External parasite drops, such as flea and tick treatments like Frontline, are critical products in pet healthcare. Proper manufacturing ensures safe, accurate dosing and consistent quality. At King Pack, we specialize in turnkey solutions for pet parasite drop production, combining filling, capping, labeling, and packaging in one fully integrated line.

In this article, we explain the key production processes, challenges, technologies, and compliance requirements. We also show how our pet parasite drop filling machines and all-in-one production lines help manufacturers improve hygiene, accuracy, and output efficiency while meeting EU and FDA GMP standards.

What Are Pet External Parasite Drops?

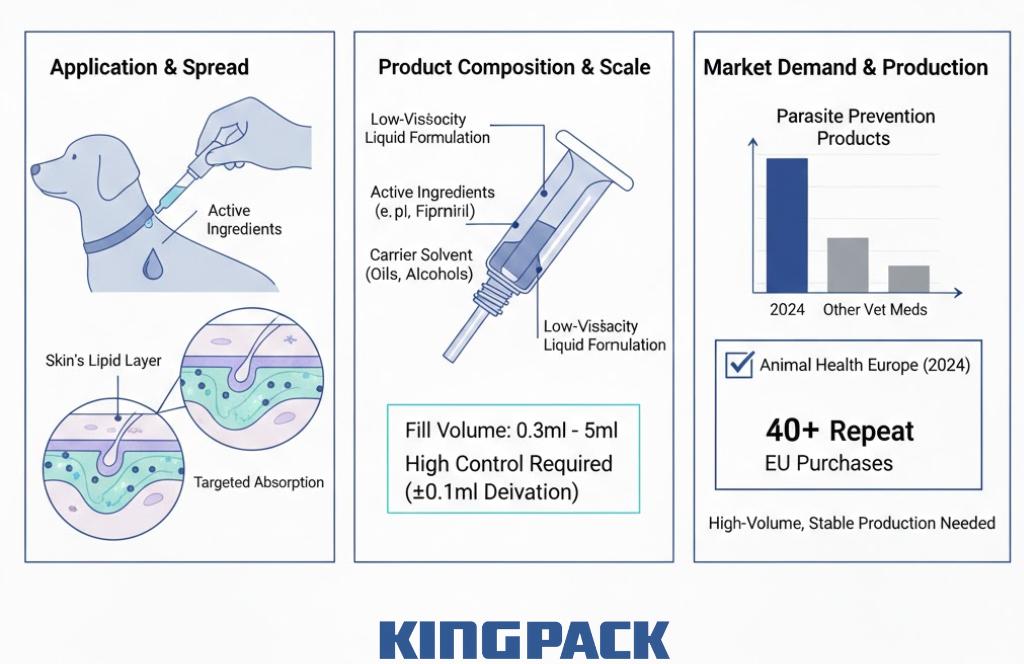

Pet external parasite drops are topical treatments applied directly to the skin, usually at the back of the neck or along the spine. These products are commonly known as spot-on treatments. They are widely used to prevent or treat fleas, ticks, mites, and other external parasites.

Most commercial formulations follow a Frontline-type structure. Active ingredients are dissolved in carriers such as oils, alcohols, or solvent blends. The formulation spreads through the skin’s lipid layer after application. Packaging size is small, but control requirements are high. Typical fill volumes range from 0.3 ml to 5 ml. At this scale, even a small deviation becomes significant.

Recommended Reading: What Are the Adjustment Methods of the Capping Machine? A Comprehensive Guide – King Pack Machinery

Production Process Overview for Parasite Drop Products

A typical all-in-one parasite drop line integrates multiple processes into a single, automated system. At King Pack, we design production lines that include:

- Liquid preparation and filtration

- Automatic bottle or pipette feeding

- High-precision micro-filling

- Plugging and capping

- Labeling and cartoning

This seamless flow reduces manual handling, lowers contamination risk, and ensures consistent dosing for small-volume liquids.

