Modern toothpaste production is no longer just about filling tubes—it’s about precision, speed, and compliance. High-speed toothpaste tube filling machines streamline operations, allowing manufacturers to produce consistent, high-quality products at scale.

This guide breaks down everything you need to know about these machines, including technical features, efficiency metrics, and regulatory compliance. We’ll highlight the benefits of adopting these systems and provide practical insights to help you choose the right solution for your production line.

Achieving Mass Production Quality: Why Specialized Toothpaste Filling is Different

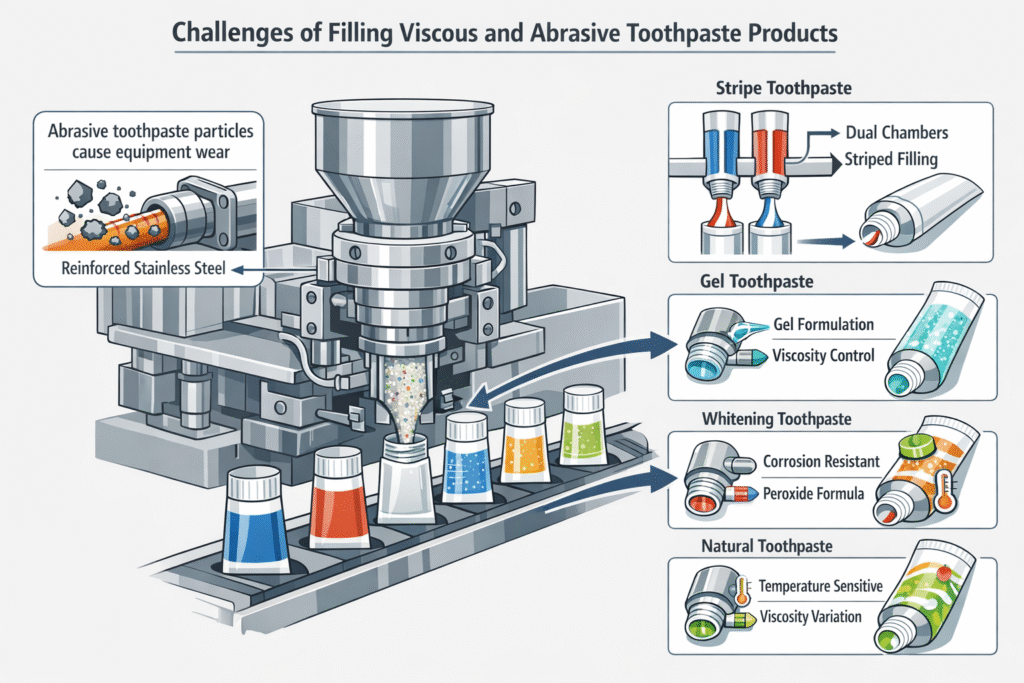

Toothpaste manufacturing presents unique technical challenges that distinguish it from other packaging applications. The product’s high viscosity, abrasive particle content, and multi-phase formulations (including stripe patterns) require specialized pump technology, materials selection, and quality control systems.

King Pack specializes in tube filling and sealing equipment designed for the specific demands of toothpaste production. Our machinery handles both plastic laminate and aluminum tubes with precision dosing systems that maintain ±0.5% accuracy across production runs exceeding 100,000 units daily.

Metal tube filling and folding machine

Challenges of Filling Viscous and Abrasive Products (Toothpaste Specifics)

Toothpaste formulations contain abrasive particles including silica, calcium carbonate, and sodium bicarbonate that serve as cleaning agents but create significant wear on filling equipment. Standard filling pumps designed for lotions or creams fail prematurely when processing toothpaste due to these abrasive components.

