The beauty industry runs on innovation and speed. Every new product launch demands packaging that looks flawless, performs reliably, and stays hygienic through production. For manufacturers, that means finding equipment that can keep up with constant change without compromising quality.

King Pack’s range of cosmetic filling and packaging machines is built around that exact need. Our systems handle everything from silky serums to dense creams with precision and care. In this article, we’ll look at current packaging trends, King Pack’s core equipment modules, and how King Pack’s machines simplify complex cosmetic production.

Trends & Demands in Cosmetic Packaging

The cosmetic industry continues to surge, with the global cosmetics market projected to grow at a Compound Annual Growth Rate (CAGR) of 6.64% from 2025 to 2032. This momentum reflects a broader shift in beauty manufacturing — brands must stay agile, clean, and visually striking in how they package their products.

Key trends shaping cosmetic packaging include:

1). Rapid Product Launches & Multi-format Demands

Innovation is accelerating. While older data on “launches doubling in the past decade” is hard to verify reliably, the sheer volume of new products is clear — the industry still reports thousands of new global cosmetic launches annually.

To meet this demand, King Pack offers modular systems like the KPGFW-180 High-Speed Filling & Sealing Machine and the KPGZW-60 Tube Filling Machine, which support quick changeovers between bottle, tube, and jar formats.

2). Hygiene, Cleanability & GMP Compliance

Microbial contamination is a real risk in cosmetics manufacturing. A study in MDPI Cosmetics found that many finished cosmetics (especially creams) can harbor potentially harmful microorganisms if not properly controlled.

To counter this, King Pack integrates CIP/SIP (Cleaning-in-Place / Sterilisation-in-Place) systems and builds contact parts from stainless steel, designed for easy disassembly and rigorous cleaning — helping meet GMP and ISO hygiene standards.

3). High Precision Filling & Aesthetic Packaging

In cosmetics, packaging isn’t just functional — it’s part of the brand experience. Uneven fills, air bubbles, or leakage can damage a product’s look and feel. King Pack’s servo-driven piston fillers, such as dual-head cream filling lines, and compact filling-sealing machines like the KPGFW-180, ensure consistent volumes, clean edges, and a premium finish.

These trends highlight why machines must be both flexible and precise. As product lines diversify — think serums, creams, gels, sprays — King Pack’s equipment helps manufacturers switch formats quickly without sacrificing accuracy or hygiene.

Recommended Reading: How to Choose a Tube Filling Machine Brand: In-Depth Analysis of Four Major Regions – King Pack Machinery

Core Equipment Modules for Cosmetic Packaging Lines

A modern cosmetic packaging line brings multiple systems together — from mixing and emulsifying to filling, capping, and labeling. King Pack designs each module to work seamlessly with the others, maintaining product quality, consistency, and visual appeal throughout production.

Emulsifying & Mixing Systems (Creams, Lotions, Gels)

KPZ-500L Vacuum homogenizing emulsifier – King Pack Machinery

Every cosmetic product starts with perfect blending. Creams, gels, and lotions require stable emulsions to achieve smooth texture and uniform consistency.

King Pack’s Vacuum Emulsifier Machine and Homogenizing Mixer combine high-shear mixing with vacuum deaeration to remove air pockets, ensuring consistent results.

| Machine | Ideal For | Key Features |

| Vacuum Emulsifier (KPE Series) | Creams, gels, balms | High-shear homogenizing, vacuum air removal, temperature control |

| Planetary Mixer | Thick pastes or wax-based products | Dual-motion agitation, heating jacket |

| Liquid Mixer (KPL Series) | Toners, serums, liquid soaps | Gentle mixing, adjustable speed, stainless-steel tank |

These systems produce smooth, stable formulations that maintain their texture and appearance throughout the production process.

Filling Machines for Liquids, Creams, Tubes

Liquid Foundation Filling and Capping Machine – King Pack Machinery

Accurate filling is crucial for both hygiene and efficiency. King Pack offers flexible solutions depending on product type and viscosity. Our Multi-Head Piston Filling Machine delivers ±1% accuracy for creams and gels, while the Servo Tracking Filling Machine handles thin liquids like foundations and shampoos.

For tube packaging, the KPGZW-60 Tube Filling & Sealing Machine supports plastic, laminated, and metal tubes.

| Machine | Ideal For | Key Features |

| Multi-Head Piston Filler | Creams, lotions, gels | High accuracy, minimal air inclusion |

| Servo Tracking Filler | Liquid foundations, shampoos | Precise nozzle movement, anti-spillage |

| KPGZW-60 Tube Filler & Sealer | Creams, gels | Automatic tube loading, ultrasonic or hot-air sealing |

| Eye Drop / Serum Bottle Filler | Serums, small liquids | Cleanroom precision, small-volume dosing |

These machines scale from pilot batches to high-output production when integrated with conveyors and capping units.

