Mayonnaise is one of the most widely used condiments in the world, appearing in everything from salads to sandwiches. But what many don’t realize is that it can also offer certain health benefits when made with quality ingredients.

Research shows that mayonnaise prepared with plant-based oils is a source of essential fatty acids, which support heart health and brain function, while its vitamin E content adds antioxidant benefits. These advantages, however, rely on proper production. In this article, we’ll cover the health benefits of mayonnaise and why specialized machines are vital for consistent, high-quality production.

Defining Mayonnaise: Ingredients and Common Usage

Mayonnaise is a semisolid oil-in-water emulsion made through careful blending of oil, vinegar, egg yolk, and spices, traditionally containing 70-80% oil. This creamy condiment serves multiple culinary purposes, from sandwich spreads to salad dressings and cooking ingredients.

The basic composition includes vegetable oils (soybean, canola, or olive), egg yolks as natural emulsifiers, acid components (vinegar or lemon juice), and seasonings like salt and mustard. Modern variations incorporate different oils and additives to enhance nutritional profiles and extend shelf life.

Recommended Reading: How Long Do Sealed Sauce Packets Really Last? Shelf Life, Storage & Safety Tips – King Pack Machinery

Why Is Mayonnaise Good For You? Mayonnaise Mayo Health Benefits

Contrary to popular belief, mayonnaise offers several nutritional advantages when consumed as part of a balanced diet. Mayonnaise is an excellent source of vitamins E and K, essential nutrients often lacking in modern diets.

The healthy fats in mayonnaise, particularly when made with quality oils like olive or avocado oil, provide essential fatty acids that support cardiovascular health and nutrient absorption.

Besides its fats and vitamins, mayonnaise offers benefits when used wisely:

- Boost Hair Health: The oils and proteins in mayo help moisturize dry hair, making strands smoother.

- Helps Nail Strength: Applying a small amount can moisturize cuticles and reduce brittleness.

- Improves Skin Health: Its oils and lecithin can act as emollients, softening and repairing skin.

- Relief From Burns: Some home remedies use mayo (cool, plain) to give mild soothing effects to sunburn (though this is anecdotal, not medical).

- Get Rid of Lice: Traditionally, thick mayo or oil is left on hair for hours to suffocate lice (again, a folk remedy more than clinical proof).

What is the Nutritional Value of Mayonnaise?

Understanding mayonnaise’s nutritional profile helps dispel common misconceptions about its health impact. One cup of mayonnaise contains 1440 calories and 160 grams of fat, with 24 grams being saturated fat, making portion control essential for healthy consumption.

However, realistic serving sizes tell a different story. Regular mayonnaise has just 1 to 2 grams of saturated fat per tablespoon, about the same as olive oil, making moderate consumption more reasonable than these large-volume statistics suggest.

Nutritional Breakdown Per Tablespoon (15g):

- Calories: 90-100

- Total Fat: 10-11g

- Saturated Fat: 1-2g

- Sodium: 70-120 milligrams

- Vitamin E: 8% Daily Value

- Vitamin K: 10% Daily Value

Answering Your Top Mayonnaise FAQs

- Is Mayo Nutritious? Yes, if consumed in moderation. It delivers healthy fats and fat-soluble vitamins.

- Is Mayonnaise Heart-Healthy? Because most fat in mayo is unsaturated, it can fit inside balanced diets. It’s low in saturated fat.

- How Frequently is “Often”? Use mayo sparingly—one tablespoon occasionally is reasonable in many diets.

- Which Is the Best Mayo For You? Pick versions with good oils (olive, MUFA-rich), low sodium, minimal additives, or egg-free recipes for dietary restrictions.

Why Mayonnaise Making Machine is Important?

Consistency, Emulsion Quality, and Reducing Manual Errors

Industrial mayonnaise production relies on precise mayonnaise machines and filling machines to maintain consistent texture and emulsion quality. The emulsification stage is crucial, requiring accurate blending of vegetable oil, egg yolk, and water. Traditional manual methods cannot achieve the uniformity needed for commercial operations, leading to variations in texture, appearance, and shelf life.

