Alcohol-based pet external sprays are widely used for disinfecting skin, treating parasites, and supporting wound care. These products rely on fast evaporation and strong antimicrobial action, which makes alcohol an effective carrier. At the same time, alcohol introduces serious safety risks during manufacturing..

At King Pack, we design explosion-proof filling machines specifically for alcohol-based spray production. Our systems focus on controlled filling, vapor management, and certified safety components.

This article explains why pet external spray manufacturing is high-risk, what technical safeguards are required, and how compliant equipment protects both people and production.

Why Alcohol-Based Pet Sprays Are High-Risk Products

Alcohol-based formulations behave very differently from water-based liquids during filling. Ethanol and isopropanol evaporate quickly, producing flammable vapor clouds even at room temperature.

In enclosed production areas, these vapors can accumulate around filling heads, pumps, and conveyors.

The concentration of alcohol used in pet sprays is often high. Many disinfectant and flea spray formulas exceed 60 percent alcohol content. At these levels, the flash point is low, and even a small ignition source can trigger fire or explosion.

Ignition risks exist throughout the filling process. Motors, sensors, static discharge, and even friction inside tubing can generate sparks. Without proper safeguards, a routine production shift can become a serious safety incident.

From a business perspective, the risks extend beyond the factory floor. Regulatory bodies, insurers, and brand partners expect strict compliance for flammable liquid handling. A single incident can halt production, trigger investigations, and damage long-term brand trust.

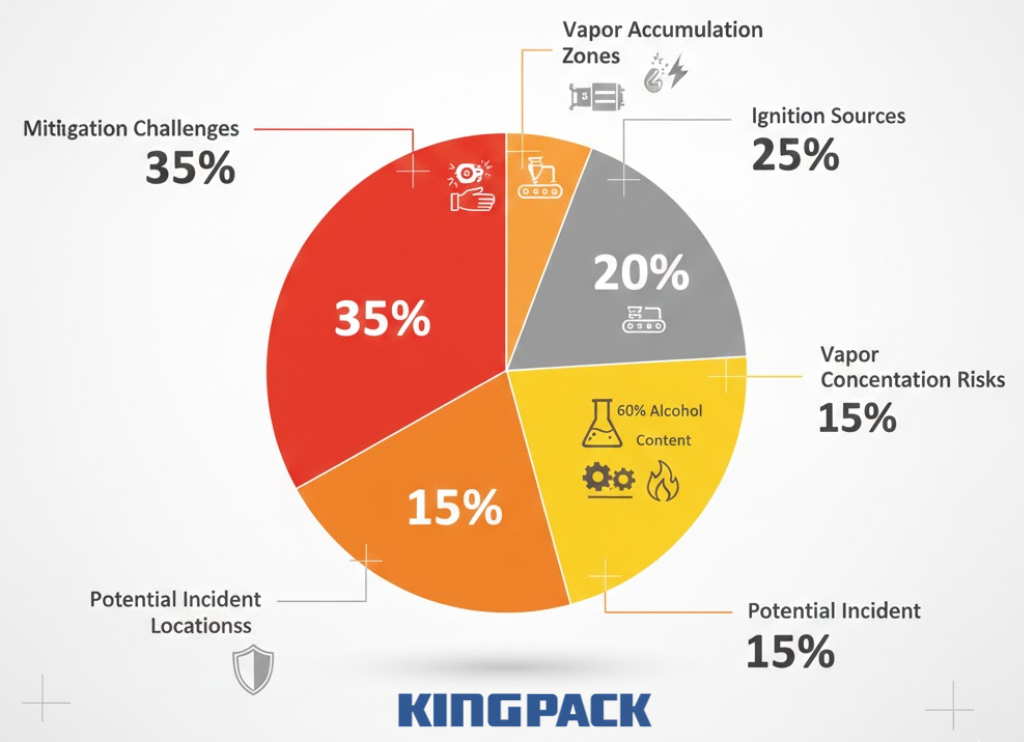

Common Risk Factors in Alcohol-Based Spray Production

- High vapor release during open filling and capping

- Static buildup caused by liquid movement and dry air

- Electrical components not rated for explosive atmospheres

A report from gov.uk noted that over 70 percent of flammable liquid incidents in packaging plants were linked to non-certified equipment or inadequate vapor control. For pet external spray manufacturing, explosion-proof design is a baseline requirement rather than an upgrade.