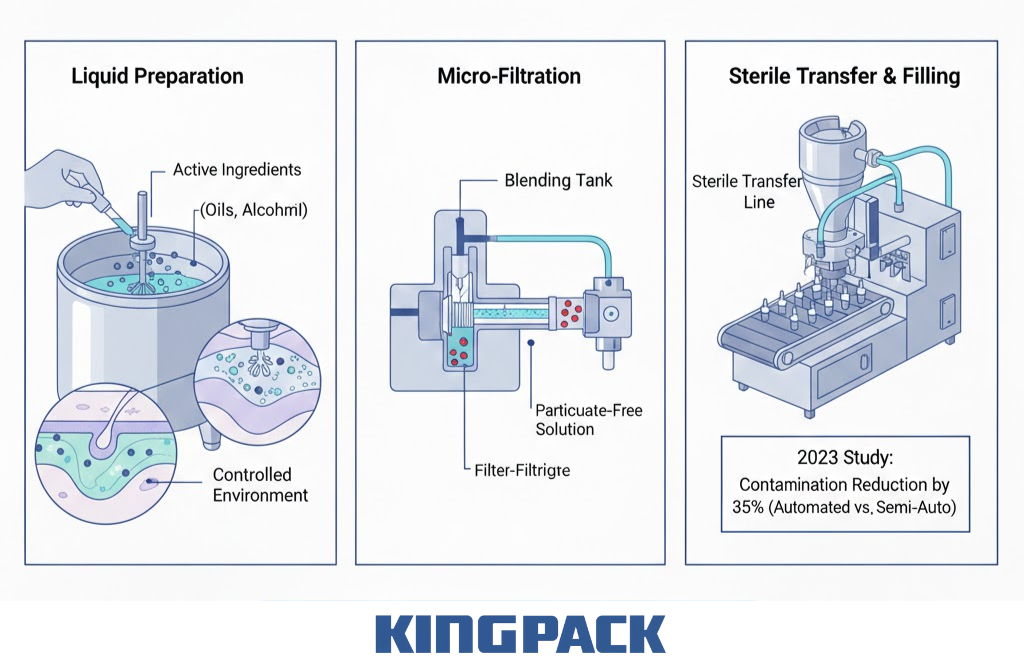

Step 1: Liquid Preparation and Filtration

The first stage of production involves blending the active ingredient with the carrier liquid, which may be oil, solvent-based, or part of a daily chemical product formulation. Precise mixing using continuous blenders or multi-vacuum extruder technology is critical, as uneven dispersion can affect dose consistency downstream. Once blended, the liquid passes through micro-filtration or hot washing lines to remove fine particles that could interfere with dosing or compromise product quality.

Filtered solutions also help protect downstream equipment such as High Speed Automatic Tube Filling Machines, Sauce Bottle Filling Machines, or Cup Filling/Sealing Equipment. Clean liquid reduces nozzle blockage, pump wear, and inconsistent flow during micro-dose filling, especially for PET IV drop or medical products requiring tight control.

King Pack pet parasite drop filling machines are designed to work with filtered formulations and closed transfer tunnels, minimizing exposure. This supports sterility and helps maintain formulation integrity throughout the filling process.

Recommended Reading: Emulsifying Mixer Machine: Factors Affecting The Emulsification Result – King Pack Machinery

