The pet pharmaceutical and care market is expanding rapidly. Pet owners increasingly demand safe, effective, and high-quality medicines. This makes precision and sterility in production essential.

At King Pack, we specialize in high-precision pet drop filling machines. Our solutions help manufacturers produce eye drops, ear drops, oral supplements, and veterinary prescription liquids reliably. Every bottle is filled with consistent volume and sterility.

In this article, we will explain why pet drop filling requires specialized equipment, explore its key applications, highlight critical buying factors, and show how our machines support modern production standards.

Why Pet Drop Filling Requires Specialized Equipment

Filling drops for pets is not the same as general liquid filling. Eye and ear drops must remain sterile to prevent contamination. Oral supplements require precise micro-dosing. Even small deviations can affect product safety and effectiveness.

Pet bottles usually range from 5 ml to 30 ml. Handling such small volumes consistently requires precise pumps and controls. Manual filling is not reliable for modern production. Automated systems reduce errors and improve repeatability.

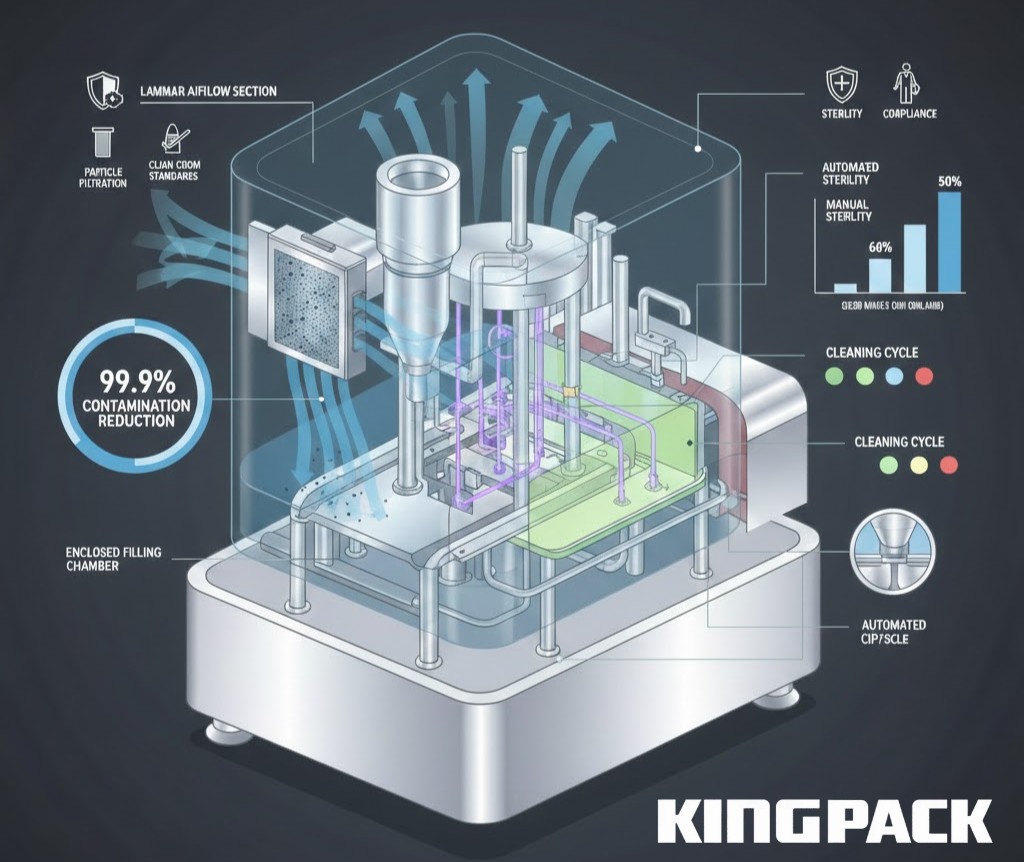

Regulatory standards are stricter than ever. By 2026, pet medicines must comply with GMP guidelines. Machines need hygienic designs, quick changeover capability, and minimal human contact. Our machines feature closed filling chambers, stainless steel product paths, and CIP/SIP readiness to meet these requirements.

