Modern tube packaging demands more than speed—it requires precision in sealing and durability in coding. Each tube leaving the line must be protected from contamination, while labels and codes must survive handling, storage, and distribution.

In this article, we will talk about hot air, ultrasonic, and mechanical sealing options, plus laser and inkjet coding systems. The guide also covers validation and inspection techniques to maintain compliance and consistent product quality.

Defining Seal Integrity: Why the Right Sealing Technology is Non-Negotiable

Seal integrity protects product quality from the moment tubes leave production lines until consumers squeeze out the final portion.

A compromised seal allows oxygen, moisture, and microbial contamination to enter, degrading product performance and potentially creating safety hazards. Selecting appropriate sealing technology based on tube material, production volume, and product characteristics is fundamental to packaging success.

King Pack’s tube filling and sealing machines incorporate advanced sealing technologies including hot air sealing and ultrasonic sealing. Our equipment supports batch number and date coding, crimp jaw equipped with date/lot coder systems, and advanced sealing with hot-air sealing or ultrasonic sealing technology, providing complete solutions for diverse tube packaging requirements.

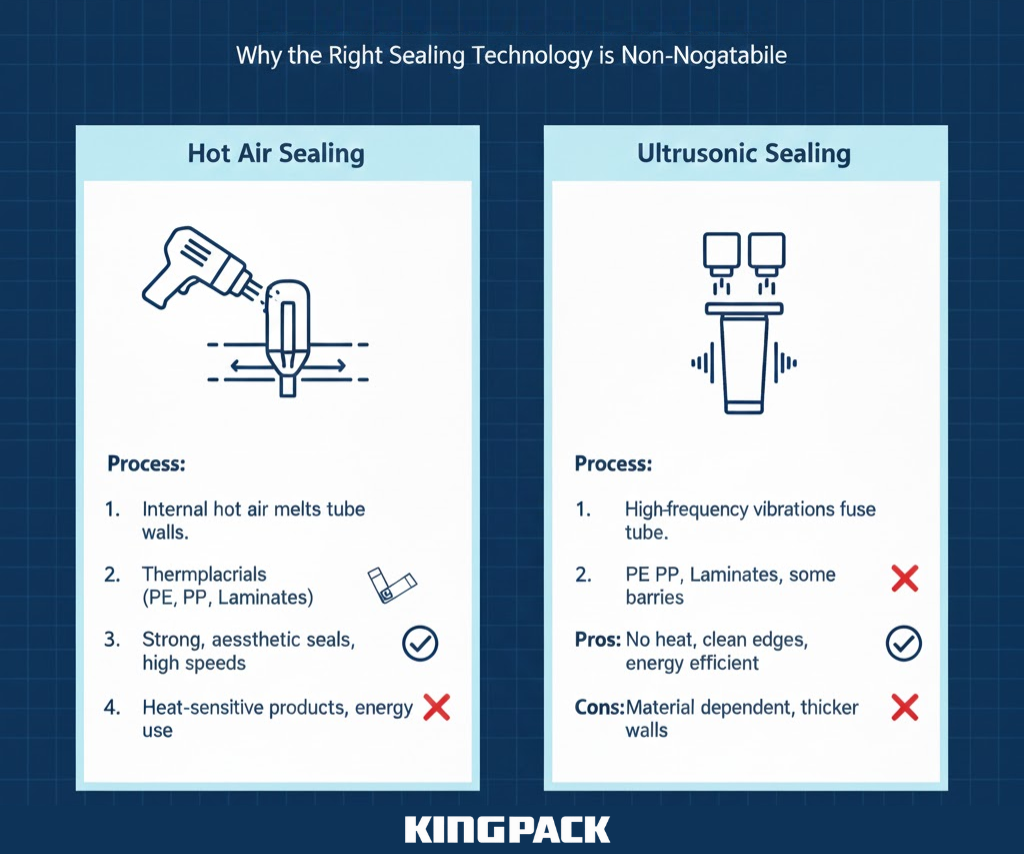

Structured Comparison: Hot Air, Ultrasonic, and Impulse Sealing – Pros and Cons

Three primary sealing technologies dominate tube packaging, each offering distinct advantages for specific applications and tube materials.

