The cosmetics industry continues expanding rapidly, with the cosmetic packaging machinery market size increasing from USD 5.22 billion in 2025 to USD 8.69 billion by 2034, growing at 5.83% CAGR. Lipstick remains one of the most popular cosmetic products, requiring specialized equipment for efficient production.

That’s why cosmetic brands now rely on lipstick filling machines because they combine accuracy and efficiency with strict hygiene standards that manual work struggles to maintain. In this article, you’ll learn about the working principles of these machines, the types commonly used in the industry, and practical tips to choose the right one for your business.

What is a Lipstick Filling Machine?

Definition and Purpose

A lipstick filling machine is specialized equipment designed to automate the process of filling molten lipstick formula into tubes, molds, or containers. Lipstick Making Machines are used in cosmetics manufacturing to automate the process of creating lipstick products, including blending, filling, and molding.

These machines handle the complete filling workflow from melting raw materials to final product cooling and capping. They maintain precise temperature control throughout the process to prevent formula degradation while achieving consistent fill weights and appearance.

The primary purpose extends beyond simple container filling to encompass quality control, contamination prevention, and production efficiency that meets commercial cosmetic standards.

Recommended Reading: Emulsifying Mixer Machine for Cosmetics Production – King Pack Machinery

Importance for Cosmetic Factories and Brands

For cosmetic factories, lipstick filling machines provide the consistency and speed required for commercial viability. Lipsticks, lip balms and lip glosses are very popular cosmetic products that require highest quality in the end product, making automated filling essential for meeting market demands.

Established brands benefit from the scalability these machines offer, allowing production increases without proportional labor cost increases. Small boutique brands gain access to professional-quality production that competitors using manual processes cannot match.

Quality consistency builds brand reputation while reducing waste and rework costs associated with manual filling variations.

How Do Lipstick Filling Machines Work? Step-by-Step Workflow of a Lipstick Filling Line