The veterinary pharmaceuticals market is expected to reach $7.6 billion by 2026, growing at a CAGR of 6.2%. This growth emphasizes the need for accurate, sterile, and scalable filling solutions. Small-breed pets also increase the demand for smaller bottles and precise dosing.

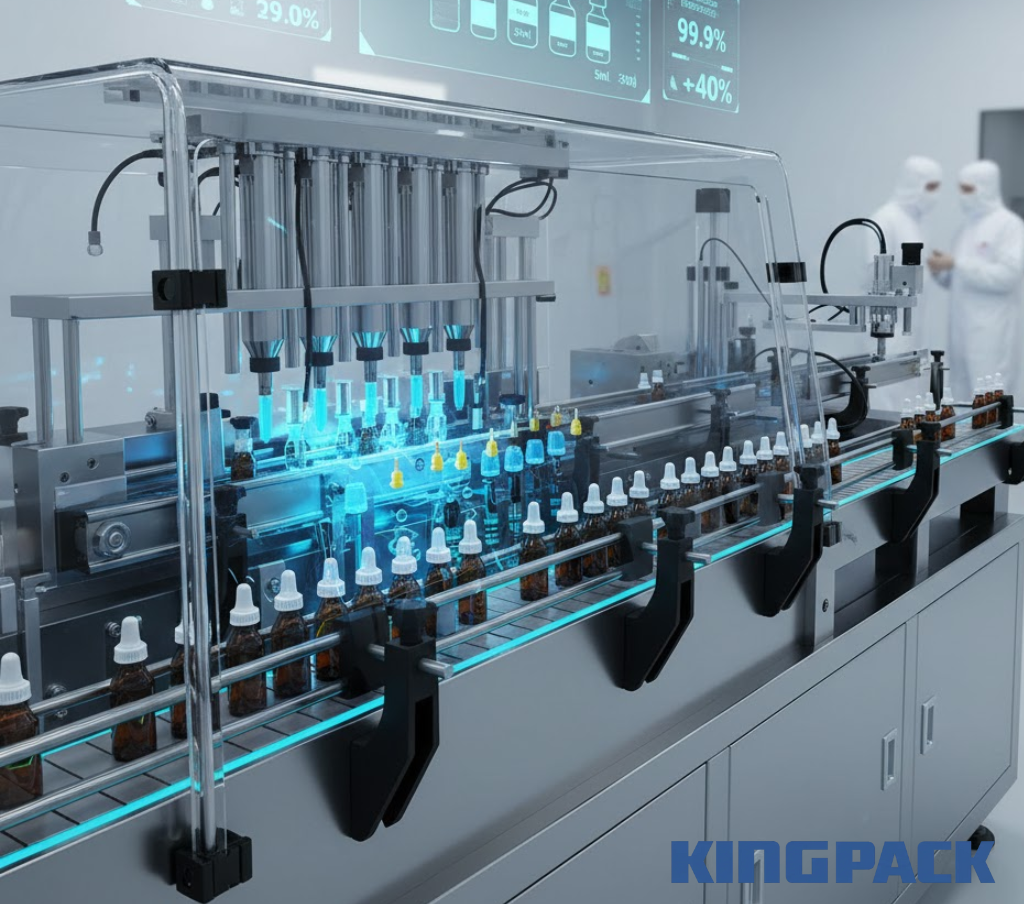

At King Pack, we design our pet eye drop filling machines with servo-driven dosing. This ensures precise volume control in enclosed filling zones. Our automatic dropper bottle filling machines combine filling, dropper insertion, and capping. The result is efficient, sterile, and highly reliable production.

