Pharmaceutical industry is under constant pressure to produce safe, high-quality injectable drugs in bulk. However, without advanced equipment, it is almost impossible to respond to the increasing demand for medicines while maintaining precision and sterility.

Vial-filling machines resolve this problem. These machines speed up production, reduce human error, and preserve the integrity of sensitive medicines. And how they do that? Well, in this article, we’ll look at that! We will look at how these machines improve efficiency and accuracy and highlight what manufacturers should consider before investing in the right machine for their production needs.

Key Benefits of Vial Filling Machines

1. Improved Efficiency: Automation in Vial Filling Lines

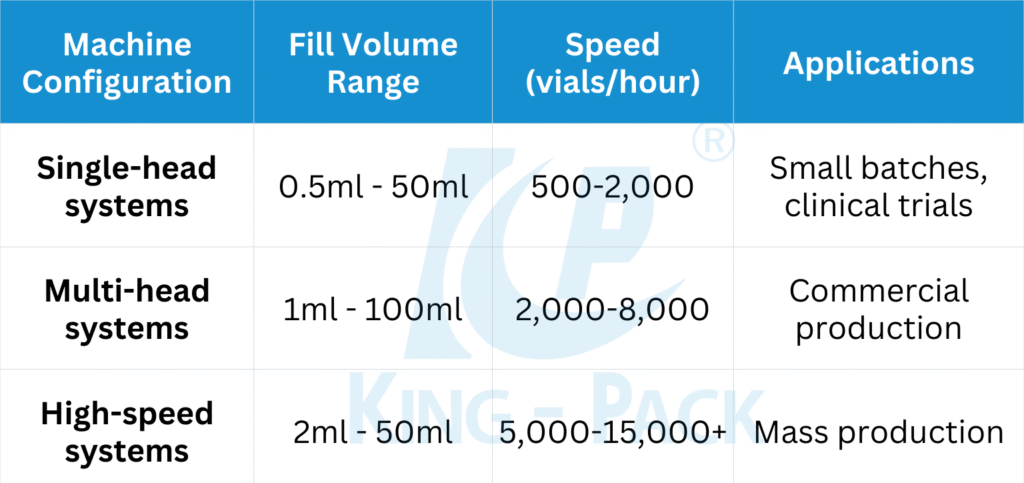

Automated vial filling lines eliminate the production lags caused by manual handling. For manual filling of vials, the best that operators can do is fill 50 to 100 vials per hour. On the other hand, automated systems require minimal supervision and are capable of filling 2,000 to 15,000 vials per hour. Because of this difference, manufacturers are able to meet high demand without compromising on quality.

Also, what makes these systems efficient isn’t only their speed but their setup as well. In the past, each step—washing, sterilizing, filling, and sealing—was often handled on separate equipment or even manually. This meant longer transfer times and more chances for contamination. Modern vial filling lines link all stages into one continuous process. This keeps up production while keeping vials sterile.

