Pull out a tube of striped toothpaste and squeeze it. Perfect stripes emerge every time. No mixing. No mess. Just clean lines of color flowing onto your brush.

Most people never stop to wonder how this happens. The stripes seem like pure magic. But there’s real engineering behind those colorful lines. The secret involves specialized filling machines, careful control of material properties, and clever nozzle design.

This isn’t just about making toothpaste look pretty. The technology reflects decades of packaging innovation. It shows how manufacturers balance marketing appeal with production efficiency. In this article, we’ll explore how striped toothpaste works—from the filling process and nozzle design to the science of rheology that keeps colors separate yet flowing in perfect harmony.

Why Toothpaste Has Stripes

Marketing vs Functional Aspects

Striped toothpaste was invented by Leonard Marraffino in 1955, with the patent issued in 1957 and subsequently sold to Unilever, which marketed the novelty under the Stripe brand-name in the early 1960s. The invention changed oral care packaging forever.

Do the stripes actually do anything? Sometimes yes, sometimes no. Many striped toothpastes combine different formulations in each color. One stripe might contain whitening agents. Another might focus on cavity protection. A third could deliver breath freshening ingredients.

But plenty of striped toothpastes use colors purely for visual impact. The stripes don’t represent different active ingredients. They just make the product stand out on store shelves. Both approaches work in the marketplace.

Visual Appeal and Consumer Perception

Toothpaste sits in your bathroom. You see it twice daily. The appearance matters more than most manufacturers admit. Plain white paste looks clinical and boring. Stripes suggest sophistication and multiple benefits working together.

Although Stripe was initially very successful, it never again achieved the 8% market share that it cornered during its second year. That early success proved consumer interest in visual innovation. Other brands rushed to copy the concept.

Children especially respond to striped toothpaste. The colorful appearance makes brushing teeth less of a chore. Parents appreciate anything that encourages good oral hygiene habits. This psychological element drives significant sales volume.

Recommended Reading: How to Manufacture Toothpaste: The Role of Filling & Sealing Machines in Production – King Pack Machinery

Packaging Differentiation in Oral-Care Market

Walk down any supermarket aisle. Dozens of toothpaste options compete for attention. Most contain similar active ingredients. Fluoride concentrations vary little between brands. Actual performance differences are small.

Packaging becomes the main differentiator. Striped toothpaste offers instant visual distinction. It communicates complexity and advanced formulation without requiring customers to read ingredient lists. The stripes do marketing work before anyone opens the tube.

Premium brands use stripes to justify higher prices. The visual complexity suggests superior technology. Consumers associate the striped appearance with better performance, even when chemical formulations closely match cheaper alternatives.

