Pet healthcare products are no longer niche items. Ointments, creams, and nutrition pastes now play a major role in daily pet care and veterinary treatment. As demand grows, manufacturers face higher expectations for quality, hygiene, and production stability.

At King Pack (KPFilling), we work with pet pharmaceutical and pet care manufacturers worldwide. Many produce high-viscosity products such as hairball remedies, ear medications, skin creams, and veterinary prescription ointments. These products place heavy demands on filling and sealing equipment.

This article explains how pet ointment and cream filling machines have evolved. We focus on why modular design matters, how it solves real production challenges, and how our equipment supports reliable, GMP-oriented manufacturing.

Recommended Reading: Everything You Need to Know About Vial Packaging Machines – King Pack Machinery

Growing Demand for Pet Ointment and Cream Packaging

The pet healthcare market continues to expand. Owners spend more on preventive care, treatment, and nutrition. This trend directly affects packaging requirements.

Ointments and creams differ from liquid products. They are thicker, often sticky, and sometimes abrasive. Many contain oils, salts, herbal extracts, or active pharmaceutical ingredients. These characteristics complicate filling, sealing, and cleaning.

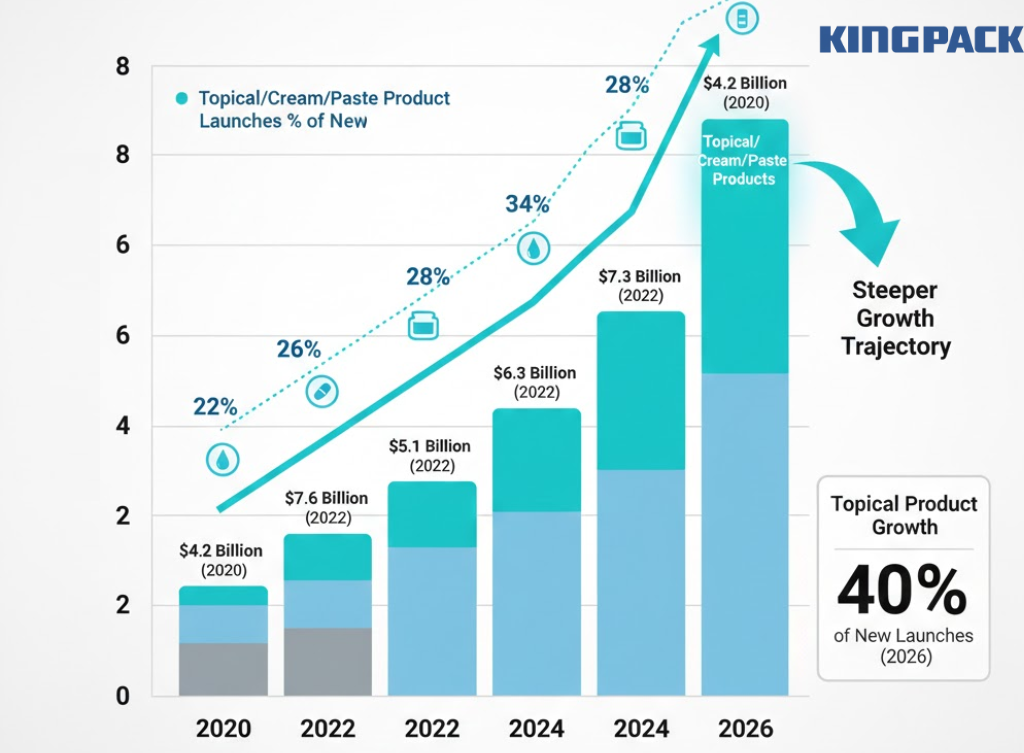

Studies show that topical and paste-based pet products represent over 34% of new veterinary product launches. This growth has pushed manufacturers to upgrade from manual or semi-automatic systems to automated filling and sealing machines.

Manual handling creates risks. Inconsistent dosing, poor sealing, and contamination issues appear quickly as volumes increase. Automation helps control these risks, but only if the equipment suits paste and cream formulations.

Typical Applications of Pet Ointment and Cream Filling Equipment

Pet ointment and cream packaging covers several product types. Each presents slightly different technical demands, but all benefit from stable, modular equipment.