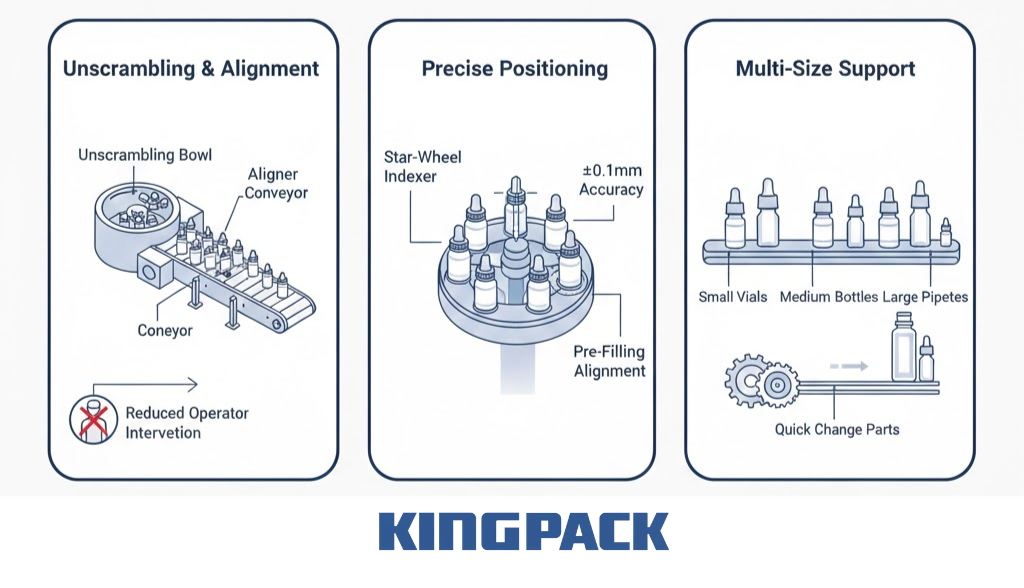

Step 2: Automatic Bottle / Pipette Feeding

Efficient feeding and orientation are essential for high-speed production. Our automatic bottle and pipette feeding systems unscramble and align PET bottles, preforms, or pipettes before filling. This reduces operator intervention and supports continuous operation.

Key benefits include:

- Reduced human contact for better hygiene

- Precise positioning for filling accuracy

- Support for multiple container types, including PET bottles, juice bottles, or cosmetic bottles