Capping & Closure (Pump Heads, Screw Caps, Snap Caps)

Lip Gloss Filling & Plugging and Capping Machine – King Pack Machinery

Capping protects products and ensures shelf stability. King Pack’s automatic capping systems apply consistent torque to avoid leaks.

The Rotary Capper works for bottles and jars, the Pump Head Capping Line suits lotions and sprays, and the Dual-Head Explosion-Proof Liniment Filler and Capper handles volatile liquids safely.

| Machine | Ideal For | Key Features |

| Rotary Capper | Bottles, jars | High-speed torque control |

| Pump Head Capping Line | Lotions, sprays | Automated pump placement |

| Dual-Head Explosion-Proof Capper | Perfumes, toners | Safety design for volatile liquids |

Automatic feeding and sorting units reduce manual labor while maintaining production speed.

Labeling & Coding (Front/Back, Wrap-around, Vision Inspection)

Heat Shrinking And Sleere labeling Machine – King Pack Machinery

Labeling and coding finalize the product’s presentation. King Pack offers machines for wrap-around, front/back, or dual-side labeling with optional vision inspection to detect misaligned or missing labels.

Batch codes, QR codes, and expiration dates can be printed directly on containers for traceability and brand consistency.

| Machine | Ideal For | Key Features |

| Wrap-around Labeler | Tubes, bottles | Precise application, continuous operation |

| Front/Back Labeler | Bottles, jars | Dual-sided labeling, adjustable speed |

| Vision Inspection Labeler | All container types | Detects misaligned/missing labels, quality control |

These modules ensure products not only look premium but also meet regulatory and traceability requirements, completing the production line efficiently.

Recommended Reading: How an Automatic Tube Filling and Sealing Machine Works – King Pack Machinery

Packaging & Integration Solutions

Cosmetic brands often deal with multiple product types — from squeeze tubes to glass dropper bottles. King Pack’s integration expertise helps unify all these packaging needs.

Tube Filling & Sealing Systems for Creams & Gels

Tubes remain popular for hand creams, facial cleansers, body lotions, and hair treatments. They protect products from air exposure, provide controlled dispensing, and offer excellent portability for consumers.

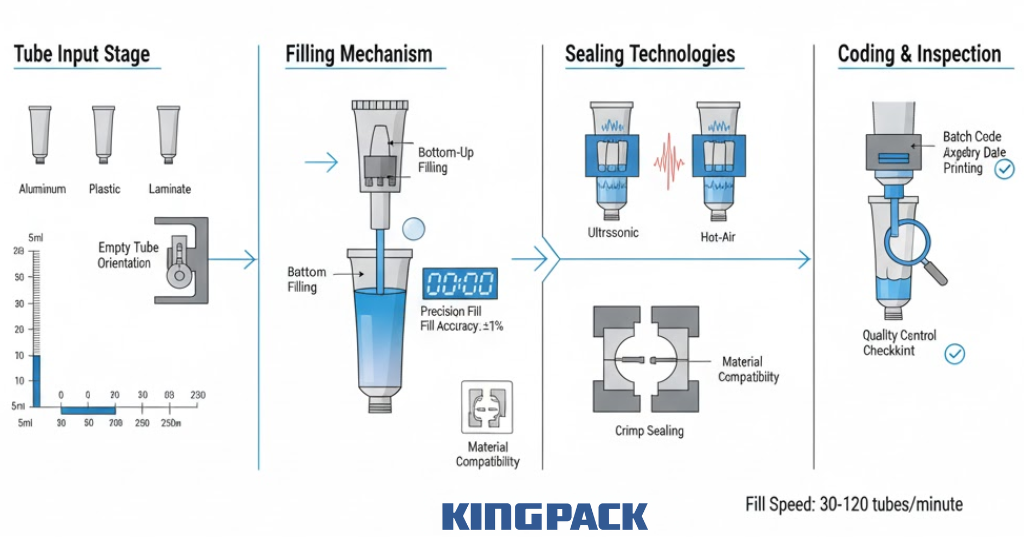

King Pack’s tube filling and sealing machines handle the complete process from empty tube input to sealed, coded, and inspected finished tubes. The system orients tubes, fills from the bottom to minimize air pockets, folds and seals tube ends, and applies batch coding in a continuous operation.

Here are Tube Filling Line Capabilities:

- Tube sizes from 5ml to 250ml

- Output speeds: 30-120 tubes per minute depending on configuration

- Fill accuracy: ±1% of target volume

- Material compatibility: aluminum, plastic, laminate

- Sealing options: ultrasonic, hot-air, crimping

- Integrated printing for batch codes and expiry dates

These machines process various tube materials including aluminum (traditional but recyclable), plastic (economical), and laminate tubes (premium barrier properties). Sealing methods include ultrasonic, hot-air, and crimp sealing depending on material type.

