Packaging efficiency is no longer just about individual machines—it’s about the full production line. Automating the process from filling to palletizing can cut manual labor by up to 40%, increase throughput, and reduce human error.

This guide explores how fully integrated systems streamline operations, improve quality consistency, and deliver measurable ROI. You’ll see how automation transforms workflows from the first filled container to the pallet ready for shipment.

Defining Full Automation: Beyond the Filler – Understanding End-to-End Integration

Full automation means eliminating manual intervention at every stage of the packaging process. Products flow continuously from filling stations through capping, labeling, case packing, and finally to palletizing without human hands touching the package.

This seamless integration requires careful coordination between equipment, control systems, and material handling components.

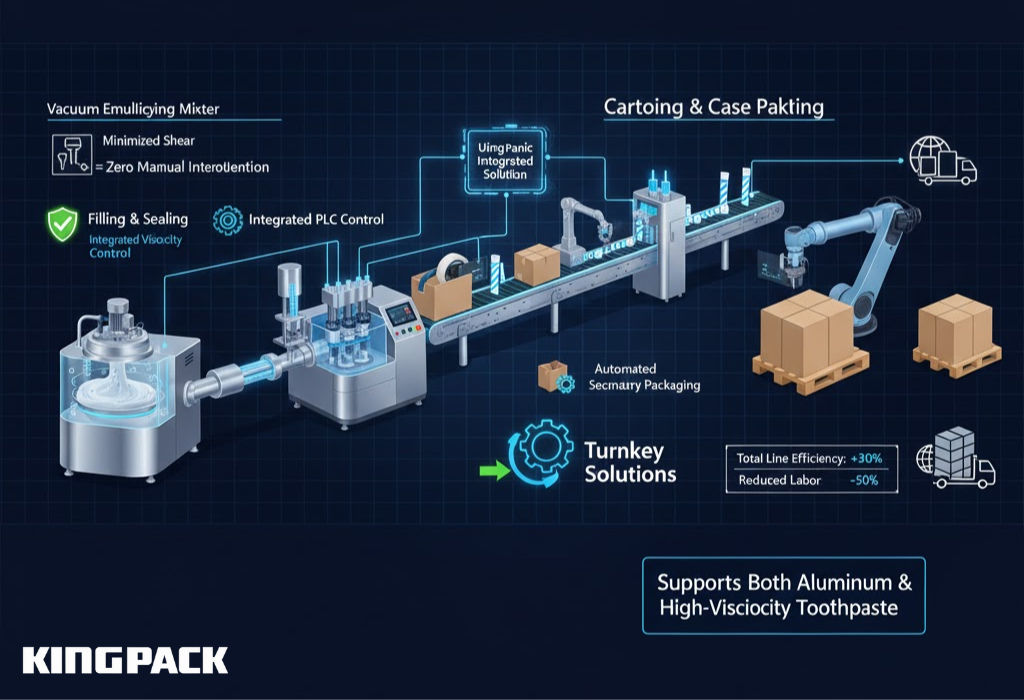

King Pack specializes in creating these integrated solutions, offering customized packaging lines tailored to specific production needs. With over 20 years of experience in pharmaceutical and cosmetic industries, the company designs systems that seamlessly integrate filling, capping, and labeling machines into existing production lines or build complete turnkey operations from the ground up.

Recommended Reading: Automatic Honey Sachet Packing Machine – King Pack Efficient Liquid Sachet Solutions – King Pack Machinery

Structured Definition: The Core Components (Primary, Secondary, and Tertiary Packaging)