Step 3: High-Precision Micro Filling

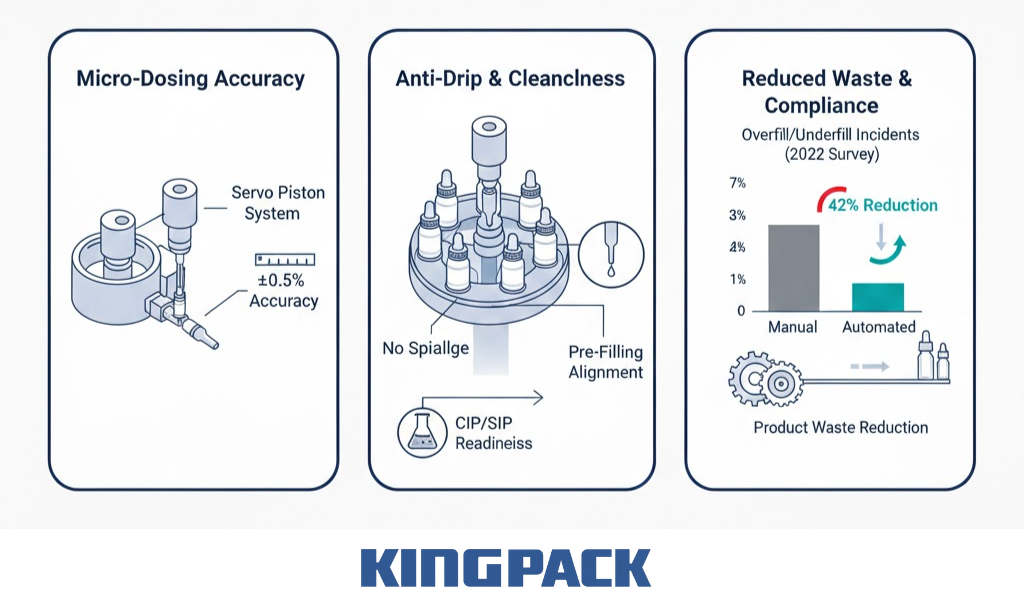

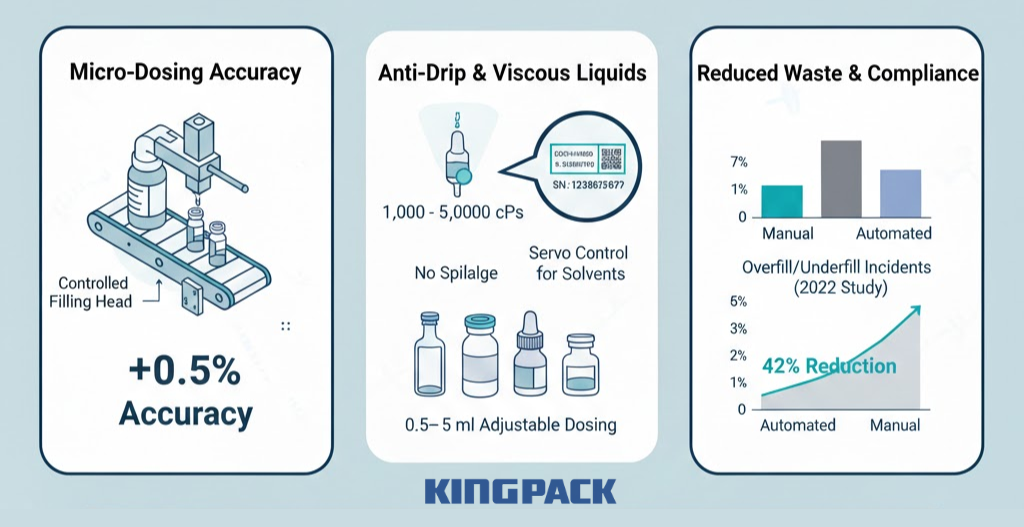

High-precision micro filling is the most critical step in parasite drop production. Volumes typically range from 0.5 ml to 5 ml, where even small deviations affect safety and treatment performance. Accuracy at this scale depends on controlled motion, stable flow, and clean cut-off at every cycle.

King Pack machines use servo-driven piston systems, peristaltic pumps, or volumetric filling technology to achieve this control. Servo pistons deliver defined volumes through digitally controlled strokes, while peristaltic pumps provide smooth, isolated flow for sensitive formulations.

Both maintain stable output across long production runs and consistently achieve ±0.5 percent accuracy, even at very small fill volumes.

Filling precision is supported by nozzle design, UVC lamp units for contamination control, and CIP system compatibility. Anti-drip nozzles prevent spillage after cut-off, keeping containers clean and avoiding overfill. This combination of dosing control, clean cut-off, and hygienic design helps protect product quality while supporting multi-SKU production.

Recommended Reading: What You Should Know About Liquid Filling Machines – King Pack Machinery

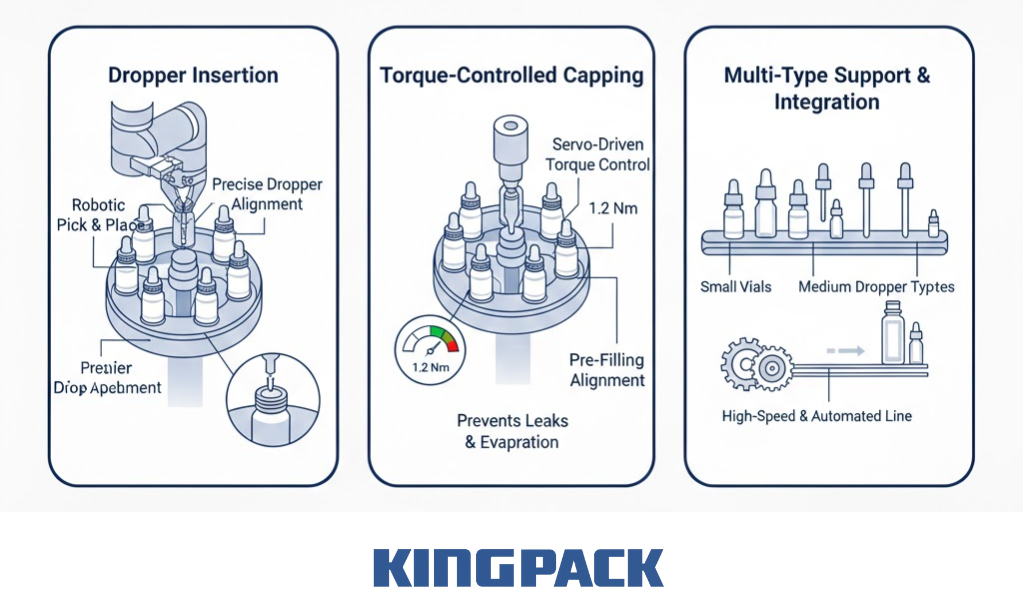

Step 4: Plugging and Capping

After filling, containers require precise dropper insertion or pipette fitting. Torque-controlled capping modules ensure a secure seal without damaging bottles or caps.