Modern Mayonnaise Makers and Vacuum Homogenizers use advanced rotating blades and emulsifying mixers to create fine oil droplets, eliminate microbubbles, and prevent flocculation. This precision ensures stable emulsions that manual processes cannot match, improving both product quality and reliability.

Recommended Reading: How Are Ketchup Packets Made – King Pack Machinery

Scaling Up Production

Commercial operations demand output levels that manual mixing cannot support. Automated mayonnaise manufacturing equipment can process thousands of liters per hour while maintaining consistent quality across long production runs. High-shear emulsification systems allow continuous processing in industrial settings, meeting market demand efficiently.

Using automated systems also reduces labor requirements and minimizes safety risks associated with large-scale manual mixing. The controlled production environment lowers contamination risks, supporting compliance with strict food industry safety standards.

Click Here to Check Our Products

What Does a Mayo Production Machine Include?

Parts and Systems: Vacuum System, Emulsifier/Homogenizer, Control System, Platform

A modern mayonnaise production line relies on advanced equipment designed for consistency, hygiene, and efficiency. Each component works in harmony to create a smooth and stable emulsion while meeting rigorous food industry safety standards. From the vacuum pump system to the filling and capping stages, every part of the setup ensures the product retains its taste, texture, and shelf life, even under the demands of large volume producers.

Below are the key parts and systems that make up a complete mayonnaise production machine:

1. Vacuum Emulsification System

The vacuum system plays a central role in the mayonnaise-making process. By drawing ingredients below the liquid’s surface during mixing, it prevents air from being incorporated. This is critical, as trapped air can cause foaming, reduced stability, and a shorter shelf life. Vacuum emulsion mixing also improves density and appearance, producing a glossy, uniform texture.

An additional benefit is processing at lower temperatures, which protects sensitive nutrients, reduces oxidation, and preserves the freshness of oils and other raw materials. For industrial-scale operations, this translates to longer-lasting flavor and higher overall product quality. Many machines in the market now integrate vacuum emulsifying homogenizing mixers to combine high-shear emulsification with vacuum control for optimal results.

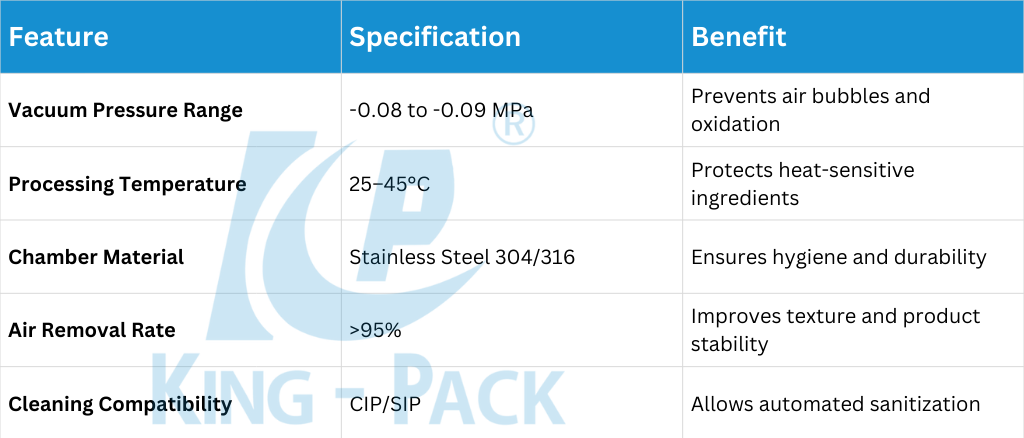

The following table shows the technical specifications of Vacuum System:

2. High-Shear Emulsifier/Homogenizer

The emulsifier or high-pressure homogenizer is the core of the production line. Using rotor–stator structures and sometimes central blade mixers or wall scraping mixers, it generates intense shear forces that reduce oil droplets to less than one micron. The result is a stable emulsion with uniform droplet distribution, crucial for the creamy texture expected in mayonnaise.

This high-shear technology supports the production of high viscosity emulsions, flavored variations, or traditional formulations, maintaining batch-to-batch consistency. Integrated ultrasonic technology or aeration systems in some models further enhance texture and product stability. These systems are also scalable, allowing machine & equipment manufacturers to meet growing demand in the mayonnaise market efficiently.