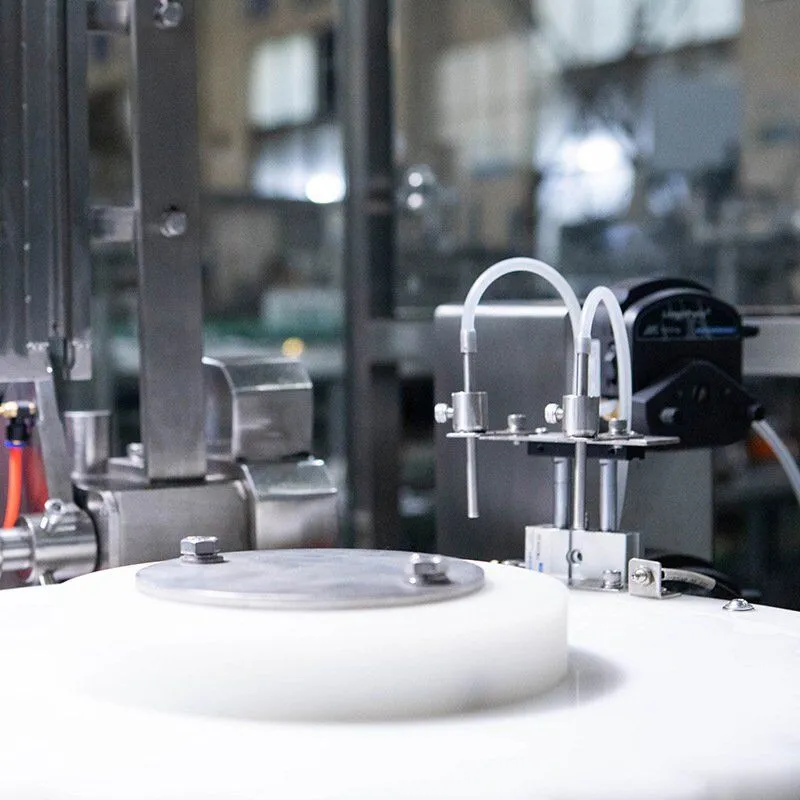

KPYLX series Vial bottle liquid filling machine

Another area where these machines add value is in the product changeovers. In the traditional systems, it would take a lengthy downtime for the vial size to be changed. These new drug filling machines are quite fast. It takes only 15–30 minutes with advanced tooling systems to change the size. This flexibility enables manufacturers to make multiple vial formats with fewer interruptions.

King Pack’s Machinery builds modular fill systems on the principle of operational efficiency. Our vial filling machines are equipped with predictive maintenance to identify issues before they cause downtime. Remote monitoring is also available that gives production teams real-time access to machine performance. All these factors combine to keep output consistent and downtime to an absolute minimum!

2. Increased Accuracy: Accurate dosing and minimized product loss

Traditional vial filling techniques tended to be error-prone. Manual or semi-automatic systems depended greatly on human skill, which may lead to inconsistent dosing, common overfills, or underfills. All of these problems not only created safety issues but also caused unnecessary product loss.

New vial filling machines eliminate these issues with sophisticated dosing technology. They have coefficient of variation (CV) levels below 1%, a level of accuracy meeting USP standards for injectable drug and biologic applications. Positive displacement pumps and servo-driven filling machinery provide this accuracy regardless of vial size or product type.

KPGZ series Vial Filling Plugging Capping Machine

This enhancement translates directly into cost savings. Where manual processes may waste expensive biologics with repeated overfills, automated systems reduce overfill by 2–5%. For expensive drugs, this means significant monetary savings. Concurrently, avoiding underfills eliminates rejected batches and rework that plagued conventional methods.

Another significant change is quality confirmation. Previously, samples alone were inspected with Statistical In-Process-Control (IPC). Today, high-tech machines employ 100% IPC with weight verification. Each vial is tracked in real time, and the system can automatically set filling parameters when necessary. This balance of accuracy and control provides producers with the level of consistency that old methods could not match.

3. Aseptic Production: Prevention of Contamination

Previously, there was more risk of contamination when filling vials manually and using simple cleanroom installations. Open vials were placed closer to the operators, and despite strict protocols, human interaction tended to bring variability. Traditional systems used frequent manual cleaning and inspection, but these could not always provide sterility.