Recommended Reading: Tube Sealing and Coding Technology Guide 2026: Achieving High-Integrity Seals and Serialization Compliance – King Pack Machinery

Key Applications of Pet Drop Filling Machines

Pet drop filling machines are used across veterinary and pet care industries. Accuracy, sterility, and flexibility are essential for every product type.

Pet Eye Drops and Ear Drops

Eye and ear drops demand strict sterile handling. Our pet eye drop filling machines deliver micro-volumes with high precision. The enclosed filling zones minimize human contact. Stainless steel product paths make cleaning simple. Optional laminar airflow is available for high-sterility needs. Automatic dropper insertion and capping complete the process.

Oral Liquid Supplements for Pets

Pet vitamins and tonics require consistent dosing for every bottle. Our small volume liquid filling machines ensure stable volumes for low-viscosity liquids.

They accommodate multiple bottle sizes and integrate filling with capping and labeling. Multi-SKU production is simple with quick changeovers. Reduced manual handling improves line efficiency and consistency.

Disinfectant and Care Solutions

Pet shampoos, ear cleaners, and disinfectants benefit from our semi-automatic or fully automatic filling lines. Our machines maintain accuracy while handling different viscosities. They minimize spillage and speed up production. Small and medium batches can run without compromising quality.

Veterinary Prescription Liquids

Prescription medicines require strict GMP compliance. Our servo piston filling machines deliver precise micro-volumes and maintain sterility. Enclosed filling zones reduce contamination risk. Stainless steel surfaces allow thorough cleaning. CIP/SIP readiness makes changeovers between different formulas fast and reliable.

Core Buying Factors for Pet Drop Filling Equipment

Selecting pet drop filling equipment requires a close look at how the machine performs in real production. Accuracy, hygiene, bottle handling, and automation all affect product safety, compliance, and long-term efficiency. A weakness in any one area can create risks that are costly to fix later.

Manufacturers also need to think beyond current output. Product ranges expand, regulations tighten, and batch sizes change. Equipment should support these shifts without forcing frequent replacements or complex upgrades.

At King Pack, we design pet drop filling machines around these core factors. The goal is steady performance today and flexibility for future growth.

Filling Accuracy and Repeatability

Filling accuracy directly affects pet safety and regulatory approval. Eye drops, ear drops, and oral liquids rely on precise micro-dosing. Even small volume variations can lead to inconsistent treatment or failed inspections.

Eye Drop Bottle Filling and Capping Machine – King Pack Machinery

Modern pet drop production depends on controlled dosing systems rather than manual or gravity-based filling. King Pack machines maintain stable volume control across all common bottle sizes, with accuracy levels suitable for both over-the-counter and prescription products. Repeatability stays consistent during long runs and across different SKUs.