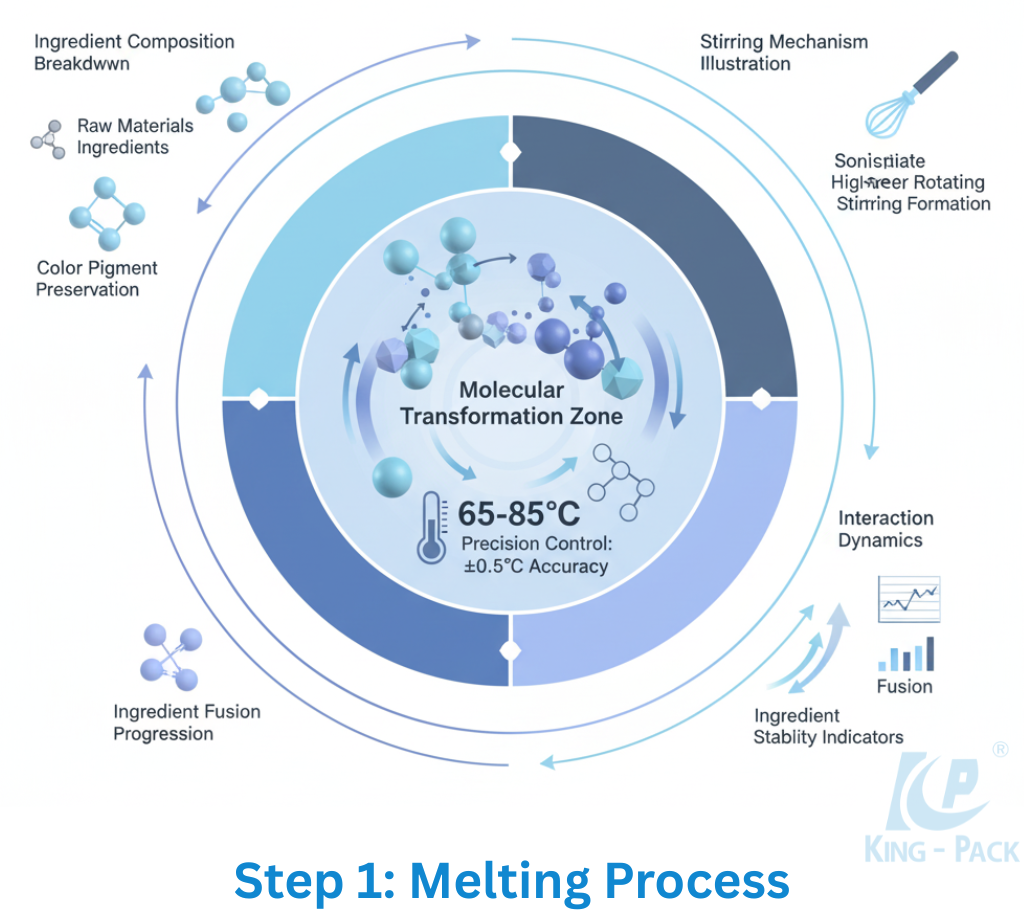

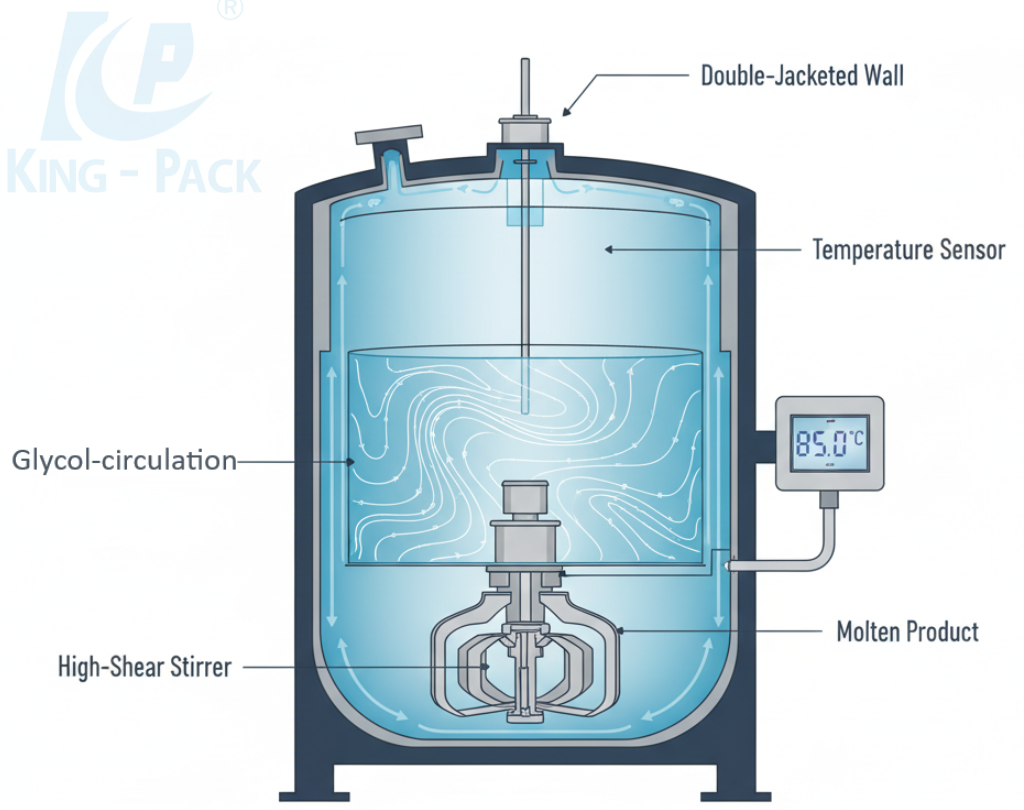

Step 1: Melting Process

The production workflow begins with raw material melting in temperature-controlled tanks. Lipstick formulas typically require heating to 65-85°C to achieve proper flow characteristics while preserving color pigments and active ingredients.

Advanced melting systems incorporate stirring mechanisms to maintain homogeneous mixtures and prevent ingredient separation. Temperature sensors provide precise control that prevents overheating damage to heat-sensitive components.

King Pack’s heating and mixing systems provide the precise temperature control needed for lipstick production, maintaining formula integrity throughout the melting process.