Modern toothpaste varieties introduce additional complexity:

- Stripe Toothpaste: Multi-chamber systems maintain separate red and white (or blue and white) formulations, combining them during filling to create consistent stripe patterns visible when consumers dispense product

- Gel Formulations: Transparent or translucent gels exhibit different flow characteristics than traditional paste, requiring pump adjustments to maintain accurate fill weights

- Whitening Products: Peroxide-containing formulations demand specialized materials resistant to oxidative degradation

- Natural Toothpaste: Formulations without synthetic thickeners often show greater viscosity variation with temperature changes

King Pack’s toothpaste manufacturing process equipment addresses these challenges through hardened stainless steel components, positive displacement pumps that compensate for viscosity variations, and multi-chamber filling systems for stripe products.

Recommended Reading: How Striped Toothpaste Works – Tube Filling, Rheology & Manufacturing Insight – King Pack Machinery

Minimizing Downtime and Maximizing Output: The Role of Machine Reliability and Support Infrastructure

Production line stoppages cost toothpaste manufacturers thousands of dollars per hour in lost output and labor inefficiency. High-speed filling equipment must operate continuously for 16-20 hours daily in typical two-shift operations, with minimal downtime for changeovers, maintenance, or troubleshooting.

Critical reliability factors include:

- Robust Component Selection: Industrial-grade servo motors, heavy-duty bearings, and oversized drive systems that operate well below maximum capacity ratings

- Predictive Maintenance Systems: Sensors monitoring vibration, temperature, and performance metrics that predict component failure before breakdowns occur

- Modular Design: Quick-change components allowing operators to replace worn parts in minutes rather than hours

- Local Technical Support: Access to trained service technicians, spare parts inventory, and remote diagnostic capabilities

Manufacturers operating in regions with established packaging equipment support networks benefit from faster response times and lower inventory requirements for spare parts. Companies expanding into new markets should evaluate supplier capabilities for local service before making capital equipment investments.

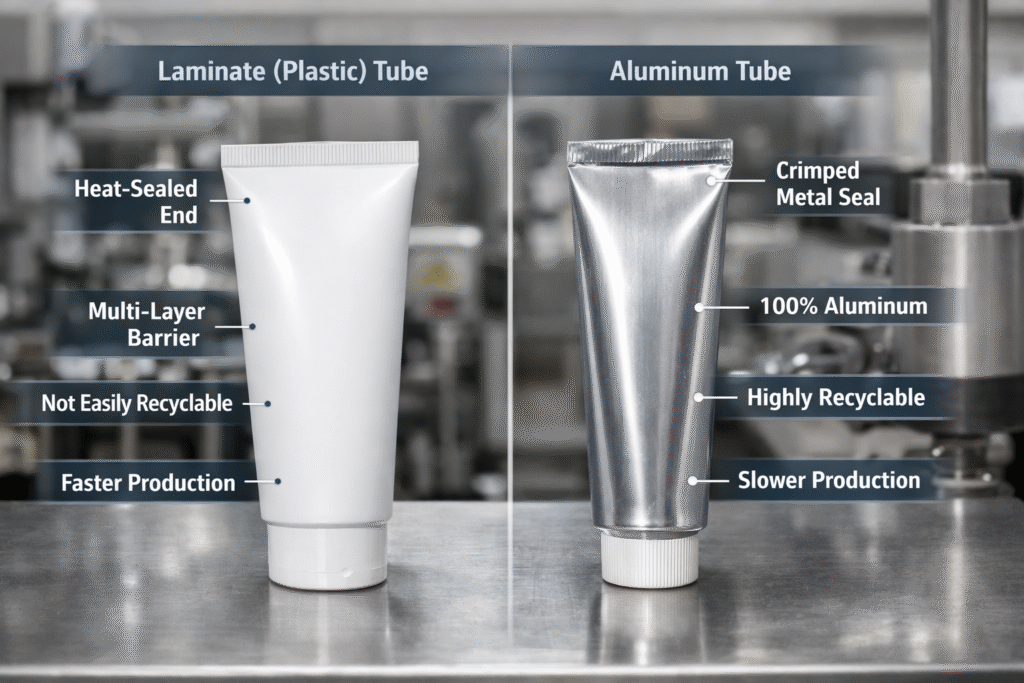

Tube Material Technology: Choosing Between Laminate (Plastic) and Aluminum Tubes

Tube material selection impacts sealing technology, production speed, cost structure, and environmental sustainability. Understanding the tradeoffs between laminate and aluminum tubes guides appropriate equipment specification.