The Tube-Filling Mechanism Behind the Stripes

Single-Tube vs Multi-Chamber Filling Techniques

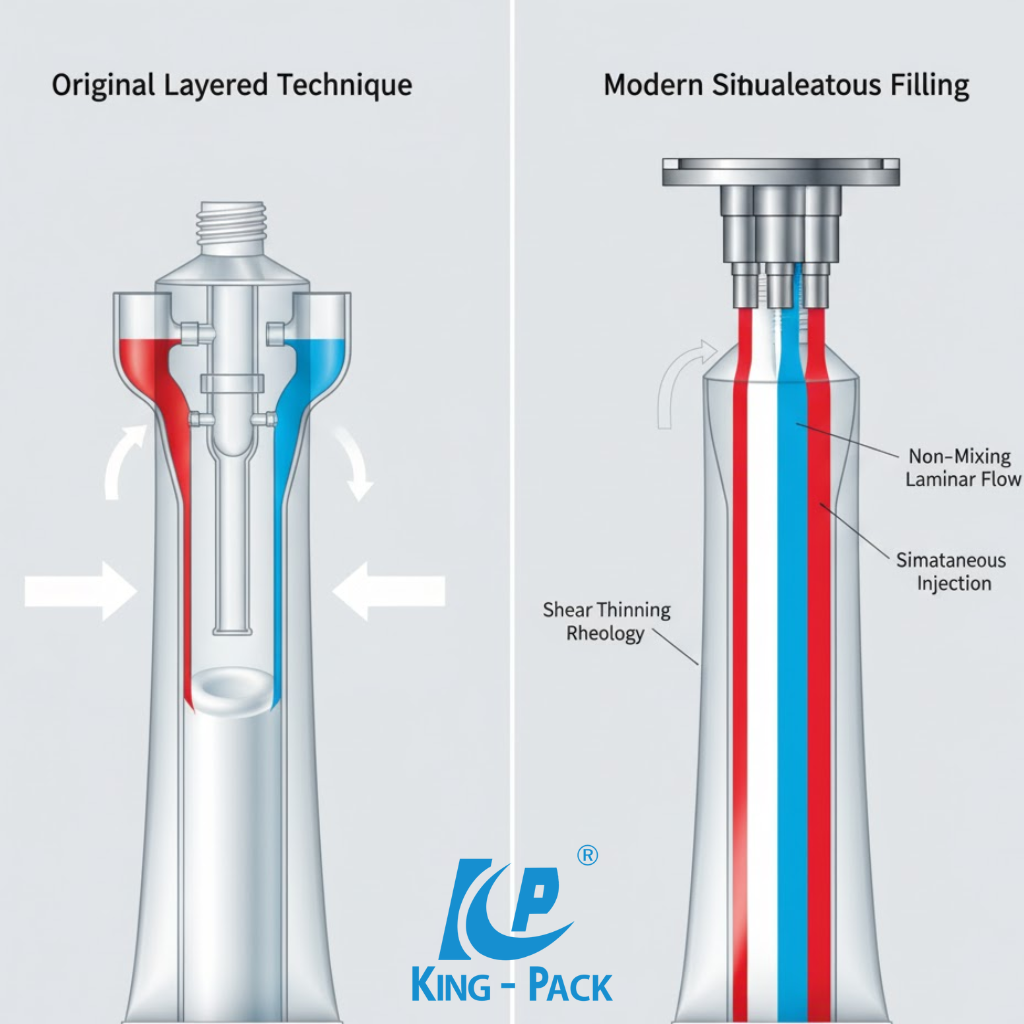

Early toothpaste filling methods relied on simple engineering. Marraffino’s single-tube design, still used in many Toothpaste Filling and Sealing Machines, worked by placing the main paste—usually white—at the crimp end of the toothpaste tube.

A small filling head channeled the base material through the center while the colored paste filled the outer space. The process used gravity and precise pressure control instead of complex electronics.

The method involved layered filling. The colored portion was dispensed near the tube opening first, followed by the bulk paste. Inside, a narrow pipe structure kept both materials separated during storage. This design was compatible with early aluminum tube filling setups and basic conveyor belts that carried the tubes through sealing stations.

Modern production has moved far beyond this. With advances in Toothpaste Manufacturing Equipment and automatic filling and sealing machines, manufacturers now achieve higher production speed and consistent filling volume across large batches. Stainless steel construction in the machinery helps maintain hygiene while handling raw materials that include foaming agents like sodium lauryl sulfate.

In 2016, Colgate-Palmolive introduced a new process allowing multi-colored pastes to be filled directly into composite tubes using synchronized nozzles. This eliminated the need for internal compartments. Today’s striped toothpaste filling machines, including High speed tube filling and sealing machines, can pump multiple colors at once—producing patterns such as Three Color Striped Toothpaste or color bar toothpaste.

These systems often include volumetric fillers, servo-driven pumps, and industrial mixers that blend materials evenly before dispensing. Some setups even use Plastic Tube Filling lines with automatic batch code marking and Toothpaste Packaging Machines for labeling and sealing.

From the simple manual methods inspired by the ancient Egyptians to today’s Full Automatic Striped Toothpaste Filling systems, the manufacturing process has evolved into a blend of precision mechanics and automation. Modern Tooth Paste Filling Machines and Tube Filling and Sealing Machines now manage everything—from multi-color filling to final packaging—ensuring every tube leaves the line perfectly striped and ready for market.