Hairball Remedy and Nutrition Paste

Hairball remedies and nutrition pastes are common in pet nutrition. These products usually have high viscosity and sticky textures. They may also include fibers or abrasives.

Filling accuracy matters. Overfilling increases cost. Underfilling damages brand trust. Our high-viscosity filling modules handle these pastes smoothly and consistently. A recent review reported that paste-format supplements showed 29% faster growth than liquid formats, largely due to ease of administration.

Ear and Skin Medication Creams

Ear and skin creams require controlled dosing and clean sealing. Many contain antibiotics, antifungals, or anti-inflammatory agents.

For these products, we often recommend:

- Servo piston filling for dosing control

- Enclosed filling areas

- Reliable tube or bottle sealing

These features reduce contamination risk and support GMP compliance.

Recommended Reading: Vial Filling Machines and Processing Solutions – King Pack Aseptic Technology – King Pack Machinery

Veterinary Prescription Ointments

Prescription ointments require precise filling and strong traceability. Batch consistency is critical.

Our systems support:

- Stable dosing for repeated batches

- Material compatibility with active ingredients

- Cleanable structures for validation

This helps manufacturers meet regulatory expectations without slowing production.

Pet Care Topical Products

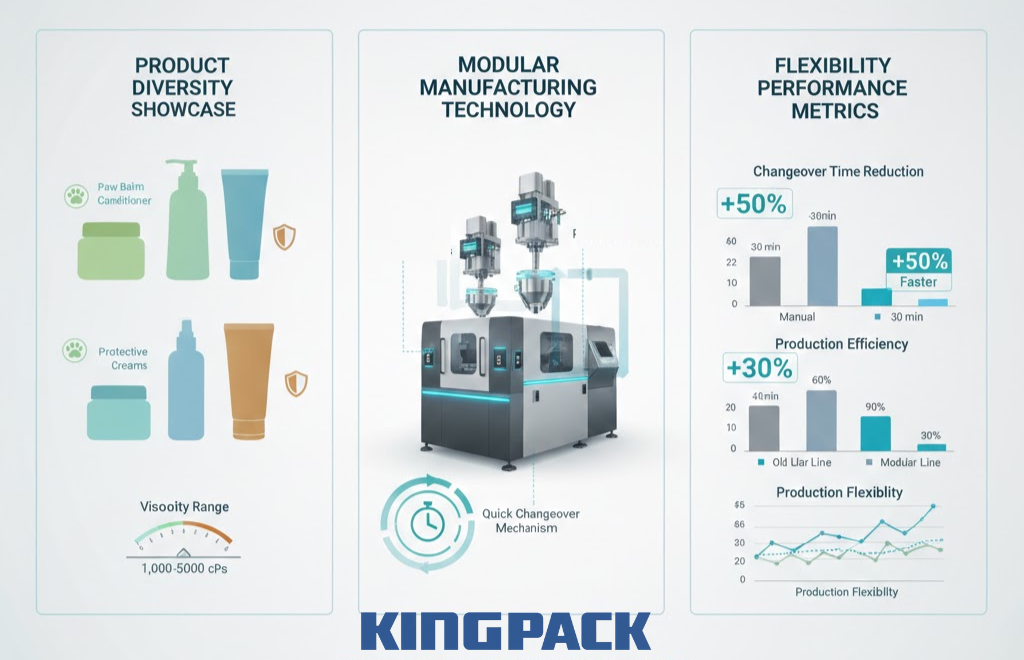

Pet care products include paw balms, skin conditioners, and protective creams. These often run in multiple SKUs with different packaging formats.

Modular equipment allows fast changeover between:

- Tube sizes

- Bottle formats

- Viscosity ranges

This flexibility reduces downtime and supports frequent product launches.

Key Challenges in Filling and Sealing Pet Ointments and Creams

Ointments and creams create challenges that liquid filling machines cannot handle well. We design our equipment to address these issues directly.

High Viscosity and Abrasive Ingredients

Paste products do not flow easily. Some resist pumping. Others trap air or cling to surfaces.