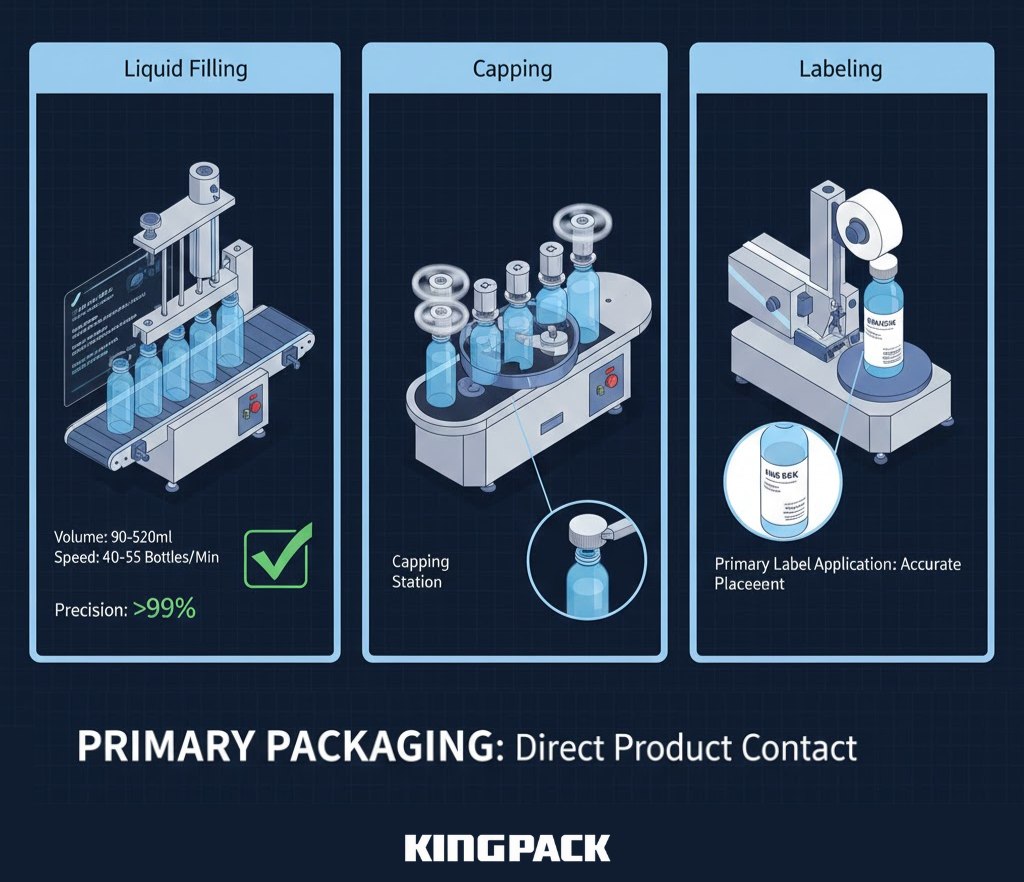

Primary Packaging

Primary packaging involves direct product contact—the bottle, tube, or vial that holds the product. This stage includes filling, capping, and primary labeling operations. King Pack’s liquid filling machines handle volumes from 90ml to 520ml with filling speeds of 40-55 bottles per minute and precision exceeding 99%.