Recommended Reading: What Is the Manufacturing Process of Toothpaste? – King Pack Machinery

Nozzle Design: Separate Holes for Colours

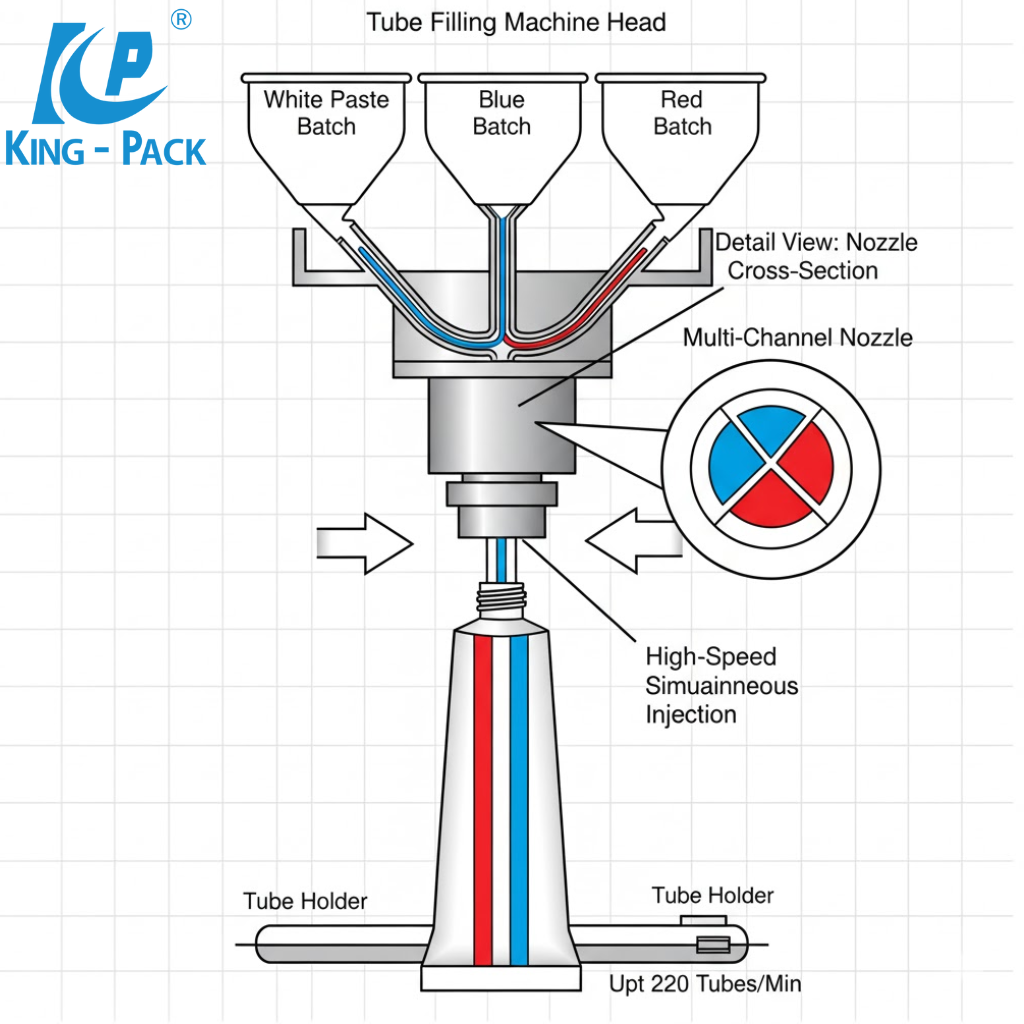

Each tube of toothpaste is filled from the bottom using a filling machine that funnels the toothpaste, just like the machines that fill ice cream cones; we get the stripes in by drawing on different colors of paste, and merging these into a divided nozzle, that keeps the colors separate but dispenses them at an even and consistent flow into the tube.