Comparative Analysis: Laminate vs. Aluminum Tubes

| Characteristic | Laminate (Plastic) Tubes | Aluminum Tubes |

| Material Cost | $0.08-$0.15 per tube | $0.15-$0.25 per tube |

| Aesthetics | Excellent full-color printing, matte/gloss finishes, complex graphics | Limited printing area, traditional crimped appearance |

| Barrier Properties | Good oxygen/moisture barriers with EVOH layer | Excellent complete barriers to oxygen, light, moisture |

| Sealing Technology | Hot air sealing (180-220°C) or ultrasonic sealing | Mechanical crimping and folding |

| Production Speed | 80-200 tubes per minute | 60-120 tubes per minute |

| Line Speed Impact | Faster sealing cycles enable higher throughput | Crimping mechanics limit maximum speed |

| Sustainability | Recyclability challenges with multi-layer construction | Highly recyclable, infinite recycling potential |

| Consumer Appeal | Modern, flexible, easy to squeeze completely | Traditional quality perception, heritage branding |

| Equipment Investment | $150,000-$400,000 (high-speed lines) | $180,000-$450,000 (includes crimping systems) |

Laminate Tube Advantages

Laminate tubes dominate modern toothpaste packaging due to cost advantages and superior graphics capabilities. Multi-layer laminate construction combines polyethylene, polypropylene, and barrier materials (EVOH or metallized films) to achieve oxygen transmission rates below 2 cc/m²/day—adequate for typical 18-24 month toothpaste shelf life requirements.

Our filling and sealing equipment efficiently processes these eco-friendly tubes without compromising production speed or seal quality.

Recommended Reading: Toothpaste Tube Materials: A Sustainable Solution – King Pack Machinery

Aluminum Tube Applications

Aluminum tubes maintain strong positions in premium toothpaste segments and markets where traditional packaging conveys quality. The complete oxygen barrier prevents fluoride degradation and oxidation of flavor components, extending shelf life to 36+ months.

Premium brands use aluminum tubes’ heritage associations, particularly in European and Asian markets where traditional packaging communicates established quality.

Mechanical crimping creates the characteristic flat tail familiar to consumers. Modern crimping systems produce consistent folds with embossed batch codes and expiration dates integrated into the crimping operation.

The Core of Precision: Dosing and Accuracy in Toothpaste Filling

Fill weight accuracy directly impacts profitability and regulatory compliance. Overfilling reduces profit margins through product giveaway, while underfilling risks regulatory penalties and consumer complaints about perceived value.

The Importance of Accurate Volume Control and Reducing Product Giveaway

High-performance toothpaste filling machines achieve dosing accuracy of ±0.5% to ±1.0% across their operating range, meeting pharmaceutical standards adapted for oral care products. At ±0.5% accuracy, a 100g tube should contain between 99.5g and 100.5g of product.

Economic Impact of Dosing Precision

Consider a manufacturer producing 10 million tubes annually at a target fill weight of 100g. Product cost averages $2.50 per kilogram.

| Dosing Accuracy | Average Overfill | Annual Product Waste | Cost Impact |

| ±2.0% | 2.0g per tube | 20,000 kg | $50,000 |

| ±1.0% | 1.0g per tube | 10,000 kg | $25,000 |

| ±0.5% | 0.5g per tube | 5,000 kg | $12,500 |

Upgrading from ±2.0% to ±0.5% accuracy saves $37,500 annually for this operation. Larger manufacturers producing 50-100 million tubes yearly realize proportionally greater savings.

