Tube packaging has become a practical choice for food brands looking to extend shelf life while offering easy dispensing and portion control. Unlike cosmetic or industrial filling, food applications demand precise temperature control, sterile environments, and materials that meet regulatory requirements.

In this complete guide, we will break down food tube filling equipment for 2026, with a focus on aseptic technology, sealing performance, and food safety compliance. The goal is to help manufacturers understand what’s required to run safe, efficient, and scalable food tube operations.

Defining Food-Grade Filling: The Critical Difference Between Standard and Aseptic Processing

Food-grade tube filling equipment must meet stringent sanitation requirements that exceed standards for cosmetic or industrial applications. Every surface contacting food products requires pharmaceutical-grade stainless steel (316L), validated cleaning procedures, and documentation proving microbial contamination control.

King Pack specializes in food-grade filling equipment designed specifically for the unique demands of food processing. Our tube filling and sealing machines handle viscous products from sauces to nut butters while maintaining compliance with USDA and HACCP standards through 316 stainless steel contact parts that prevent cross-contamination.

The Principles of Aseptic Filling vs. Hot Filling

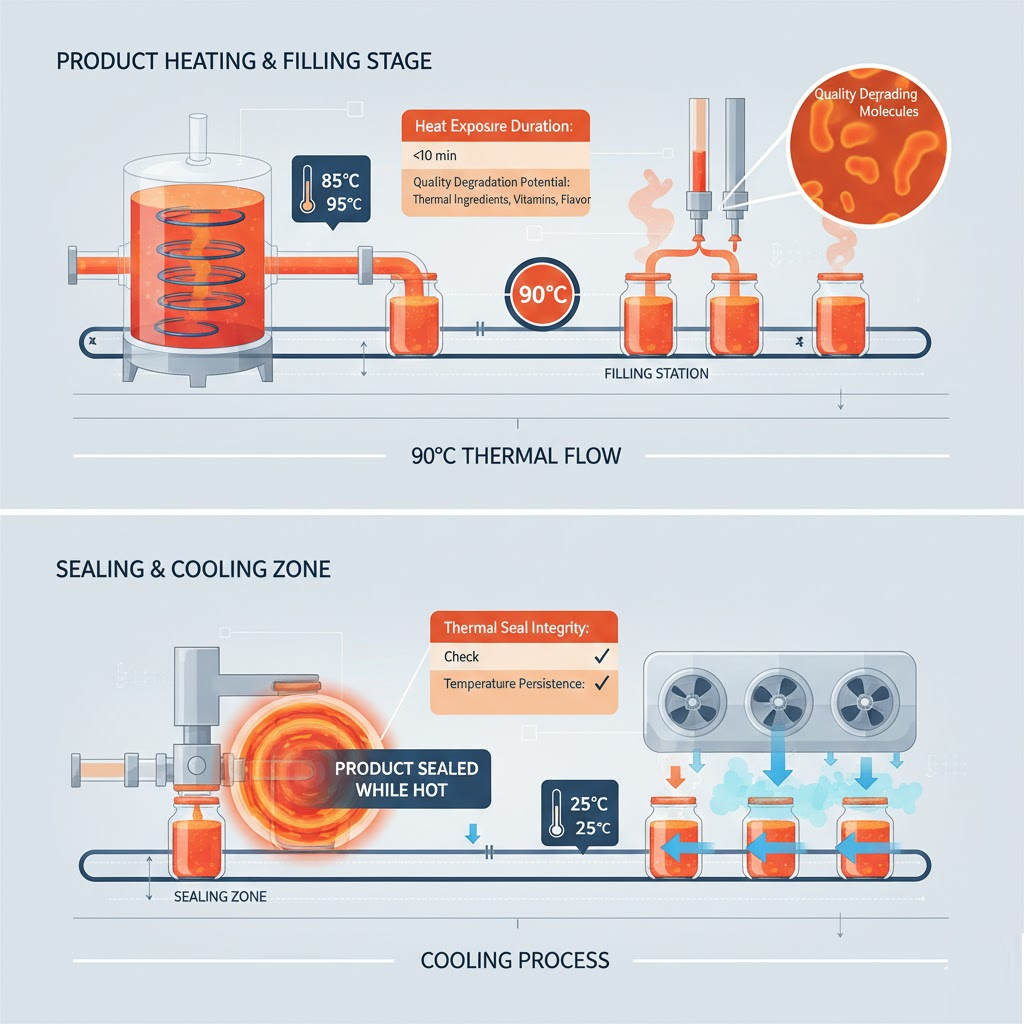

Food manufacturers choose between aseptic filling and hot filling based on product characteristics, desired shelf life, and production economics. Each approach offers distinct advantages for different applications.

Aseptic Filling Process

Aseptic filling sterilizes product and packaging separately before combining them in a sterile environment. This process preserves heat-sensitive nutrients, colors, and flavors that degrade during traditional hot filling.

The sequence follows these steps:

- Product Sterilization: High-temperature short-time (HTST) processing heats products to 135-150°C for 2-10 seconds, destroying microorganisms while minimizing nutrient degradation

- Rapid Cooling: Products cool to filling temperature (20-30°C) immediately after sterilization

- Tube Sterilization: Empty tubes pass through hydrogen peroxide vapor, UV light, or electron beam sterilization

- Sterile Filling: Products fill tubes within enclosed sterile chambers protected by HEPA-filtered positive air pressure

- Hermetic Sealing: Tubes seal immediately after filling in the sterile zone