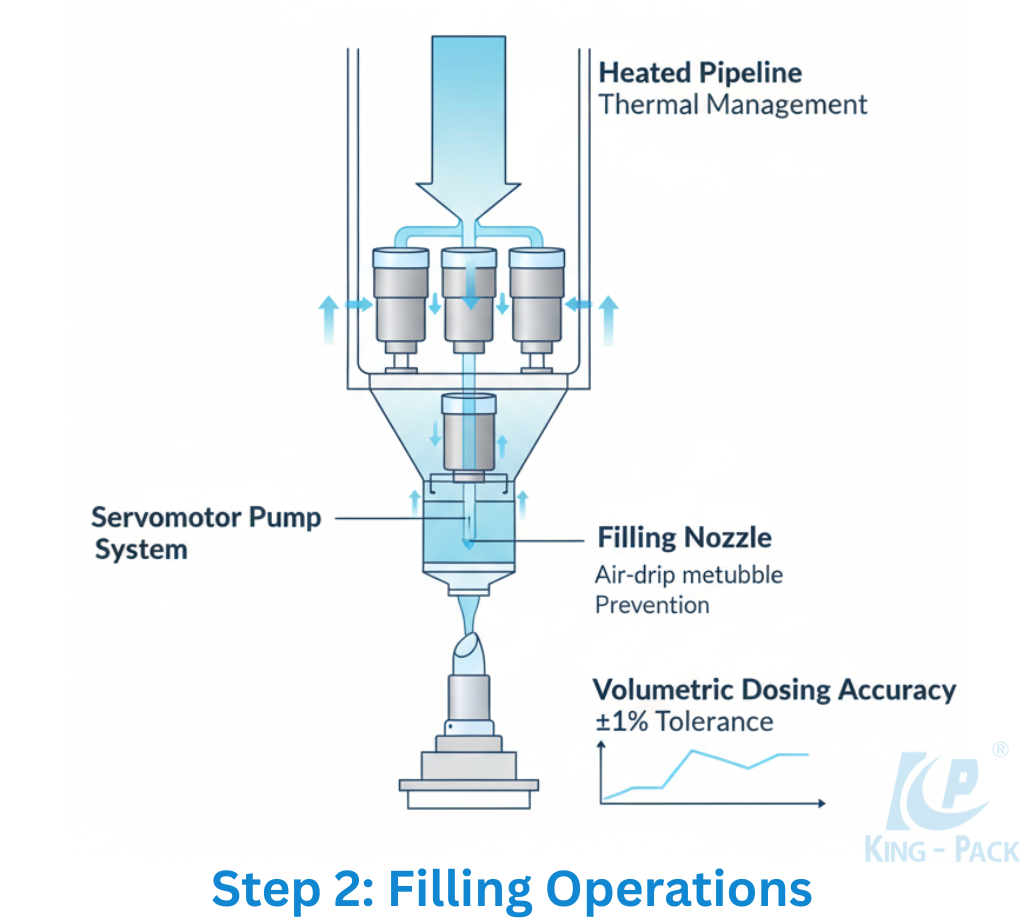

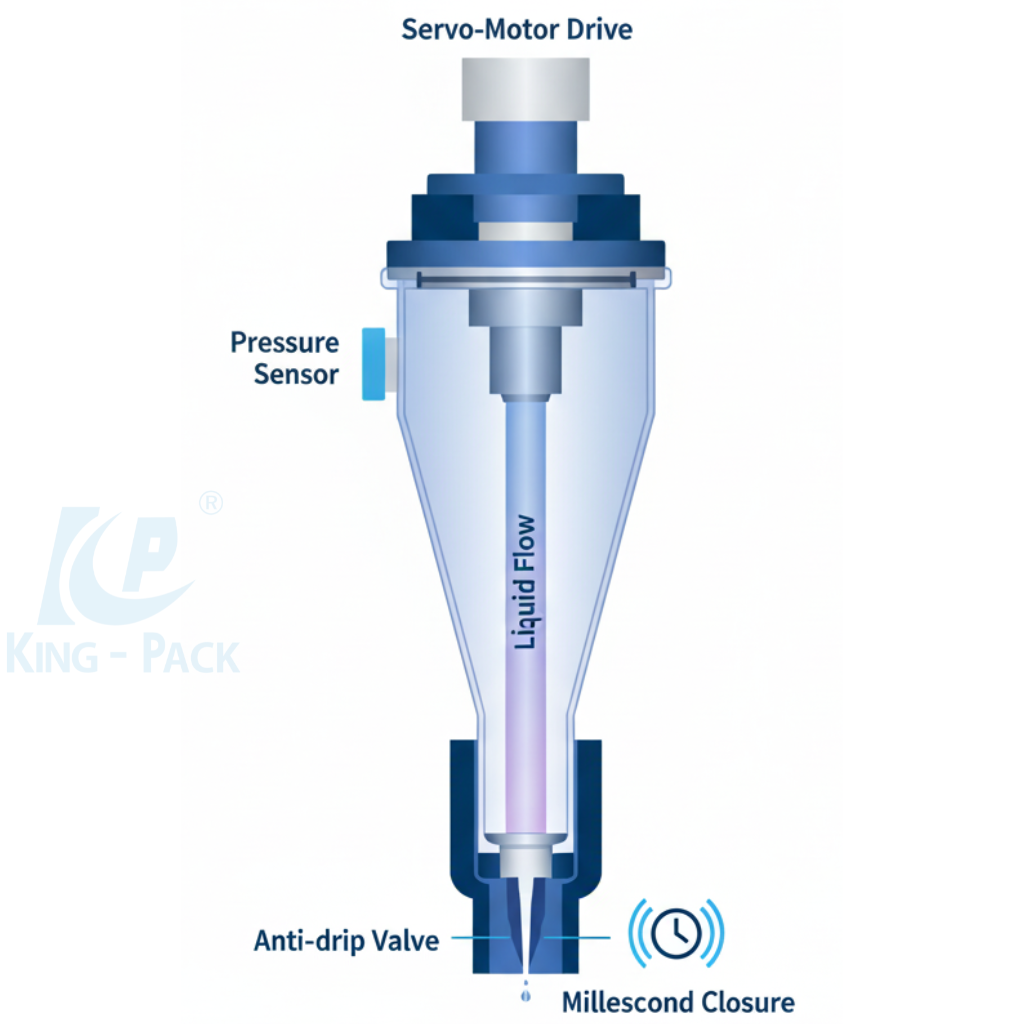

Step 2: Filling Operations

In next step, molten formula transfers from melting tanks to filling nozzles through heated pipelines that prevent premature cooling. Modern machines achieve production speeds up to 60 lipsticks per minute using 4 pumps driven by servomotors for greater efficiency.

Filling accuracy depends on volumetric or gravimetric dosing systems that maintain consistent fill weights within ±1% tolerance. Nozzle design prevents dripping and air bubble incorporation that could affect final product appearance.