Recommended Reading: How is Toothpaste Manufactured and How Tube Filling Machines and Emulsifying Equipment are Used in this Process? – King Pack Machinery

Technology Enabling Precision

Servo-driven positive displacement pumps deliver the repeatability required for pharmaceutical-grade accuracy:

- Piston Pumps: Precisely controlled stroke length and speed provide volume accuracy independent of viscosity variations

- Gear Pumps: Rotating gears capture fixed product volumes, delivering consistent output across wide viscosity ranges

- Progressive Cavity Pumps: Helical rotor and stator create progressive cavities that gently move product without pulsation

Modern systems incorporate real-time weight monitoring with automatic compensation algorithms that adjust fill volumes based on observed trends, preventing drift outside specification limits.

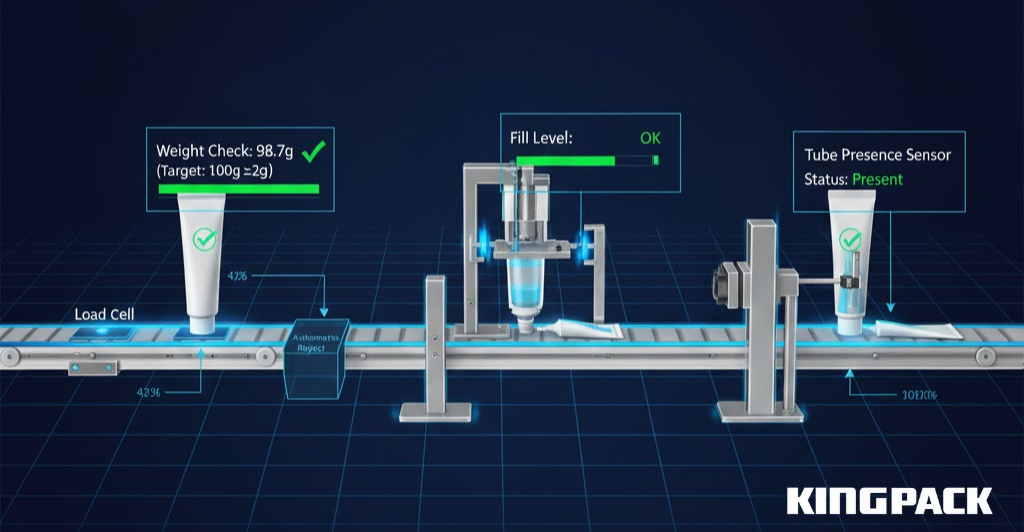

Integration of Quality Control (QC) Systems: Tube Orientation, Print Registration, and Foreign Object Detection

Automated quality control begins before filling and continues through final packaging. Multiple inspection stations catch defects before they reach consumers, protecting brand reputation and preventing costly recalls.

Pre-Fill Inspection

Vision systems play a key role in ensuring toothpaste tubes are ready for filling. They check tube orientation, detect damaged threads, and confirm print registration before the tubes reach the filling station. Cameras identify misaligned tubes and trigger rotation mechanisms to position them correctly for the filling nozzles.

High-resolution imaging also spots damaged threads that could prevent proper capping. At the same time, the system verifies color marks and batch codes within ±1.5mm, ensuring every tube meets quality standards and brand requirements.

In-Process Monitoring

In-process monitoring keeps toothpaste tube filling accurate and efficient. Multiple sensors track key parameters throughout the operation. Load cells measure each tube’s weight immediately after filling, automatically rejecting any units that fall outside specifications.

Sensors also confirm the presence of tubes at every station, preventing waste from missed placements. Optical or ultrasonic sensors check fill levels before sealing, ensuring each tube meets quality standards before moving to the next step.

Post-Seal Quality Checks

Final inspection stations verify seal integrity and coding accuracy:

- Seal Inspection: Vision systems examine seal dimensions, surface quality, and absence of wrinkles or burns

- Code Verification: OCR systems read batch codes, expiration dates, and manufacturing information, rejecting tubes with illegible codes

- Leak Detection: Automated systems apply pressure or vacuum to detect seal failures before tubes enter cartoning equipment

Recommended Reading: How To Fill Toothpaste Tubes Using Tube Filling Machine? – King Pack Machinery

Technical Features & Compliance: Essential Requirements for High-Volume Production

Machine Design for Global Compliance: Features Meeting GMP and FDA Standards

Toothpaste manufacturing falls under cosmetic regulations in most jurisdictions, requiring Good Manufacturing Practice (GMP) compliance that parallels pharmaceutical standards.

