Introduction

The cosmetics industry has experienced unprecedented growth in recent years, driven by increasing consumer demand for high-quality skincare and beauty products. And every high-quality cosmetic cream depends on good emulsification. Without proper blending of oil, water, and active ingredients, creams might separate, feel grainy, or have an unstable texture.

In this article, we explore how vacuum homogenizing emulsifier machines work, why they are vital in cosmetic cream production, what specs to watch, and how choosing the right machine — like those from King-Pack Machinery — affects product quality and efficiency.

Importance of Emulsification in Cosmetic Creams

The cosmetic emulsifier market is estimated to grow by USD 624.94 million from 2024 to 2028 at a CAGR of 7.1%, reflecting the critical role these systems play in modern manufacturing. This growth underscores the increasing sophistication of cosmetic formulations and the corresponding need for advanced emulsifying equipment.

The science of emulsification involves creating stable dispersions of oil and water phases through mechanical energy and appropriate emulsifying agents. In cosmetic applications, this process must achieve particle sizes typically ranging from 0.1 to 50 microns, depending on the desired product characteristics. The uniformity of particle size distribution directly impacts product stability, texture, appearance, and consumer acceptance.

Professional emulsifying mixer machines create the high-shear conditions necessary for breaking down oil droplets and dispersing them uniformly throughout the water phase. King-Pack Machinery’s vacuum emulsifier machines are specifically engineered to meet these demanding requirements, delivering consistent results across diverse formulation types.

Role of Vacuum Homogenization in Achieving Stable Emulsions

Vacuum homogenization combines high shear mixing with a vacuum environment. The vacuum helps remove air (reduce foam), prevents air bubbles that could destabilize the emulsion, and improves absorption of any powders or volatile actives.

For example, many vacuum emulsifier homogenizers (like those from Ginhong) work under vacuum to avoid aeration in creams, ointments, and lotions. Under vacuum, the mixture passes through rotor-stator homogenization heads to reduce particles, and the absence of air improves both visual quality and texture.

Recommended Reading: How Does an Emulsifying Machine Work? – King Pack Machinery

How the Emulsifying Mixer Machine Works

Structure and Components

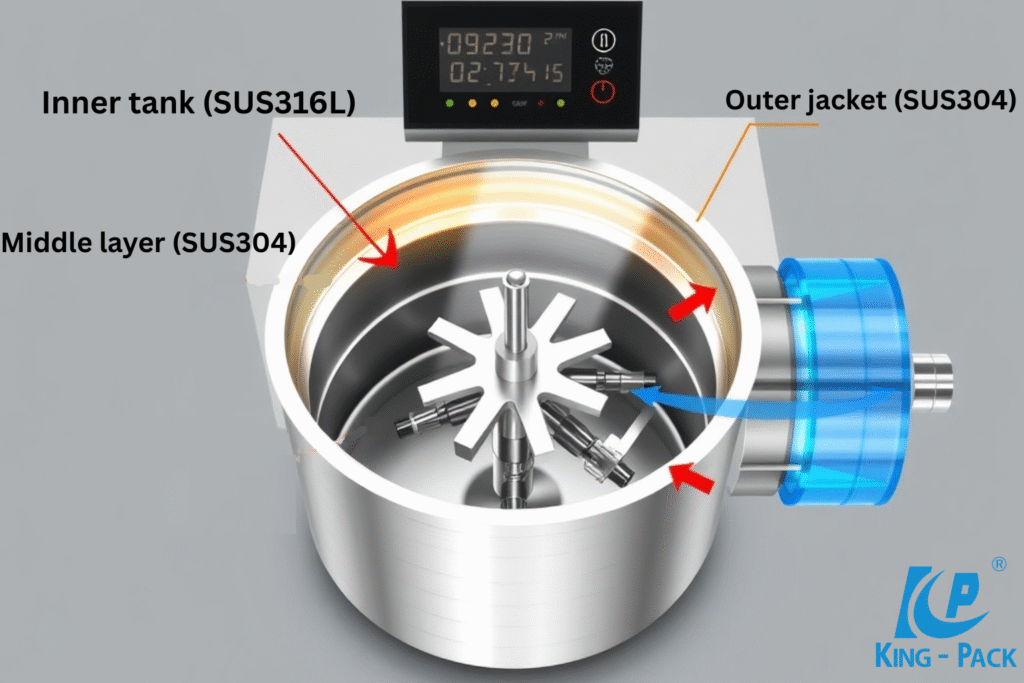

Modern emulsifying mixer machines are built with advanced engineering to meet the strict demands of cosmetic manufacturing. A standard setup often features a triple-layer mixing vessel:

- An inner tank of SUS316L stainless steel for direct product contact, offering superior corrosion resistance.