Common risks include:

- Inaccurate dosing

- Product smearing

- Blocked filling paths

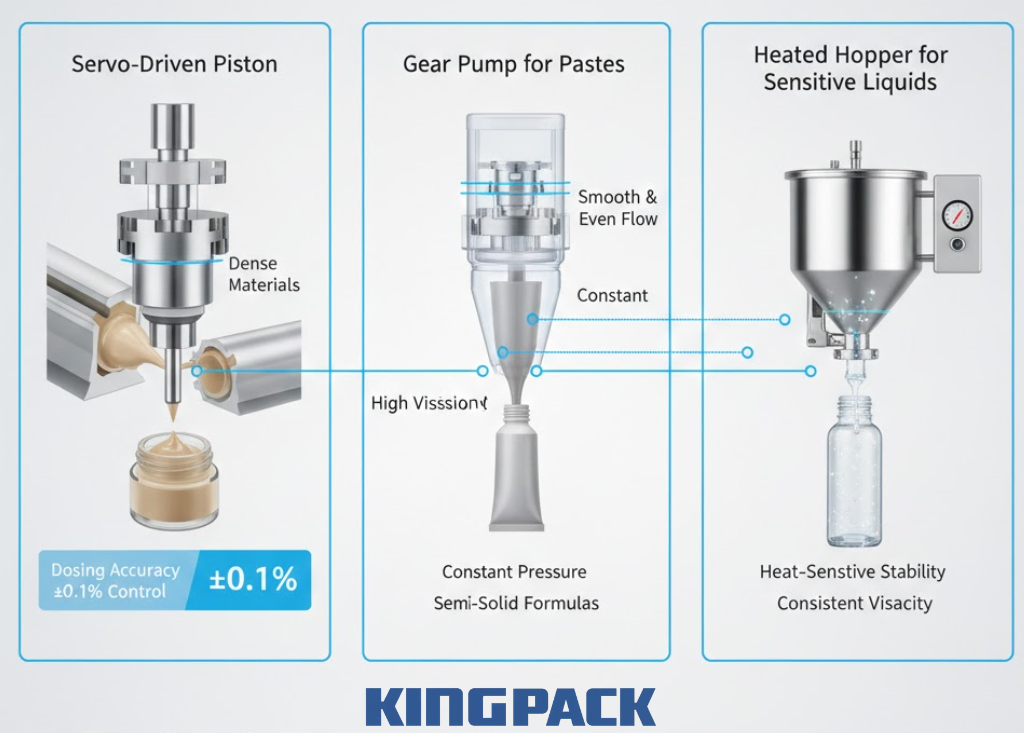

According to a recent study, improper pump selection caused up to 18% dosing variation in high-viscosity products. This highlights the need for dedicated paste-filling technology. Our solutions use servo piston systems, gear pumps, and heated hoppers when needed. Each module matches the product’s flow behavior.