| Sealing Method | Operating Principle | Speed (TPM) | Energy Efficiency | Tube Compatibility | Visual Quality | Change Parts Required | Best Applications |

| Hot Air Sealing | Heated air (180-220°C) melts thermoplastic layers | 60-200 | Moderate | All plastic/laminate tubes (PE, PP, EVOH) | Excellent | Yes (nozzles per size) | High-volume production, premium appearance |

| Ultrasonic Sealing | High-frequency vibration (20-40 kHz) creates friction heat | 20-60 | High (70% less than thermal) | Plastic/laminate (PE, PP) | Good | Minimal | Small-batch production, quick changeovers |

| Impulse Sealing | Electrical pulse heats sealing element momentarily | 30-80 | Very high | Thin-wall plastic tubes | Fair | Moderate | Specialty applications, heat-sensitive products |

| Mechanical Crimping | Physical folding and compression | 40-100 | Very high (no heating) | Aluminum tubes only | Traditional/iconic | Yes (crimp patterns) | Metal tubes, toothpaste, ointments |

Hot Air Sealing Technology

Hot air sealing uses 180–220°C with 1.5–3.0 seconds dwell time, achieving 15–25 N/15mm seal strength. Heated air jets directed at the open tube end soften thermoplastic materials, allowing sealing jaws in the Hot Air Sealing Unit to compress and weld the layers together. Cooling stations solidify the seal before tubes advance to subsequent operations.

Advantages of hot air sealing include:

- Universal Material Compatibility: Works with virtually all thermoplastic tube materials including polyethylene, polypropylene, and laminated tubes with barrier layers

- Professional Appearance: Creates clean, uniform seals with consistent dimensions and smooth surfaces

- High Production Speeds: Achieves 60–200 tubes per minute on semi-automatic or automatic tube filler systems, depending on tube size and material thickness

- Strong, Reliable Seals: Produces hermetic closures that withstand typical distribution stresses

Disadvantages include higher energy consumption compared to ultrasonic methods and requirement for tube-size-specific filling nozzles and Hot Air Sealing Unit settings, increasing changeover complexity when processing multiple tube diameters.