Recommended Reading: The Importance of Tube Filling Machine and Tube Sealing – King Pack Machinery

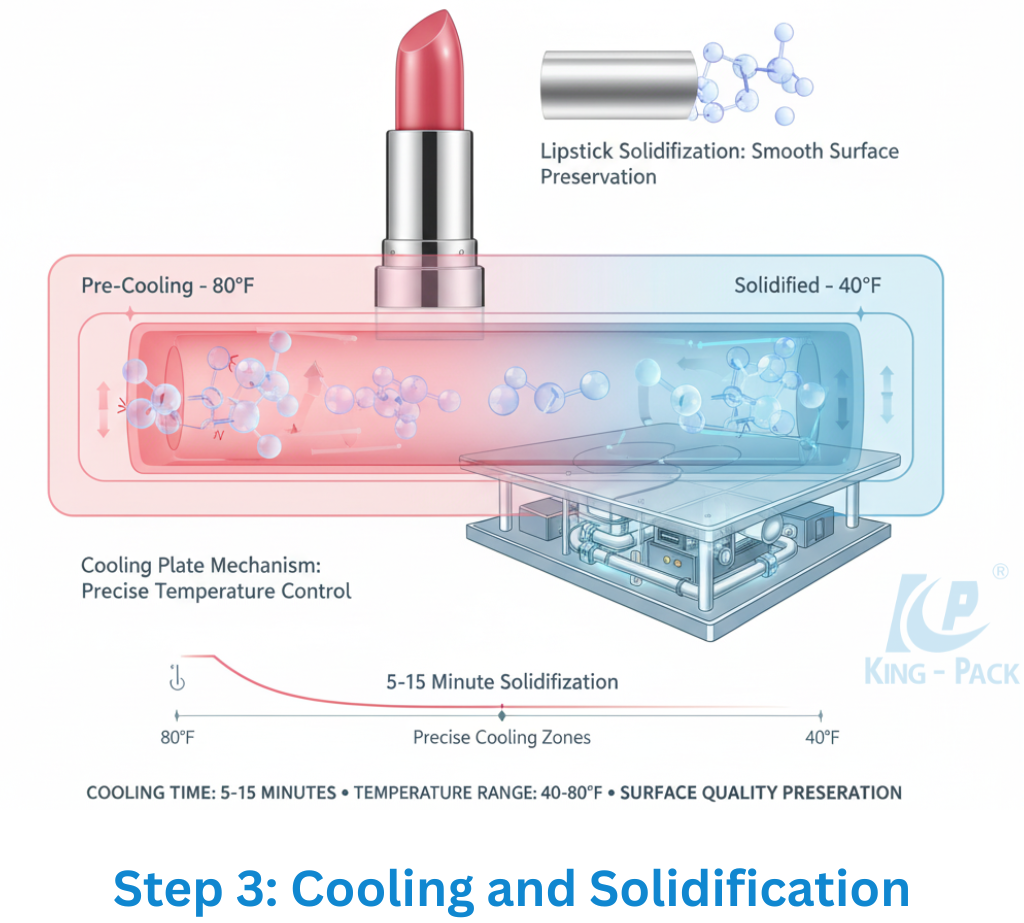

Step 3: Cooling and Solidification

After filling, products move through controlled cooling zones where temperature gradually decreases to room temperature. This gradual cooling prevents cracking and maintains smooth surface finish essential for premium lipstick appearance.

Cooling time varies by formula composition but typically ranges from 5-15 minutes for complete solidification. Advanced systems use refrigerated cooling plates to accelerate the process while maintaining product quality.