Corrosion and Chemical Compatibility

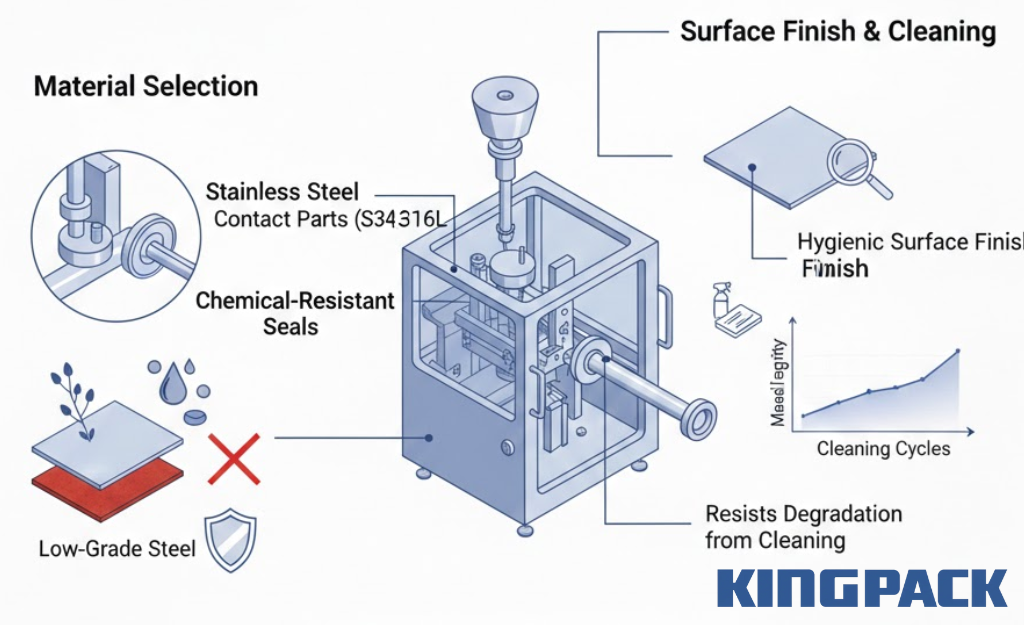

Many pet ointments contain oils, salts, or active compounds that attack standard materials.

Material selection matters. Poor choices lead to:

- Seal degradation

- Surface corrosion

- Product contamination

At KPFilling, we use SS304 or SS316L contact parts and chemical-resistant seals. This protects both the equipment and the product. A 2023 Veterinary Manufacturing Safety report showed that corrosion-related failures caused 22% of unplanned downtime in topical drug packaging lines. Proper material selection reduces this risk.

Cleaning and Cross-Contamination Control

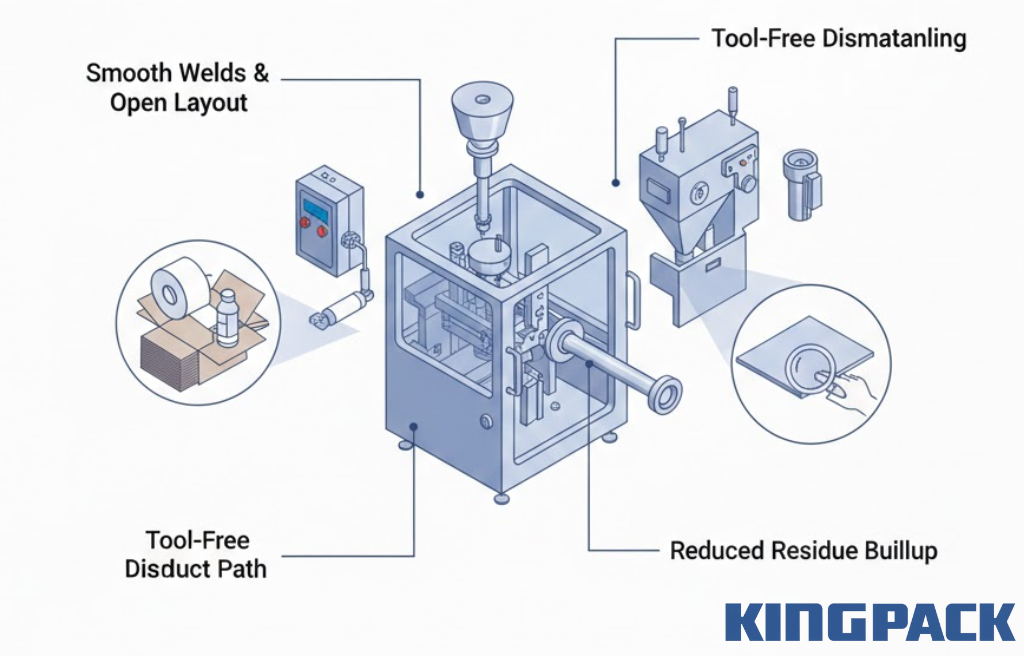

Pet pharmaceutical factories often run many SKUs on the same line. Cleaning speed affects output. Manual cleaning increases downtime and validation effort. Complex machine structures slow changeover.

Our machines feature smooth product paths and tool-less disassembly. CIP-ready designs reduce cleaning time and support repeatable validation.

Recommended Reading: How Does a Tube Filling Machine Work? – King Pack Machinery

Why Modular Design Matters in Veterinary Cream Filling Machines

Modular design is not a trend. It is a direct response to changing production requirements across veterinary products.

Instead of relying on one fixed machine type, modular systems allow manufacturers to adjust filling and sealing operations without replacing the entire Tube Filling & Sealing Machine line. This approach supports long-term use and better capacity planning.

