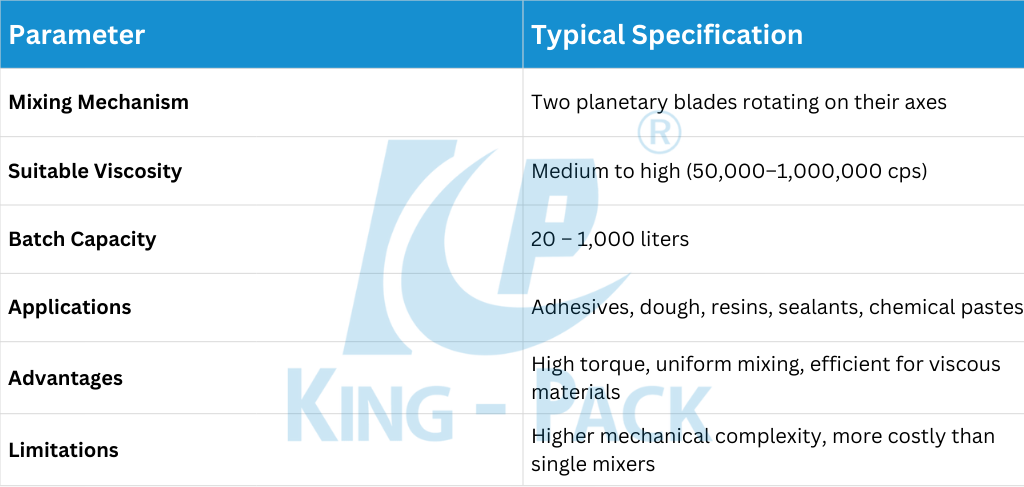

2. Double (Twin) Planetary Mixer

Equipped with two blades instead of one, this version offers higher torque and more uniform mixing. It is especially effective for heavy-duty tasks like kneading dough, blending adhesives, or mixing high-solid pastes in chemical and pharmaceutical industries.

The following table shows the technical specifications of this type:

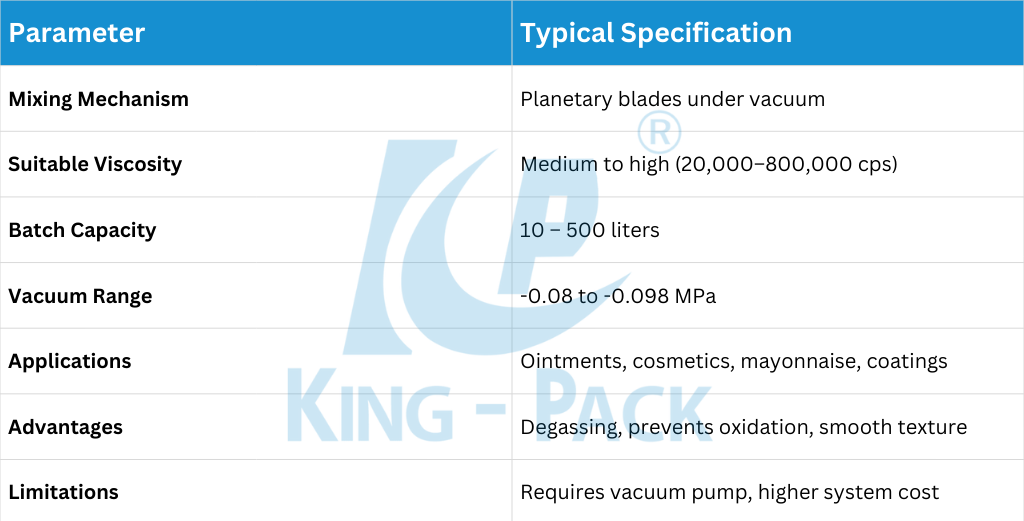

3. Vacuum Planetary Mixer

This model can operate under vacuum conditions, which removes trapped air and prevents oxidation. It is ideal for products that require smooth textures and longer shelf life, such as mayonnaise, ointments, and specialty coatings.

The following table shows the technical specifications of this type:

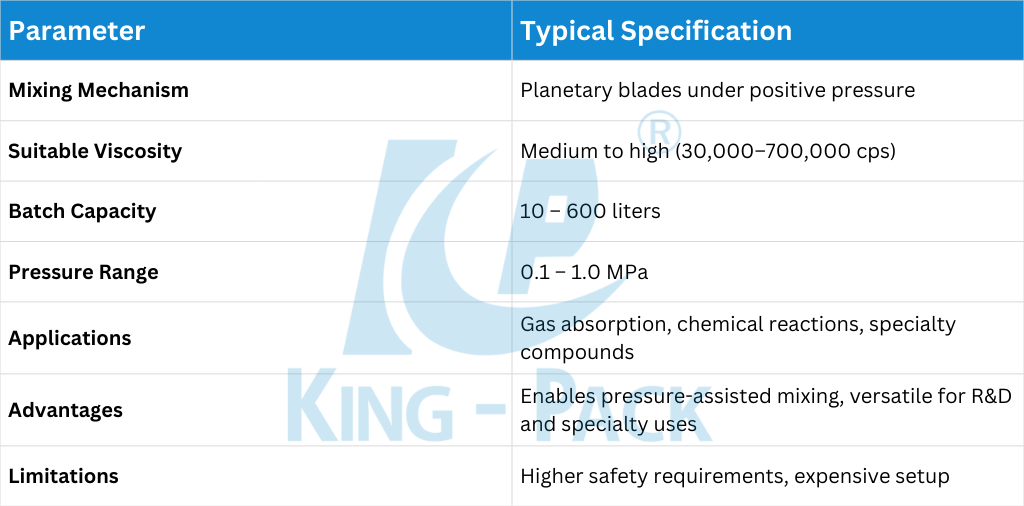

4. Pressure Planetary Mixer

In contrast to vacuum systems, this mixer allows positive pressure to be applied inside the vessel. This setup is useful for processes where gas absorption is necessary or when mixing needs to be carried out in controlled atmospheres.

