The shift toward flexible packaging is a definitive trend in the global consumer market. This format offers an unparalleled combination of strong shelf presence, exceptional barrier protection, and user convenience. This makes it the preferred choice for a vast range of products, from fine powders and granular solids to high-value liquids and pharmaceutical doses.

At King Pack, we offer premade pouch packing machines to handle a wide range of products while maintaining steady and predictable production. In this article, we will discuss how premade pouch machines work. You’ll also find practical guidance on choosing the right setup for your product, along with real-world applications across food, pharmaceuticals, and daily chemical categories.

Why Use Premade Pouches vs Form-Fill-Seal Pouches?

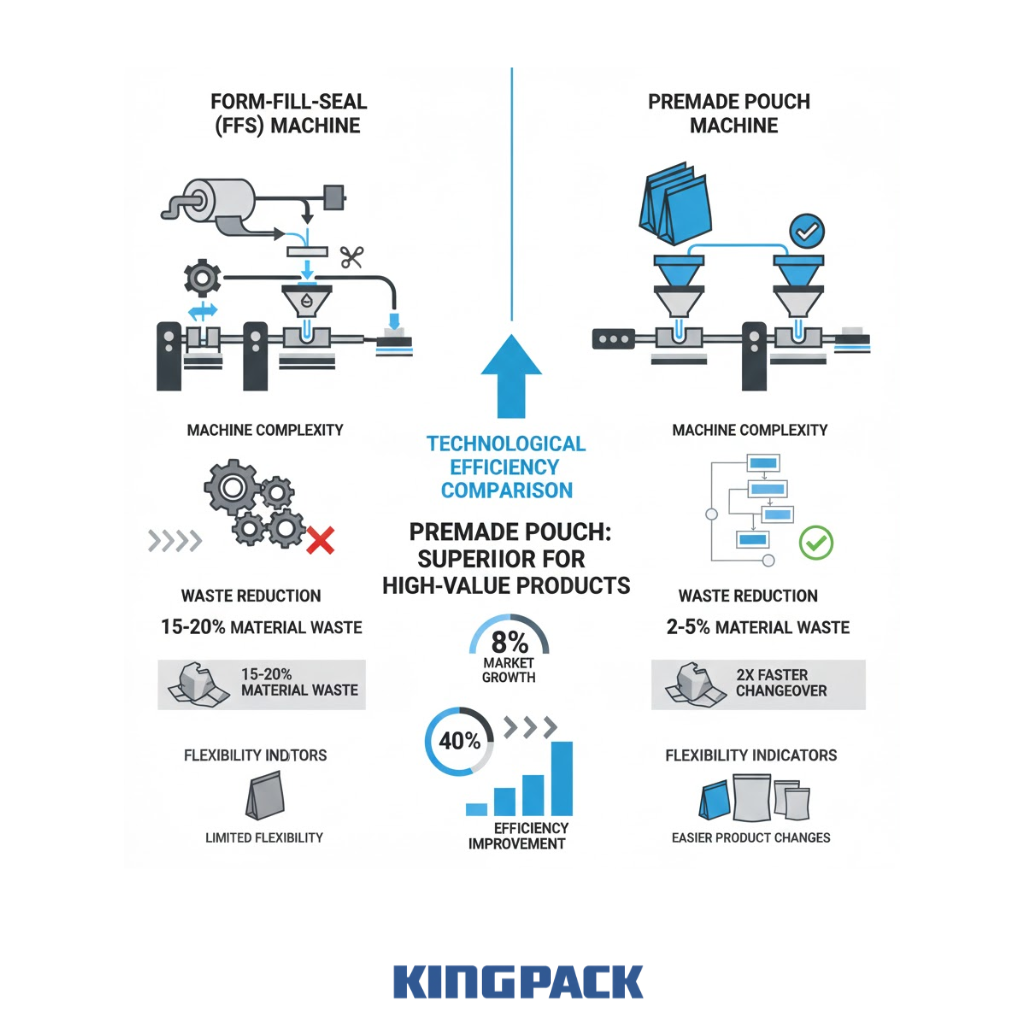

Premade pouches are pre-formed bags (e.g., doypacks, zip pouches) that are picked, opened, filled, and sealed — rather than formed from a roll of film. The choice between a premade pouch packing machine and a Form-Fill-Seal (FFS) machine is a foundational production decision.

