The modern consumer demands portability, convenience, and sustainability in their product packaging. This shift has driven the flexible packaging segment to the forefront of the global market, with the spout pouch emerging as a dominant format for liquid and semi-liquid goods.

In this article, we will explore King Pack’s spout pouch filling solutions. We’ll also cover the key features, technology, and operational advantages of these machines, including their ability to fill, clean, and cap pouches with precision while maintaining hygiene standards.

What Is a Spout Pouch and Why It’s Popular

A spout pouch, sometimes called a doypack, is a flexible, pre‑made pouch equipped with a screw cap or spout. These pouches can stand upright (gusset or bottom), making them ideal for liquids, semi-liquids, gels, and viscous products. Their reclosable design and portability have made them increasingly popular, especially in consumer-focused sectors.

Globally, the spout pouch packaging market is witnessing strong demand. According to industry research, the spout pouch market was estimated at USD 2.23 billion in 2024, and it’s projected to grow at a compound annual growth rate (CAGR) of 3.9% through 2034.

In parallel, the premade pouch filling machine market (which includes spout pouch fillers) is expected to rise from USD 2.5 billion in 2023 to over USD 4 billion by 2033, reflecting growing adoption of flexible packaging machinery.

Recommended Reading: Premade Pouch Filling Machine — Unlocking New Packaging Speed & Market Competitiveness – King Pack Machinery

Key Industries & Product Applications (Food, Cosmetics, Chemicals)

The versatility of the spout pouch filling machine allows it to serve a vast spectrum of industries, adapting seamlessly to products ranging from thin liquids to thick pastes.

| Industry | Typical Products Packaged in Spout Pouches | Key Requirement |

| Food & Beverage | Fruit purees, yogurts, juices, sauces, cooking oils, honey, baby food | High hygiene (CIP compatibility), precise volume control, hermetic sealing |

| Cosmetics & Personal Care | Lotions, shampoos, creams, liquid soap refills, hand sanitizers | Drip-free filling, compatibility with viscous and abrasive materials, maximum product evacuation |

| Industrial & Chemical | Adhesives, lubricants, detergents, household cleaners, fertilizer concentrates | Corrosion resistance, accurate dispensing of chemicals, durable capping |

The food and beverage sector remains the primary driver, accounting for a substantial share of the market. This adoption is heavily supported by the pouch’s ability to maintain product freshness and simplify on-the-go consumption, particularly in categories like baby food and functional beverages.

King Pack’s spout pouch filling machines are well-suited for these sectors, offering hygienic, precise, and efficient solutions.

Advantages of Using Premade Spout Pouches Over Other Packaging Formats

The shift from rigid packaging, such as glass bottles and plastic jars, to premade spout pouches delivers concrete advantages across the supply chain, impacting logistics, cost, and environmental footprint.

Some of the main benefits of using premade spout pouches are:

- Reduced packaging cost: Flexible pouches use less material than rigid containers.

- Portability & convenience: Lightweight and resealable for the consumer.

- Sustainability potential: Less plastic usage; potential for recyclable or mono-material pouches.

- Shelf appeal: Dynamic shapes (stand-up, gusset) and high-quality print.

- Less waste: Efficient filling machines can reduce overfill and product loss.

In short, spout pouches provide a convenient, cost-effective, and consumer-friendly option — and King Pack’s machinery helps brands take full advantage of those benefits.

Main Features & Technology

A high-performance spout pouch filling and capping machine must offer more than just speed; it requires integrated intelligence, robust mechanics, and precision handling. King Pack’s equipment is designed with this holistic efficiency in mind, typically employing the highly reliable rotary indexing table design for continuous, accurate processing. Below are their key technical features.

PLC & HMI Control for Precise Operation

The nerve center of our automatic spout pouch machine is the integrated Programmable Logic Controller (PLC) system, managed through a user-friendly Human-Machine Interface (HMI) touch-screen panel.

- Centralized Control: The PLC governs all critical functions, including pouch feeding, volumetric or flowmeter filling, cap torque application, and safety interlocking mechanisms.