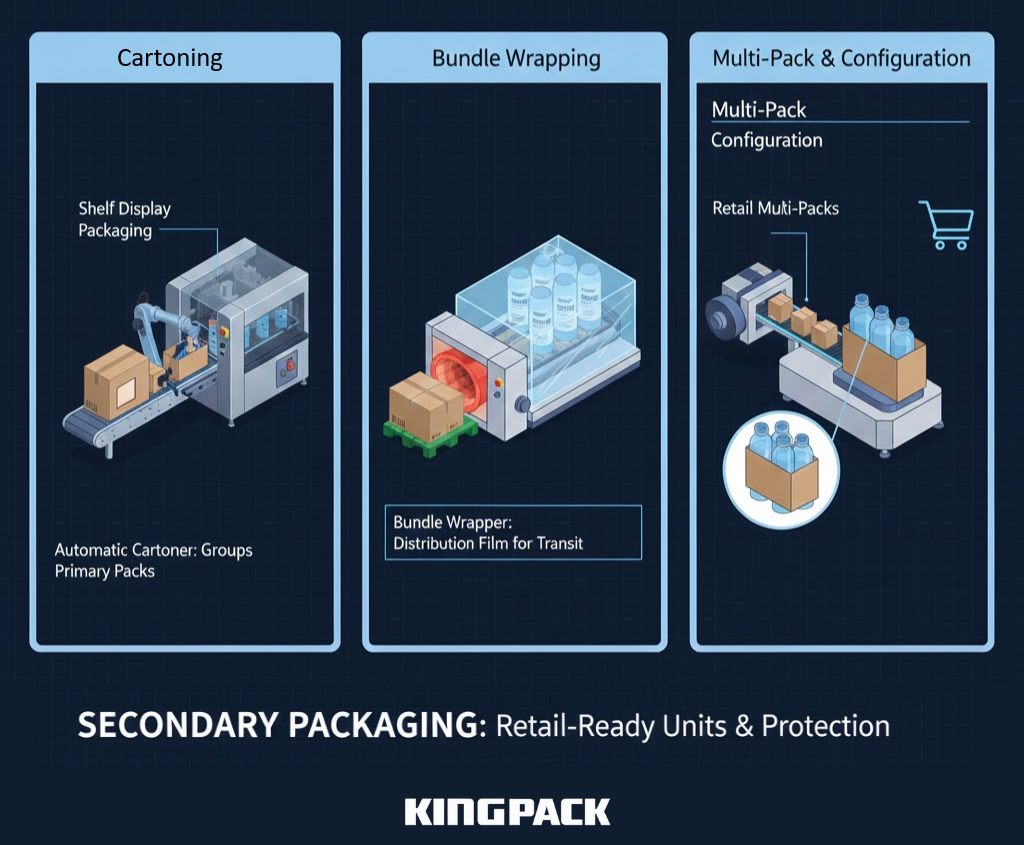

Secondary Packaging

Secondary packaging groups primary packages into retail-ready units. This includes cartoning, bundle wrapping, and multi-pack configurations. Equipment at this stage prepares products for shelf display and protects primary packaging during distribution.