Recommended Reading: Types of Food Packaging Machines: Applications, Benefits, and Industry Uses – King Pack Machinery

Hot Filling Process

Hot filling heats products to 85-95°C, fills them into tubes at elevated temperatures, then seals while hot. Residual heat continues sanitizing the tube interior and seal area after filling. This simpler process requires less capital investment but subjects products to prolonged heat exposure that degrades quality.

| Processing Method | Product Temperature | Shelf Life (Ambient) | Nutrient Retention | Equipment Cost | Best Applications |

| Aseptic Filling | 20-30°C | 12-24 months | 85-95% | $$$$ | Baby food, specialty sauces, organic products |

| Hot Filling | 85-95°C | 6-12 months | 70-80% | $$ | Ketchup, mustard, standard condiments |

| Cold Filling + Preservatives | 4-15°C | 3-6 months | 90-98% | $ | Fresh sauces, refrigerated products |

Aseptic filling represents the gold standard for premium food products. The process maintains product quality while delivering extended shelf life without refrigeration. Products retain fresh flavors, natural colors, and heat-sensitive nutrients that distinguish premium brands from economy alternatives.

Technical Challenge: Handling High-Viscosity and Particulate Foods (Sauces, Purees, Gels)

Food products present filling challenges that differ fundamentally from pharmaceutical creams or cosmetic lotions. Tomato paste, peanut butter, and fruit purees contain solid particles, exhibit non-Newtonian flow behavior, and maintain viscosities reaching 500,000 centipoises (cP) or higher.

King Pack’s equipment handles products from free-flowing gels at 100 cP to heavy pastes at 500,000 cP with dosing accuracy to within ±0.5%. Our paste tube filling machines incorporate vertical screw pumps and piston fillers specifically designed for viscous food products like honey, nut butters, and concentrated sauces.

Viscosity Management Strategies

Filling liquid and paste products with high viscosity requires careful equipment selection and process control:

- Temperature Control: Heated hoppers and product reservoirs maintain consistent viscosity throughout production runs. Medium speed filling helps avoid product separation or flow issues.

- Pump Selection: Ceramic pumps, piston fillers, or volumetric filling systems deliver precise fill volumes regardless of thickness. Level Fillers and Paste Fillers are ideal for thick cosmetic products or CBD products.