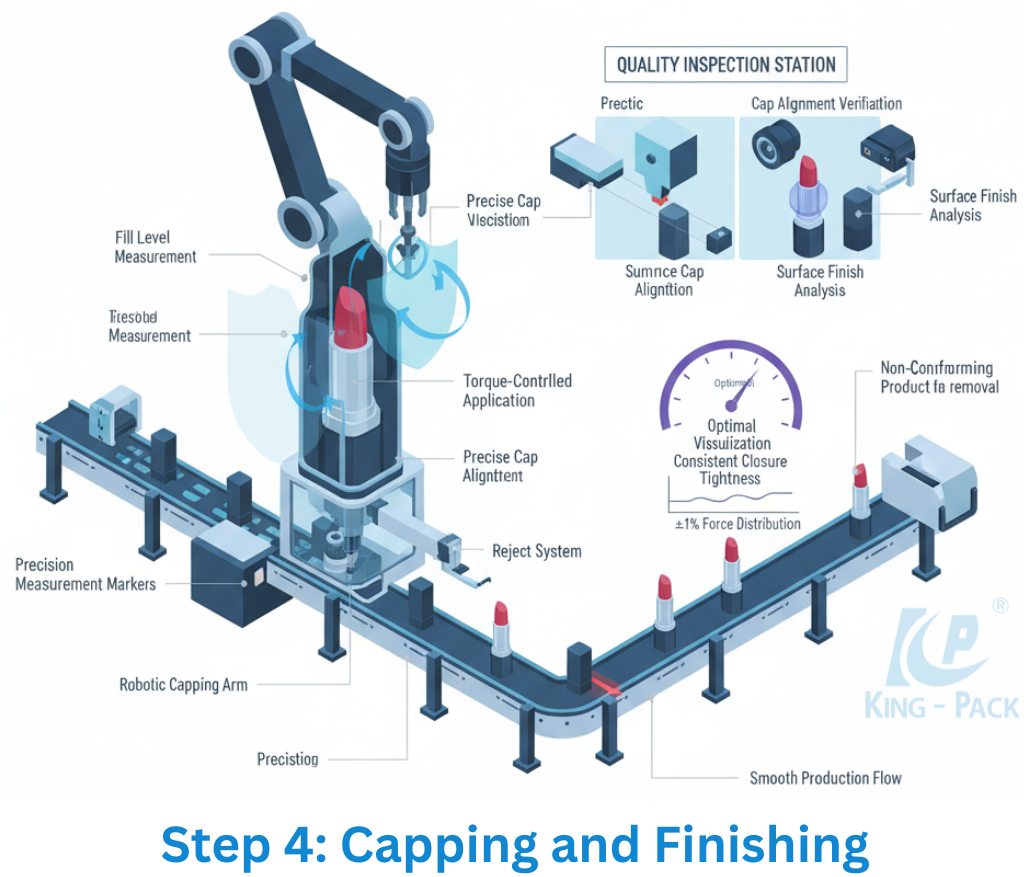

Step 4: Capping and Finishing

Final operations include cap application, torque control, and optional labeling. Automated capping maintains consistent tightness while preventing damage to lipstick bullets during closure application.

Quality inspection stations check fill levels, cap alignment, and surface finish before packaging. Reject systems automatically remove non-conforming products without stopping production flow.

Recommended Reading: Tube Filling Machines: Uses, Types, and Benefits Across Industries – King Pack Machinery

Types of Lipstick Filling Machines

Manual, Semi-Automatic, and Fully Automatic

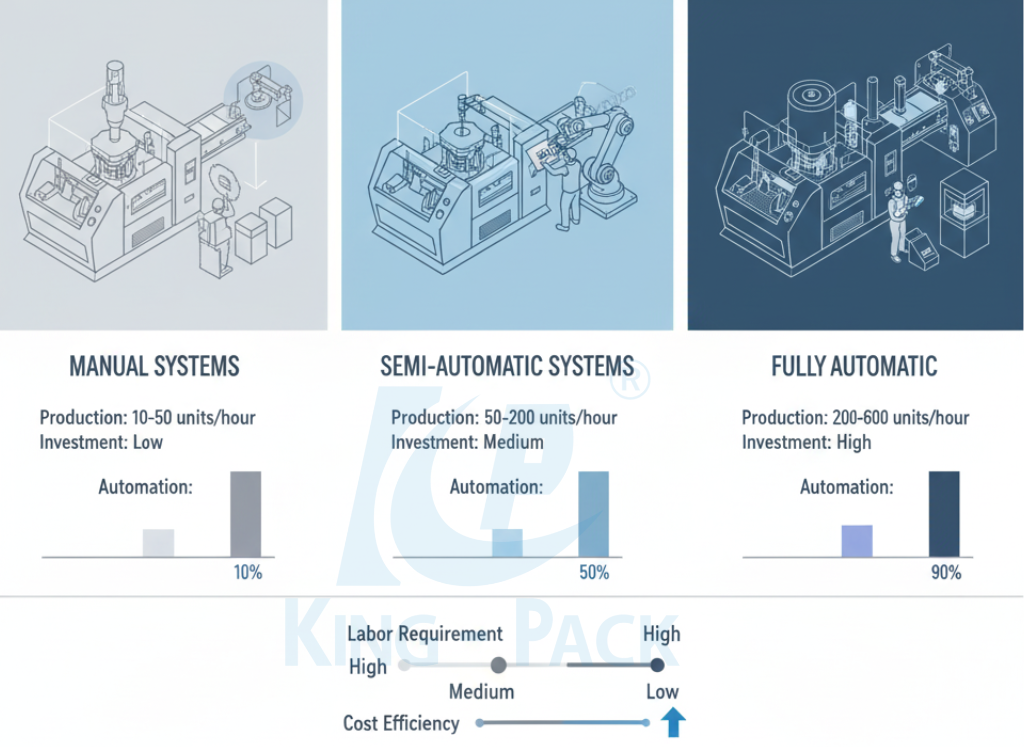

Lipstick filling machines are available in different levels of automation, and choosing the right one depends on your production goals, scale, and budget. Each type comes with its own advantages and limitations, making it important for manufacturers to evaluate factors like batch size, labor availability, hygiene standards, and investment capacity.

- Manual Systems: Basic heating and filling equipment requiring complete operator control for all functions. These systems suit research and development or very small-scale production with limited budgets.

- Semi-Automatic Systems: Combine automated filling with manual material handling and mold operations. They offer a balance between cost and efficiency for medium-scale operations.

- Fully Automatic Systems: Complete production lines with automated material handling, filling, cooling, and packaging. These systems maximize efficiency while minimizing labor requirements and contamination risks.

| Machine Type | Production Capacity | Operator Requirements | Initial Investment | Best For |

| Manual Systems | 50–150 pieces/hour | Full operator control | Lowest | R&D labs, start-ups, very small batches |

| Semi-Automatic | 200–600 pieces/hour | 1–2 operators | Moderate | Small to medium-scale production |

| Fully Automatic | 600–1800+ pieces/hour | 1 supervisor (monitoring) | Highest | Large-scale, continuous production |

Tube vs Bullet Lipstick Filling Machines

Tube Filling Machines: Designed for filling lipstick directly into retractable tubes with integrated mechanisms. These machines handle the complete assembly process, including bullet formation and tube integration.

Bullet Filling Machines: Focus on creating lipstick bullets in molds that are later assembled into tubes. These machines offer the possibility of designing standard and mini lipsticks, jumbo, slim sticks, lip balm and foundation sticks.