- Real-time Monitoring: The HMI provides operators with real-time feedback on production status, error diagnosis, and operational parameters (e.g., temperature, speed, and fill volume). This intelligent monitoring capability allows production managers to optimize cycles and promptly address any inconsistencies, ensuring maximal uptime.

- Recipe Management: Manufacturers can store and instantly recall specific operating recipes tailored to different pouch sizes or product viscosities, significantly reducing changeover time between production batches.

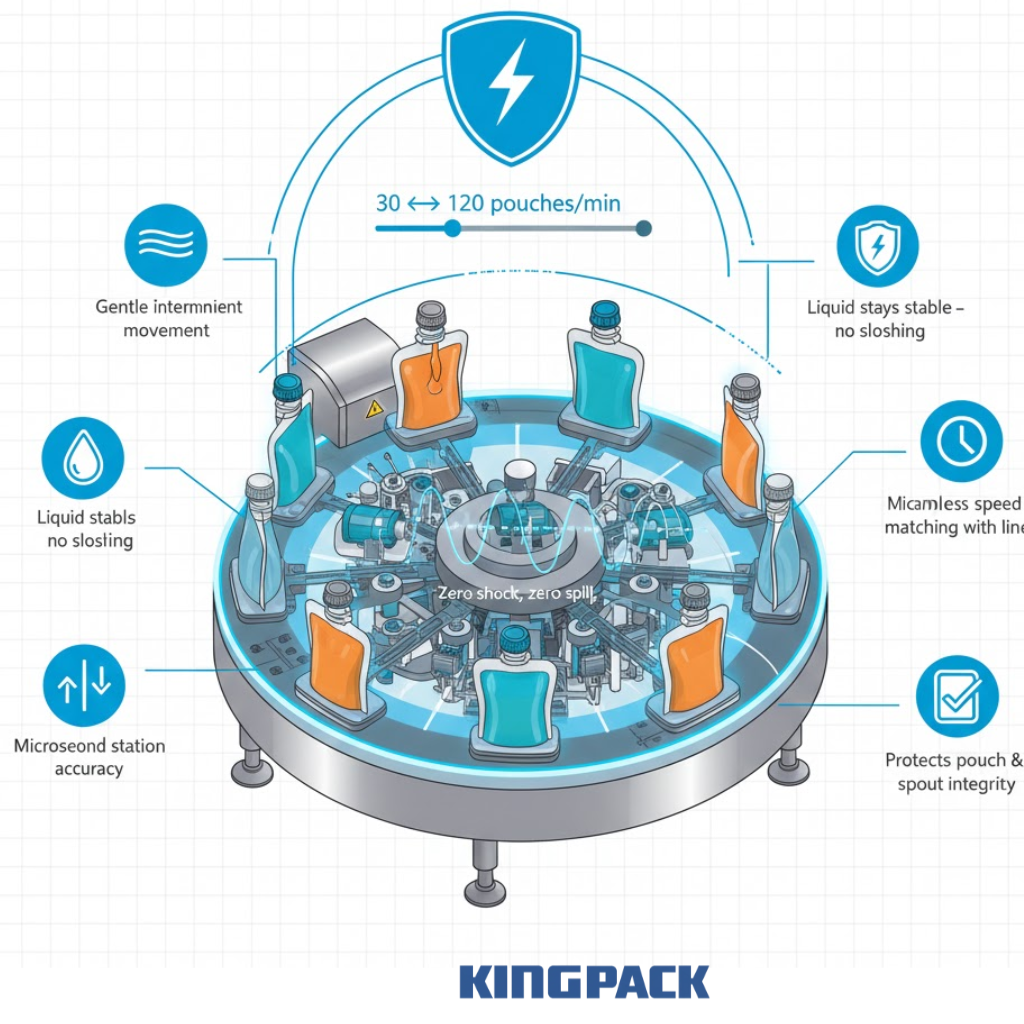

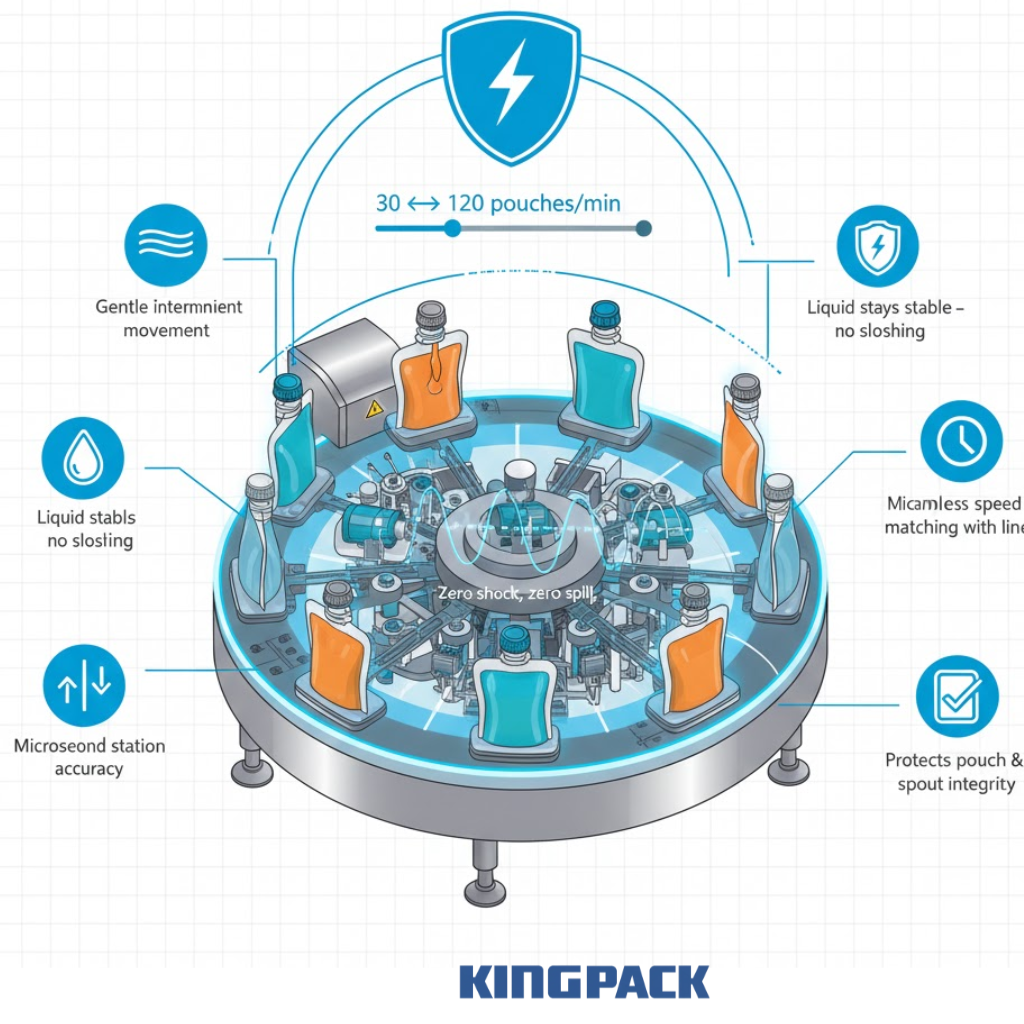

Variable Speed System & Precision Indexing Table

Efficiency in rotary pouch filling relies on synchronized, intermittent movement. Our machines utilize a variable frequency drive (VFD) and precision indexing systems to achieve this synchronization.

The VFD allows for fine-tuning the machine’s production speed (pouches per minute), enabling the machine to ramp up or slow down based on upstream or downstream equipment requirements. The precision indexing table ensures that each pouch arrives at the correct station—filling, cap placement, or capping—at the exact moment required.

This servo-driven movement eliminates jarring motions, protecting the integrity of the pouches and ensuring the stability of liquid contents during transport between stations.

Recommended Reading: Packaging Machine Solutions – King Pack Packaging Equipment – King Pack Machinery

Automatic Bag Feeding, Spout Cleaning & Cap Arrangement

Automation supports both hygiene and consistent speed across the line. The system feeds premade pouches through a magazine or conveyor, and sensors check each pouch before it moves forward. This avoids misfeeds and keeps the process steady.