- Nozzle Design: Capillary nozzles, outward opening nozzles, and large-bore filling tips prevent clogging while ensuring smooth flow. Check valves and recirculation tanks support continuous product movement.

- Anti-Drip and Tube Protection: Closure stations with heat seal, fold and crimp, or heated tool sealing maintain hygiene and prevent waste. Fixing molds and crimping machines ensure uniform tube sealing.

- Handling Particulates: Products with solids, like herbal extracts in cosmetic or CBD products, require gentle pumping to preserve particle integrity and product appearance.

Products containing particulates like fruit pieces, vegetable chunks, or coffee grounds require special consideration. Pump selection must accommodate the largest particle size without damage. Gentle handling preserves particle integrity, particularly important for products where visible fruit pieces contribute to perceived quality.

Recommended Reading: How Food-Grade Tube Sealing Improves the Shelf Life of Mayonnaise – King Pack Machinery

Material Science: Selecting High-Barrier Tubes to Maximize Shelf Life

Tube material selection directly impacts product shelf life, production costs, and environmental sustainability. Food applications demand materials that provide excellent barrier properties against oxygen, moisture, and light while maintaining food-safe certifications.

Comparison Table: Laminate vs. Aluminum Tubes for Food Preservation

| Property | Laminate (Plastic) Tubes | Aluminum Tubes |

| Oxygen Barrier | Good (2-5 cc/m²/day with EVOH layer) | Excellent (complete barrier, 0 transmission) |

| Moisture Barrier | Good (1-3 g/m²/day) | Excellent (complete barrier) |

| Light Protection | Fair to Good (metallized layers improve) | Excellent (100% light block) |

| Material Cost | $0.08-$0.15 per tube | $0.15-$0.25 per tube |

| Shelf Life Achievement | 12-18 months (with proper formulation) | 24-36 months |

| Product Compatibility | Suitable for pH 3.5-8.0, limited with highly acidic | Excellent for all pH ranges, resists corrosion |

| Consumer Dispensing | Easy to squeeze, complete evacuation | Requires more force, iconic appearance |

| Sustainability | Difficult to recycle (multi-material), newer mono-material options improving | Highly recyclable, infinite recycling potential |

| Print Quality | Excellent full-color graphics, complex designs | Limited printing area, traditional appearance |

| Sealing Method | Hot air or ultrasonic sealing | Mechanical folding and crimping |

Laminate Tube Construction for Food

Modern food-grade laminate tubes use multiple polymer layers to create strong barrier protection. The outer polyethylene layer supports high-quality printing and resists moisture, while EVOH or metallized polyester layers limit oxygen exposure that can shorten shelf life.

Food-safe adhesive layers bond the materials together, and the inner polyethylene layer meets food-contact regulations. Five-layer laminate tubes are the baseline for ambient-stable products with 12-month shelf life, while seven-layer structures suit products with higher barrier demands.

Aluminum Tubes for Premium Food Products

Aluminum tubes offer unmatched barrier protection for products requiring extended shelf life or containing oxygen-sensitive ingredients like polyunsaturated fats, vitamin C, or natural colorants. The complete oxygen and light barrier prevents oxidative rancidity, color fading, and nutrient degradation.

Premium food brands increasingly specify aluminum tubes despite higher costs. The traditional appearance communicates quality and heritage, particularly valuable for artisanal products, organic foods, and specialty condiments targeting discerning consumers.

Recommended Reading: A Beginner’s Guide to Tube Filling Machines – King Pack Machinery

The Role of Hermetic Sealing and Inert Gas Flushing (Nitrogen) in Extending Freshness

Hermetic sealing creates an airtight closure that prevents oxygen ingress and moisture exchange after filling. Food tubes require seal integrity exceeding pharmaceutical standards because any contamination pathways allow spoilage microorganisms to enter and multiply.