While FFS systems are highly efficient for simple, high-speed applications using rollstock film, premade pouch machines offer distinct advantages, particularly when packaging complex or high-value products.

Some key advantages of premade pouches:

- Reduced material waste: No need to form bags from film reduces scrap.

- Design flexibility: Use complex pouch shapes, zippers, spouts, and reclosable features.

- Faster changeovers: Since pouches are pre-made, format changes can be quicker than FFS machines.

- Better brand look: Pre-printed pouches deliver consistent graphics and high-quality finishes.

Premade pouch machines reduce the burden on the packer by eliminating the film forming step, allowing the machine to focus solely on precision opening, filling, and sealing. This capability is vital for packaging high-barrier, complex pouches, such as those with zippers or specialized spout fittings.

The global stand-up pouches market, the format most often run on premade machines, was valued at USD 34.38 billion in 2024 and is projected to reach USD 64.17 billion by 2032, exhibiting a robust CAGR of 8.28%. This growth underscores the increasing preference for this format.

Recommended Reading: Multilane Packing Machines – High‑Speed Multichannel Sachet & Stick‑Pack Solutions | King Pack – King Pack Machinery

Common Industries and Products That Use Premade Pouches

The flexibility to handle a wide variety of products makes premade pouch machines essential across several key industrial sectors. The stand-up pouch, in particular, offers superior shelf appeal and is highly favored by retailers.

| Industry Sector | Primary Product Types | Examples |

| Food & Beverage | Powders, Granules, Liquids, and Solids | Protein powders, spices, coffee, sauces, nuts, dried fruits. |

| Personal Care & Cosmetics | Creams, Lotions, Gels, and Liquid Refills | Shampoo, conditioner, face creams, liquid soap, sunscreens. |

| Pharmaceuticals | Tablets, Capsules, and Fine Powdered Drugs | Single-dose medications, nutritional tablets, powdered antibiotics. |

| Daily Chemicals / FMCG | Liquids, Pastes, and Powders | Detergent powders, household cleaners, liquid cleaners, fertilizer concentrates. |

Types of Filling Mechanisms in Premade Pouch Machines

The true versatility of the premade pouch packing machine stems from its ability to integrate various specialized dosing systems onto the rotary or linear platform. King Pack utilizes a modular approach, allowing the same machine to switch fillers based on the product being run.