- A middle layer of SUS304 stainless steel for structural strength and durability.

- An outer jacket of SUS304 stainless steel designed for heating and cooling, ensuring stable temperature control.

This configuration combines durability, thermal efficiency, and mechanical strength, making it ideal for sensitive cosmetic formulations.

Inside the vessel, multiple agitation systems operate in tandem. The primary mixer uses a central shaft with precision-designed impellers to move bulk fluids and start the blending process. Alongside this, a high-shear rotor–stator homogenizer generates intense turbulence, breaking down droplets into micro- or nano-sized particles for a smooth, stable emulsion. Scraper blades keep the vessel walls clean, eliminating dead zones and ensuring even mixing across the batch.

Temperature consistency is another crucial factor in cosmetic production. Heating and cooling jackets circulate thermal fluids, achieving rapid temperature adjustments with uniform distribution. Paired with digital control systems, operators can monitor and fine-tune variables like shear speed, vessel pressure, and thermal balance, guaranteeing repeatable quality for every batch.

Recommended Reading: Your Complete FAQ Guide to Emulsifier Machine – King Pack Machinery

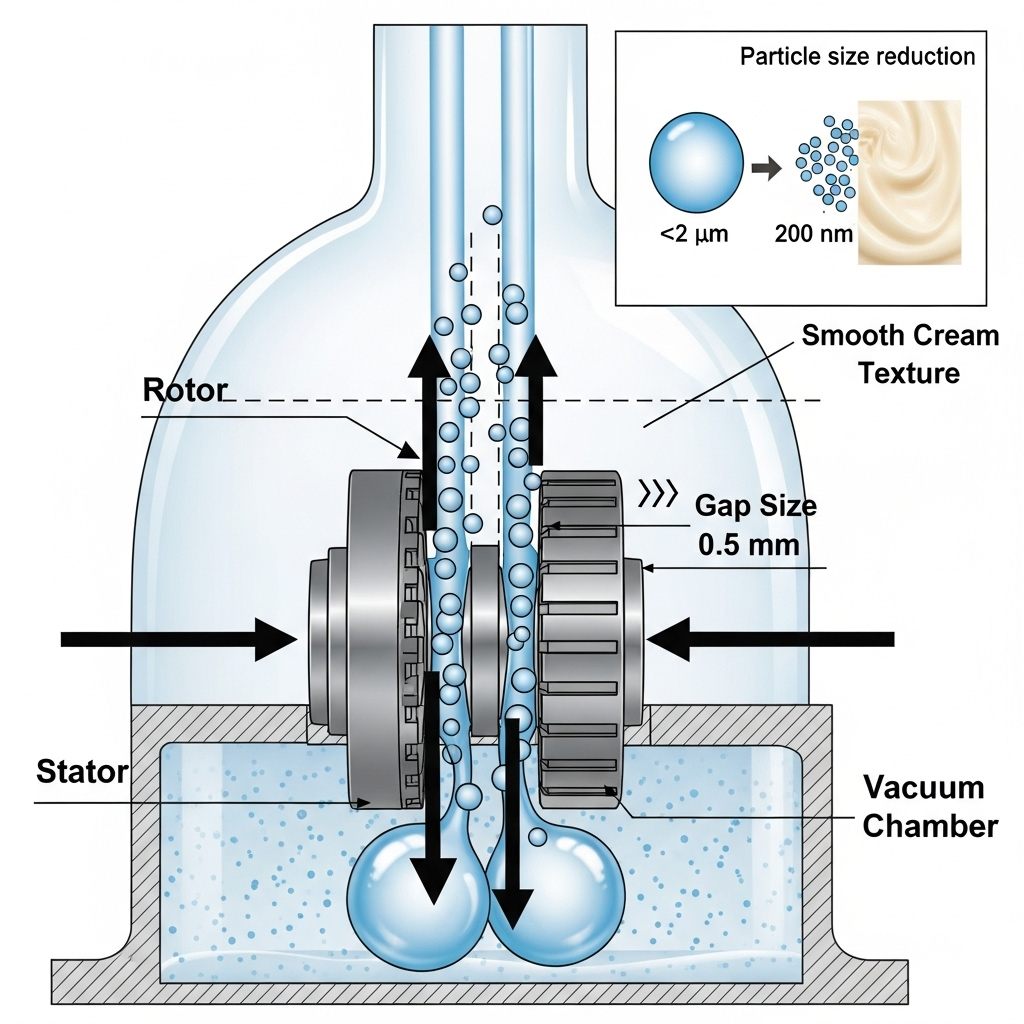

Function of the Homogenization Head

The homogenization head represents the critical component responsible for particle size reduction and emulsion formation. Material passes through narrow gaps between rotor and stator; that breaks large droplets into smaller ones. This reduces particle size, improves stability, and gives smoother texture.

Some machines can reduce droplets to 2 micrometers or less (depending on formulation and energy input). The speed of homogenization (RPM), gap size, rotor-stator design, and temperature all influence this. The vacuum ensures no air gets trapped, which otherwise may weaken structure or introduce oxidation. Data from equipment listings show machines achieving 200 nm to ~2 µm particle size in cosmetic creams using high-speed homogenization under vacuum.

Recommended Reading: The Differences Between Homogenization and Emulsification – King Pack Machinery