Key Safety Requirements for Filling Equipment

Explosion-proof filling machines are built around prevention. The goal is to eliminate ignition sources, control vapor movement, and stop the system safely when conditions move outside safe limits.

At King Pack, explosion-proof requirements are addressed at both the component level and the system level. Motors, pumps, enclosures, and control logic must all work together to maintain a safe environment during alcohol-based spray production.

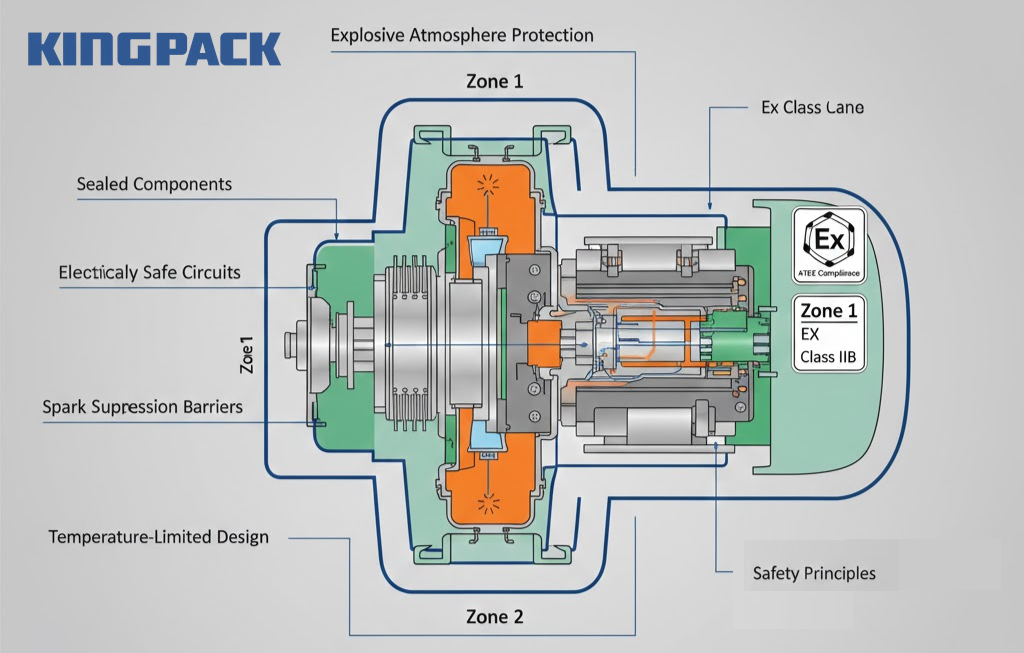

ATEX and Ex Compliance for Motors and Controls

ATEX and Ex certifications define how equipment can operate in explosive atmospheres. These standards apply to motors, sensors, control panels, pumps, and electrical connections.

ATEX-compliant filling equipment is designed so that even in the presence of flammable vapor, ignition cannot occur. Components are sealed, temperature-limited, and engineered to prevent sparks or hot surfaces.

For pet external spray filling lines, this means every active component near the filling zone must meet the appropriate zone rating. Certification labels and documentation are critical for audits, insurance reviews, and regulatory inspections.

King Pack integrates certified ATEX and Ex-rated components throughout alcohol-based spray production lines. This includes filling pumps, conveyor drives, and electrical cabinets positioned near vapor release points.