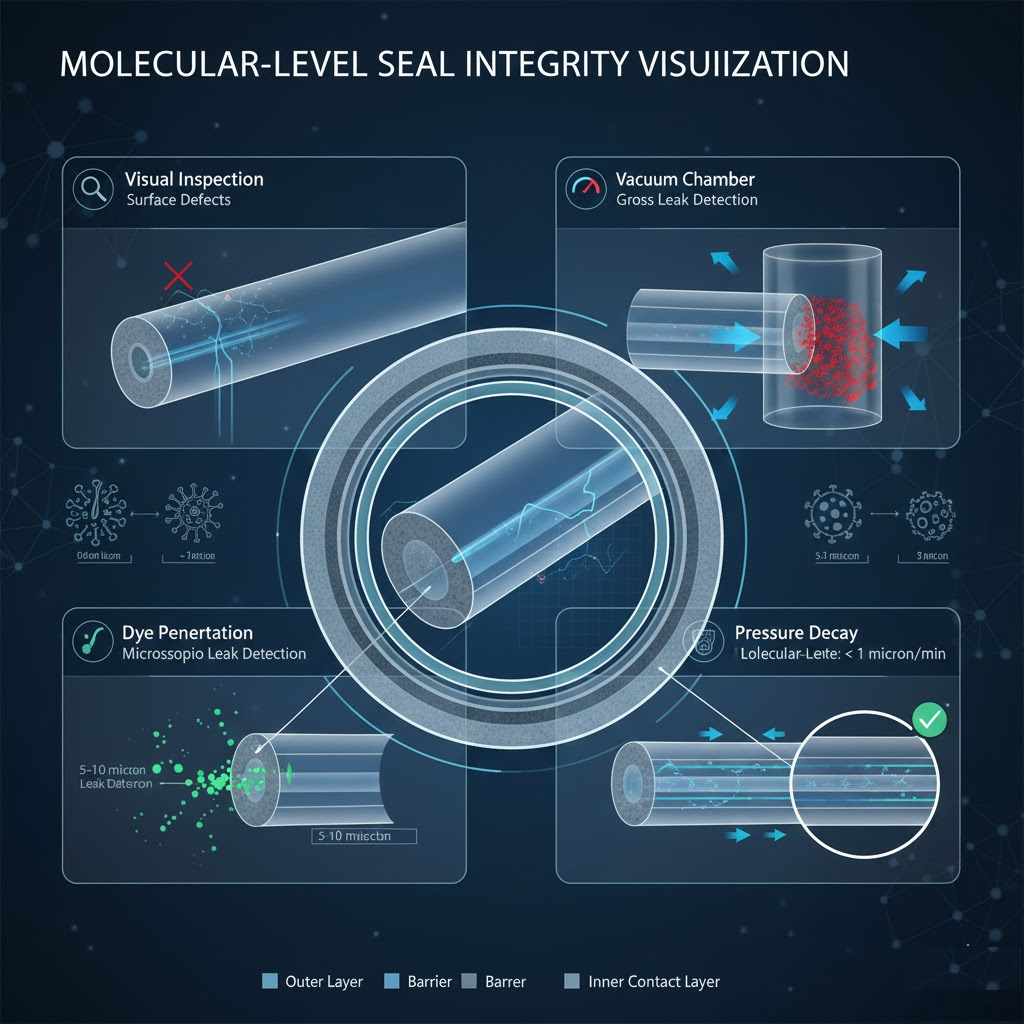

Seal Quality Verification Methods

Manufacturers employ multiple testing approaches to validate seal integrity:

| Test Method | Detection Capability | Testing Speed | Destructive/Non-Destructive |

| Visual Inspection | Gross seal defects only | Instant | Non-destructive |

| Vacuum Chamber Testing | Detects leaks ≥50 microns | 30-60 seconds per sample | Non-destructive |

| Dye Penetration | Detects leaks ≥10 microns | 5-10 minutes per sample | Destructive |

| Pressure Decay | Detects leaks ≥1 micron | 2-3 minutes per sample | Non-destructive |

Modern filling lines incorporate automated leak detection systems that test 100% of production rather than sampling approaches used with manual testing. Vision systems identify visual seal defects, while inline pressure testing catches microscopic leaks before products leave the production line.