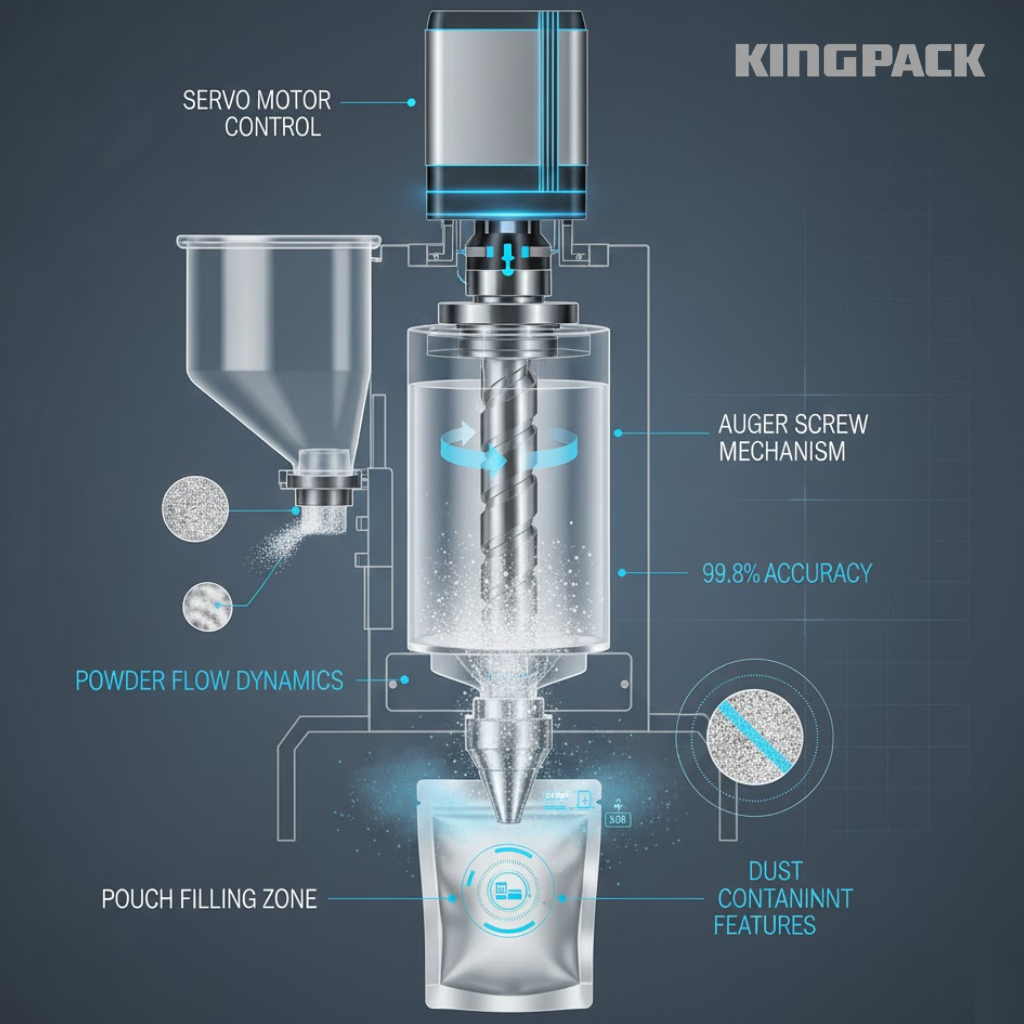

Auger Filler — Ideal for Powder Products

The auger filler is the industry standard for dosing powdered products, especially those that are non-free-flowing or dusty, such as flour, spices, protein powder, or pharmaceutical mixes.

The mechanism utilizes a rotating vertical screw (the auger) positioned directly above the pouch opening.

A servo motor controls the number of rotations, which in turn controls the precise volume or weight of powder dispensed. This ensures high volumetric accuracy and consistency, even when dealing with difficult, high-fat, or sticky powders.

Auger fillers feature a simple, contained design, which minimizes airborne dust during the filling process, contributing significantly to a cleaner production environment and reduced product loss.