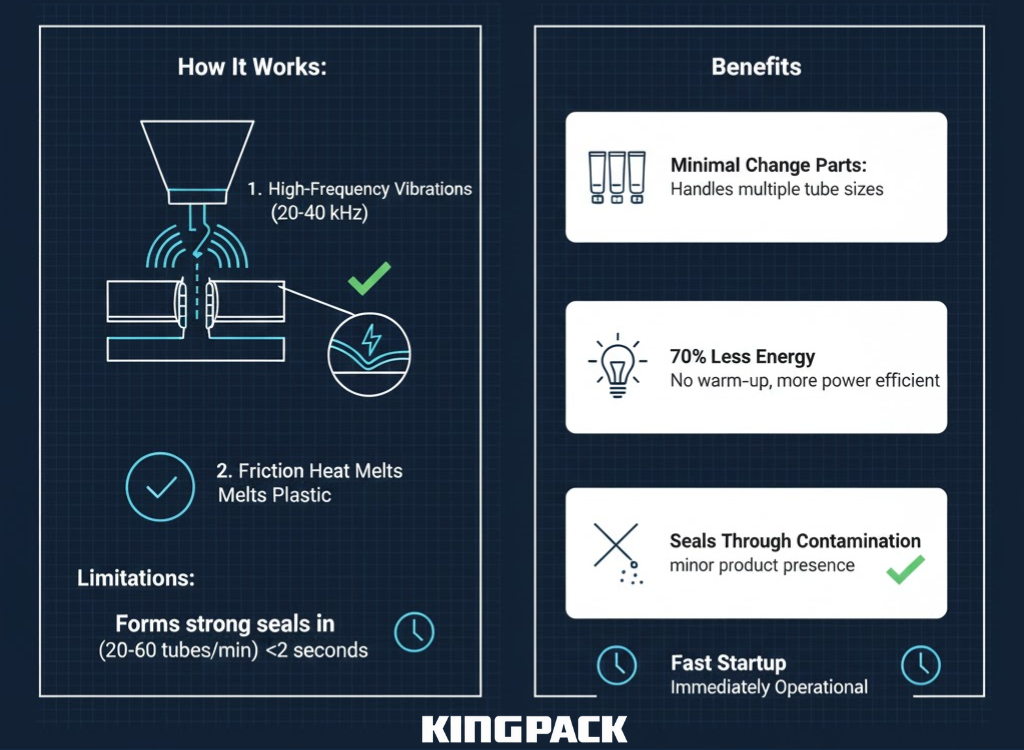

Ultrasonic Sealing Technology

Ultrasonic sealing runs at 20–40 kHz and 800–2000 watts, forming seals in under 2 seconds with 70% greater energy efficiency compared to thermal methods. High-frequency vibrations generated by the Ultrasonic system produce friction heat precisely at the seal interface, melting plastic without external heating elements.

Benefits of ultrasonic sealing:

- Minimal Change Parts: Same sealing horn handles multiple tube sizes, reducing changeover time and format part costs

- Energy Efficient: Consumes 70% less energy than hot air systems by generating heat only at the seal point

- Seals Through Contamination: Can accommodate minor product contamination in seal areas that would compromise folding sealing or punch hole seals

- Fast Startup: No warm-up period required, immediately operational when activated

Limitations include lower production speeds (typically 20–60 tubes per minute) and slightly less polished visual appearance compared to hot air sealing. Plastic Tube Filling and Sealing Machine systems with digital ultrasonic automatic tracking, sealing & coding operation, and color mark detection allow manufacturers to balance energy efficiency, production dates tracking, and filling accuracy error across production lines.

Recommended Reading: What Differentiates Tube Filling and Sealing Machine from Ultrasonic Tube Sealing Machine? – King Pack Machinery

Mechanical Crimping for Aluminum Tubes

Aluminum tubes require folding and crimping rather than thermal sealing. Mechanical systems progressively fold the tube end multiple times, then compress the folded section to create a flat, sealed tail. This traditional appearance remains popular for toothpaste, pharmaceutical ointments, and heritage brand products.

Material Science: Selecting the Seal Method Based on Tube Type (Aluminum vs. Laminate/Plastic)

Tube material composition dictates appropriate sealing technology. Mismatched sealing methods produce weak closures prone to leakage, delamination, or incomplete bonding.

| Tube Material | Construction Layers | Recommended Sealing | Critical Considerations |

| Mono-Material PE | Single polyethylene layer | Hot air or ultrasonic | Easy to seal, both methods work well |

| Multi-Layer Laminate (PE/EVOH/PE) | Polyethylene + barrier layer + polyethylene | Hot air preferred | Temperature control critical to prevent delamination |

| Aluminum Barrier Laminate | Plastic/aluminum foil/plastic | Hot air only | Requires precise temperature (aluminum doesn’t seal ultrasonically) |

| Pure Aluminum | Aluminum alloy tube body | Mechanical crimping | Cannot use thermal or ultrasonic methods |

| Co-Extruded (COEX) | Multiple plastic layers extruded together | Hot air or ultrasonic | Similar to mono-material in sealing behavior |

Plastic and Laminate Tubes

Polyethylene-based tubes seal effectively using hot air or ultrasonic methods. The choice depends on production lines, desired appearance, and equipment budget. High-volume operations benefit from Hot Air Sealing Unit systems for speed, while semi-automatic or automatic tube fillers with digital ultrasonic automatic tracking offer flexibility and lower energy costs for smaller manufacturers.

Multi-layer laminated tubes containing barrier materials (EVOH, metallized films) require careful machine parameters during hot air sealing. Excessive heat can delaminate layers, weakening the barrier, while insufficient heat produces incomplete seals. Production dates, registration marks, and color mark detection ensure traceability and quality control across filling nozzles and sealing & coding operations.