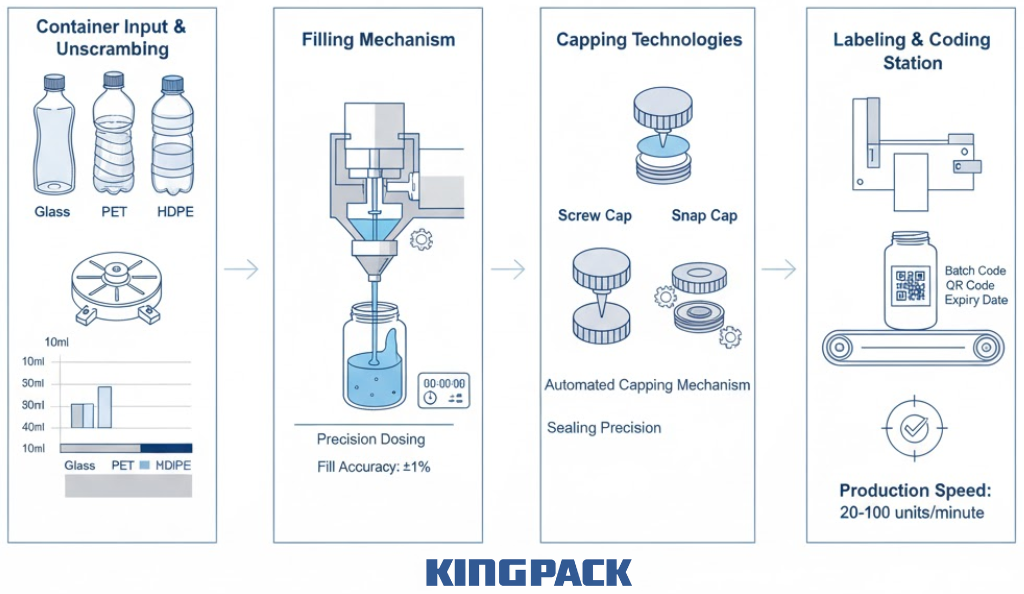

Bottle/Jar Filling Lines for Lotions & Serums

Bottles and jars remain essential for serums, lotions, and creams. King Pack’s filling lines are designed to handle a wide range of container sizes — from small glass droppers to large jars — while maintaining high precision and hygiene standards. These systems combine filling, capping, and labeling in one continuous line, ensuring every unit meets consistent volume and quality requirements.

The integrated lines also include bottle unscramblers, conveyors, and buffer tables, allowing smooth product flow between modules. Servo-driven fillers provide accurate dosing for liquid and semi-liquid products, while automatic cappers secure pump heads, screw caps, or snap closures efficiently. Labeling units apply batch codes, QR codes, and expiration dates to each container, completing the market-ready packaging.

Here are Bottle/Jar Filling Line Capabilities:

- Container sizes: 10ml–500ml

- Output speed: 20–100 bottles/jars per minute depending on model

- Fill accuracy: ±1%

- Material: glass, PET, HDPE jars

- Capping: screw caps, pump caps, snap caps

- Integrated labeling and coding

These lines can be scaled for pilot batches or high-volume production, providing cosmetic manufacturers with a reliable, automated solution for diverse products.

Modular Automation, Quick Changeover & Multi-product Flexibility

Modern cosmetic lines must switch between products quickly to keep up with market demand. King Pack’s modular automation allows manufacturers to reconfigure machines for different container types, sizes, or product viscosities without lengthy downtime.

Quick changeover systems enable tools and fixtures to be swapped within minutes, reducing batch transition delays. Integrated software and servo-controlled drives maintain accuracy and consistency across formats, from creams to liquids, tubes to jars.

Modular Automation Features:

- Fast tool and fixture changeovers (5–15 minutes)

- Multi-product compatibility on a single line

- Servo-driven control for consistent filling solutions and labeling machines

- Automated conveyor integration for seamless flow

- Software for recipe management and production tracking

By combining flexibility with automation, King Pack Cosmetics Packaging Machinery allows manufacturers to process multiple personal care products efficiently on one line, boosting output while maintaining high-quality standards and hygiene.

Recommended Reading: The Importance of Tube Filling Machine and Tube Sealing – King Pack Machinery

Material Handling & Auxiliary Systems in Cosmetic Lines

The efficiency of a packaging line depends not only on the main equipment but also on the handling systems that connect them.