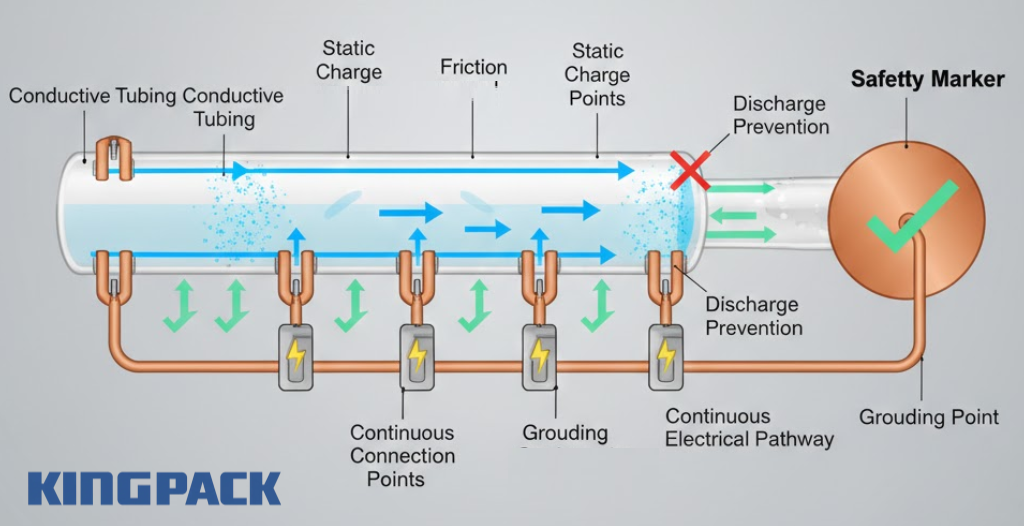

Static Dissipation in Filling Tubes

Static electricity is an underestimated hazard in alcohol filling. As liquid moves through hoses and pipes, friction generates static charge. In dry environments, this charge can discharge suddenly.

Anti-static liquid filling systems reduce this risk by using conductive tubing and proper grounding. Charges are safely dissipated instead of building up inside the system.

Grounding points must be continuous across tanks, pumps, filling heads, and conveyors. Any break in grounding increases ignition risk.

King Pack designs anti-static liquid filling layouts that maintain electrical continuity from the hopper to the nozzle. This approach supports safe isopropanol filling safety across long production runs.

Vapor Extraction and Localized Fume Control

Alcohol vapors must be removed as close to the source as possible. General room ventilation is not enough for high-speed spray filling lines.

Localized vapor extraction systems capture fumes directly at filling and capping stations. These systems prevent vapor buildup around ignition-prone components and improve air quality for operators.

Properly designed vapor extraction also supports regulatory compliance. Occupational exposure limits for ethanol and isopropanol require consistent airflow and monitoring.

King Pack integrates vapor extraction for flammable liquids into line design rather than treating it as an add-on. Duct placement, airflow rate, and enclosure design are matched to filling speed and bottle format.

Recommended Reading: Automatic Case Packaging Machine — Intelligent Transformation of End-of-Line Packaging – King Pack Machinery

Fail-Safe Interlocks and Emergency Stops

Explosion-proof equipment must respond instantly to unsafe conditions. Fail-safe interlocks shut down the line if ventilation drops, vapor concentration rises, or leaks are detected.

Modern systems rely on PLC and HMI monitoring to track critical parameters in real time. When thresholds are exceeded, filling stops automatically and alerts are triggered.

Emergency stop systems must remain functional even during power fluctuations. Redundant safety circuits protect against single-point failure.

King Pack builds emergency interlocks directly into alcohol-based spray production lines. This ensures safety responses are automatic, consistent, and verifiable during inspections.

Engineering Design Considerations for Explosion-Proof Pet Spray Lines

Beyond certified components, overall line design plays a direct role in safety. The layout of a liquid filling machine, material selection, and control points all affect how alcohol vapors move and collect during production. Poor spacing or weak sealing can raise risk even when approved parts are used.

Stainless steel is widely selected for product-contact and support structures. Marine-grade stainless steel offers strength, corrosion resistance, and stable grounding, which helps reduce static discharge during filling.

Sealed tanks and enclosed transfer lines limit vapor escape and lower operator exposure when handling alcohol-based sprays and spray can formats.

Pressure management also matters. Many pet sprays and parasite control products rely on alcohol carriers that react to pressure changes.

Filling under controlled atmospheric pressure reduces foaming and vapor spikes. Proper venting protects tanks, valves, and filling heads from internal stress while keeping the work area stable.

Maintenance access needs equal attention. Cleaning and servicing should not expose workers to flammable air pockets.

Access panels, filling valve heads, and service ports must support safe entry without breaking system integrity. King Pack designs filling machines with service points that keep protection intact during routine downtime.