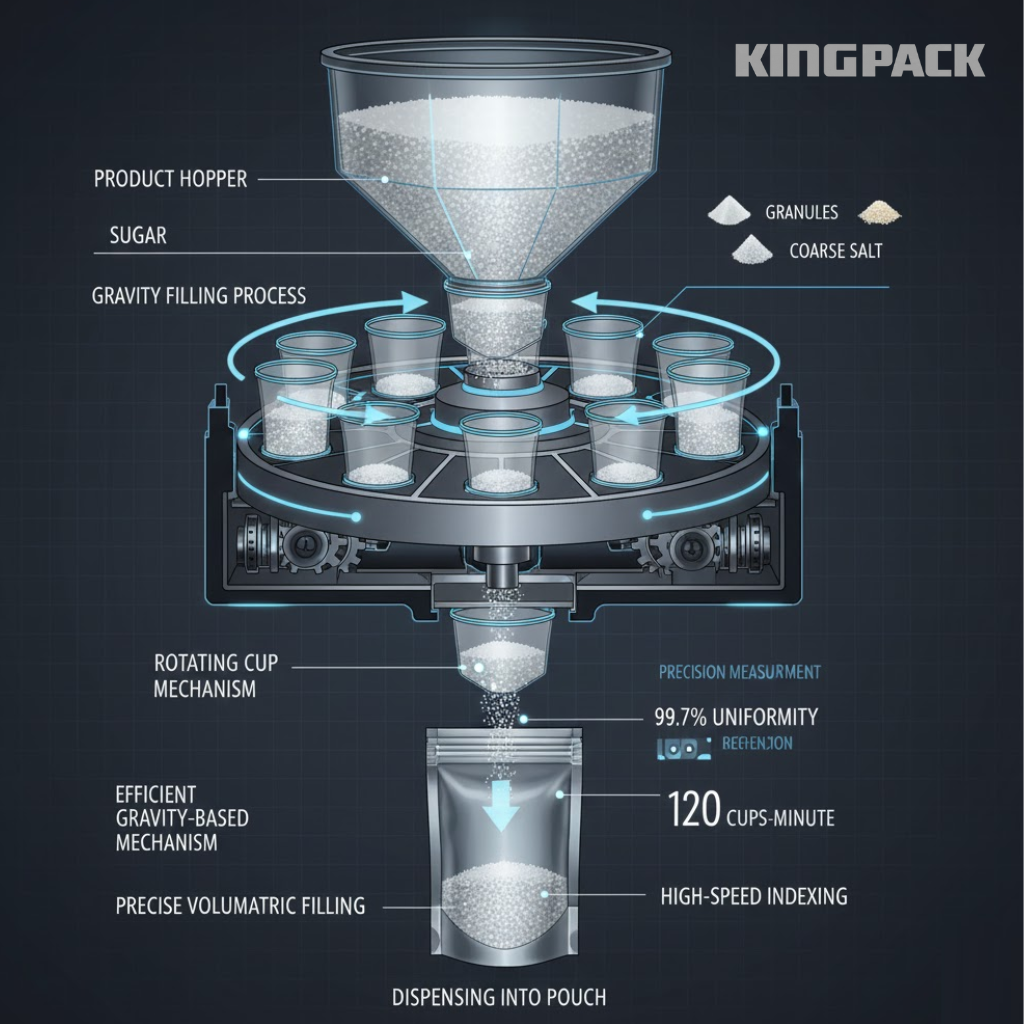

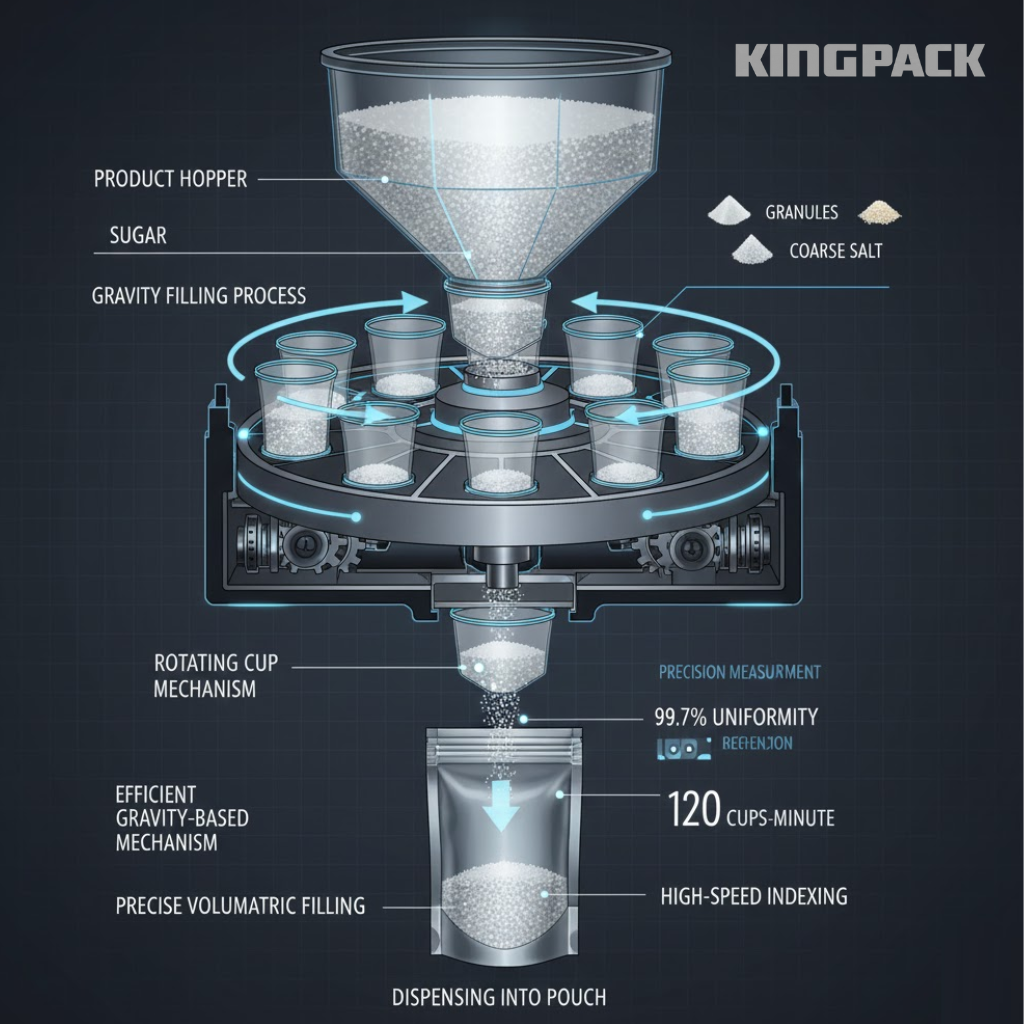

Volumetric Cup Filler — For Granules / Small Solids

For free-flowing granular products and small solid items, the volumetric cup filler provides a simple, highly efficient, and cost-effective dosing solution.