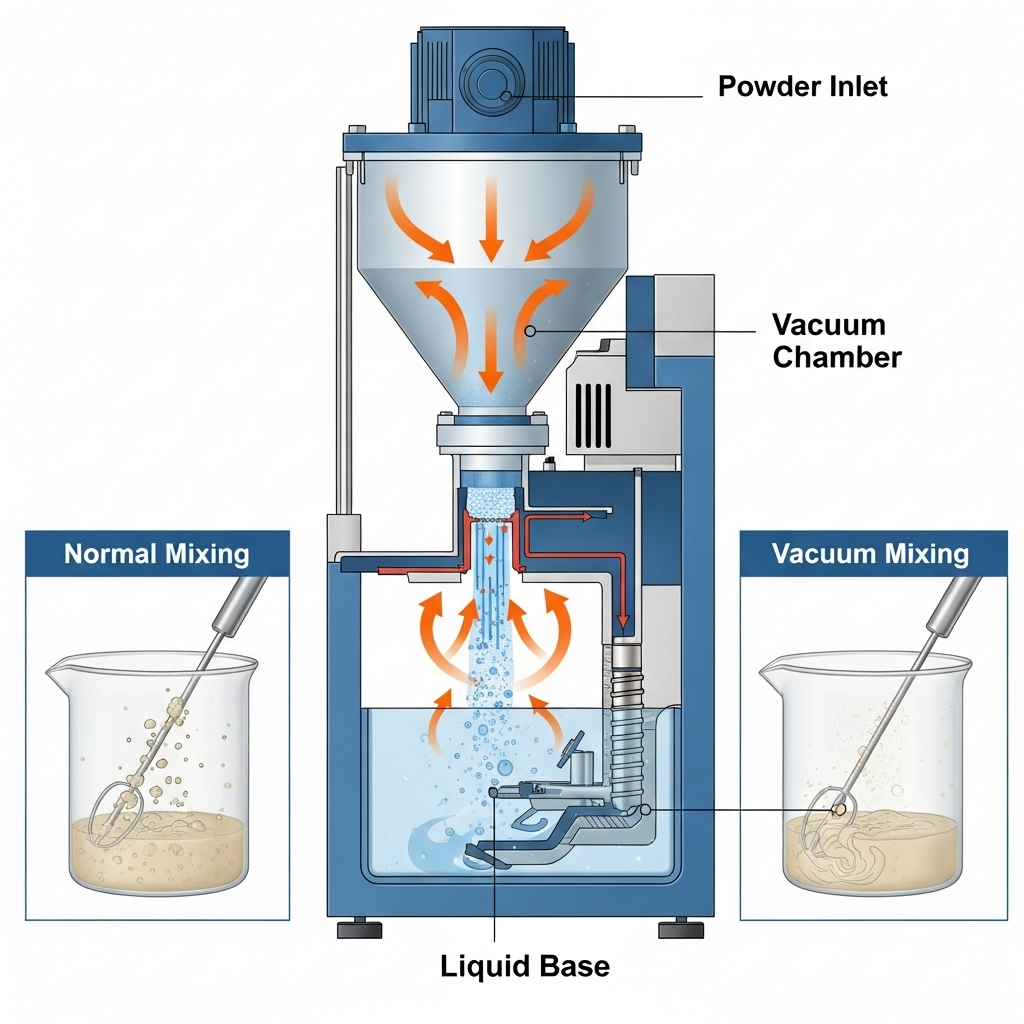

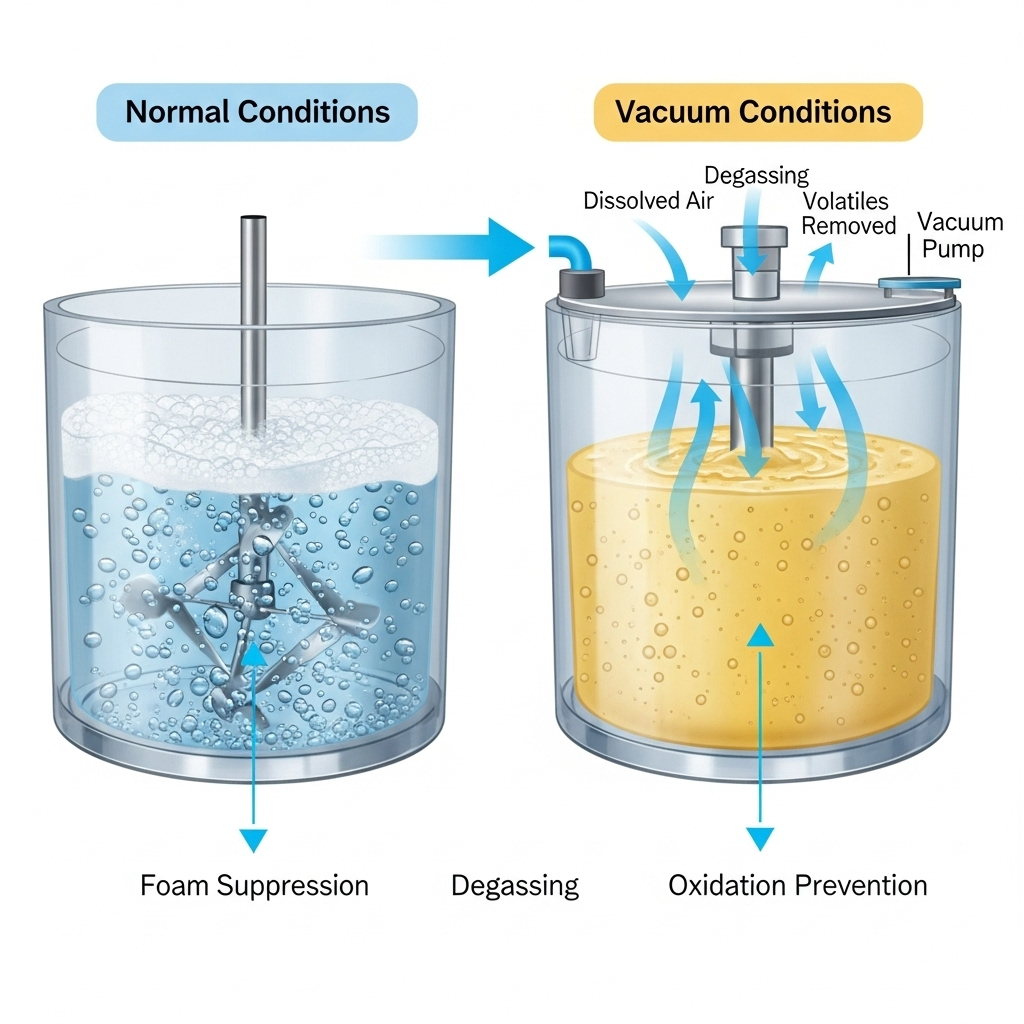

Vacuum System’s Role in Material Absorption and Foam Reduction

The vacuum system is one of the most critical components in modern emulsifying mixer machines, setting them apart from conventional mixing equipment. By creating a controlled environment, it not only enhances product quality but also improves processing efficiency and safety for operators.