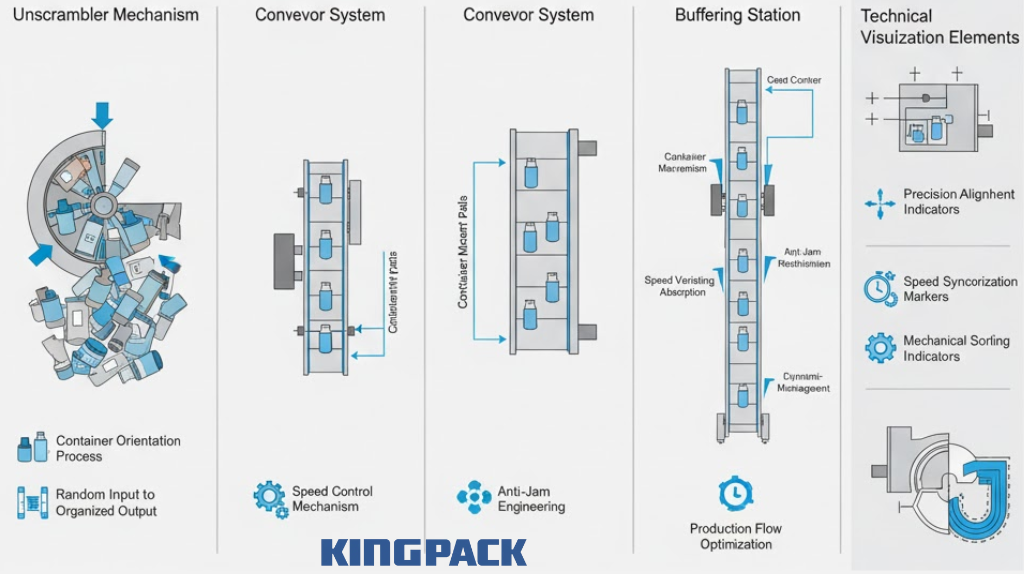

Unscramblers, Conveyors & Buffering Systems

King Pack builds full support systems to move bottles and jars smoothly through production. Our bottle unscramblers automatically feed containers upright, while belt conveyors keep spacing consistent to prevent jams.

Buffering tables are added between filling and capping stations to absorb production speed variations — a common cause of downtime in high-speed lines.

CIP/SIP Systems, Cleaning-in-Place & Sanitation Design

Cleanability is one of the biggest challenges in cosmetics manufacturing. Residue from viscous creams can clog pipes or cause bacterial growth.

King Pack integrates CIP systems with hot water or cleaning solution circulation. This not only keeps the equipment sanitized but also saves labor hours by eliminating manual disassembly.

| Cleaning System | Application | Benefit |

| CIP Loop System | Filling nozzles, tanks, pipelines | Automatic rinsing between batches |

| SIP Steam Sterilization | Contact surfaces in clean areas | Maintains microbiological safety |

| Quick-Release Valves & Seals | High-viscosity mixers | Easy maintenance, fewer parts replacement |

Rapid Format Changeover and Minimised Downtime

Every hour of downtime costs production. A case study by Cosmetics Manufacturing Journal found that automated format change systems can reduce idle time by 25–35% in small-batch facilities.

King Pack’s servo-driven height adjustments, preset parameters, and digital control panels allow fast reconfiguration without mechanical intervention — keeping lines running smoothly.

How King Pack Stands Out

King Pack isn’t just another equipment supplier. Our strength lies in combining engineering precision, customization, and global service for every cosmetic client.

Customisation for Viscous & Delicate Cosmetic Products

From dense balms to watery serums, viscosity changes everything in filling accuracy. King Pack designs tailored filling heads, agitator designs, and vacuum systems to suit each formula’s flow behavior.

For example:

- Creams → Piston filler with heating jacket

- Gels → Vacuum emulsifier + servo filler

- Serums → Peristaltic filler for micro-dosing

This customization helps maintain product texture and appearance during packaging.

Compliance with GMP / CE / ISO Standards & After-Sales Support

All machines comply with CE, GMP, and ISO 9001 standards, covering material safety, hygiene, and electrical design.

King Pack also offers on-site installation, training, and spare parts support to help teams get started quickly. Our multilingual support team assists customers across Asia, Europe, and the Americas.

Cost-Efficiency for OEM/Brand Customers & Global Reach

OEM manufacturers face tight production budgets. King Pack’s equipment is priced competitively while offering high throughput. Many systems share common components, reducing spare part inventory and training costs.

The company ships worldwide and has completed installations in cosmetics facilities across China, the Middle East, and Europe — proving reliability beyond local markets.

Conclusion

The beauty market rewards brands that combine creativity with consistency. Behind every flawless bottle or neatly sealed tube lies machinery designed to handle the finest details.

King Pack’s cosmetic packaging solutions cover every stage — mixing, emulsifying, filling, capping, labeling, and cleaning — to deliver efficiency, hygiene, and visual appeal in one integrated system.

Contact King Pack today to design your customized cosmetic packaging line and take your production from formula to finished product with confidence.