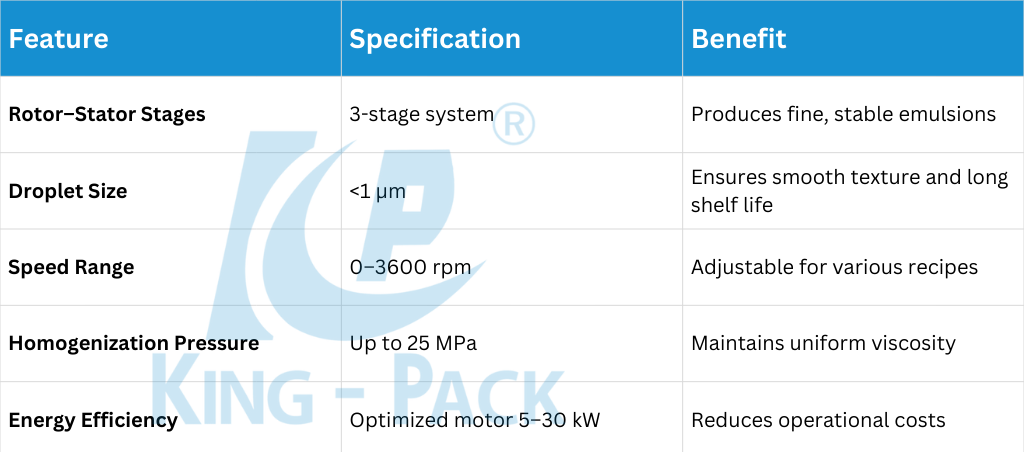

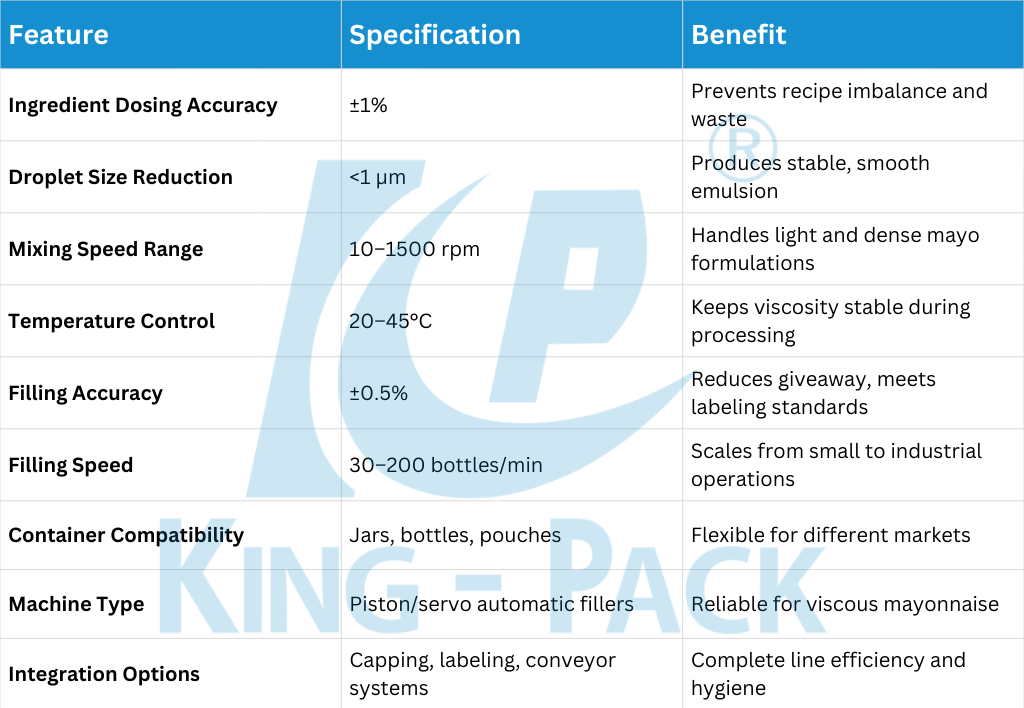

The following table shows the technical specifications of High-Shear Emulsifier/Homogenizers:

King Pack’s vacuum emulsifier machines provide the precise control needed for mayonnaise production, incorporating advanced emulsification technology that maintains product quality while maximizing production efficiency.