The choice depends on product format requirements and downstream assembly capabilities within the production facility.

Lipstick Filling Machine Construction and Components

Melting Tank: Thermal Precision Engineering

The melting tank is the first stage of lipstick production, equipped with temperature-controlled vessels and high-shear stirrers that maintain mixture consistency between 65–85°C. Sensors with ±0.5°C accuracy prevent ingredient degradation or separation.

Double-jacketed walls with glycol circulation provide uniform heating and fast transitions. Capacities range from 15–200 liters, with PLC systems managing thermal profiles for different formulations.

Recommended Reading: Top 10 Tube Filling Machine Manufacturers Today – Global Leaders in Tube Packaging Technology – King Pack Machinery

Filling Nozzle: Volumetric Precision Technology

Servo-driven nozzles deliver 0.1ml accuracy through volumetric displacement, ensuring consistent product weight and minimal waste. Pressure sensors maintain stable flow, while anti-drip valves close within milliseconds.

Nozzle manifolds are temperature-controlled to prevent clogging, and vibration dampening reduces splatter for smooth finishes. Options include pneumatic, servo, and hybrid systems.

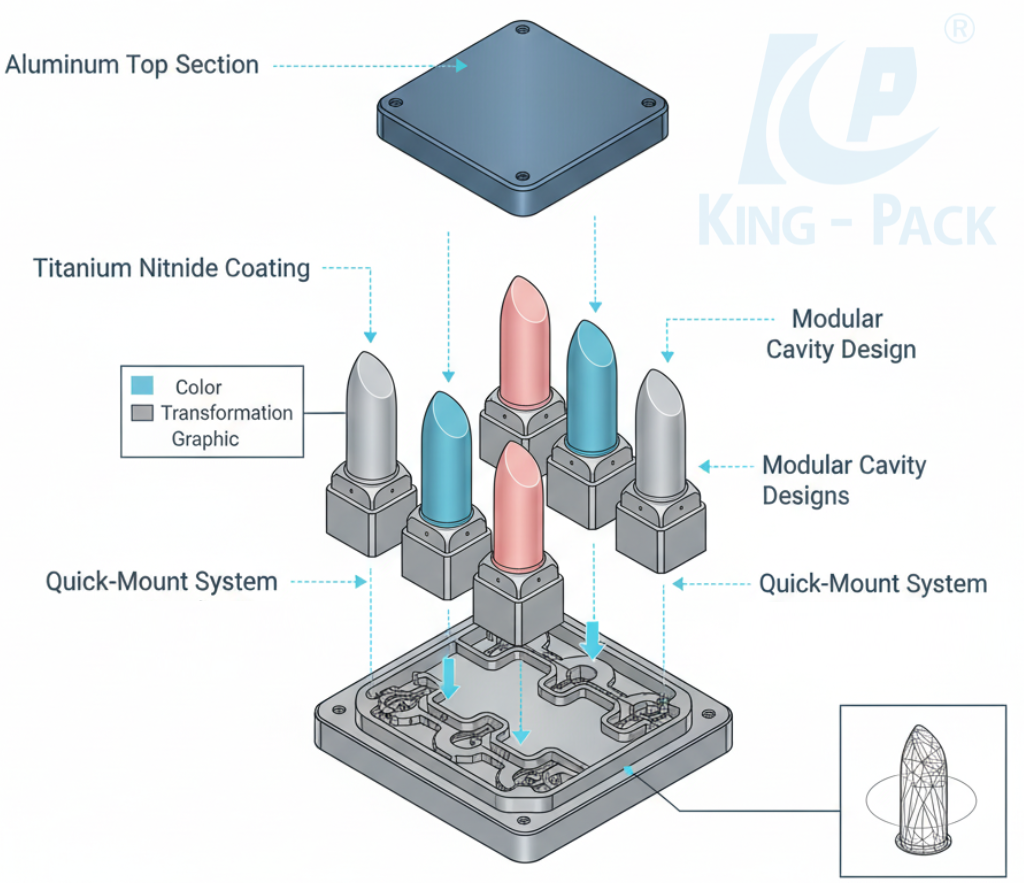

Mold System: Rapid Configuration Flexibility

Modular soft molds with aluminum tops enable format changeovers in 30 minutes and color changes in 5 minutes. CAD-engineered cavities support complex lipstick geometries.

Cooling channels and temperature-responsive alloys regulate solidification. Surface coatings like titanium nitride improve release while quick-mount systems speed up configuration changes.