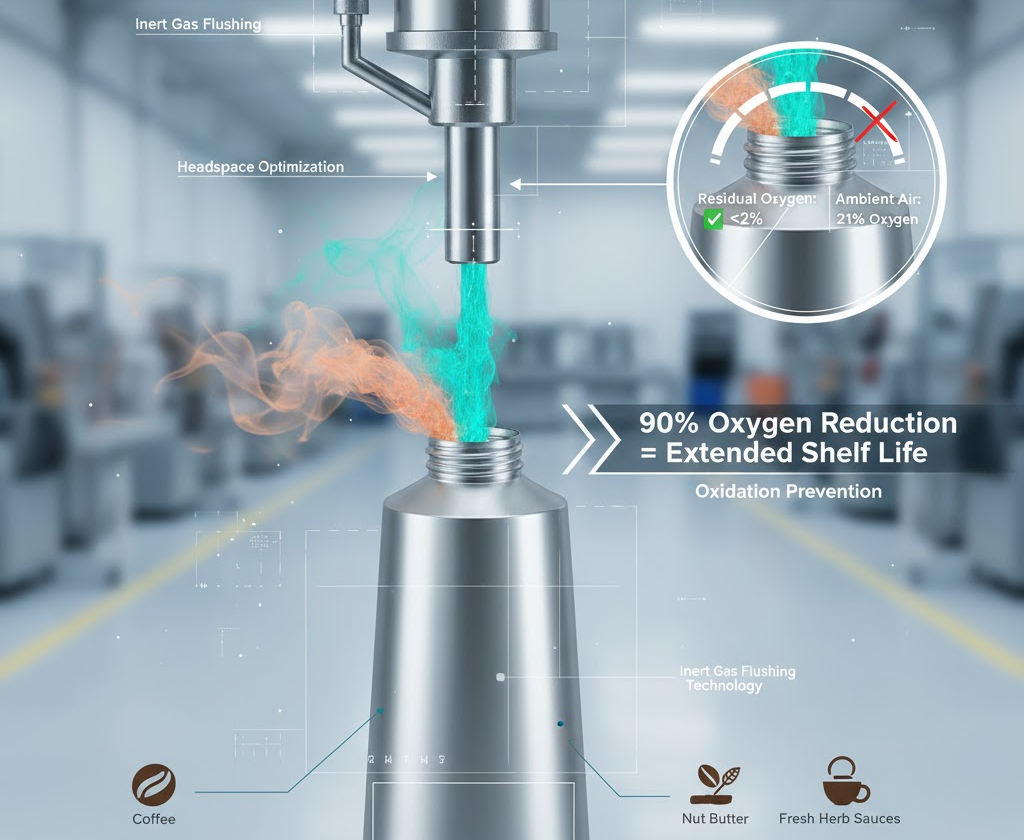

Nitrogen Flushing Technology

Inert gas flushing displaces oxygen from tube headspace before sealing, dramatically extending shelf life for oxygen-sensitive products. The process flows nitrogen through the tube during filling, purging ambient air and replacing it with inert atmosphere.

Effective nitrogen flushing reduces residual oxygen to less than 2% in the sealed tube headspace, compared to 21% oxygen in ambient air.

This 90% reduction translates to proportional increases in shelf life for products where oxidation limits stability. Coffee products, nut butters containing polyunsaturated oils, and sauces with fresh herb ingredients benefit most from nitrogen flushing.

Recommended Reading: The Differences Between Homogenization and Emulsification – King Pack Machinery

Food Safety & Compliance: A Critical Checklist for Equipment Selection

Regulatory compliance represents a non-negotiable requirement for food tube filling equipment. Machinery must meet or exceed standards established by the FDA, USDA, HACCP protocols, and GMP guidelines. Equipment design directly impacts a manufacturer’s ability to pass regulatory audits and maintain food safety certifications.