Recommended Reading: The Differences Between Homogenization and Emulsification – King Pack Machinery

3. Advanced Control Systems

A reliable mayonnaise production line must maintain strict control over every variable. Modern control systems use digital panels and PLCs (programmable logic controllers) to monitor temperature, mixing speed, vacuum pressure, and ingredient ratios. Operators can adjust these parameters in real time, ensuring recipes are followed precisely.

Automated data logging adds another advantage—allowing quality assurance teams to track performance, verify consistency, and comply with safety certifications such as HACCP or ISO. This reduces the margin for error and increases efficiency by minimizing downtime during production shifts.

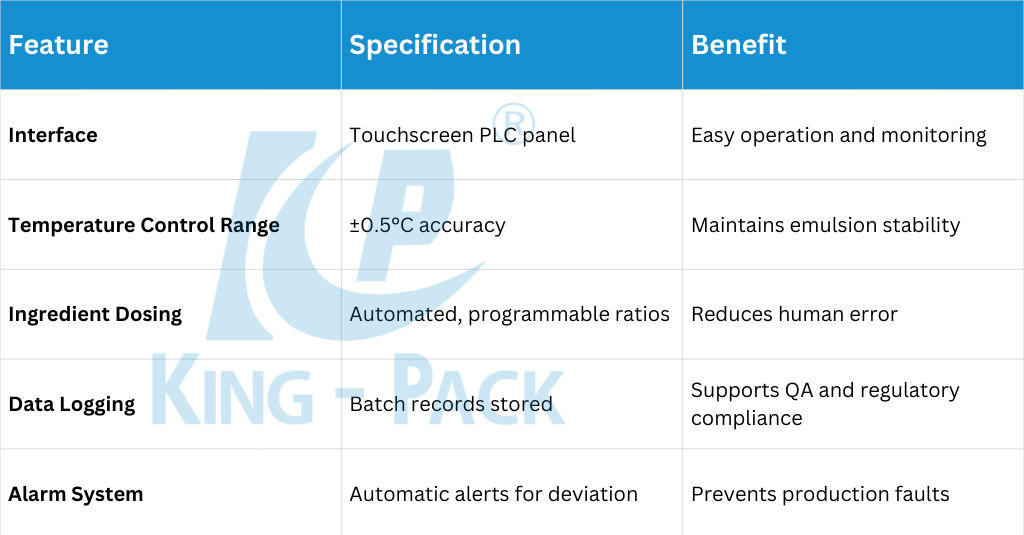

The following table shows the technical specifications of Advanced Control Systems:

4. Processing Platforms

The processing platform typically includes stainless steel tanks for water, vinegar, oil, and other ingredients. Ingredients are pumped into the emulsification tank where the vacuum system and homogenizer work together to create a uniform blend. Stainless steel is the preferred material because it resists corrosion, maintains hygiene, and supports easy cleaning between batches.

Platforms are designed to optimize workflow while supporting clean-in-place (CIP) systems. This ensures production remains sanitary without requiring excessive downtime. For manufacturers, the result is a system that balances durability, safety, and ease of maintenance.