Aluminum Tubes

Pure aluminum tubes and tubes with aluminum foil layers cannot be sealed thermally. Folding sealing and punch hole seals with Tube Sealer or Plastic Tube Filling and Sealing Machine equipment are required. Specialized crimping mechanisms progressively fold the tube end, creating the flat tail typical of pharmaceutical ointments and CBD products.

Recommended Reading: What are the advantages of tube filling machine? – King Pack Machinery

Precision Coding: Meeting Global Standards for Traceability and Product Security

Product coding transforms anonymous tubes into traceable units that support quality control, regulatory compliance, and supply chain management. Modern coding systems must produce permanent, machine-readable marks that survive distribution environments while meeting international serialization standards.

Serialization: Understanding GS1 Data Matrix and Batch Coding Requirements

Serialization assigns unique identifiers to individual packages, enabling tracking throughout supply chains from manufacture through consumer sale. This capability has become mandatory in pharmaceutical and medical device industries, with food and cosmetic sectors increasingly adopting similar practices.

GS1 Standards

GS1 provides the global framework for product identification and data exchange. The organization maintains standards for barcode formats, data structures, and serialization protocols recognized across industries worldwide.

Key GS1 data carriers for tube packaging:

- GS1 DataMatrix: Two-dimensional barcode encoding up to 2,335 alphanumeric characters in a compact square symbol. Preferred for pharmaceutical serialization due to space efficiency and error correction capabilities

- GS1-128 (formerly UCC/EAN-128): Linear barcode encoding multiple data elements (GTIN, lot number, expiration date, serial number) in a single symbol

- GS1 Digital Link: URI-based identification enabling smartphone scanning to access product information, authentication systems, and digital content

Pharmaceutical Serialization Requirements

Multiple jurisdictions mandate pharmaceutical serialization:

- United States: Drug Supply Chain Security Act (DSCSA) requires serialization for prescription drugs at the saleable unit level by November 2023

- European Union: Falsified Medicines Directive (FMD) requires unique identifiers and anti-tamper devices on prescription medicines

- China: Drug Administration Law requires electronic traceability systems for prescription drugs

- Other Markets: Brazil, South Korea, Turkey, India, and additional countries have implemented or are implementing serialization requirements

Compliance demands equipment capable of printing unique codes, verifying code quality, and integrating with enterprise serialization management systems that track serial numbers throughout distribution.

Batch Coding Standards

Beyond serialization, batch coding enables product recalls, quality investigations, and inventory management.

Batch codes typically include:

- Manufacturing date or production date code

- Lot or batch number assigned to specific production runs

- Expiration date or best-before date

- Manufacturing site identifier (for multi-site operations)

- Shift code or line identifier

Format and placement requirements vary by jurisdiction and product category. Pharmaceutical products face strict legibility requirements and specific data element mandates, while cosmetic and food products have more flexibility in code format.

Technology Focus: Laser, Inkjet, and Hot Stamp Coding – Code Permanence

Three primary coding technologies serve tube packaging applications, each offering different permanence levels, operational costs, and integration complexity.

| Coding Technology | Permanence | Resolution | Speed (char/sec) | Consumables | Substrate Compatibility | Operating Cost |

| Laser Marking | Permanent (500+ washes) | 300-600 DPI | Up to 1000 | None (electricity only) | Most plastics, some laminates | Lowest long-term |

| Continuous Inkjet (CIJ) | Good (varies by ink) | 180-300 DPI | 800-1200 | Ink, solvent, filters | Universal (all surfaces) | Moderate |

| Thermal Inkjet (TIJ) | Good to excellent | 300-600 DPI | 600-900 | Ink cartridges | Porous and coated surfaces | Moderate |

| Hot Stamp Coding | Excellent | Low (character-based) | 200-400 | Foil ribbons | Heat-stable surfaces | Higher |

Laser Marking Systems

Laser coders use focused light beams to alter surface pigmentation or ablate material layers, creating permanent marks that survive harsh environments. Laser coders produce permanent markings that withstand 500+ wash cycles, making them ideal for pharmaceutical products requiring long-term traceability.