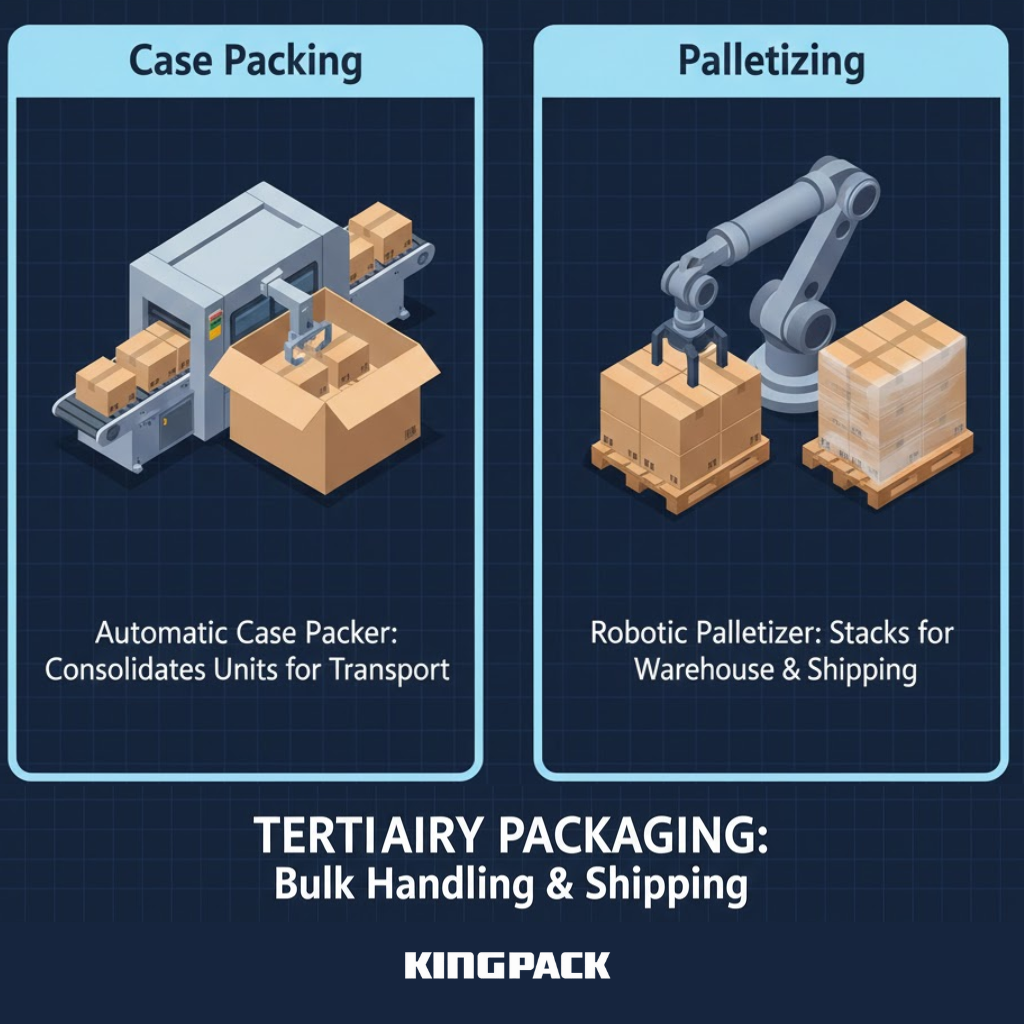

Tertiary Packaging

Tertiary packaging focuses on bulk handling and transportation. Case packing systems consolidate multiple units into corrugated cases, while palletizing equipment stacks cases onto pallets for warehouse storage and shipping. This final stage prepares products for long-distance transportation and warehouse handling.

Key Performance Indicator (KPI): What is Overall Equipment Effectiveness (OEE) and Why is it the Automation Metric?

Overall Equipment Effectiveness (OEE) measures manufacturing productivity by combining three critical factors: availability, performance, and quality. The formula is straightforward:

OEE = Availability × Performance × Quality

- Availability measures uptime against scheduled production time

- Performance compares actual production speed to ideal speed

- Quality tracks the percentage of good units produced

World-class manufacturers target OEE scores above 85%. Manual packaging lines typically operate between 40% and 60% OEE due to operator variability, breaks, and quality inconsistencies. Automated lines routinely achieve 75-85% OEE by eliminating human-related downtime and maintaining consistent speeds.

| OEE Component | Manual Line Performance | Automated Line Performance | Improvement |

| Availability | 75% (breaks, shift changes) | 90% (scheduled maintenance only) | +15% |

| Performance | 65% (operator variation) | 90% (consistent speed) | +25% |

| Quality | 92% (human error) | 98% (automated inspection) | +6% |

| Total OEE | 45% | 79% | +34% |

Phase I: Primary Packaging Integration (Filler to Sealer)

Primary packaging integration connects filling, capping, and labeling operations into a synchronized system. Success at this stage depends on managing speed variations between machines and implementing quality checks that catch defects before products advance to secondary packaging.

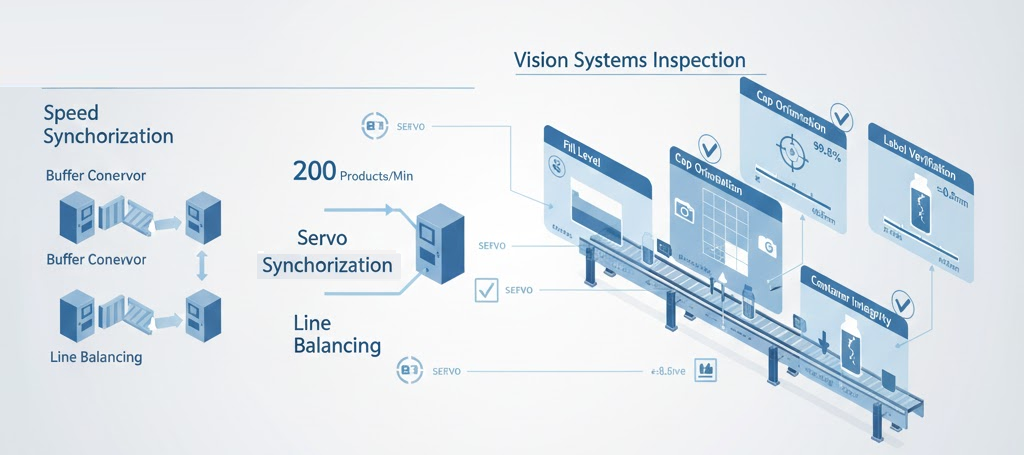

Transition Points: Integrating Fillers, Cappers, and Labelers (Addressing Speed Mismatches)

Speed mismatches create bottlenecks that limit overall line performance. A filler operating at 100 bottles per minute connected to a capper running at 80 bottles per minute wastes 20% of the filler’s capacity.