Key Requirements for GMP/HACCP Compliance in Tube Fillers

When selecting tube filling machinery for plastic tubes, laminated tubes, or pharmaceutical products, manufacturers should check the following:

- 316L Stainless Steel Construction: All product-contact surfaces must use 316L stainless steel to resist corrosion and prevent contamination of liquid products.

- CIP Capability: Semi-automatic tube fillers and automated filling systems should have clean-in-place cycles for wash, rinse, and sanitize, reducing contamination risks.

- Sanitary Design: Equipment should avoid horizontal surfaces, dead legs, and crevices. Tri-clamp connections are preferred over threaded fittings to prevent residue buildup.

- HEPA-Filtered Filling Zone: RT60 Tube Fillers, hot air tube fillers, and ultrasonic (high-frequency) tube filling systems should use HEPA-filtered air to protect critical filling areas.

- Validated Sterilization: Suppliers must provide protocols confirming sterilization of product pathways, filling nozzles, and sealing sections.

- Automated Batch Documentation: Tube filling systems should record batch numbers, fill weight, and seal temperature to ensure traceability.

- Personnel Barriers: Physical or automated barriers should limit operator contact. Safety interlocks should prevent operation during manual access.

King Pack’s filling machinery combines these features with automatic tube loading, servo drives, and double-jacket hoppers, maintaining hygienic conditions for liquid and paste products while improving production speed.

Conclusion: Technology and Safety — The Future of Food in Tubes

Food tube filling continues to evolve as brands demand better safety, longer shelf life, and reliable production. Advances in aseptic processing, sealing technology, and barrier materials allow manufacturers to protect product quality while meeting strict food safety rules.

As sustainability and traceability gain importance, equipment design is shifting toward recyclable materials, smarter controls, and connected systems. Manufacturers that invest in the right technology now will be better prepared to meet regulatory demands and changing consumer expectations.

Request a Technical Consultation on Food Tube Filling Solutions

Food tube filling requires specialized expertise combining food science, process engineering, and regulatory knowledge. Generic packaging equipment rarely delivers acceptable results for the unique demands of food applications.

Working with experienced suppliers helps food manufacturers avoid costly mistakes, accelerate time to market, and achieve regulatory compliance.

Technical consultations should evaluate:

- Product characteristics including viscosity, pH, particle size, and stability

- Desired shelf life and distribution conditions (ambient, refrigerated, frozen)

- Production volume requirements and future growth projections

- Existing facility capabilities including utilities, clean room classification, and floor space

- Regulatory requirements based on product category and target markets

- Budget constraints and ROI expectations

King Pack offers comprehensive consultation services backed by extensive experience in food-grade tube filling equipment. Our technical team can assess your specific requirements and recommend optimal solutions that balance performance, compliance, and cost considerations. Contact us today for more details!

Frequently Asked Questions (FAQs) on Food Tube Filling

What is the cost difference between aseptic and non-aseptic tube filling machines?

Aseptic systems typically cost 3–5 times more than hot filling lines due to sterile chambers, tube sterilization, and validated cleaning. Hot filling lines start near $150,000, while aseptic systems usually begin around $500,000.

How is tube contamination prevented during high-speed filling?

Sterile filling zones use HEPA-filtered air, automated tube handling, and vision inspection to block contamination. CIP systems clean product paths between batches, and anti-drip nozzles reduce cross-contamination.

What tube materials work best for acidic foods like ketchup or mustard?

Highly acidic products require aluminum tubes or special laminates with acid-resistant inner layers. EVOH barrier layers and food-safe coatings prevent material breakdown and flavor transfer.

What viscosity can a standard food tube filler handle?

Standard piston fillers manage up to 200,000 cP, covering most sauces and purees. Heavier products like nut butters need specialized pumps or temperature control to reduce viscosity during filling.