Two primary laser types serve tube coding:

- CO2 Lasers (10,600 nm wavelength) work well on organic materials including plastics, paper, and certain coatings. They create marks by burning or melting surface layers.

- Fiber Lasers (1,064 nm wavelength) excel on metals and engineered plastics. They produce high-contrast marks through surface oxidation or color change reactions.

Advantages include zero consumable costs, permanent codes resistant to solvents and abrasion, and ability to produce high-resolution 2D barcodes. Disadvantages include higher capital costs ($15,000-$50,000) and limitations with certain tube materials that don’t respond well to laser energy.

Recommended Reading: How is Toothpaste Manufactured and How Tube Filling Machines and Emulsifying Equipment are Used in this Process? – King Pack Machinery

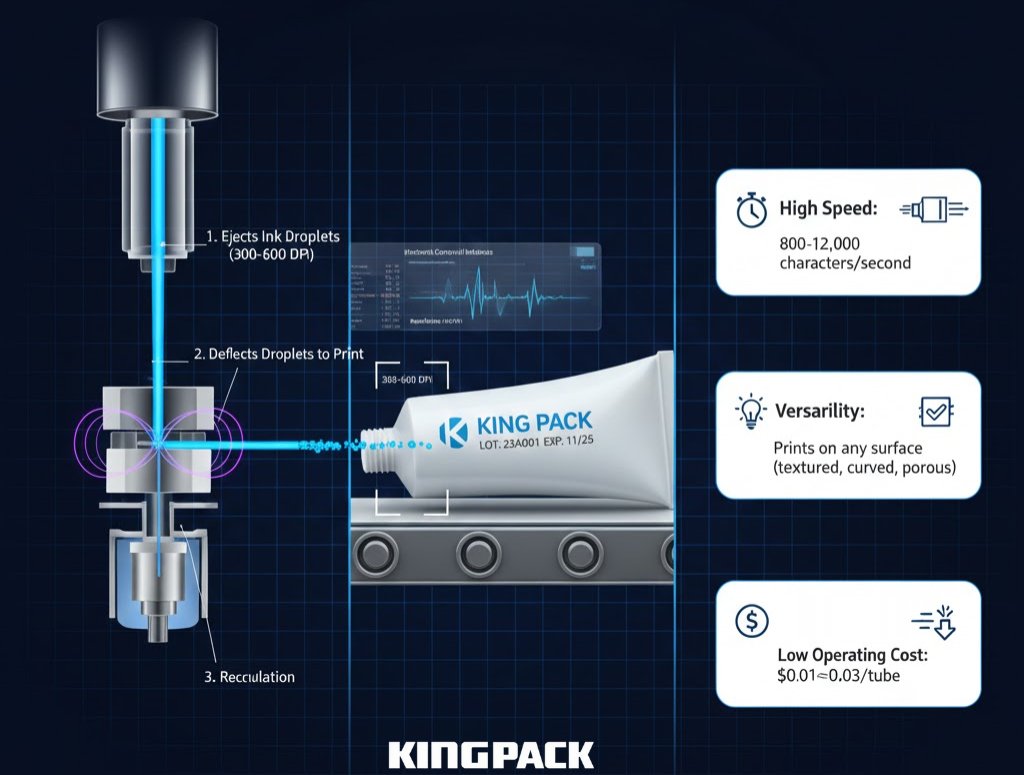

Continuous Inkjet (CIJ) Printing

CIJ systems eject continuous streams of ink droplets, deflecting selected drops to form characters on passing tubes. These systems dominate high-speed production environments due to reliability and versatility.

Inkjet printers deliver 300–600 DPI resolution for batch and expiry details, producing clear, readable codes across diverse surfaces. Modern CIJ systems achieve excellent code permanence using specialized inks formulated for specific substrates.

Benefits include printing on any surface (textured, curved, porous), high-speed operation (800-1,200 characters per second), and ability to change messages instantly through electronic controls. According to industry studies, operating costs mainly come from ink, solvent, and routine filter replacement, and typically range from $0.01 to $0.03 per tube depending on code complexity and print requirements.