Recommended Reading: The Ultimate Guide to Vial Filling Machines for Your Business – King Pack Machinery

Regulatory Compliance and Worker Safety

Explosion-proof design follows regulatory rules as much as engineering logic. ATEX and IECEx standards define how filling machines, pressure systems, and electrical parts must perform in explosive zones across global markets.

Local fire codes and workplace safety laws also apply. Many regions require formal risk reviews, certified equipment records, and ongoing safety checks tied to liquid filling packing machines and spray production lines.

GMP and ISO guidelines influence alcohol-based spray manufacturing as well. These standards focus on product quality but also support controlled environments, clear documentation, and stable operating procedures.

Training carries the same weight as equipment choice. Operators need clear knowledge of flammable liquids, startup and shutdown steps, and emergency response actions. Even a high-speed servo filling machine cannot offset weak safety habits or poor process control.

ROI of Investing in Explosion-Proof Filling Systems

Explosion-proof filling machines cost more at the start, yet the return goes beyond accident prevention. Avoiding fires and vapor incidents protects production schedules, staff, and long-term operations.

Safety failures often cause extended shutdowns. Lost output, inspections, and damaged client trust can exceed the price of a certified liquid filling machine by a wide margin.

Insurance providers also review equipment design when setting coverage terms. Facilities using certified explosion-proof systems often receive lower premiums and broader protection due to reduced risk profiles.

For brands producing pet sprays, flea control products, and alcohol-based disinfectants, safety shapes reputation. Buyers and regulators expect visible risk control. Explosion-proof filling lines signal responsibility, technical strength, and long-term reliability.

The following are the safety investment benefits in Alcohol-Based Spray Production:

- Reduced risk of fire, explosion, and injury

- Lower insurance premiums and regulatory costs

- Stronger trust with regulators, partners, and brand clients

Recommended Reading: Vial Filling Machines & Processing Solutions – King Pack Aseptic Systems – King Pack Machinery

How King Pack Designs Explosion-Proof Pet Spray Filling Lines

Explosion-proof design is never treated as a single upgrade. It is a full system approach that manages ignition risk across every stage of alcohol-based spray production.

At King Pack, engineering starts with how vapors move, how liquids flow through filling valve heads, and how operators interact with automatic and semi-automatic equipment during daily runs.

King Pack explosion-proof solutions rely on fully automatic liquid filling packing machines built for vapor-heavy environments.

These systems support stable output without sacrificing safety, even when running alcohol-based parasite control sprays and flea re-infestation treatments. High-speed servo filling machines and controlled atmospheric pressure help stabilize flow and limit vapor spikes near the filling zone.

Rather than modifying general-purpose equipment, King Pack develops alcohol spray filling lines specifically for flammable formulations. This includes spray can handling, sealed transfer paths, and pressure-controlled filling modules. Purpose-built design reduces risk and makes regulatory approval easier to manage.

Certified ATEX and Ex Equipment

All components operating near the filling area meet ATEX or Ex certification requirements. This includes motors, peristaltic diaphragm pumps, sensors, solenoid valves, and electrical control panels used within carbonated and non-carbonated liquid filling machines.

Component selection is based on zone classification and vapor density. Surfaces are engineered to limit heat buildup and avoid spark generation during continuous operation.

Each certified part carries clear product details, traceable labeling, and complete documentation to support audits, after-sales service, and secured trading service reviews.

Anti-Static Tubing and Grounding Systems

Static discharge remains a major ignition risk in alcohol filling. Even advanced automatic filling systems face danger without proper grounding.

King Pack installs conductive tubing, grounded stainless steel fittings, and bonded connectors across all liquid filling machine paths.

Product-contact parts made from marine-grade stainless steel reduce charge buildup during pumping, dosing, and dispensing. Grounding continuity is tested during setup and verified before production begins, supporting long shifts in low-humidity environments.

Localized Vapor Extraction

Vapor control must occur at the source. King Pack integrates localized extraction systems directly into filling, capping, and labeling stations on pet spray lines.