The following three approaches address this challenge:

- Buffer Conveyors: Accumulation zones between machines absorb temporary speed differences, allowing upstream equipment to continue operating when downstream equipment pauses

- Servo Synchronization: Modern control systems coordinate multiple machines to run at matched speeds, with automatic speed adjustments based on real-time line conditions

- Line Balancing: Strategic equipment selection places machines with compatible speeds in sequence, minimizing the need for buffering

King Pack’s integrated packaging solutions feature servo-driven systems that synchronize speeds across multiple stations. Our food and beverage filling lines deliver outputs from 60 to 220 bottles per minute with filling accuracy of ±1-2%, designed for seamless integration with downstream capping and labeling equipment.

Recommended Reading: Vertical Automatic Flour Packaging Machine – King Pack Powder Packing Solutions – King Pack Machinery

Technology Focus: Vision Systems and Quality Checks for Flawless Primary Packaging

Automated vision systems perform multiple inspection tasks in milliseconds:

- Fill Level Verification: Cameras measure product height in containers, rejecting under-filled or over-filled units before they reach capping stations

- Cap Presence and Orientation: Vision systems confirm caps are present, properly seated, and correctly oriented before applying torque

- Label Inspection: High-resolution cameras verify label placement accuracy within ±1mm, check for print defects, and confirm barcode readability

- Container Integrity: Systems detect cracked containers, damaged threads, and foreign material contamination

Rejected products divert to separate collection bins, triggering alerts when rejection rates exceed programmed thresholds. Data logging tracks rejection causes, enabling targeted process improvements.

Phase II: End-of-Line (Secondary & Tertiary) Automation

End-of-line automation transforms individually packaged products into palletized loads ready for shipment. This phase delivers the greatest labor reduction potential, replacing multiple manual workers with automated systems that operate continuously at consistent speeds.

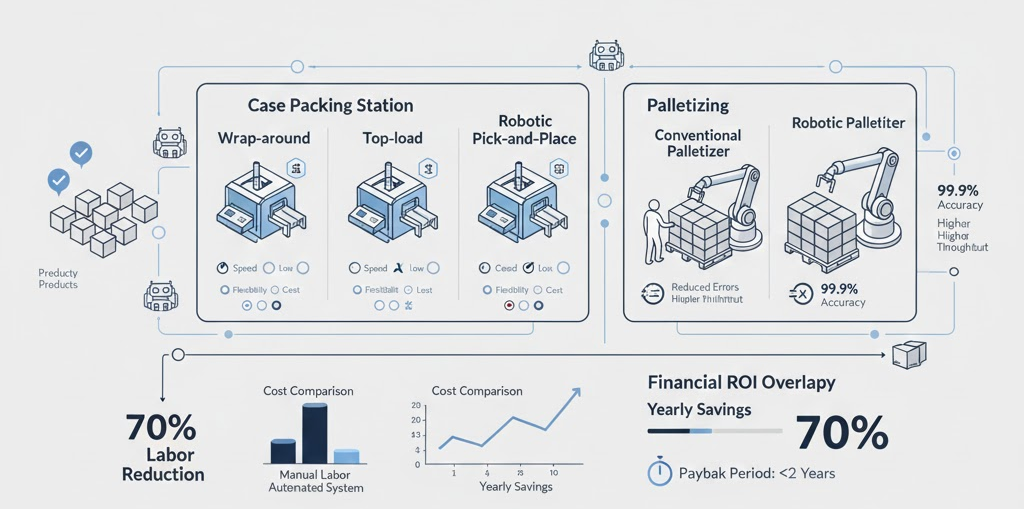

The Case Packer: Choosing Between Wrap-Around, Top-Load, and Robotic Pick-and-Place Systems