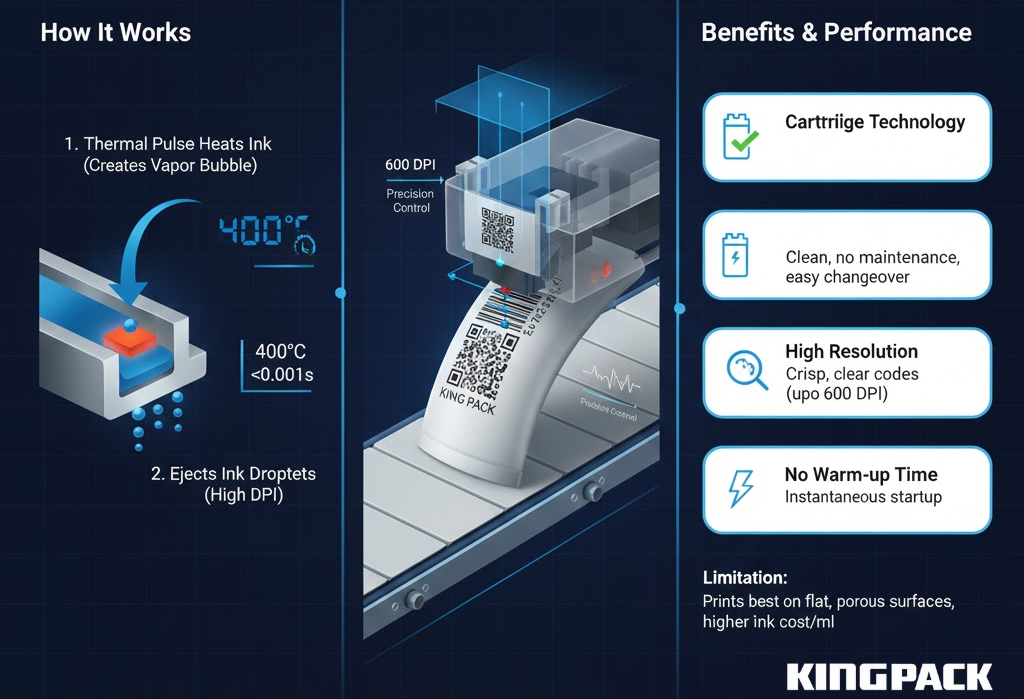

Thermal Inkjet (TIJ) Systems

TIJ printers use heated print heads to eject ink droplets on demand, creating sharp, high-resolution codes. These systems offer excellent print quality with simpler operation compared to CIJ technology.

TIJ advantages include high resolution suitable for small 2D barcodes, minimal maintenance requirements, and simplified operation with no continuous cleaning cycles. Ink cartridge costs are higher per impression than CIJ bulk ink, making TIJ more economical for small to medium production volumes.