Flexible Filling Modules

Different products behave differently during filling. Thick creams flow slowly. Dense pastes require controlled pressure. Heat-sensitive formulas react to small shifts in temperature and filling volume.

A modular filling platform allows manufacturers to select the most suitable filling technology for each product. Servo-driven piston dosing fillers manage high-viscosity materials with stable filling precision. Flow-based systems support smooth paste movement where consistency matters. Heated hoppers and temperature and pressure controls help maintain stability for sensitive formulations during filling and sealing tubes.

As product ranges expand, filling modules can be changed or upgraded using standardized change parts instead of replacing the full filling and sealing machines. This protects earlier investments and shortens upgrade timelines. Production remains flexible as new veterinary creams and ointments enter the line.

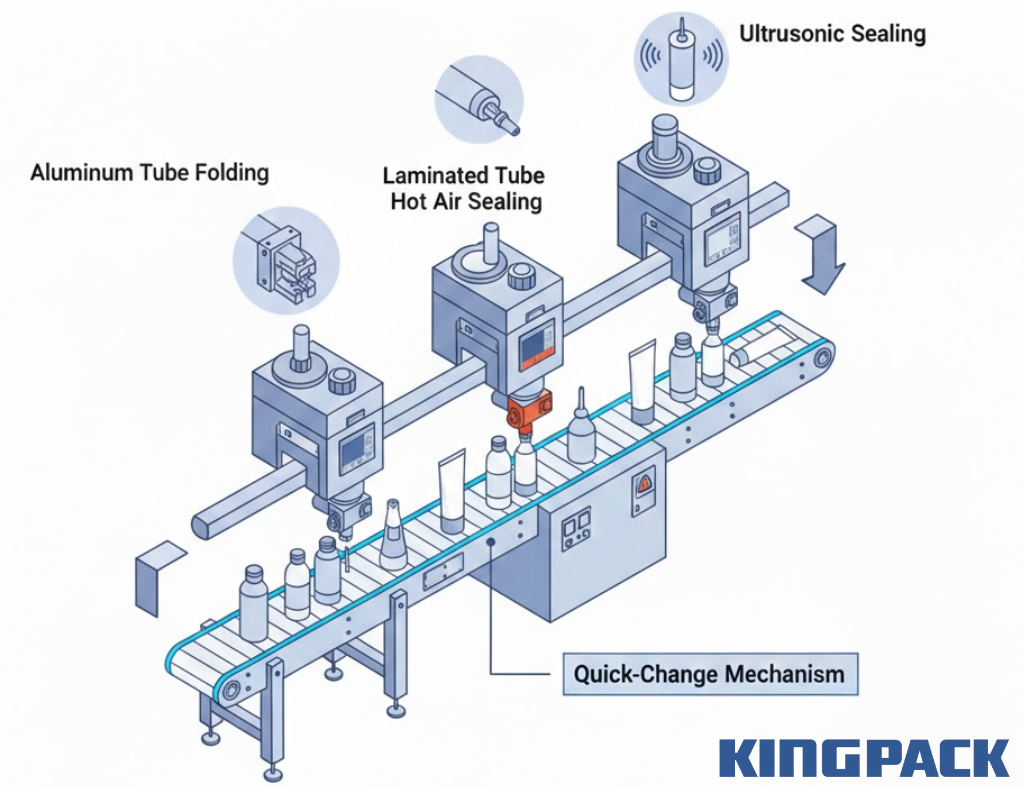

Interchangeable Sealing Units

Packaging formats vary across veterinary product lines. Pet ointments often use laminated tubes or metal soft tubes, while other formulations rely on bottles or alternative container types. Each format requires a specific sealing option.

Interchangeable sealing units support this flexibility on a single production line. Aluminum tubes fold cleanly using controlled crimping systems. Laminated tube filling and sealing relies on hot air sealing with precise sealing heads. Advanced systems also support ultrasonic sealing for consistent closure quality.

Manufacturers switch sealing units without rebuilding the entire line. Multiple packaging formats run on shared equipment, and setup time stays short when packaging needs change.

Quick Changeover and Expansion

Modular design supports growth without disrupting daily operations. As demand increases, new capabilities are added without stopping production for extended periods.