Features include:

- Uniform torque to prevent leaks

- Support for multiple dropper and pipette types

- Integration with automated filling to maintain line speed

Proper capping is particularly important for alcohol-based, oil-based, or cosmetic formulations, as evaporation or leakage can compromise quality.

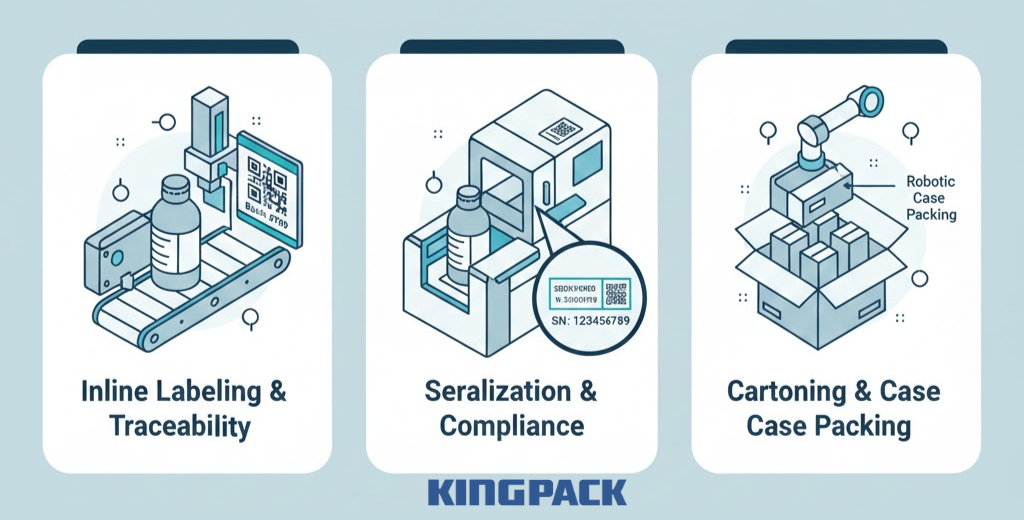

Step 5: Labeling and Cartoning

Once capped, containers move to labeling and secondary packaging. Our production lines support:

- Inline labeling with batch coding for traceability

- Serialization-ready systems for regulatory compliance

- Cartoning and case packing for shipment

Integrated labeling and cartoning reduce manual handling, maintaining sterility and lowering operational errors. Systems are compatible with Premade Pouch Packing, BrandMultipack Machines, or other downstream packaging equipment to create a smooth, continuous production workflow.

Key Challenges in Pet Parasite Drop Manufacturing

Pet parasite drops present unique production challenges that require specialized solutions.

Micro-Dose Accuracy

Small volumes increase sensitivity to dosing errors. Overfill can waste product, while underfill can compromise efficacy. Our high-precision micro-filling machines maintain ±0.3–0.5% accuracy, even at high line speeds.