Here are essential GMP features:

- Sanitary Construction: All product-contact surfaces fabricated from 316 stainless steel with electropolished finishes (Ra ≤0.8 micrometers)

- Enclosed Filling Zones: HEPA-filtered positive pressure areas prevent airborne contamination during filling operations

- CIP Capability: Automated cleaning systems with validated procedures remove product residues between production runs

- Documentation Systems: Automated batch record generation capturing critical parameters (fill weight, seal temperature, operator ID, timestamp) for every tube produced

- Material Traceability: Systems tracking raw material lots through production to finished goods, enabling targeted recalls if quality issues arise

These features become non-negotiable for manufacturers exporting to regulated markets including the United States, European Union, and major Asian markets.

Automated Tube Handling and Cartoning Integration (End-to-End Solutions)

Modern production lines go beyond tube filling to include automated cartoning and packing. Tubes leaving a rotary tube filling machine or cream filling machine move directly into Toothpaste Packing Machine systems that form cartons, insert leaflets, print batch numbers, and close boxes without manual handling.

Key integration elements include:

- Buffer Conveyors: These balance speed differences between fully automatic machines, allowing stable output from tube filling to cartoning.

- Product Transfer Systems: Automatic tube loading and guided transfer units move laminated tubes between stations without affecting the filling volume or sealing quality.

- Central Line Control: PLC control links filling machines, cartoners, and downstream units, keeping filling mechanisms synchronized across the line.

- Flexible Machine Matching: Lines can combine semi-automatic tube filling stations with machines like Toothpaste Packaging Machine R45, Toothpaste Tube Filing And Sealing Machine R30, Model Toothpaste Filling Machine R60, or DG-003 Toothpaste Filling Machine, based on output needs and budget.

King Pack supports manufacturers with line planning, equipment selection, and layout optimization, helping align production goals with available space, utilities, and investment levels.