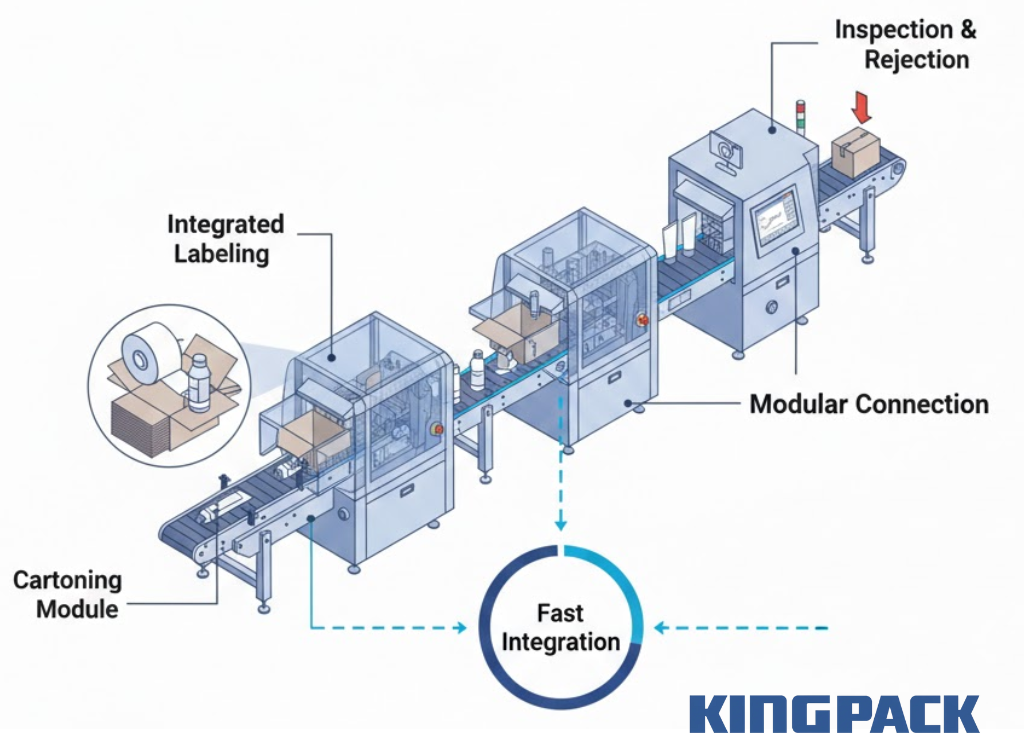

Labeling, cartoning, inspection, and batch coding modules integrate into the existing layout and connect through the same control panel. These additions match the current Automation Grade and work with established machine dimensions. Expansion feels planned rather than reactive.

Downtime remains low and bottlenecks are easier to manage. Modular equipment reduces line upgrade costs by an average of 27 percent compared to fixed-design systems. This makes scaling predictable and cost-aware.

Integrated labeling and cartoning also limit manual handling, helping maintain hygiene while reducing operational errors.

Recommended Reading: Types of Pharmaceutical Packaging – Comprehensive Guide by King Pack Packaging Solutions – King Pack Machinery

Equipment Features for Pet Ointment and Cream Packaging

Reliable production depends on practical machine design. We focus on features that support daily operation.

Easy-Clean Hygienic Structure

Cleaning routines need to fit into tight production schedules. Equipment with poor access or complex parts increases downtime and puts pressure on staff. A hygienic structure keeps cleaning fast and repeatable.

Our machines use smooth welds and open layouts that allow operators to reach product-contact areas easily. Parts come apart without heavy tools in many cases, which simplifies washdown and inspection. This layout reduces residue buildup between runs.

These design choices support GMP validation and daily hygiene checks. Operators spend less time cleaning and more time running the line. The result is better consistency without adding extra labor.

Corrosion-Resistant Materials

Material selection plays a major role in machine lifespan. Pet ointments often contain oils, salts, and active compounds that can damage low-grade surfaces over time. Equipment must hold up under repeated exposure.

We use stainless steel contact parts such as SS304 or SS316L, along with seals that resist chemical wear. Surface finishes are chosen to handle frequent cleaning without breaking down. These materials maintain their integrity during long-term use.