Under vacuum conditions, ingredient absorption becomes far more efficient. The reduction in atmospheric pressure removes air barriers that normally slow down wetting and dispersion. This is especially valuable when powders are added to liquid phases, as the vaum draws them in rapidly, shortening processing times and ensuring more complete ingredient utilization.

Foam reduction is another major advantage. Many cosmetic ingredients—such as surfactants and proteins—produce foam when agitated mechanically. Excessive foam can disrupt product stability, texture, and appearance. Vacuum processing suppresses foam formation by removing the trapped air that stabilizes bubbles, resulting in smoother, more uniform emulsions.

Degassing also happens continuously during vacuum mixing. By eliminating dissolved air and volatile compounds, the system prevents oxidation and extends shelf life. For sensitive formulations, reduced oxygen levels protect active ingredients and improve long-term stability. In addition, the vacuum environment supports the removal of residual solvents or other volatiles that could impact product safety or performance.

Here are the key technical roles of vacuum systems in emulsifying machines:

- Rapid absorption of powders and other raw materials into liquid phases.

- Foam suppression during agitation, improving texture and appearance.

- Continuous degassing to remove dissolved air and volatiles.

- Oxidation prevention, extending shelf life and product stability.

- Efficient removal of residual solvents in sensitive formulations.

Modern vacuum systems are built with precision pumps and advanced controls that maintain consistent pressure levels throughout the mixing cycle. Depending on the formulation, the operating range can go from partial vacuum conditions of 50–80 kPa to high vacuum levels below 10 kPa.

King-Pack Machinery integrates high-performance vacuum pumps and smart controls into its emulsifying systems. Our equipment delivers the exact vacuum conditions needed for both large-scale and specialty formulations while keeping operational costs and maintenance low. This balance of performance and reliability makes King-Pack Machinery a trusted choice for cosmetic manufacturers worldwide.

Recommended Reading: Emulsifier Machine: Types of Vacuum Emulsifying Mixers & Applications – King Pack Machinery

Technical Specifications of Emulsifying Mixer Machine

Speed and Shear Capabilities

The efficiency of a batch vacuum emulsifier or Shampoo Cosmetic Mixer depends heavily on its speed and shear capacity. Low-speed mixing at 0–60 RPM is ideal for blending phases gently, while homogenizer high shear mixers running at 3000–3500 RPM or higher create the turbulence needed to break oil and water phases into fine, stable droplets. The design of the homogenizer head and rotor-stator assembly, along with the clearance gap, is critical for achieving homogenous dispersion.

Machines from King-Pack Machinery are equipped with advanced homogenizer heads that sustain precise shear forces, giving cosmetic manufacturers control over droplet size, viscosity material, and consistency. This precision ensures creams, lotions, and other emulsions feel smooth, stable, and professional-grade.

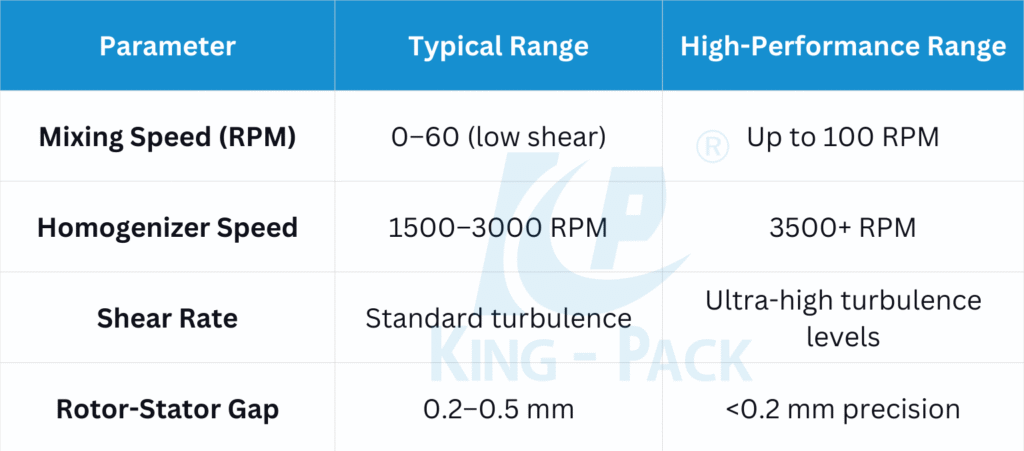

Here are the common technical ranges for speed and shear:

Particle Size Reduction Achieved

One main goal of high shear mixers and batch vacuum emulsifiers is reducing droplet size for improved emulsion stability and sensory feel. Standard cosmetic creams usually reach droplet sizes in the 1–5 µm range, while advanced systems can achieve 200 nm to 2 µm, enhancing absorption and preventing separation. Nano-scale emulsions are especially important in modern formulations like serums and lightweight lotions.

By using homogenizer high shear mixer technology under vacuum, these emulsifying mixers provide consistent particle reduction across batches, helping brands scale production without losing quality. Pressure difference and pH range control further optimize emulsification for Industrial Chemical Liquid and cosmetic formulations.

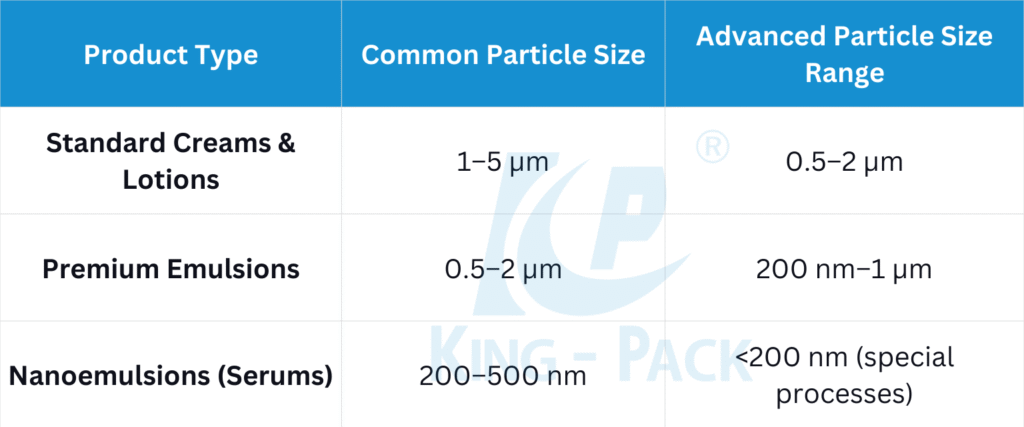

Here are the typical particle size ranges achieved:

Material Compatibility and Construction Quality

Emulsifying mixers, including liquid soap making machines and lab mixers, require high-quality construction for hygiene and durability. Contact parts are typically made from stainless steel 316L with mirror or electropolished finishes to prevent residue build-up. Jackets around vessels allow precise heating and cooling of oil and water phases.

King-Pack Machinery designs machines follow GMP, CE, and ISO compliance, giving manufacturers confidence in meeting both international regulations and consumer safety expectations. Vacuum systems handle pressures down to -0.1 MPa, ensuring performance under demanding production conditions. Secured Trading Service options are available for easy sourcing and procurement of equipment worldwide.