This mechanism utilizes adjustable telescopic cups or a fixed-volume turret that rotates beneath a product hopper. The cups are filled by gravity and then indexed over the pouch opening, where a shutter or gate releases the measured dose.

This method is exceptionally quick and ideal for products with uniform density, such as sugar, coarse salt, rice, and certain granular chemicals. Its simplicity of operation and robust construction makes it a preferred choice for high-throughput, bulk-product packaging where product uniformity is consistently high.

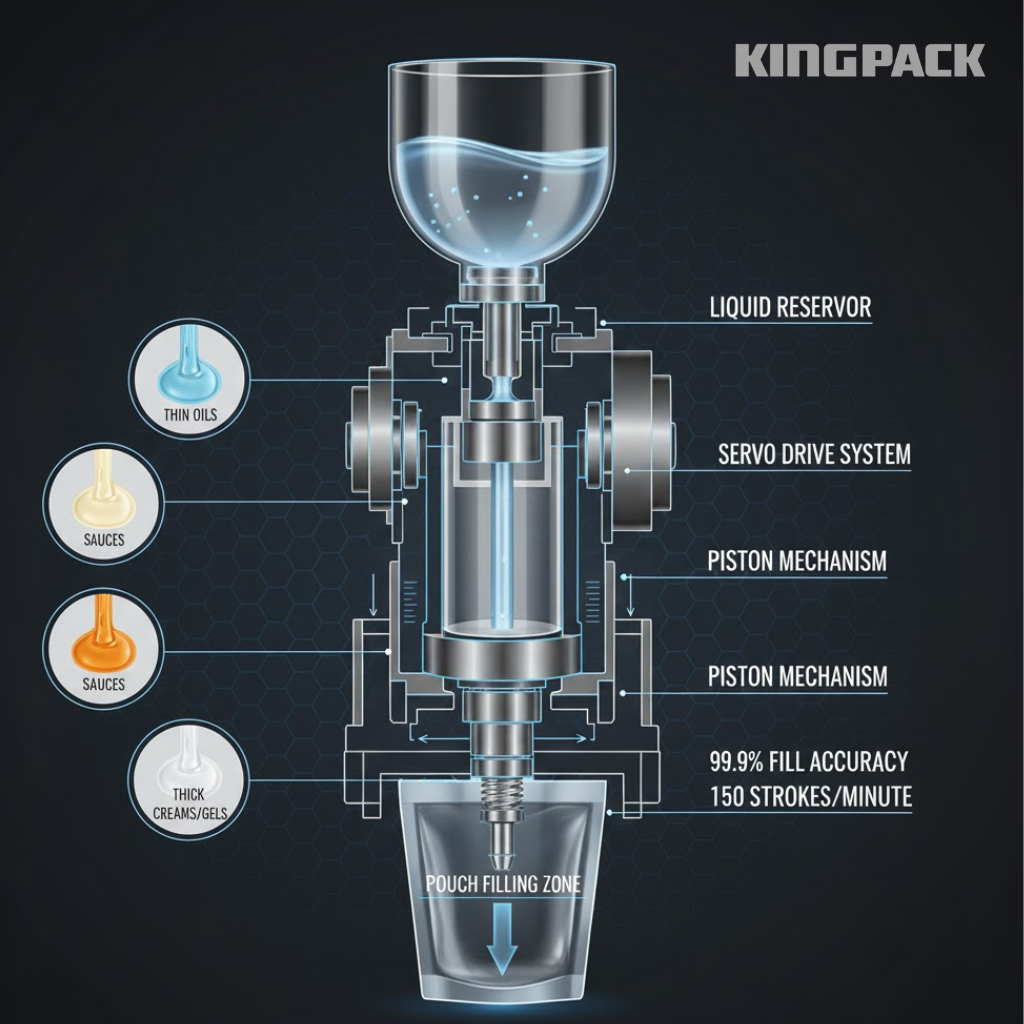

Piston Pump — For Liquid Applications

The piston pump is the definitive solution for precise filling of liquids and pastes, ranging from thin oils and sauces to thick creams and gels.