Case packing technology selection depends on product characteristics, production volume, and packaging requirements:

| Case Packer Type | Best Applications | Speed Range | Flexibility | Capital Cost |

| Wrap-Around | Stable products in uniform groups | 15-25 cases/min | Low (dedicated to one case size) | $ |

| Top-Load | Fragile or irregular products | 10-20 cases/min | Medium (adjustable lanes) | $$ |

| Robotic Pick-and-Place | Mixed SKUs, varied configurations | 8-15 cases/min | High (infinite pattern options) | $$$ |

Wrap-around case packers form corrugated cases around product groups already arranged in the correct pattern. These systems offer high speeds and minimal product handling but require pre-arranged product groups and uniform case sizes.

Top-load case packers drop products into pre-formed cases from above. Side guides arrange products into proper patterns before loading. These systems handle delicate products gently but operate at lower speeds than wrap-around systems.

Robotic pick-and-place systems use vision-guided robots to pick products from conveyors and place them in cases following programmed patterns. These systems handle multiple SKUs on the same line and accommodate frequent product changes without mechanical adjustments.

The Palletizer: Achieving High-Volume Throughput with Conventional vs. Robotic Palletizing

Palletizing represents the final step in packaging automation, stacking cases onto pallets in stable patterns that withstand transportation stresses.

Two technologies dominate this space:

| Feature | Conventional Palletizers | Robotic Palletizers |

| Footprint | 15-25 square meters | 8-12 square meters |

| Capital Cost | $120,000-$200,000 | $80,000-$150,000 |

| Speed | 25-35 cases/minute | 10-20 cases/minute |

| Pattern Flexibility | Limited (mechanical changes required) | Unlimited (software programming) |

| Product Range | Optimized for single product type | Handles multiple sizes and weights |

| Maintenance | Higher (more mechanical components) | Lower (fewer moving parts) |

| Setup Time | 2-4 hours for product change | 15-30 minutes (recipe change) |

Conventional palletizers use mechanical layer-forming systems to arrange cases into complete layers before transferring them to pallets. These high-speed systems excel in single-product, high-volume operations where pattern changes are infrequent.

Robotic palletizers employ industrial robots (typically 4-6 axis articulated arms) to pick individual cases or groups and place them following programmed patterns. Modern systems using FANUC or ABB robots achieve reliability exceeding 99.5% uptime with proper maintenance.

For manufacturers running multiple products or frequent pattern changes, robotic systems deliver superior flexibility. Operations focused on maximizing throughput for single products benefit from conventional palletizer speed advantages.

Recommended Reading: Automatic Sauce Packaging Machine – King Pack High-Precision Sachet Filling Solutions – King Pack Machinery

Maximizing ROI: The Financial Case for Automation

Packaging automation requires substantial capital investment. Understanding the financial return helps justify expenditure and guides equipment selection decisions.

Data Point Focus: Calculating the 40% Labor Reduction: A Breakdown of Labor Cost vs. Machine Investment

A typical manual packaging line employing 10 workers across three shifts (30 total workers) processes 50 units per minute. Labor costs average $35,000 annually per worker including benefits, totaling $1,050,000 yearly.

Here’s Manual Operation Costs (Annual)

- 30 workers × $35,000 = $1,050,000

- Product waste (3% due to human error) = $180,000

- Quality issues and rework = $75,000

- Total Annual Cost: $1,305,000

Here’s Automated System Investment

- Integrated filling, capping, labeling line: $450,000

- Case packing system: $180,000

- Robotic palletizer: $120,000

- Conveyor and integration: $100,000

- Installation and commissioning: $50,000

- Total Capital Investment: $900,000

Here’s Automated Operation Costs (Annual)

- 18 workers (40% reduction) × $35,000 = $630,000

- Maintenance and parts: $65,000

- Energy costs: $40,000

- Product waste (0.5% with automated controls) = $30,000

- Total Annual Cost: $765,000

Annual Savings: $1,305,000 – $765,000 = $540,000

ROI Calculation Formula:

Payback Period = Total Capital Investment ÷ Annual Savings

Payback Period = $900,000 ÷ $540,000 = 1.67 years (approximately 20 months)

This simplified calculation demonstrates a clear financial case for automation. Most manufacturers achieve payback within 18 to 36 months, with systems delivering value for 10-15 years with proper maintenance.