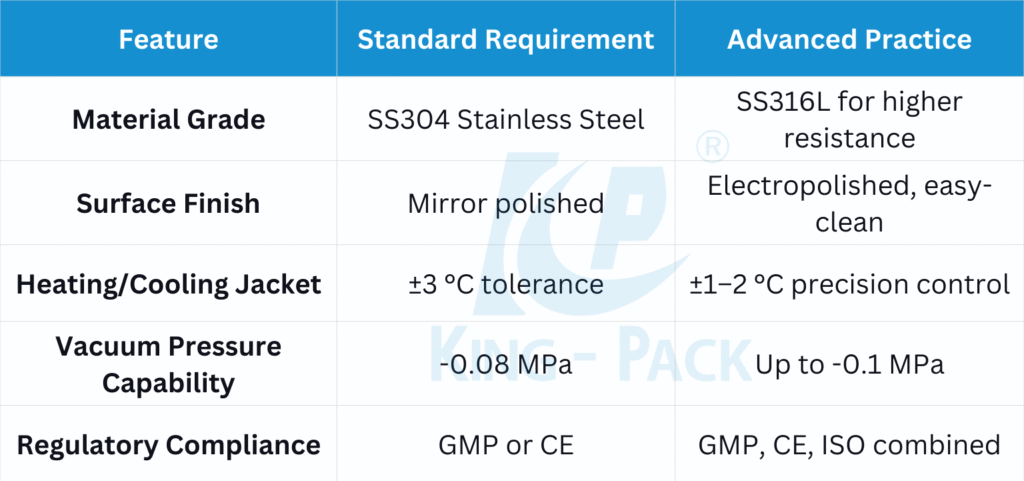

Here are the essential construction and material specifications:

Click here to check our products

Applications in Cosmetic Manufacturing

Suitable for Creams, Lotions, and Other Emulsions

Emulsifying mixer machines are essential in cosmetic production because they handle a wide range of product types. From creams, lotions, pharmaceutical ointments, sunscreens, facial masks, and emulsified gels, these systems achieve homogenous dispersion of oil and water phases. The ability to switch between oil-in-water (O/W) and water-in-oil (W/O) emulsions makes them versatile for lightweight and rich-textured formulations.

The type of product determines the required shear force and rotor–stator design. Sunscreens need fine, stable dispersions to hold UV filters evenly, while thicker creams require high shear force and a strong homogenizing head to avoid separation. Modern batch vacuum emulsifying mixers allow precise control over these parameters, ensuring emulsion stability for every formulation.

Modern cosmetic brands increasingly look for nanoemulsions, especially in serums and lightweight creams. Research published in Colloids and Surfaces B: Biointerfaces highlights that nanoemulsions below 500 nm improve skin penetration and stability of active ingredients. This makes emulsifying mixers not just mixing tools, but essential equipment for delivering advanced skincare benefits.

Benefits in Large-Scale Production

Scaling production without losing quality is a major challenge in cosmetics manufacturing. Automatic vacuum emulsifying mixers address this by maintaining consistency across large batches. Their PLC automatic control and electric control system reduce batch-to-batch variation, which builds consumer trust and protects brand reputation.

Vacuum function and scraper blades minimize product loss inside the Vacuum Emulsifying Mixer Tank, saving money and increasing yield. Foam reduction under vacuum also speeds up production cycles. Heating/cooling systems and temperature regulation ensure precise processing conditions for sensitive formulations.

King-Pack Machinery designs emulsifying mixer machines for industrial-scale needs. Features like fluidized Bed Mixer options, high shear homogenizers, PLC panels, and large-capacity 316L stainless steel vessels give manufacturers flexibility to produce at scale without compromising quality. This combination of efficiency and reliability makes these machines ideal for brands looking to grow.

Maintenance and Performance Optimization

Regular Maintenance Practices

- Cleaning: CIP cleaning system cleans vessel walls, homogenizing head, and scrapers.

- Lubrication of mechanical seals and bearings.

- Inspection of rotor-stator gaps for wear, which can affect emulsion stability.

- Checking vacuum seals and pump performance.

Enhancing Machine Longevity and Efficiency

- Use high-quality materials like stainless steel 316L or Anti-Corrosive PE Plastic for corrosion resistance.

- Optimize process parameters (temperature, speed, homogenization time) for each formulation to prevent overworking the machine.

- Use vacuum function to avoid oxidation or trapped air, protecting product quality and extending equipment life.

- Maintain operation logs, including particle size and stability tests, to detect drift and maintain consistent output.

Conclusion: Significance of Choosing the Right Emulsifying Mixer Machine

Selecting the correct vacuum homogenizing emulsifier machine is essential. If machine speed, shear capability, vacuum integrity, material compatibility, or construction quality are wrong, the final cosmetic product will suffer — in texture, stability, or appearance.

The right emulsifying mixer machine improves consistency, reduces waste, and helps maintain longer shelf life. With well-designed machines (like those provided by King-Pack Machinery), cosmetic manufacturers achieve uniform creams, better active ingredient delivery, and cost savings in production.

If you’re considering upgrading your cosmetic cream line, reach out to King-Pack Machinery: our machines are built for precision, hygiene, and scalable performance.