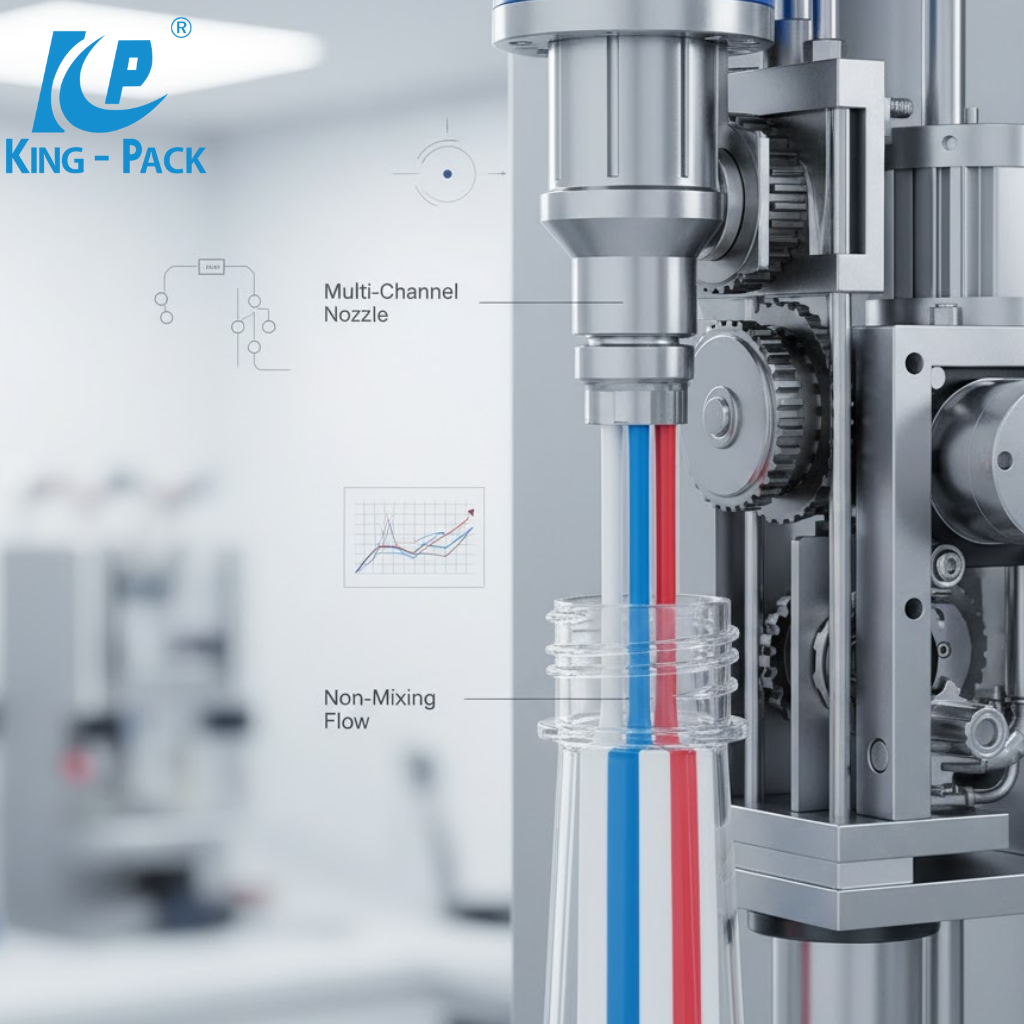

The filling nozzle contains multiple channels. Each channel carries one color. The channels remain separate until the moment paste enters the tube. At the dispensing point, streams merge but don’t blend.

There are high speed tube feeders on the market which can feed up to 220 tubes a minute and can even be worked without an operator; the different colored toothpastes are made in separate batches, each of which goes into its own nozzle, and the nozzles inject the different colors into the tubes at the same time, leading to the striping effect.

Modern filling equipment from manufacturers like King Pack incorporates these multi-channel nozzles into automated production lines. The systems handle tube orientation, filling, and sealing without human intervention. Speed and consistency are critical for commercial viability.

Recommended Reading: How do They Fill Toothpaste Tubes Using Tube Filling Machine? – King Pack Machinery

How Two or More Pastes Flow Together Without Mixing

This seems impossible at first glance. Two liquids flowing side by side should swirl together. Pump ketchup and mustard through adjacent pipes and they’ll create a muddy mess. But toothpaste behaves differently.

Instead of using sections, colored pastes are added to the tube one at a time; because of their precise consistency, the pastes don’t blend when poured or pumped, instead, they behave as solids inside the toothpaste tube.