Extraction ports are placed near nozzles, spray can openings, and bottle mouths where vapor release is highest. Airflow levels adjust to filling speed and container size, from small refill port formats to larger bottle designs. This approach limits vapor spread and reduces strain on general ventilation systems.

Emergency Interlocks with PLC and HMI Monitoring

Safety systems must react instantly. King Pack equips explosion-proof filling machines with PLC-controlled interlocks that track ventilation performance, leak detection, and system pressure in real time.

If unsafe conditions appear, the system stops filling automatically. Alerts display through the HMI interface to guide operator response. Emergency stops stay active during power fluctuation, and redundant circuits reduce single-point failure while supporting full safety validation records.

Turnkey Alcohol-Based Spray Production Lines

Explosion-proof performance improves when machines operate as a complete system. King Pack delivers turnkey filling lines that integrate bottle feeding, liquid filling machines, capping units, product label application, and inspection stations.

Line layout limits vapor travel and avoids excess transfer points. Sealed tanks, controlled pressure zones, pneumatic lifting systems, and grounded conveyors work together to keep production stable.

This integrated setup shortens commissioning time and lowers long-term operational risk for alcohol-based pet spray manufacturing.

Recommended Reading: Packaging Machine Solutions – King Pack Packaging Equipment – King Pack Machinery

Engineering Comparison: Safety Features in Alcohol-Based Spray Filling

Different safety systems address different risks. The table below summarizes how key engineering features contribute to explosion prevention in pet external spray manufacturing.

| Safety Feature | Primary Risk Addressed | Function in Production | Benefit to Operations |

| ATEX / Ex-Certified Motors | Electrical ignition | Limits heat and sparks | Compliance and fire prevention |

| Anti-Static Tubing | Static discharge | Dissipates electrical charge | Stable filling and reduced ignition risk |

| Vapor Extraction System | Flammable vapor buildup | Removes fumes at source | Safer workspace and cleaner air |

| Emergency Interlocks | Equipment failure or leaks | Automatic shutdown | Prevents escalation of incidents |

| Sealed Stainless Tanks | Vapor release and pressure | Controls evaporation | Improved safety and consistency |

King Pack combines these elements into a single, coordinated safety strategy rather than treating them as optional upgrades.

Recommended Reading: Tube Sealing and Coding Technology Guide 2026: Achieving High-Integrity Seals and Serialization Compliance – King Pack Machinery

Regulatory Compliance and Worker Safety in Alcohol-Based Spray Production

Regulatory compliance is a moving target for flammable liquid manufacturing. ATEX and IECEx standards define equipment requirements, but local authorities often add additional fire and workplace safety rules.

Pet external spray manufacturing facilities are expected to document risk assessments, equipment certifications, and maintenance schedules. Missing or incomplete documentation can delay approvals or trigger shutdowns.

GMP and ISO guidelines also influence line design. While focused on quality, these standards reinforce the need for controlled environments, validated processes, and traceable safety systems.

Worker safety depends on both equipment and procedures. Operators must be trained to recognize vapor risks, follow startup and shutdown protocols, and respond to alarms correctly.

FAQ – Safe Filling for Alcohol-Based Pet Sprays

What is ATEX certification and why is it required?

ATEX certification confirms that equipment can operate safely in areas with flammable vapors. It is required for alcohol-based pet sprays used to control flea build-up, Black Carpet beetles, and similar pests, including unscented spray and citronella scent formulas. Certified systems reduce ignition risk during filling and handling.

How can static be controlled in alcohol filling lines?

Static control relies on conductive paths and solid grounding across the system. King Pack uses marine-grade 304 stainless steel parts, bonded fittings, and secure brass joints to limit charge buildup during liquid transfer. This setup supports safe filling for stain free and environmentally friendly spray products.

What type of ventilation is needed for flammable liquids?

Localized vapor extraction at filling and capping points is critical. These systems pull vapors away before they spread, even in areas affected by bathroom humidity or limited airflow. General ventilation alone cannot provide the deep reach needed for safe alcohol vapor control.

Can explosion-proof equipment handle different spray formulas?

Yes. Properly designed lines can handle multiple formulas, including citronella spray refill products and alcohol-based pest treatments. Adjustments account for product dimensions, flow rate, and container type without changing core safety features.