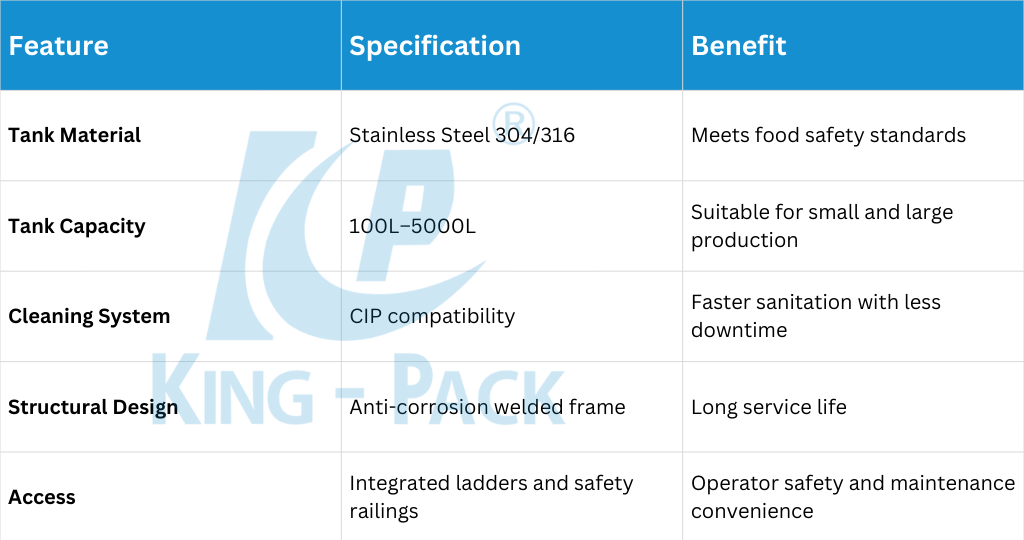

The following table shows the technical specifications of Processing Platforms:

5. Mixing and Filling Procedures

The production process starts with ingredient measurement and sequential dosing into the mixing tank. The vacuum system pulls in liquids like water and vinegar, followed by controlled oil addition. High-shear emulsifiers reduce droplet sizes below 1 micron, creating tightly packed structures that enhance viscosity and stability.

Recommended Reading: What are the precautions for filling and sealing machine? – King Pack Machinery

Maintaining high viscosity is crucial for mayonnaise, as it improves mouthfeel and prevents separation. Temperature control throughout mixing ensures the product remains consistent. Once the emulsion is ready, filling and capping machines integrate with the emulsifier to package the mayonnaise in jars, bottles, or sachets, maintaining hygiene from start to finish.

Mayonnaise Production Process Steps

The mayonnaise production process starts with careful preparation and precise measurement of all ingredients. Using controlled dosing systems, the water phase is blended first, followed by the gradual addition of oil to form a stable emulsion. Advanced vacuum homogenizers and emulsifying mixers ensure high-shear emulsification, producing a smooth, consistent texture. Rotating blades and sweep wall stirrers refine particle size, while homogenization mixers further stabilize the emulsion, preventing flocculation and ensuring uniform thickness throughout the batch.

Once the mixture reaches the desired consistency, quality control checks are carried out. These include monitoring pH levels, measuring viscosity, analyzing particle size, and performing microbiological testing to ensure safety and consistent product quality. Integrated measurement & control systems detect deviations early, while vacuum emulsion mixing and vacuum defoaming processes maintain emulsion stability, reduce air incorporation, and improve overall product appearance.

Temperature control and viscosity monitoring are critical to maintaining consistency, while industrial-scale mixers with stainless steel 304 construction provide durability and hygiene suitable for the food industry. Once the mayonnaise is ready, automated filling machines and capping systems transfer the product into jars or bottles efficiently, minimizing manual handling and contamination risks. Discharge systems, top trays, and user-friendly interfaces help streamline operations and support high throughput in commercial production.

With modern mayonnaise homogenizer mixers combined with automated filling lines, manufacturers achieve a seamless production workflow. Each step, from mixing and emulsifying to packaging, is optimized for accuracy, hygiene, and efficiency. This controlled process ensures that every jar or bottle meets regulatory standards, maintains product stability, and delivers the creamy mouthfeel that consumers expect. Automated systems also support scalability, allowing producers to meet market demand while maintaining consistent quality across all production runs.

Recommended Reading: Cream Tube Filling Machine: The Ultimate Guide – King Pack Machinery

Conclusion

Mayonnaise offers surprising health benefits. However, process used to make it is complex emulsification process that requires specialized machinery to achieve commercial viability and consumer acceptance. At King Pack, we provide complete mayonnaise production solutions—from emulsification to filling and capping—helping brands scale confidently without compromising on quality.

If you’re ready to strengthen your production line with reliable, high-performance technology, visit King Pack Filling Machine and connect with our team today.