Each dose is controlled by the stroke volume of a precision-machined piston, driven by a servo or pneumatic system. This positive displacement action ensures unrivaled volumetric accuracy, making it perfect for high-value liquid products where product giveaway must be minimized.

The design is inherently anti-drip, as the piston acts as a positive shut-off device, ensuring the seal area remains clean. King Pack utilizes models like the KPL-160HPL (Horizontal Type Premade Bag Packing Machine for Liquid/Paste) capabilities to handle difficult viscous fluids.

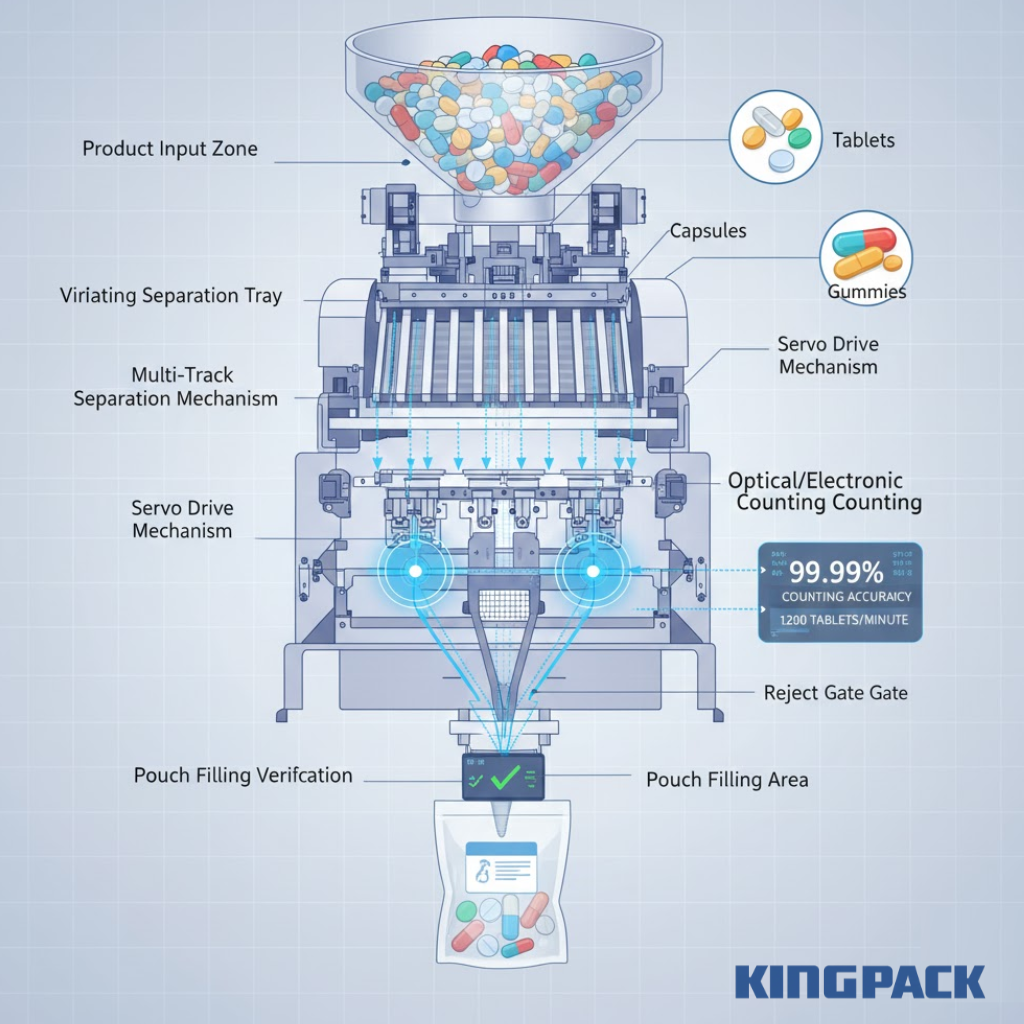

Tablet / Capsule Counting Filler — For Pharmaceuticals

For the pharmaceutical and nutraceutical industries, accuracy is regulated and non-negotiable. Tablet and capsule counting fillers are integrated into the premade pouch machine to meet these stringent demands.