For products that require extra care, an optional spout-cleaning step can be added. This uses air or inert gas to clear the spout and create a clean environment inside the pouch before filling starts.

Caps are handled through an automatic sorting setup. A vibratory bowl or centrifugal sorter arranges each cap in the right direction and moves it to the loading point. This approach removes manual handling and helps maintain GMP-friendly conditions.

Filling Mechanism to Prevent Splattering and Foaming

The filling phase is arguably the most critical function of the packaging line, where accuracy and cleanliness directly determine product quality and profitability. Our machines utilize sophisticated, specialized technology designed to maintain filling precision while actively mitigating product disturbance, which is the primary cause of foaming and spillage.

King Pack integrates various filler types to ensure optimal performance based entirely on the product’s physical characteristics and viscosity. This customization is essential for efficiency and material conservation.

| Filler Type | Product Viscosity/Nature | Primary Advantage |

| Piston Filler | Thick, highly viscous liquids (jams, pastes, heavy creams). | Superior volumetric accuracy and reliable dispensing force for challenging, dense products |

| Peristaltic/Lobe Pump | Sensitive, shear-sensitive, or highly sterile products (certain chemical solutions, cosmetics). | Non-contact filling path to maintain product integrity and purity |

| Flow Meter (Mass/Magnetic) | Low-viscosity, free-flowing liquids (juices, water, thin oils). | Exceptional weight-based accuracy and optimized throughput for high-speed liquid applications |

To actively combat foaming and splashing—a common challenge with detergents, soaps, and certain beverages—our systems employ “bottom-up” or diving nozzle technology.

The nozzle moves deep into the pouch before dispensing starts. As the liquid flows, the nozzle rises at a controlled pace so the stream stays under the surface of the filling product. This reduces turbulence, cuts down on trapped air, and limits foam, which helps keep every pouch consistent.

A servo-controlled cut-off stops drips the moment the fill is complete. This keeps the pouch opening clean and supports a smooth, secure seal. The result is a cleaner process and better protection for the product.

Filling & Capping Process Flow

Here’s a typical step-by-step of how King Pack’s spout pouch machine works:

- Pouch Feeding → Inflating → Filling

- Pouches are automatically taken from a magazine.

- They are gently inflated (air or vacuum) so the shape is stable.

- The indexing table aligns each pouch, and the fill nozzle fills the correct volume.

- Spout Washing & Cap Loading

- If needed, spouts are flushed/cleaned.

- A cap feeder or magazine arranges caps, orients them, and places them on the spout.

- Sealing / Capping → Final Output

- A capping head (torque-controlled) closes the caps.

- The completed pouch is discharged, ready for secondary packaging or inspection.

This sequence ensures a streamlined, efficient cycle with minimal manual intervention.

Technical & Performance Advantages

Selecting King Pack means choosing reliability and high-level performance engineering. Our machines offer concrete advantages that optimize throughput and reduce operational friction.

Adjustable Output via Variable Frequency Drive

The integration of the VFD technology allows manufacturing plants to adjust production speed dynamically. This is a crucial element of lean manufacturing, enabling the line speed to be matched precisely to other upstream or downstream machines (e.g., sterilization equipment, labelers, or case packers).

This ability to modulate the output prevents bottlenecks, minimizes product backlog or starvation, and maintains a smoother operational flow, which directly translates to reduced wear and tear on components and higher average efficiency over time. Furthermore, the electronic speed control provides softer starts and stops, protecting delicate mechanisms during operational changes.

Recommended Reading: Multilane Packing Machines – High‑Speed Multichannel Sachet & Stick‑Pack Solutions | King Pack – King Pack Machinery

High Filling Accuracy & Repeatability

Accuracy is the foundation of profitability in liquid filling. Under-filling results in consumer complaints and potential regulatory issues, while consistent over-filling translates to significant material waste and loss of profit over millions of units.

King Pack machines deliver high repeatability, ensuring that every pouch receives the identical fill volume, batch after batch. This precision is achieved through closed-loop control systems.

For example, if a flowmeter system detects a slight variance in liquid density, the PLC instantly adjusts the filling time or pump speed to ensure the target mass or volume is met with superior precision. This level of control minimizes product giveaway, maximizing the return on investment (ROI) from raw materials.