This protects the machine from corrosion and early failure. It also keeps product contact areas stable and safe. Over time, the right materials reduce maintenance needs and extend service life.

Automated Line Configuration for Pet Pharmaceutical Creams

Filling and sealing machines perform best when they work as part of a complete line. Ointments and creams place high stress on upstream and downstream handling. Poor integration leads to stoppages, waste, and unstable output. At KPFilling, we design modular automated lines that move products smoothly from feeding to final packaging.

From Tube or Bottle Feeding to Sealing

Pet ointments and creams commonly use tubes, though some products run in bottles or jars. Our modular lines support both.

A typical automated process includes:

- Container or tube feeding

- High-viscosity filling

- Sealing or capping

- Discharge to labeling or cartoning

Each module matches the speed of the next. This avoids backflow and pressure buildup, which are common with thick pastes.

Typical configuration comparison:

| Stage | Manual Setup | Modular Automated Line |

| Feeding | Hand loading | Automatic feeder |

| Filling | Semi-controlled | Servo-controlled |

| Sealing | Manual or basic | Integrated sealing unit |

| Output stability | Inconsistent | Stable and repeatable |

A 2023 Packaging Line Efficiency Study showed that fully integrated filling and sealing lines improved output stability by 35% compared to semi-automated setups.

Secondary Packaging Integration

Primary filling is only part of the process. Downstream packaging affects throughput and presentation quality. Our modular systems integrate easily with:

- Labeling machines

- Date coding and inspection

- Cartoning systems

Adding these modules later does not require redesigning the core filling machine. This protects long-term flexibility. Manufacturers who automate secondary packaging often see labor savings and fewer handling defects.

Speed Matching and Buffering

High-viscosity products move slowly. If one module runs faster than the next, pressure builds up and causes mess or downtime. We design speed matching into every line. Buffering systems absorb small variations and keep the rhythm stable.

This approach:

- Reduces stop-start cycles

- Protects seals and pumps

- Improves overall equipment effectiveness

How King Pack Designs Modular Pet Ointment Filling Solutions

Modular design works only when engineering supports it. We focus on mechanical stability, hygiene, and long-term service.

High-Viscosity Handling Technology

Paste products behave differently from liquids. Some resist flow. Others stick to surfaces.

Our filling systems address this with:

- Servo-driven piston filling

- Gear pump options for steady paste flow

- Heated hoppers for temperature-sensitive formulas

Anti-drip nozzle design prevents smearing and tailing. This keeps tubes and bottles clean before sealing. Internal project data from KPFilling shows fill weight deviation under ±0.5% for ointments above 20,000 cps viscosity when using servo piston systems.

Automatic Filling and Capping Machine – Disinfectant Production Line – King Pack Machinery

GMP-Oriented Mechanical Design

GMP compliance depends heavily on mechanical design details. Small construction choices influence how easily a line can be cleaned, inspected, and validated over time. This is why hygienic engineering is built into our systems from the start.

Product contact areas use smooth, sanitary welds and continuous flow paths. Surfaces are finished to reduce residue retention and support consistent cleaning. Open mechanical layouts allow operators to inspect critical zones without disassembly.

These design choices reduce cleaning time and improve repeatability. Validation becomes simpler because the system behaves the same way from batch to batch. Daily operation also becomes more predictable, which supports long-term compliance.

Recommended Reading: What Are the Adjustment Methods of the Capping Machine? A Comprehensive Guide – King Pack Machinery

Turnkey Modular Lines

King Pack supplies complete modular filling lines rather than standalone machines. Each line is designed as a coordinated system, with feeding, filling, and sealing working together to maintain accuracy and hygiene.

Layouts are adapted to available floor space and expected production growth. Modules can be added or upgraded as demand changes, without requiring a full line replacement. Expansion focuses on minimizing downtime and preserving validated processes.

This modular approach protects investment over time. Manufacturers gain the flexibility to introduce new formats or increase output while keeping the same core filling platform in place.

Business Benefits of Modular Veterinary Cream Filling Machines

Modular design goes beyond engineering decisions. It directly influences cost control, production speed, and final product consistency.