These mechanisms utilize advanced electronic or optical counting technology to verify the exact number of pills, capsules, or gummies being dropped into the pouch. Systems often use vibrating trays or multi-track counting channels to separate and count product at high speeds.

This electronic verification system ensures near-perfect accuracy (often exceeding $99.98\%$), providing essential compliance for prescription medications and consumer safety for supplements.

Recommended Reading: Packaging Machine Solutions – King Pack Packaging Equipment – King Pack Machinery

Compatible Premade Pouch Types

A key differentiator of King Pack’s equipment is its universal handling capability, allowing one machine to run dozens of different pouch styles with minimal adjustment, maximizing packaging format flexibility.

Stand-up Pouches (Doypacks)

The Stand-up Pouch, or Doypack, is the most recognizable and fastest-growing format in this category. Its reinforced bottom gusset allows the pouch to stand vertically on the shelf, offering exceptional display value and shelf-level visibility.

These pouches are favored for their high product-to-package weight ratio and their resealability, which enhances consumer convenience. They are used extensively for pet food, liquids with spouts, and premium food items.

Zipper Pouches

Zipper pouches incorporate a plastic track zipper, allowing consumers to easily reseal the package after opening. This helps preserve product freshness and extend shelf life, which is particularly valuable for multi-use items like coffee, protein powders, and snacks.

King Pack machines handle these pouches with precision: the rotary station has dedicated devices that open and hold the zipper correctly during filling. After the product is deposited, the pouch is sealed above the zipper line, ensuring a secure and user-friendly package.

Spout Pouches

Spout pouches are designed for pourable liquids and viscous products, such as baby food purées, sauces, or concentrated cleaners. The pouch integrates a heat-sealed or ultrasonically welded spout, typically positioned at the corner or center, through which the product is filled.

King Pack’s premade pouch machines detect the spout and fill the product accurately before applying a cap or sealing the pouch. Spouted pouches are a growing segment, reaching a market size of USD 14.5 billion in 2024 (Source: Mordor Intelligence), reflecting their dominance in convenient liquid dispensing formats.

Flat Bags, 3-Side Seal, 4-Side Seal & Custom Shapes

Beyond Doypacks, the machines can process simpler, economical formats as well as uniquely designed packages:

| Pouch Type | Description | Application Focus |

| Flat Bags | Basic flat pouches requiring only three or four seals. | Cost-effective, high-speed single-serving packets. |

| 3-Side Seal | Sealed on three sides, with the top open for filling and final sealing. | Often used for small dry goods and promotional items. |

| 4-Side Seal | Sealed on all four sides, typically used for small, two-part packets. | Sachets and controlled-dose pharmaceutical or cosmetic packs. |

| Custom Shapes | Contoured or uniquely shaped pouches (e.g., promotional items). | High brand recognition and specialized marketing campaigns. |

Recommended Reading: Premade Pouch Filling Machine — Unlocking New Packaging Speed & Market Competitiveness – King Pack Machinery

Technical & Operational Advantages

King Pack’s rotary premade pouch systems are built for industrial-level performance, integrating advanced automation to maximize output and reliability while minimizing operator intervention.

Full-Automation: Bag Feeding, Filling, Sealing & Output

The core benefit of the premade pouch machine is its complete, hands-free automation across all critical stations.

The process begins with the Automatic Bag Feeding station, where vacuum suction cups reliably pick up pre-stacked pouches from the magazine and transfer them to the rotary clamps.

Subsequent stations automatically open the pouch, verify its status (No Fill / No Seal detection), execute the precision filling using the integrated mechanism, and finally, seal the pouch with heated jaws and discharge the finished product. This seamless sequence, running at up to 60-200 cycles per minute, ensures non-stop, high-volume production.

PLC Touch-Screen Control for Easy Operation

The operational efficiency of the system is managed through a state-of-the-art Programmable Logic Controller (PLC) coupled with an intuitive Human-Machine Interface (HMI) touch-screen.

This digital control system centralizes all critical parameters: seal temperature, fill volume, machine speed, and product recipes. Operators can quickly and accurately set up new jobs or recall stored product settings without manual adjustments to the mechanical components.