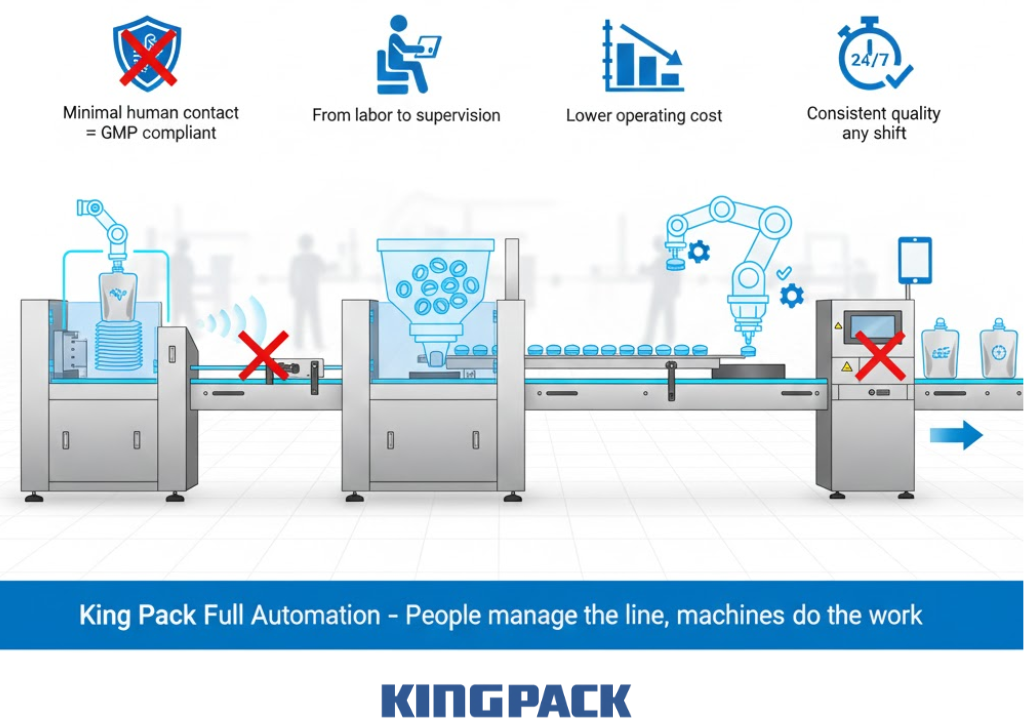

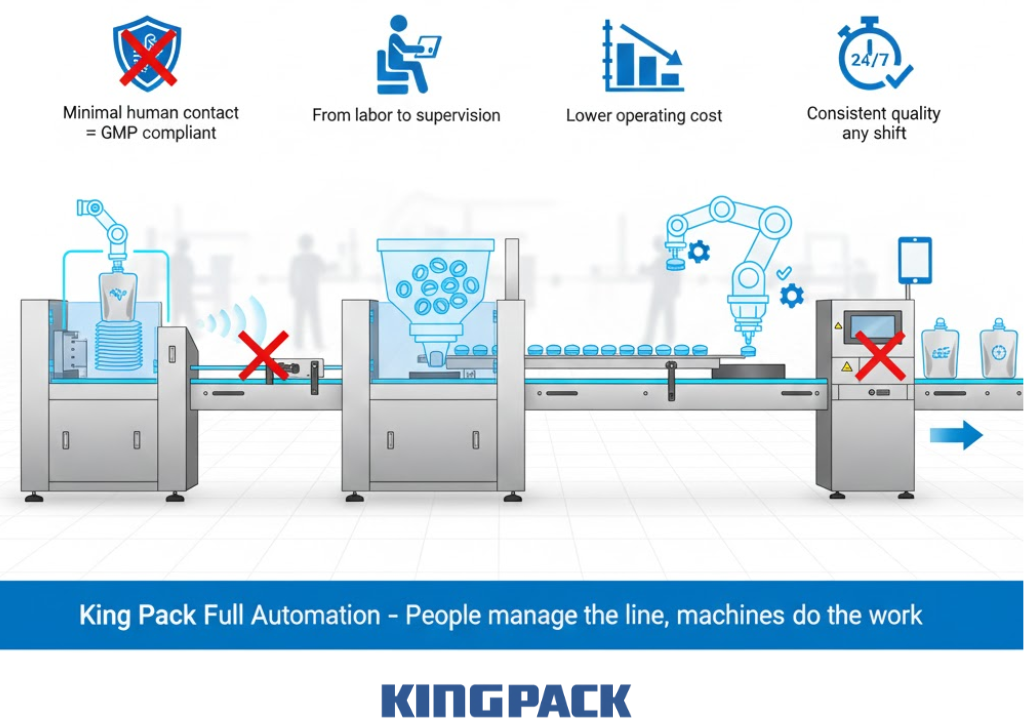

Labor Saving through Automation & Intelligent Feeding

A fully automatic spout pouch machine is a powerful tool for reducing reliance on manual labor for repetitive, contamination-prone tasks.

- Streamlined Operations: Tasks such as pouch loading, cap sorting, cap placement, and final capping are all mechanized. This shift allows human operators to transition from performing physical labor to managing and monitoring the technical process, increasing the overall quality and safety of the line.

- Reduced Handling: The automated process minimizes human contact with both the pouch and the cap, significantly lowering the risk of microbial contamination and supporting stringent food safety protocols.

Machine Design & Hygiene

King Pack’s equipment is built for durability and hygiene. The stainless steel frame (304 or 316) resists corrosion and supports food-safe or cleanroom environments, while all contact parts—including nozzles and surfaces—use food-grade materials to ensure product safety.

Cleaning and maintenance are simple thanks to removable components like filling heads, spout clamps, and nozzles. This design reduces downtime and supports strict hygiene practices, including clean-in-place (CIP) procedures.

To maintain safe operations, King Pack includes:

- Transparent dust cover to prevent contamination and protect operators.

- Emergency stop buttons at key stations.

- Diagnostic software that detects faults, warns about maintenance, and guides troubleshooting.

These features help protect both operators and product integrity.

How to Choose the Right Spout Pouch Machine

Selecting the right machine depends on several key factors. Here’s how to evaluate your options:

Selecting the right spout pouch filling capping machine depends on several factors:

Assess Product Viscosity & Filling Volume