The following table shows the technical specifications of this type:

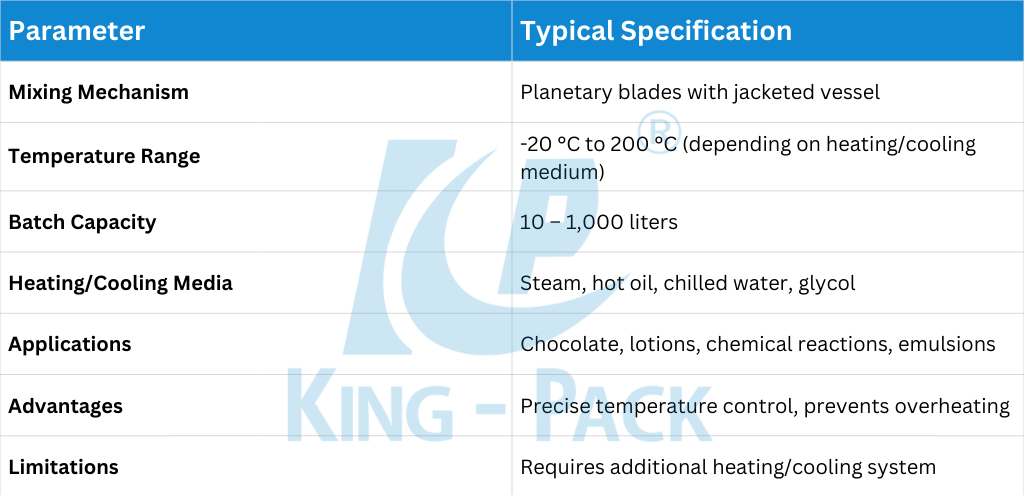

5. Jacketed Planetary Mixer

The vessel is fitted with a jacket that enables heating or cooling during mixing. Applications include chocolate processing, chemical reactions, and cosmetics where temperature control is critical to maintain texture and stability.

The following table shows the technical specifications of this type:

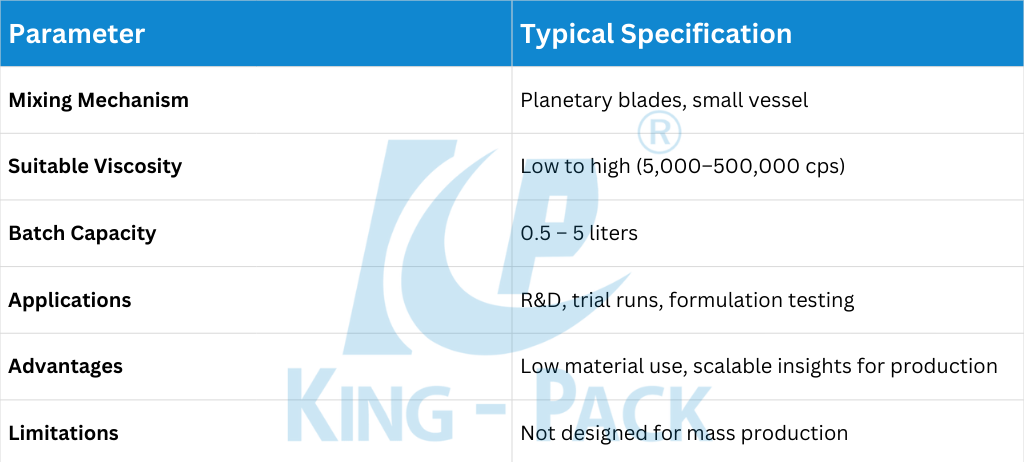

6. Small Lab Planetary Mixer

Designed for research and development, these compact mixers allow trials on small batches. They help companies optimize formulations before scaling up to full production, reducing both time and resource costs.

The following table shows the technical specifications of this type:

Choosing the right type depends on product characteristics, required batch volumes, and process conditions. A food manufacturer may prefer vacuum or jacketed systems for texture-sensitive products, while a chemical company might require double planetary mixers for viscous adhesives.

Considerations & Limitations

While planetary mixers offer strong advantages, they do come with some trade-offs. Their throughput per unit size is often lower compared to continuous mixing systems, and the mechanical design involves more moving parts, seals, and maintenance needs. These factors can increase both downtime and upkeep costs.

Another challenge is energy demand. High-viscosity materials require significant torque, which drives up power consumption. Scaling from lab units to industrial production can also be complex, as mixing behavior doesn’t always transfer directly to larger batch sizes. This makes process development an important step before full investment.

Cost is another factor to weigh. Advanced models with vacuum capability, jacketed vessels, or smart control systems come at a premium. To avoid costly mistakes, manufacturers are advised to run pilot trials, test with actual formulations, and work closely with equipment vendors before committing to a purchase.

Conclusion

Planetary mixers have earned their place as a core tool in modern production environments. Their unique dual-motion mixing system ensures homogeneity even in the most viscous formulations. For businesses in cosmetics, adhesives, pharmaceuticals, food, and specialty chemicals, planetary mixers provide not only consistency but also control over critical parameters like air content, temperature, and shear intensity.

If you’re looking to upgrade your production line with reliable, high-performance mixing technology, contact KP Filling Machine. At KP Filling Machine, we offer a wide range of planetary mixers, from compact lab-scale models to fully automated industrial systems. Visit us today and discover how our planetary mixer can enhance your production process.