The HMI also provides real-time diagnostics and operational feedback, simplifying troubleshooting and reducing the learning curve for new personnel.

Automatic Bag Detection (No Fill / No Seal) Packaging Machine

Product and pouch material waste are significant operational costs. King Pack machines incorporate rigorous detection protocols to eliminate these issues.

Automatic Bag Detection sensors verify that a pouch is correctly picked, fully opened, and present at the filling station. If a pouch is missing or unopened, the PLC system prevents the filling cycle from activating (No Fill).

Similarly, the machine detects if the pouch has a defective seal or if product contamination has occurred, rejecting the packet before final sealing or discharge (No Seal), thereby saving subsequent material. This feature is key to achieving high material efficiency and consistent product quality.

Quick Format Changeover for Different Bag Sizes

Flexibility is a key driver for premade packaging. King Pack machines are designed to facilitate rapid changeovers between different bag widths and heights.

For many models, the bag width adjustment is automatically completed by a motor, allowing format changes to be executed in minutes rather than hours.

This efficiency is critical for contract packers or manufacturers running multiple Stock Keeping Units (SKUs) on the same line. The quick-change design minimizes downtime, maximizing the machine’s valuable production hours.

Hygiene, Cleanability, & Safety

Given the range of products handled—especially food, pharmaceuticals, and sensitive chemicals—machine design must prioritize absolute hygiene and operator safety.

Food / Pharma Grade Stainless Steel Construction

Adherence to Good Manufacturing Practice (GMP) is guaranteed through material choice. All product contact parts, as well as exterior panels in the wet zones, are constructed from high-grade stainless steel, predominantly SUS 304 or SUS 316L.

SUS 316L is specifically used for its superior corrosion resistance against acidic products or aggressive cleaning agents, ensuring material integrity and preventing chemical leaching into the product. The sanitary construction includes smooth, continuous welds that eliminate crevices where bacteria can harbor.

Easy Disassembly for Cleaning

Effective sanitation relies on quick and complete access to all product-touch surfaces. The machine’s design incorporates tool-less or minimal-tool disassembly features for all major components, including the filling heads, hoppers, and discharge chutes.

This modular approach facilitates efficient Clean-Out-of-Place (COP) procedures, drastically reducing the time required for deep cleaning and allowing for fast, verified changeovers between batches.

Safety Features & Error-Alarm System

Operator safety and machine longevity are ensured through multiple layers of protective design.

The machine features interlocked safety guards that immediately halt operation if an access door is opened during a cycle.

An integrated Error-Alarm System uses sensors and diagnostics to continuously monitor motor performance, temperature, and pressure. If a deviation occurs—such as film end, bag jam, or sealing element failure—the machine triggers a clear alarm and displays the specific error message on the HMI, allowing for rapid fault resolution and preventing catastrophic failure.

How to Choose the Right Premade Pouch Packing Machine

Selecting the right packaging machinery requires aligning it with your Food Products and operational needs. Here’s how to choose the ideal premade pouch packing machine for your line:

Match Filler Type to Your Product

For powders, liquids, or tablets, choose a pouch fill & seal machine that works seamlessly with your product. Proper matching ensures smooth handling and avoids slowing production capacity.

Choose Bag Format Based on Your Packaging Strategy

Decide between stand-up prefabricated bags for retail appeal or flat bags for efficiency. Bag magazine options help streamline your workflow, while Flexibles & Trays or rigid tray packaging provide versatility for different product lines.

Evaluate Production Speed, Footprint, and Support Services

Assess speed against space constraints and integrate packaging equipment with mechanical arms or Robotics & End of Line systems for maximum efficiency. Consider after-sales support and machinery installations that simplify maintenance and improve line uptime.

A careful review of your product type, packaging equipment, and workflow keeps your operations steady. Planning ahead avoids bottlenecks and ensures your packaging machinery supports future growth.

Conclusion & Call to Action

King Pack’s premade pouch packing machines are not merely pieces of equipment; they are integrated, high-precision manufacturing solutions. By combining the flexibility to run complex pouch styles with the precision of interchangeable, servo-driven filling mechanisms, we deliver efficiency and automated cleanliness across a wide range of product categories.

This is a smart packaging solution for scalable, clean, and cost-effective production in the modern global market.

Contact King Pack today to design your customized premade pouch packing line and receive a tailored quote that reflects your specific product and output requirements.