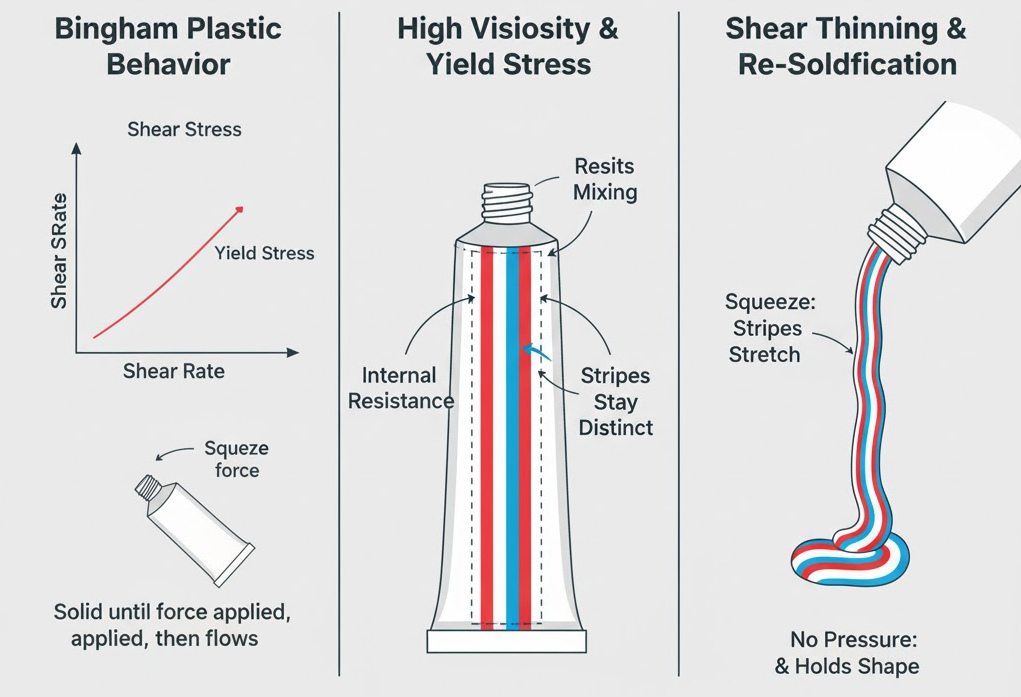

The key lies in understanding that toothpaste isn’t really a liquid. It acts more like a soft solid that only flows under pressure. This special behavior depends on its rheological properties.

Role of Rheology & Material Properties

Toothpaste isn’t a simple liquid — it’s a Bingham plastic, meaning it behaves like a solid until a certain force (yield stress) is applied, then flows. This behavior is critical for stripes: once the product is in the tube, the paste resists mixing because of its structure.

High viscosity and yield stress help keep the stripes distinct. If the paste is too runny, the streams may merge. If it’s too thick, pumping becomes a nightmare. Formulators aim for a balance: fluid enough to fill reliably, but viscous enough to maintain clarity.

Because the pastes don’t mix inside the tube, the stripe pattern stays intact over time. The internal resistance (thanks to yield stress) slows diffusion, and when consumers squeeze the tube, the stripes stretch, not blend. Once the pressure is released, the paste re-solidifies, preserving the visual design.

Filling Machine Requirements for Striped Toothpaste

Multi-Hose or Multi-Channel Feeders for Colours

Production lines need separate supply systems for each color. Large mixing tanks hold batches of white, red, blue, or whatever colors the product uses. Pumps move paste from these tanks to the filling station.

King Pack’s tube filling machines incorporate the flexible hose systems needed for multi-color applications. Each color travels through dedicated tubing to the filling nozzle. This prevents cross-contamination between batches.

The system must handle paste viscosity without clogging. Positive displacement pumps work better than centrifugal pumps for high-viscosity materials. Piston or gear pumps provide consistent flow rates regardless of back pressure.

Recommended Reading: How is Toothpaste Manufactured and How Tube Filling Machines and Emulsifying Equipment are Used in this Process? – King Pack Machinery

Synchronised Pumping of Carrier and Colour Pastes

All colors must flow at precisely matched rates. If the blue pump delivers paste 5% faster than the white pump, the stripes will gradually become more blue. Eventually the pattern fails completely.

Modern filling machines use servo motors and flow sensors to maintain synchronization. Computer control adjusts pump speeds in real time based on actual flow measurements. This prevents drift that would occur with simple mechanical linkages.

The filling sequence matters too. Paste must flow steadily without starting or stopping individual colors. Any interruption disrupts the stripe pattern. Production lines aim for continuous operation once filling begins.

Quality Control: Stripe Uniformity, Flow Consistency, Tube Crimping

Vision systems inspect filled tubes before sealing. Cameras check that stripes appear uniform and colors are properly distributed. Defective tubes get rejected automatically.

Flow consistency depends on maintaining constant paste temperature. Viscosity changes with temperature. A batch of paste that’s 5 degrees warmer flows differently than cooler paste. Climate-controlled production areas help maintain stability.