Chemical Compatibility

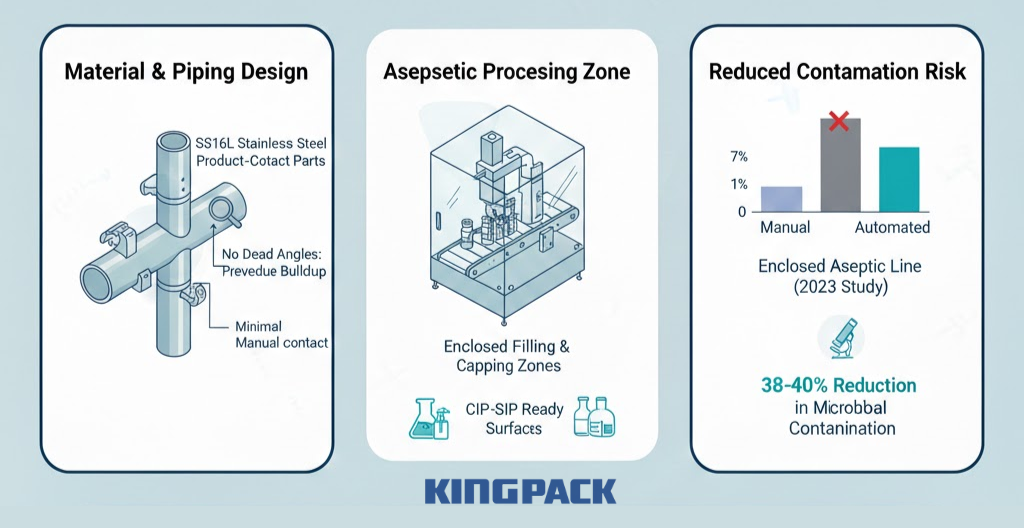

Many parasite solutions contain alcohols, oils, or solvents that can corrode standard equipment. We use chemical-resistant materials such as SS316L stainless steel for contact parts and corrosion-resistant seals to ensure long-term durability.

Hygiene and Cross-Contamination

Maintaining hygiene and preventing cross-contamination are essential in multi-product production. EU GMP and FDA cGMP standards require cleanable, enclosed systems that can be validated for sterility.

King Pack filling lines are designed with CIP/SIP readiness, dead-angle-free piping, and enclosed filling zones, reducing the risk of residue carryover between products. This combination of design features protects both the safety and consistency of every batch.

Recommended Reading: What are the precautions for filling and sealing machine? – King Pack Machinery

All-in-One Filling + Capping + Packaging Line Advantages

Integrated production lines connect filling, sealing, labeling, and packaging in one controlled flow. This approach has become standard for parasite drop production.

Integrated Automation Flow

Manual transfer between machines introduces risk. Each handoff increases exposure to air and human contact.

All-in-one lines move containers directly from filling to sealing and onward to labeling. Hygiene improves, and process control becomes easier.

| Aspect | Separate Machines | Integrated Line |

| Manual handling | High | Minimal |

| Contamination risk | Higher | Lower |

| Line balance | Difficult | Stable |

| Validation effort | Higher | Reduced |

Speed and Stability Improvement

Effective output depends on balance, not headline speed. Integrated lines synchronize module speeds and reduce stop-start cycles.

A recent study reported that balanced integrated lines improved effective output by 28–35%, even without increasing nominal speed. Stability, not speed, drives efficiency.

Labor Cost Reduction

Automation reduces dependence on skilled manual operators. Fewer operators are required per shift, training becomes easier, and validation documentation is more consistent.

This lowers long-term operating cost and improves repeatability.

Equipment Features for Parasite Drop Packaging

King Pack designs every component of our all-in-one parasite drop lines to maximize precision, hygiene, and durability.

High-Precision Filling Technology

Our peristaltic and servo piston filling systems are ideal for micro-volume parasite drops, achieving ±0.3–0.5% dosing accuracy.

Key features include:

- Anti-drip nozzles to prevent waste and contamination

- Adjustable dosing for multiple bottle sizes (0.5–5 ml)

- Servo control for viscous or solvent-based liquids

Sterile and Hygienic Design

Hygiene is central to our design. All product-contact parts use SS316L stainless steel, and piping is free of dead angles to prevent residue buildup.

Additional sterility features:

- Enclosed filling and capping zones

- CIP/SIP-ready surfaces for fast cleaning and sterilization

- Minimal manual contact to reduce contamination risk

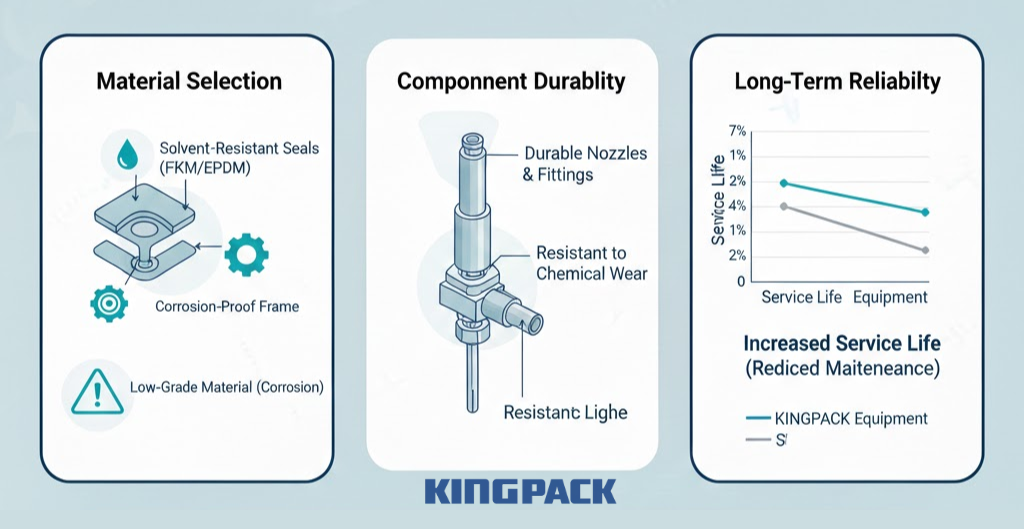

Chemical-Resistant Structure

Parasite solutions often contain solvents, oils, or alcohols, which can corrode standard equipment. We incorporate:

- Chemical-resistant seals compatible with solvents

- Corrosion-proof frames and components

- Durable nozzles and fittings resistant to wear and chemical damage

This ensures long-term reliability and prevents product compromise over repeated production cycles.

Recommended Reading: Cream Tube Filling Machine: The Ultimate Guide – King Pack Machinery

Compliance with EU and FDA Hygiene Standards

Manufacturers must meet stringent hygiene requirements for veterinary products. Our lines are designed to fully comply with EU GMP and FDA cGMP.

EU GMP for Veterinary Medicines

Our equipment allows for easy cleaning, material traceability, and hygienic operation. All welded joints are sanitary, and layouts are designed for fast inspection.

FDA cGMP Requirements

We support validation readiness, including documentation and digital traceability. CIP/SIP capability ensures thorough cleaning and sterilization, making regulatory inspections straightforward.

How King Pack Designs for Compliance

- Sanitary welding for smooth, cleanable surfaces

- Enclosed filling and capping zones

- Easy-to-inspect layouts for maintenance and regulatory checks

- Integration of labeling and batch coding for traceability

Typical Line Configuration for Pet Parasite Drops

Our all-in-one lines are modular, allowing customized configurations depending on product and production needs.

Key modules include:

- Small bottle or pipette feeding systems – unscrambling and aligning containers

- Filling + plugging + capping modules – precise micro-dosing and secure sealing

- Labeling + cartoning + case packing – integrated secondary packaging

- Buffer control and line speed matching – maintain consistent output without bottlenecks

Example Layout Table:

| Module | Function | Features |

| Bottle/Pipette Feeding | Orientation and feeding | Adjustable for multiple container sizes |

| Filling Module | Micro-dose filling | Servo/peristaltic, ±0.5% accuracy |

| Plugging & Capping | Dropper insertion, secure sealing | Torque-controlled capping |

| Labeling & Cartoning | Batch coding and packaging | Serialization-ready, inline inspection |

| Buffer & Line Control | Smooth production flow | Prevents bottlenecks, maintains speed |

This modularity allows manufacturers to expand capacity or adjust lines for new products without major redesigns.

Application Examples for Frontline-Type Products

Frontline-type parasite treatments set the standard for spot-on veterinary products. These formulations require precise dosing, stable sealing, and careful handling of aggressive solvents. Our production lines are designed to support these demands across different product formats and volume ranges.

Flea and Tick Spot-On Treatments

Flea and tick spot-on products typically use single-dose pipettes or very small PET bottles. Fill volumes are low, but the concentration of active ingredients is high. Even minor dosing variation can affect performance.

Our lines use high-precision micro-filling systems combined with PET & Preform Testing Instruments, Auto Drop Pet Stretch Blowing Machines, and preform molds to maintain stable output at volumes below 2 ml. Anti-drip nozzle design, spinning disks, and spray nozzles prevent tailing between fills, keeping pipette tips clean and reducing product loss.

Integrated feeding and filling, combined with coating systems and liquid coating equipment, maintain consistent positioning, supporting accurate dosing over long production runs. This level of control improves batch consistency and reduces overfill, lowering formulation waste while preserving bottle shapes and features.

Anti-Mite Ear Drops

Anti-mite ear drops are often packaged in small PET jars or plastic bottles with droppers. These products require cleaner filling conditions due to frequent application and contact with sensitive tissue.