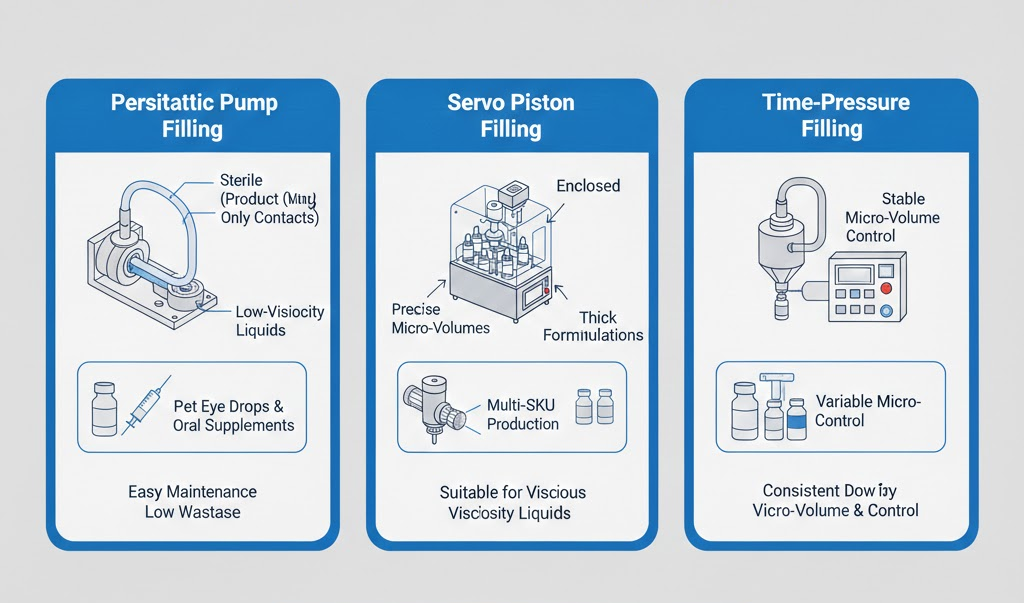

Different liquid properties require different dosing methods. Low-viscosity and sterile liquids benefit from peristaltic systems, while thicker or sensitive formulas require servo-controlled pistons. Time-pressure systems support stable dosing where flow behavior varies. Our equipment supports these technologies within the same production platform, allowing manufacturers to match accuracy to product needs.

We offer three main filling technologies:

| Technology | Ideal For | Key Feature |

| Peristaltic Pump | Sterile, low-viscosity liquids | Minimal contamination, easy cleaning |

| Servo Piston | Viscous or sensitive liquids | High precision ±0.3% |

| Time-Pressure | Stable micro-volume control | Consistent dosing at variable speeds |

Each system maintains repeatability even in multi-SKU production, ensuring product consistency and compliance.

Sterile and Hygienic Design

Sterility is a baseline requirement in pet drop production. Contamination risks increase when filling zones are open, materials are difficult to clean, or human contact is too frequent. Equipment design plays a major role in controlling these risks.

King Pack machines use enclosed filling areas and stainless steel product-contact paths to support hygienic operation. These structures limit exposure during filling and reduce the chance of airborne or manual contamination. Smooth surfaces also help prevent residue buildup between batches.

For higher sterility requirements, optional laminar airflow can be added to the filling zone. CIP and SIP compatibility allows fast cleaning and validation without full disassembly. This supports frequent product changeovers while maintaining GMP standards, which is especially important for prescription liquids and sensitive eye drop formulas.

Recommended Reading: Pharmaceutical Emulsion Mixer Machine: Vacuum Emulsifying Mixer Machine – King Pack Machinery

Compatibility With Small Bottles and Droppers

Pet drop packaging usually involves small containers, most often between 5 ml and 30 ml. Handling these bottles requires precise positioning, controlled filling, and accurate dropper placement. Poor alignment or inconsistent insertion leads to leakage and rejects.

King Pack automatic dropper bottle filling machines are built to handle standard pet bottle formats with stable performance. Filling, dropper insertion, and capping run within a single coordinated line. This reduces manual handling and keeps every step synchronized.

Changeovers between bottle sizes or formulas are designed to be straightforward. Adjustments can be made without affecting filling accuracy or sterility. This makes the equipment suitable for manufacturers running multiple products on the same line.