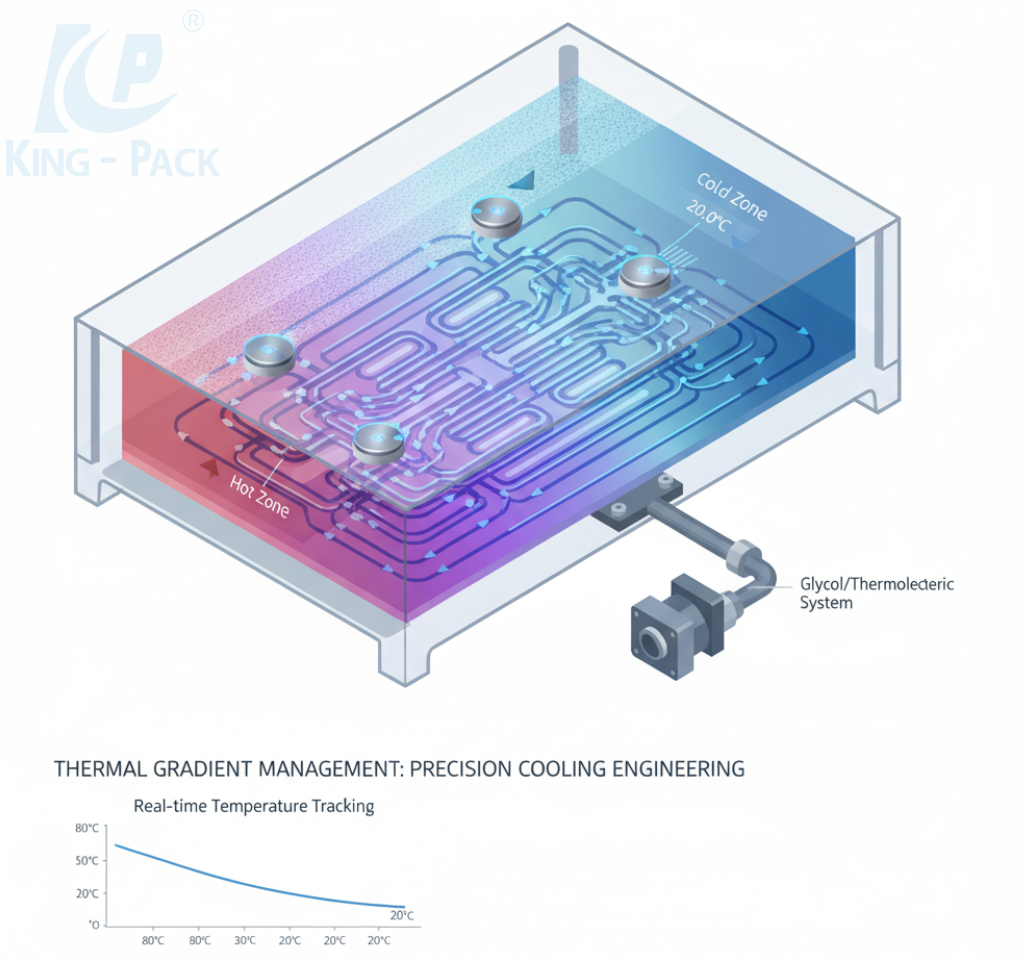

Cooling Plate: Thermal Gradient Management

Cooling plates operate between –10°C and +5°C using glycol or thermoelectric systems. Graduated cooling prevents thermal shock, producing uniform textures.

Micro-textured stainless surfaces enhance heat transfer and reduce defects. Integrated sensors track temperature and solidification in real time, optimizing energy use with adaptive cooling zones.

Control Panel: Intelligent Production Management

Touchscreen HMI panels manage recipes, production tracking, and diagnostics. Secure access levels protect operations while data logging supports quality documentation.

Networked control systems allow cloud monitoring and predictive maintenance. Interfaces are multilingual and customizable, ensuring flexibility across global facilities.

Optional Features: Production Enhancement Technologies

Modern lipstick filling lines can be upgraded with optional systems that boost efficiency and product quality. These technologies streamline finishing processes, reduce manual handling, and maintain consistency across large-scale production runs. By integrating modular add-ons, manufacturers can scale operations without replacing core machinery.

- Inline Labeling – High-speed applicators can process 120–250 units per minute. They support wrap-around, front/back, and variable data labeling, with options for date and batch coding to meet compliance standards.

- Automated Capping – Torque-controlled servo systems apply closures with programmable tightness and automatically detect sealing irregularities. Multi-head configurations allow smooth handling of different cap designs.

- Enhanced Cooling – Multi-stage refrigeration systems use programmable thermal gradients to accelerate solidification while protecting surface quality. Energy-efficient modular designs integrate easily into existing production lines.

Materials: Advanced Hygiene Engineering

Product-contact surfaces utilize specialized 316L stainless steel alloys with electropolished finishes, providing exceptional corrosion resistance and minimal surface roughness. These materials support repeated sterilization cycles, meeting stringent pharmaceutical and cosmetic manufacturing standards with surface roughness measurements below 0.4 µm.

Pharmaceutical-grade silicone compounds used in sealing systems demonstrate exceptional chemical resistance, maintaining flexibility across temperature ranges from -40°C to +180°C. Advanced polymer technologies incorporate antimicrobial additives, providing additional contamination prevention beyond traditional material capabilities.