Faster Market Response

Pet care markets move quickly, with new formulations and packaging formats introduced each year. Modular tube filling and sealing machines give manufacturers the flexibility to respond without extended lead times. Filling technology and filling volume settings can be adjusted through change parts rather than replacing the full machine type, allowing new SKUs to enter production sooner.

Shorter setup times, standardized sealing options, and reduced mechanical rework help improve time-to-market. This flexibility supports manufacturers as they respond to shifting customer expectations and tighter regulatory requirements.

Lower Maintenance Cost

Maintenance expenses often increase when equipment is rigid and difficult to access. Modular systems simplify service work through accessible machine layouts and shared components across filling and sealing machines. Issues are easier to diagnose, which reduces unplanned downtime.

Shorter maintenance cycles lower long-term service costs. Equipment remains productive for longer periods, and spare parts planning becomes more predictable across the system lifecycle.

Faster maintenance cycles also lower long-term service costs. Equipment stays in operation longer, and spare parts management becomes more predictable over the life of the system.

Maintenance comparison:

| Factor | Fixed Design Machine | Modular Machine |

| Spare parts | Custom | Standardized |

| Repair time | Long | Shorter |

| Upgrade cost | High | Lower |

Improved Product Quality and Consistency

Enhanced product quality begins with consistent filling and controlled sealing. When filling volume and dose precision remain stable, customers receive the same product performance every time. Servo-driven dosing combined with high-speed tube filling and sealing systems ensures uniform fill weights, clean tube closures, and a consistent finished appearance across production runs.

As mechanical and automation control improves, variation caused by manual adjustment decreases. Operators spend less time correcting issues and more time monitoring performance through control panels and digital monitoring. This reduces quality complaints and strengthens confidence in the product on the shelf, whether it is a facial cleanser, daily chemical product, or medical product.

Scalable Production Capacity

Production demand rarely stays constant. Modular design equipment allows capacity to grow without disrupting existing operations. Manufacturers can increase output by adding compatible filling and sealing modules, running within safe operation speeds, or integrating additional packaging stages such as Premade Pouch Packing or BrandMultipack Machines.

This approach avoids full line replacement and large capital investments. Growth occurs in stages, making planning more predictable, reducing operational risk, and keeping the original tube filling platform in service.

Frequently Asked Questions (FAQ)

What filling system is best for pet ointments?

Servo piston filling works well for most creams and ointments. Gear pumps ensure stable paste flow, while heated hoppers maintain temperature-sensitive products. High Speed Automatic Tube Filling Machines also support precise dosing for medical products, facial cleanser formulations, and daily chemical products.

Can one machine handle different paste viscosities?

Yes. Modular filling systems allow adjustment or replacement of filling modules to match various viscosities. This flexibility benefits the cosmetics industry, cosmetics sector, and chemical products production lines without the need for full equipment replacement.

How can pet cream filling equipment be cleaned efficiently?

Hygienic design, smooth surfaces, and CIP system-ready structures reduce cleaning time and simplify validation. Dust containment features and UVC lamp units further protect product integrity during cleaning cycles.

Are aluminum and laminated tubes both supported?

Yes. Modular sealing units support aluminum tube folding and laminated tube sealing with hot air or ultrasonic methods. They also work alongside Premade Pouch Packing or Plastic Ampoule Form Fill Seal Machines for diverse packaging formats.

How does modular design support future expansion?

Modules can be added or upgraded without replacing the entire line, reducing cost and downtime as production grows. Expansion is compatible with BrandMultipack Machines, Cup Filling/Sealing Equipment, Sauce Bottle Filling Machines, and other packaging stages managed by the Modernization team or OEM Parts Department.

Closing Perspective

Pet ointment and cream production demands equipment capable of handling high-viscosity fluids, chemical products, and strict hygiene standards. Fixed-design machines often struggle to meet these evolving requirements.

At King Pack, we design modular Tube Filling & Sealing Machines and high-speed tube filling and sealing systems that provide flexibility, durability, and GMP-compliant operation. Our servo-driven dosing, precise filling technology, and controlled sealing ensure consistent product quality, reduced downtime, and scalable production capacity.

Contact us to learn how our modular filling and sealing solutions can optimize your pet care product lines and support your growth with confidence.