Accessing Government Incentives and Subsidies for Factory Automation

Many regions offer financial incentives to support automation upgrades and manufacturing investment. These programs often apply to semi-automatic machines, packaging upgrades, and new manufacturing equipment used across different industries.

Common incentive programs include:

- Investment Tax Credits: Tax deductions that can cover 10–30% of equipment costs for systems such as carton sealers, case erectors, or a labelling machine

- Accelerated Depreciation: Faster write-offs for capital investments like an Ink Jet Coding Machine, Domino Ax150i, or Vial Packaging Machine, improving early cash flow

- Workforce Development Grants: Funding for training operators on upgraded systems used in sectors like 3PL industries or the wet wipes industry

- Energy Efficiency Rebates: Incentives tied to lower power use, waste management improvements, or reduced material usage

Manufacturers should consult local development agencies and tax advisors to confirm eligibility. When combined, these incentives can lower the effective Budgetary Price of new equipment by 15–25%, improving return on investment and shortening payback periods.

Recommended Reading: Packaging Machine Solutions – King Pack Packaging Equipment – King Pack Machinery

Industry 4.0 & Smart Packaging: Future-Proofing Your Line

Modern packaging lines incorporate connectivity and data collection capabilities that extend beyond simple automation. Industry 4.0 integration transforms packaging equipment from isolated machines into networked systems that optimize performance and predict maintenance needs.

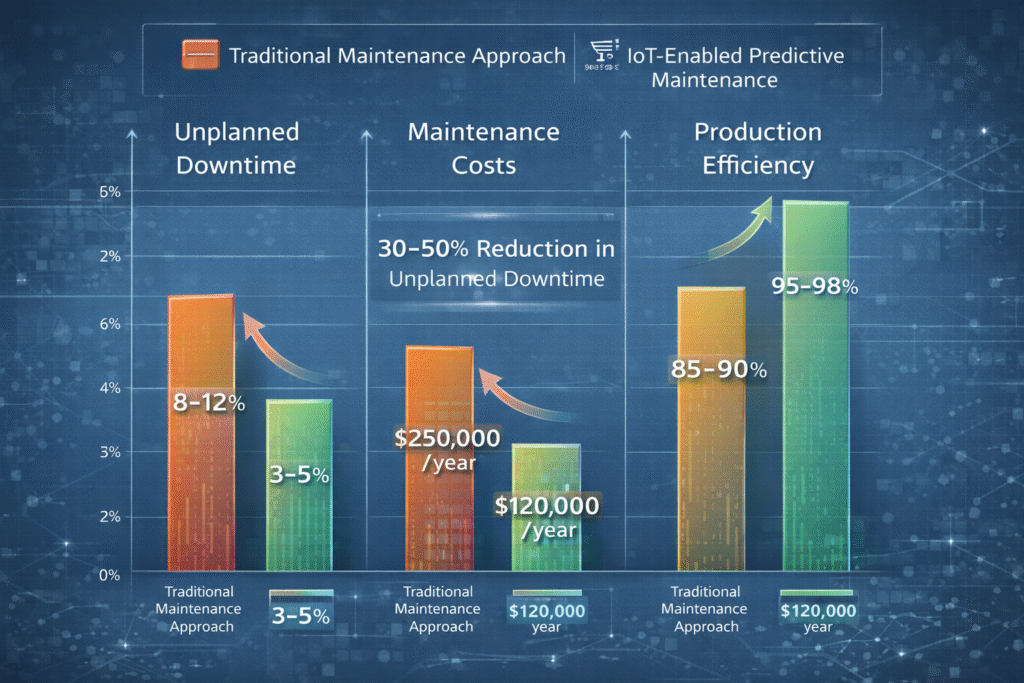

Data Point Focus: Utilizing IoT for Predictive Maintenance to Eliminate Unexpected Downtime

Modern monitoring systems use Internet of Things (IoT) sensors to track key conditions across manufacturing equipment in real time on an Automatic Packing Line or Automatic Production Line:

- Vibration Monitoring: Identifies bearing wear, imbalance, or misalignment in core-line machinery before failure

- Temperature Tracking: Flags overheating motors, drives, and electrical components during long continuous operation

- Power and Load Monitoring: Detects abnormal current draw that signals mechanical resistance or component wear

- Cycle and Output Tracking: Links machine cycles and Bottles Per Minute data to maintenance intervals for critical parts

Predictive maintenance based on IoT data can cut unplanned downtime by 30–50% compared to reactive repairs. Instead of stopping production unexpectedly, maintenance teams can plan service during scheduled breaks in the production process.

Advanced systems connect the monitoring system to a touch screen control panel or maintenance software, triggering alerts and work orders when issues develop. This approach improves operational flexibility and keeps conveyor lines and packaging automation machinery running consistently.

Remote Monitoring and Diagnostics: Support and Uptime

Connected equipment enables technical support teams to diagnose problems remotely, often resolving issues without on-site visits.

Secure VPN connections allow equipment suppliers to:

- View real-time production data and identify performance issues

- Access machine diagnostics and error logs to troubleshoot problems

- Adjust parameters remotely to optimize performance

- Monitor system health and recommend preventive actions

King Pack provides comprehensive technical support through their global service network. Our team offers remote diagnostics and on-site assistance to maintain system performance and minimize downtime. With over 3,000 completed projects across 60+ countries, the company brings extensive experience in supporting diverse manufacturing operations.

For manufacturers in regions with limited local technical resources, remote support capabilities become especially valuable. Real-time troubleshooting can resolve problems in hours rather than days, preventing extended production stoppages while waiting for on-site service visits.

Recommended Reading: Multilane Packing Machines – High‑Speed Multichannel Sachet & Stick‑Pack Solutions | King Pack – King Pack Machinery

Conclusion: Taking the First Step Toward Your Automated Future

Building a fully automated packaging line represents a significant commitment. The benefits include lower labor needs, better quality consistency, higher throughput, and improved workplace safety, which together deliver strong returns.

Success requires careful planning, proper equipment selection, and integration with experienced suppliers.

Start by evaluating current operations to identify bottlenecks and labor-intensive processes. Calculate existing costs including direct labor, product waste, and quality-related expenses. These baseline numbers establish the foundation for ROI calculations and help prioritize automation investments.

Request a Technical Consultation on Automated Line Solutions

Every manufacturing operation faces unique challenges based on products, production volumes, facility constraints, and budget considerations. Direct consultation with automation specialists helps identify optimal configurations and develop realistic implementation timelines.

King Pack’s technical team evaluates production requirements, existing equipment, and facility layouts to design integrated solutions that deliver measurable improvements. Our experience across pharmaceutical, cosmetic, food, and beverage industries provides insights into addressing common challenges and avoiding costly mistakes.

Technical consultations typically include:

- Production capacity analysis and bottleneck identification

- Equipment compatibility assessment for integrating new automation with existing machinery

- Utility requirements evaluation (compressed air, electrical, floor space)

- Preliminary ROI calculations based on current labor costs and projected savings

- Implementation timeline development with minimal production disruption

Contact King Pack to schedule a consultation and begin planning your automated packaging line transformation.

Frequently Asked Questions (FAQs) on Packaging Automation

What is the typical payback period (ROI) for a fully automated packaging line?

Most manufacturers see payback within 18–36 months, depending on labor costs, production volume, and system scope. High labor rates and multi-shift operations usually shorten the return period.

How does the OEE metric relate to manual labor reduction?

Higher OEE means more output with fewer operators. Automation improves availability, speed consistency, and quality, allowing the same production volume with less labor.

What is the difference between conventional and robotic palletizers?

Conventional palletizers run faster and suit single-product, high-volume lines. Robotic palletizers offer greater flexibility for multiple products and patterns, with slightly lower speeds.

What’s required to integrate machines from different vendors into one line?

Integration relies on common communication protocols, compatible PLC systems, and well-matched conveyors. An integration specialist coordinates controls, handshakes, and operator interfaces to keep the line running smoothly.