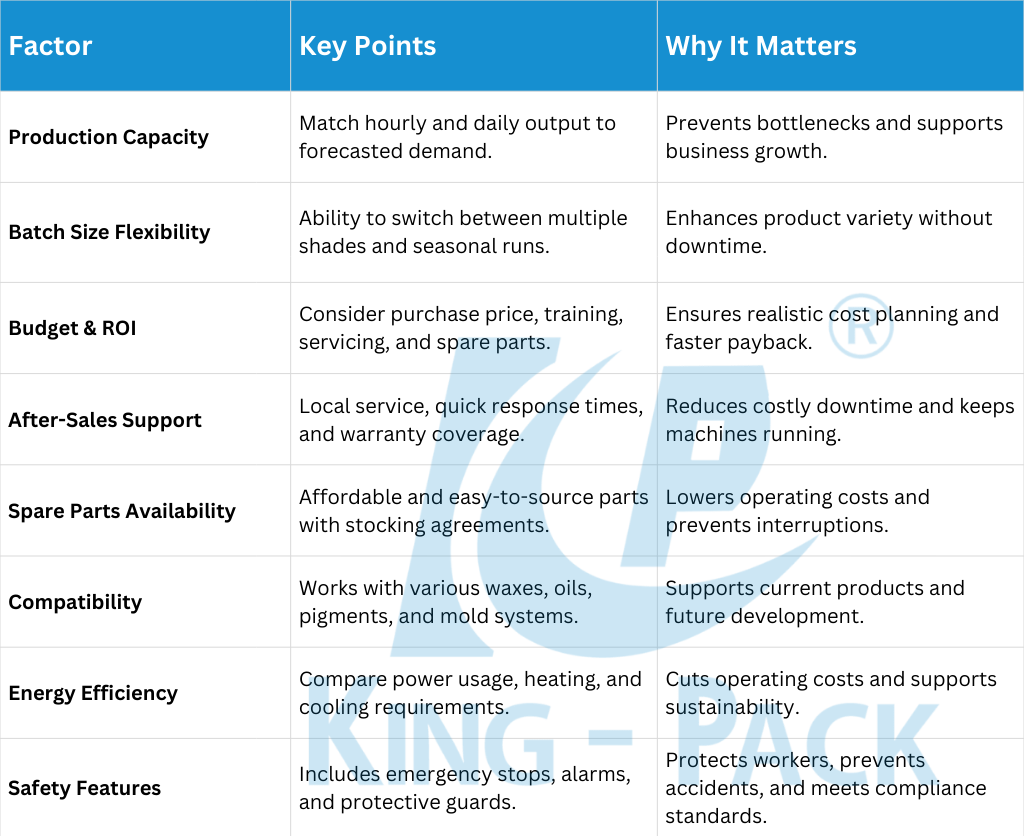

What to Consider Before Buying a Lipstick Filling Machine

When selecting a lipstick filling machine, production scales should be your first consideration. Assess your current batch size and anticipate future demand, especially during seasonal peaks. Machines equipped with servo motors and vision-controlled systems can maintain precise production speeds while allowing smooth transitions between different shades or product formats.

Budget and return on investment (ROI) are equally important. The total cost includes installation, operator training, spare parts, and routine maintenance. Automated systems reduce manual errors, minimize downtime, and improve efficiency compared to small-batch manual operations, shortening the payback period. Financing and tax incentives may also help spread costs over time.

After-sales support and spare parts availability should not be overlooked. Machines with tool-less mold changing and modular components support quick format changes, enabling new product launches without replacing the entire equipment line. Built-in energy-saving features and safety protections enhance both operational reliability and high-quality output, ensuring long-term value for manufacturers.

Maintenance and Troubleshooting Tips

Regular Cleaning and Sanitization of Tanks and Nozzles

Establish standardized cleaning procedures for all product-contact surfaces, including aluminum mold heating functions, diving nozzles, and filling pumps, using cosmetic-grade cleaning agents compatible with stainless steel construction. Daily cleaning prevents residue buildup that can affect product quality and consistency.

Daily Cleaning Checklist:

- Clean melting tanks and stirring mechanisms

- Sanitize filling nozzles and product pathways

- Inspect cooling plates for residue buildup

- Check temperature sensor accuracy

- Document cleaning procedures and any issues

Nozzle maintenance requires particular attention, as dried lipstick or lip gloss residue can cause filling inconsistencies and contamination risks. Use appropriate solvents and precision cleaning tools designed for delicate components.

Cooling System and Motor Maintenance

Cooling system upkeep includes checking heat-conducting oil levels, cleaning condensers, and verifying cooling process parameters. Proper operation is essential for optimizing production cycles and ensuring high-quality output.

Motor maintenance follows manufacturer specifications, including lubrication schedules, bearing inspections, and checking copper motor connections. Preventive maintenance minimizes unexpected downtime and keeps the production system running efficiently.

Finally, the temperature control system should be calibrated regularly using certified instruments to maintain precise processing throughout the operating range. This helps ensure consistent product quality across batches in both small-batch manual operations and large-scale industrial manufacturing.

Conclusion

Lipstick filling machines represent essential equipment for any cosmetic operation serious about professional production standards. These systems deliver the speed, consistency, and hygiene control necessary for commercial success while meeting regulatory requirements.

Beyond efficiency, modern systems also provide the flexibility to handle diverse lipstick formats, integrate optional features, and support future scaling. For brands competing in a fast-moving beauty market, the right machine isn’t just a tool—it’s a long-term investment in product quality and customer satisfaction.

If you’re planning to upgrade your production line or launch a new cosmetics venture, explore the advanced lipstick filling solutions offered by KP Filling Machine. We offer reliable equipment that can help you bring products to market faster while maintaining the highest standards of quality. Contact us for a quote.