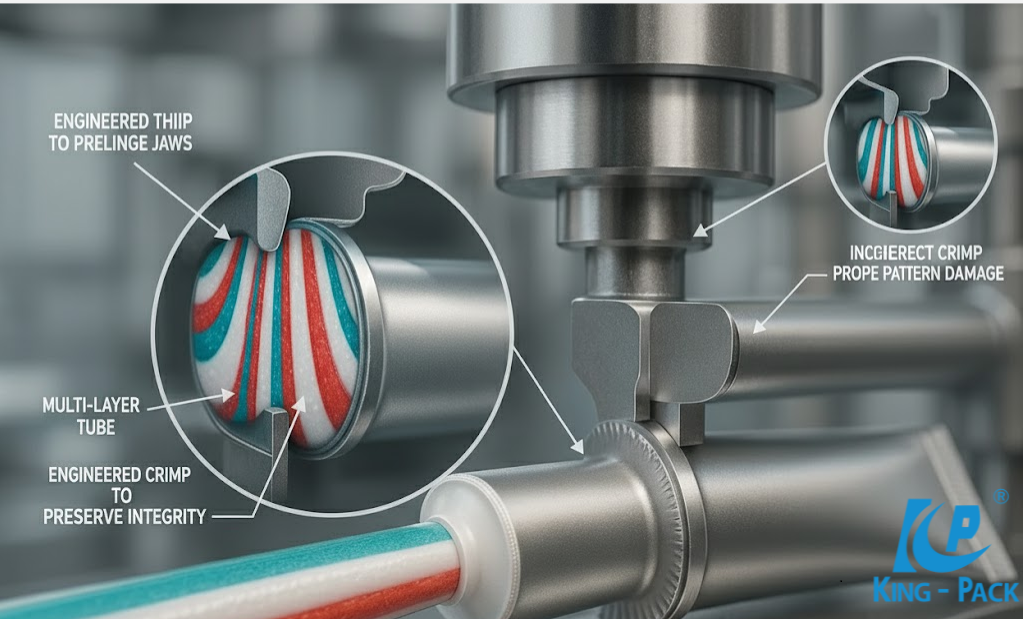

Tube crimping presents its own challenges. The crimp seal must close the tube without disrupting paste distribution near the opening. Too much pressure squeezes paste backward and mixes colors. Too little pressure creates weak seals that leak.

Packaging Line Integration & Tube Dynamics

The tube itself plays a major role in stripe preservation. Most striped toothpaste uses laminate tubes — often multilayer plastic — that give both barrier protection and structural strength. King Pack’s fillers work well with laminated as well as plastic tubes, giving flexibility in material choice.

When sealing, the machine must handle the tail crimping carefully. If the crimp is too aggressive, it can compress and smear the stripes. King Pack’s machines are engineered to fold or crimp without damaging the pattern. That means the visual design you carefully engineered remains sharp, even after sealing.

From the user’s point of view, stripes must survive everyday use. Thanks to the paste’s rheology, stripes retain their structure through repeated squeezes. The barrier properties of the tube also guard against color bleeding or ingredient separation over shelf life.

Recommended Reading: What Do They Use to Make Toothpaste? – King Pack Machinery

Implications for Oral-Care Manufacturers

For manufacturers, adding a striped line raises important trade-offs. There’s more complexity in equipment, more risk in formulation, and tighter process control. But if marketed well, stripes bring real brand value.

Here are some key considerations:

- Production efficiency: Multi-feed, synchronized filling lines cost more to set up, but once optimized, they run reliably.

- Brand value: Stripes support premium positioning. Consumers see them as more advanced or effective.

- Troubleshooting: Common problems include bleeding color or misaligned stripes. These often come down to pump calibration, nozzle wear, or paste consistency.

Manufacturers using King Pack systems benefit from its modular design: they can start with a standard tube line and later upgrade to multi-color by adding extra feed lines or pump controls.

Conclusion

Striped toothpaste represents more than aesthetic choice. It demonstrates precision engineering in action. The stripes depend on controlled rheology, specialized filling equipment, and careful process management. And modern tube filling machines from King Pack provide the control precision needed for multi-color applications.

Our systems integrate filling, sealing, and quality inspection into automated production lines that maintain consistent stripe quality at commercial speeds. Contact King Pack to explore advanced tube-filling solutions for multi-colour paste products.

We offer customized systems designed to match your product viscosity, production scale, and visual requirements. Our team can help you optimize both performance and presentation, ensuring your striped toothpaste stands out on the shelf while maintaining production efficiency.