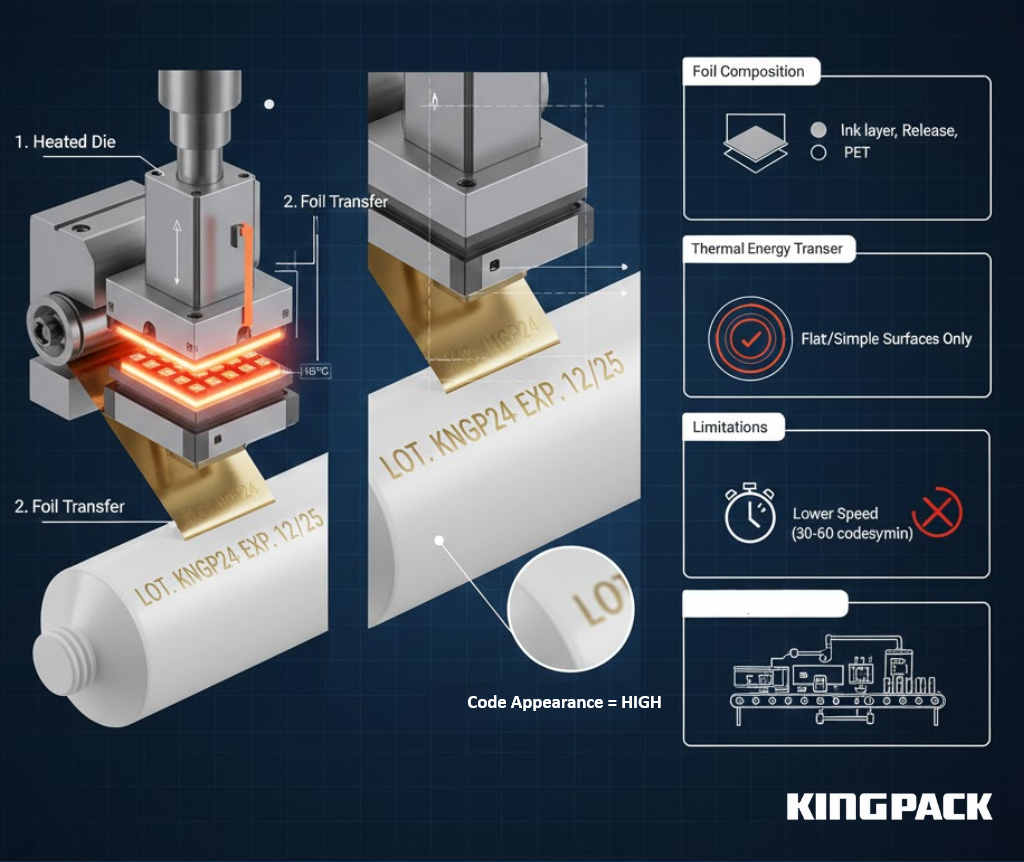

Hot Stamp Coding

Hot stamp coders transfer dry foil to tube surfaces using heated characters. This mature technology produces durable codes resistant to fading, though limited to alphanumeric characters rather than complex barcodes.

Applications include production date and batch number marking on pharmaceutical tubes and cosmetic packaging requiring simple, permanent identification. Lower flexibility compared to digital printing technologies has reduced hot stamp usage, though it remains viable for basic coding requirements.

Recommended Reading: How To Fill Toothpaste Tubes Using Tube Filling Machine? – King Pack Machinery

Conclusion: Sealing and Coding — The Final Assurance of Quality

Tube sealing and coding define product quality at the final stage of packaging. Selecting the right technology for the tube material and production volume ensures reliable seals and permanent, readable codes.

Integrated vision systems and validation protocols catch defects before products leave the line. Together, they support regulatory compliance, reduce recalls, and maintain consumer trust in the brand.

Request a Technical Consultation on Sealing and Coding Solutions

Every packaging operation faces unique challenges based on tube materials, production volumes, product characteristics, and regulatory requirements. Direct consultation with equipment specialists helps identify optimal configurations balancing performance, compliance, and budget considerations.

Technical consultations typically evaluate:

- Tube material specifications and barrier requirements

- Production capacity needs and future growth projections

- Product formulations including viscosity, pH, and particulate content

- Regulatory requirements for traceability and serialization

- Integration with existing production equipment

- Budget parameters and ROI expectations

Contact King Pack to schedule a consultation and discuss your tube sealing and coding requirements. Our technical team can recommend equipment configurations that deliver superior results for your specific applications.

Frequently Asked Questions (FAQs) on Tube Sealing and Coding

How does ultrasonic sealing differ from hot air sealing in terms of speed and energy consumption?

Ultrasonic sealing uses much less energy by heating only the seal area but runs at lower speeds. Hot air sealing is faster, making it better for high-volume production.

What factors determine the best coding technology (Laser vs. Inkjet) for a tube?

Material type, code permanence, and production volume drive the choice. Laser suits permanent, high-volume marking, while inkjet fits mixed materials and lower upfront cost.

What is the primary method used to test the integrity of a sealed tube?

Vacuum chamber testing is the most common method. It detects leaks by observing bubbles under reduced pressure without damaging the tube.

Why is the permanence of the batch code critical for pharmaceutical traceability?

Permanent batch codes support recalls and quality investigations over the full product life. Faded or damaged codes break traceability and create compliance risk.