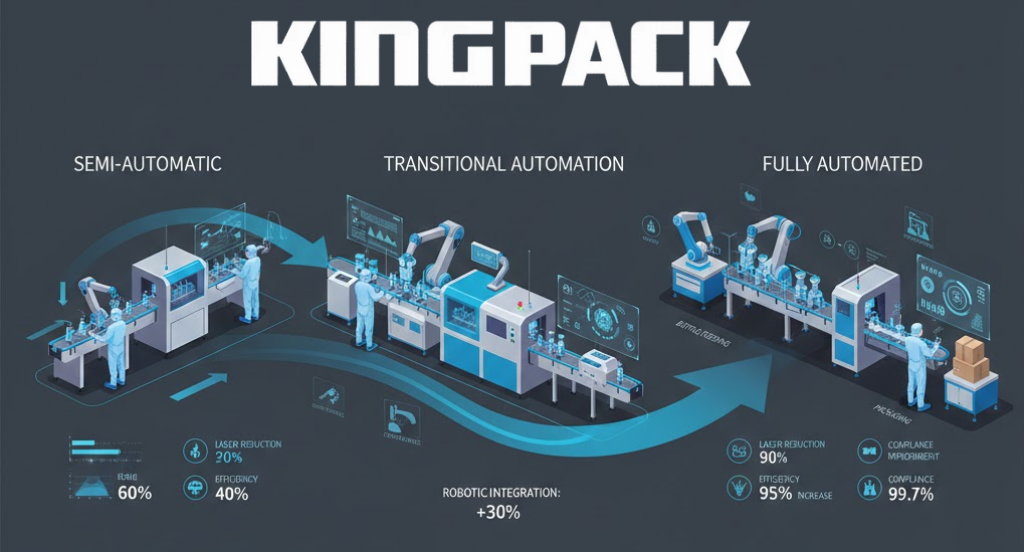

Automation Level

The level of automation affects speed, labor, and scalability. Semi-automatic lines are suitable for small or niche batches. Fully automatic lines integrate filling, dropper insertion, capping, labeling, and even cartoning.

According to Pet Pharma Insights 2024, 62% of manufacturers preferred fully automated lines to maintain GMP compliance while meeting increasing demand. King Pack designs automation solutions that match production scale and product variety.

Sterility Standards for Pet Drop Production in 2026

Maintaining sterility is the foundation of pet drop production. Eye drops, ear drops, and prescription liquids must remain free from contamination, as even minor impurities can compromise product safety.

In 2026, pet medicine manufacturers are expected to follow pharmaceutical-grade GMP standards, including hygienic design, traceability, and cleanable surfaces. Our equipment is built to meet and exceed these standards. We provide enclosed filling systems, stainless steel product paths, and optional laminar airflow to minimize contamination risk.

Cleaning and validation are critical. Our machines are CIP (Clean-in-Place) and SIP (Sterilize-in-Place) compatible. This allows fast cleaning between batches and reduces downtime during multi-SKU production. A study found that contamination risk increases by 40% in micro-volume filling without closed systems and proper airflow, underlining the need for high-standard equipment.

Key sterility features of our pet drop filling machines include:

- Enclosed filling zones to reduce human contact

- Stainless steel contact parts for easy cleaning

- Optional laminar airflow for sensitive liquids

- CIP/SIP readiness for quick sanitation

- Smooth surfaces and rounded corners to prevent residue buildup

Recommended Reading: Packaging Machine Solutions – King Pack Packaging Equipment – King Pack Machinery

Filling Technologies for Pet Drop Machines

Selecting the right filling technology depends on the liquid type, bottle size, and production speed.

Peristaltic Pump Filling is ideal for sterile, low-viscosity liquids. The product only contacts the tubing, which reduces contamination and simplifies cleaning. It is excellent for pet eye drops and oral supplements.

Servo Piston Filling is suitable for higher-viscosity liquids or sensitive formulations. It delivers precise micro-volumes, achieving ±0.3% repeatability. This makes it ideal for thick veterinary formulations and multi-SKU production.

Time-Pressure Filling provides stable micro-volume control and is useful for low-volume bottles or liquids with varying viscosity. Its digital control ensures consistent dosing across different batches.

Advantages of different filling technologies:

- Peristaltic Pump: Easy maintenance, sterile handling, low wastage

- Servo Piston: High precision, suitable for viscous liquids, repeatable micro-dosing

- Time-Pressure: Stable flow for variable viscosities, consistent micro-volume control

By offering all three systems, we ensure manufacturers can select the technology that best suits their product type and production scale.