Low-viscosity liquids like juices or sauces work well with standard discharge nozzles and faster packaging speed. High-viscosity products, gels, or foamy liquids require anti-drip sealing rings, dwell-time control, or servo-driven mechanisms to maintain accurate filling volume and reduce product wastage. Semi-automatic spout pouch filling machines handle smaller runs, while automatic dual head filling systems support higher capacities.

Choose Between Inline or Rotary Models

Inline semi-automatic machines are cost-effective and ideal for mid-range production. Rotary Packing Machines or Unified Flex systems offer higher throughput for large-scale operations. Both setups integrate PLC control, HMI system, or digital panel interfaces for precise packaging operations and efficient cap handling.

Evaluate Automation, Maintenance, and Support

Decide if you need Automatic capping, spout capping, screw-on cap options, or full integration with an automatic bottle filler. Consider power supply, Transmission system reliability, and low-pressure protection for safe operation. Support for spare parts, installation, and operator training ensures smooth long-term performance and helps optimize shipping costs.

Secure Your Production Line Future with King Pack Filling Machine Solutions

The spout pouch filling machine is a central asset for any company packaging liquid and semi-liquid products. It represents not just a piece of equipment, but a strategic investment in product protection, cost efficiency, and alignment with consumer demands for convenience and sustainability.

The ability to guarantee fill accuracy to within $ \pm 0.3%$, coupled with the logistical and material advantages of flexible packaging, provides an undeniable competitive edge. King Pack Filling Machine Solutions are engineered for precision, durability, and seamless integration, offering manufacturers the robust machinery required to dominate in high-demand global markets.

We do not just supply machinery; we deliver complete filling and capping solutions built for your product’s unique requirements. Contact King Pack today to consult with our engineering team and learn how our automatic rotary systems can maximize your production throughput and guarantee superior product quality.