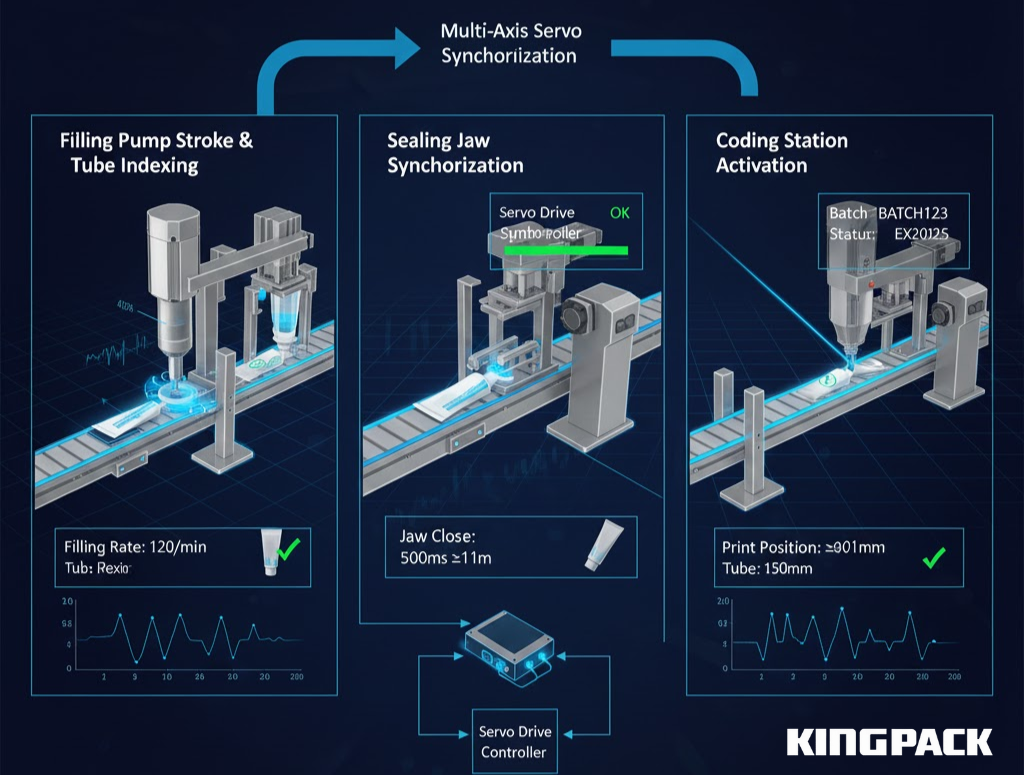

System Components: Defining the Key Technologies

Servo motors provide precise control over filling strokes, tube indexing, and sealing operations. Unlike pneumatic systems that vary with air pressure fluctuations, servo drives deliver consistent performance through programmable speed profiles and position accuracy to ±0.01mm.

Multi-axis servo controllers synchronize complex operations:

- Filling pump stroke rate matches tube advance speed

- Sealing jaw closing coordinates with tube arrival timing

- Coding stations activate precisely when tubes reach printing positions

Conclusion: Investing in Future-Proof Toothpaste Filling Technology

Investing in a high-speed toothpaste tube filling machine shapes your production capabilities for years. Choosing the right system means balancing current output needs with flexibility to handle new formulations, tube types, and market demands. A future-proof machine helps reduce downtime, adapt to changes, and maintain consistent quality across all batches.

Key factors include scalable, modular designs that grow with your business, quick changeover for multiple product types, and compatibility with sustainable or recyclable tubes. Integration with Industry 4.0 tools enables real-time monitoring and predictive maintenance, while a strong global support network ensures access to technical help and spare parts whenever needed.

Request a Technical Consultation on High-Speed Tube Filling Solutions

Every production facility faces unique challenges based on facility layout, existing equipment, product formulations, and market requirements. Direct consultation with filling equipment specialists helps identify optimal configurations for specific needs.

King Pack’s technical team offers comprehensive consultation services evaluating:

- Product characteristics including viscosity, abrasive content, and formulation complexity

- Production capacity requirements and future growth projections

- Tube material preferences and sustainability objectives

- Integration requirements with existing equipment

- Regulatory compliance needs for target markets

- Budget parameters and return on investment expectations

Contact King Pack to schedule a consultation and discuss your toothpaste tube filling requirements. Our experience across pharmaceutical, cosmetic, and food industries provides valuable insights into addressing common challenges and avoiding costly mistakes.

Frequently Asked Questions (FAQs) on High-Speed Tube Filling

What is the typical speed (TPM) of a high-speed automatic toothpaste filling machine?

These machines run at 80–200 tubes per minute, depending on tube type, size, and sealing method. Laminate tubes usually reach higher speeds than aluminum tubes. Production conditions and changeover frequency also affect real-world throughput.

How does hot air sealing differ from ultrasonic sealing for laminate tubes?

Hot air sealing melts tube ends with heated air, giving a polished finish at 100–200 TPM. Ultrasonic sealing uses vibrations to generate heat, saving energy and allowing quick size changes, though speeds are slightly lower at 60–100 TPM.

What are the primary factors that affect dosing accuracy in a tube filler?

Accuracy relies on pump type, product viscosity, mechanical precision, and fill volume. Servo-driven pumps with weight monitoring can maintain ±0.5% accuracy across production runs.

Is CIP (Clean-in-Place) capability necessary for a toothpaste filling machine?

CIP reduces cleaning time, ensures consistency, and supports GMP compliance. Multi-product facilities benefit most, while single-product lines may manage with manual cleaning if schedules allow.