Recommended Reading: Automatic Case Packaging Machine — Intelligent Transformation of End-of-Line Packaging – King Pack Machinery

Line Integration for Pet Drop Production

5–50 ml Oral Liquid Filling Production Line – King Pack Machinery

Filling is only one part of an efficient production line. Proper integration of feeding, filling, capping, labeling, and packaging is crucial to maintain speed and sterility.

Our turnkey solutions start with a bottle unscrambler that feeds bottles into the line. They then pass through filling, dropper insertion, and capping stations. Labeling machines follow, and for large production lines, we integrate cartoning systems.

Buffer zones and speed-matching mechanisms prevent bottlenecks and maintain a consistent production rhythm. This ensures even at high speeds, the process remains sterile and accurate.

Our integrated line benefits include:

- Reduced manual handling and contamination risk

- Stable micro-volume dosing across all bottles

- Quick changeovers for multi-SKU production

- Automated capping, dropper insertion, and labeling

Challenges in Pet Drop Filling and How We Solve Them

Producing pet drops presents unique challenges. Micro-volume accuracy is one of the biggest. Our servo-controlled filling systems, combined with peristaltic and piston pumps, deliver precise doses with repeatability, ensuring every PET bottle meets standards.

Dripping and stringing can occur during micro-volume filling. Our precision nozzles and automatic pneumatic valves prevent this, keeping bottles clean and avoiding product waste.

Maintaining sterility at high production speeds is another challenge. Enclosed filling zones, food-grade stainless steel surfaces, and optional laminar flow systems maintain sterility even during continuous high-speed operations.

Multi-SKU production is increasingly common. Manufacturers often fill multiple bottle sizes and formulas on a single monoblock filling line. Our equipment allows quick changeovers, enabling smooth transitions without compromising accuracy or hygiene.

How King Pack Designs Pet Drop Filling Solutions

We focus on high-precision, GMP-oriented equipment for pet pharmaceuticals and care products.

- High-Precision Filling Systems: Servo motors, peristaltic controls, and piston pumps provide stable micro-dosing for small-volume liquids. Accuracy ensures consistent dosing for every PET bottle.

- GMP-Friendly Mechanical Design: All product-contact parts use stainless steel, and enclosed chambers reduce contamination risk. CIP/SIP-ready systems allow fast cleaning and validation between batches.

- Turnkey Integration Capability: We integrate filling, dropper insertion, capping devices, labeling machines, and cartoning into a single production line. This reduces manual handling, minimizes errors, and increases throughput.

Trends in Pet Drop Filling Equipment for 2026

Precision and smart control are the main trends. Manufacturers need machines that monitor each micro-dose and provide digital feedback for traceability. Compact sterile lines are popular. Smaller footprints reduce contamination and make production more flexible.

Flexibility is in high demand. Lines now handle multiple container types, PET bottle sizes, and viscosities without complex adjustments. PLC control systems, touch screens, and digital monitoring provide real-time quality control, reporting, and easier regulatory compliance.

Other emerging trends:

- Remote monitoring and predictive maintenance

- IoT-enabled machines for data collection and analysis

- Modular lines for quick adaptation to new products

- Automation of packaging, labeling, and bottle rinsing alongside filling

Frequently Asked Questions (FAQ)

What accuracy should a pet drop filling machine achieve?

Our machines maintain ±0.5% accuracy for small-volume bottles. Servo-controlled systems can reach ±0.3% for sensitive liquids.

Are pet drops required to follow pharmaceutical GMP?

Yes. Most veterinary and pet medicine products must comply with GMP to ensure safety and efficacy.

Which filling system is best for pet eye drops?

Peristaltic pump systems are ideal for sterile, low-viscosity liquids. Servo piston systems are suitable for viscous or sensitive formulations.

Can one line handle different bottle sizes and liquids?

Yes. Our machines are designed for multi-SKU production with quick changeovers between bottle sizes and formulations.

How easy is cleaning and changeover for pet drop machines?

All King Pack machines are CIP/SIP-ready, with stainless steel contact parts and enclosed chambers. Cleaning and validation are fast and efficient.