We design these lines with enclosed filling zones using HEPA filters, air handling units, and dust containment measures to reduce airborne exposure and limit operator contact.

Filling, dropper insertion, and capping run in a continuous sequence with torque-controlled capping, v-belt drive, and SMARTlink system integration, ensuring reliable sealing without damaging closures or bottles. This configuration supports stable production while meeting hygiene expectations for veterinary ear medications, including PET IV drop or medical products.

Deworming Liquid Drops

Some deworming treatments use dropper formats similar to parasite spot-on products. Formulations may vary in viscosity and dosage volume depending on animal size and treatment protocol.

Our Semi Automatic Auto Drop Series and Auto Drop Pet Blow Moulding Machines handle multiple fill volumes within the same line. Recipe-based control allows quick adjustment between products without mechanical rework.

PET Jar And Bottle Blowing, PET extrusion equipment, and injection molding systems support consistent bottle shapes and features. This flexibility benefits manufacturers producing multiple deworming SKUs on shared equipment. Accurate dosing, supported by Class 0 certified air compressors and Atlas Copco compressor solutions, ensures repeatable performance while simplifying regulatory documentation.

Preventive External Parasite Solutions

Preventive parasite products often run at higher volumes and require stable, continuous production. Packaging formats may include both pipettes and small plastic bottles, with full labeling and secondary packaging requirements.

For these applications, we integrate filling, capping, labeling, inspection, and coating equipment into a single automated flow. Balanced line design, combined with Top Load Tester, Secure Seal Tester, and Bottle Burst Tester, supports higher speed without compromising accuracy or hygiene.

Vibration tables, Bottle Scan 360, and Preform Perpendicularity Tester ensure quality control while reject handling keeps throughput stable. This integrated approach reduces labor dependency and improves overall equipment effectiveness during long production campaigns, supporting environmentally friendly practices, PET recycling, and high-alloy stainless steel components across production lines.

Across all these applications, our KPFilling automatic dropper bottle filling machines deliver consistent results. Stable micro-filling, controlled sealing, and integrated packaging reduce waste and improve throughput. Manufacturers benefit from reliable product quality and predictable production performance across diverse parasite treatment lines.

Recommended Reading: Pharmaceutical Emulsion Mixer Machine: Vacuum Emulsifying Mixer Machine – King Pack Machinery

How King Pack Builds Turnkey Parasite Drop Production Lines

We focus on precision, modularity, and compliance.

- Precision Micro-Filling Expertise: Our filling systems maintain high dosing accuracy, even with viscous or solvent-based liquids. Anti-drip nozzles and servo-controlled dosing eliminate spillage, ensuring each container meets standards.

- Modular Expansion Capability: Lines can be customized for current capacity and expanded later. Modules for capping, labeling, or cartoning can be added or upgraded without major downtime.

- Global Installation and Validation Support: We support clients worldwide with installation, training, and validation. CIP/SIP processes, batch record systems, and documentation support ensure lines are inspection-ready.

Frequently Asked Questions (FAQ)

What filling system is best for parasite drops?

Servo piston systems work well for viscous or solvent-based liquids, while peristaltic pumps are ideal for sterile, low-viscosity solutions.

How small can the filling volume be?

Our lines handle micro-volumes as low as 0.5 ml with ±0.5% accuracy.

Can one line handle different bottle sizes?

Yes. King Pack lines are modular and adjustable for multiple bottle formats and pipette sizes.

How to meet EU/FDA hygiene standards?

Enclosed filling zones, stainless steel contact parts, CIP/SIP-ready design, and batch traceability support full compliance.

Can the line integrate cartoning and case packing?

Yes. Our all-in-one lines combine filling, capping, labeling, cartoning, and case packing in a single, synchronized process.

Closing Perspective

Pet external parasite drops require precision, hygiene, and chemical resistance. Manual or fragmented production lines often struggle to maintain these standards at scale. At King Pack, we provide fully integrated parasite drop filling, capping, and packaging lines that ensure safe, accurate, and efficient production. Our automated systems support regulatory compliance while offering flexibility for future product changes.

Contact us today to learn how our solutions can streamline your parasite drop production and improve overall efficiency.