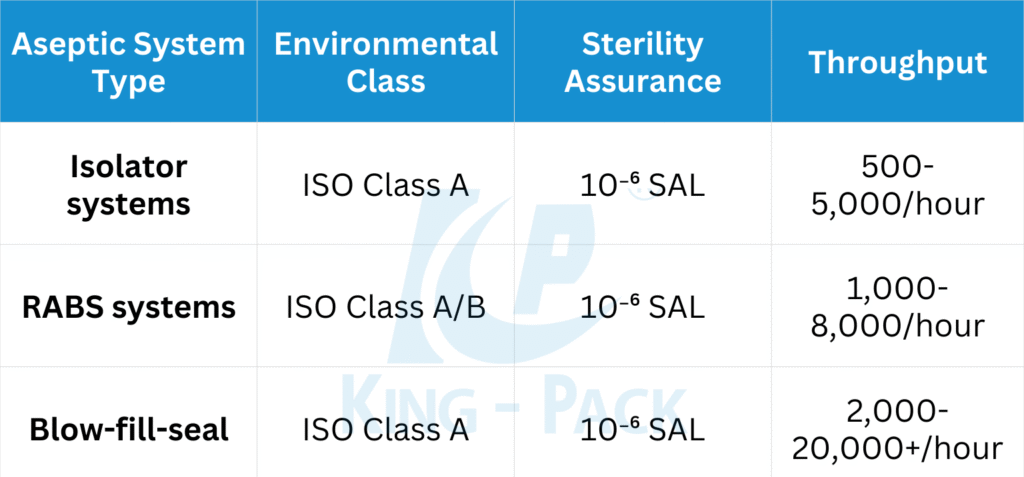

Modern aseptic filling equipment does it very differently. They are used in ISO Class A environments with HEPA-filtered laminar airflow for the preservation of sterile conditions. Continuous monitoring for particles and microbial sampling ensures the cleanroom environment remains compliant during production.

Vial bottle liquid washing and drying filling linkage line

Barrier technologies provide even greater reduction in risk. Isolator systems ensure complete physical separation of the operator from the product, removing the potential for direct human contact. RABS (Restricted Access Barrier Systems) offer partial access but retain strict sterile barriers. In contrast to traditional older methods of cleanroom practice, these systems greatly enhance product safety.

King Pack’s Machinery incorporates state-of-the-art sterilization into its aseptic filling machines. Hydrogen peroxide vapor (VHP) is used to sterilize equipment surfaces between production runs, while decontamination cycles routinely achieve a 6-log reduction in biological indicators. Such practices give manufacturers assurance of sterility in every batch.

4. Scalability: Handling Large-Scale Pharmaceutical Production

Traditional vial filling processes tended to fall behind increasing pharmaceutical demand. Semi-automated and manual systems were constrained by throughput in fixed amounts and inflexible configurations. Increasing production typically required the investment in new equipment or operation of several small lines, both of which raised expense and complication.

Latest vial filling technology has revolutionized this problem. The size of the Pharmaceutical Filling Machine Market, which was USD 5.2 billion in 2024, is anticipated to grow to USD 9.8 billion by the year 2033 at a CAGR of 7.5%. This growth demonstrates a definite drift toward scalable solutions that allow manufacturers to grow without having to replace complete systems.

Modular construction is crucial here. Rather than constructing a new line from the ground up, extra filling heads, conveyors, or inspection stations can be appended to current systems. At King Pack’s, our vial filling machinery is designed with this flexibility in mind, enabling capacity to increase as required by the market while minimizing capital investment.

Multi-format capability introduces a further degree of efficiency. One line can handle vials from 2ml to 100ml, glass or plastic. Earlier systems took hours to reconfigure for every format, but now universal conveyors and recipe-driven software change over without a hitch. Parameters adjust automatically. This reduces downtime and keeps output quality high.

With these improvements, manufacturers can respond faster to market changes, launch new products with less disruption, and scale production to meet global demand—all while avoiding the limitations that held back older systems.

Types of Vial Filling Equipment

1. Pharmaceutical Vial Filling Machine

Pharmaceutical vial filling machines handle diverse product types including solutions, suspensions, and lyophilized powders. These systems accommodate viscosity ranges from water-thin solutions to thick suspensions. Temperature control manages heat-sensitive biologics during processing.

Dosing technology options include peristaltic pumps, piston pumps, and servo-controlled systems. Peristaltic pumps handle shear-sensitive products without contact contamination. Piston pumps deliver high accuracy for low-viscosity solutions.

2. Aseptic Vial Filling Equipment

Aseptic vial filling equipment operates under the highest sterility standards required for parenteral products. The aseptic filling machines market size was evaluated at USD 1.84 billion in 2024 and is projected to surge around USD 3.12 billion by 2034 with a CAGR of 5.42%.

Isolator-based systems provide complete barrier protection during filling operations. These systems use positive pressure differentials and HEPA-filtered air supply. Glove ports allow operator intervention while maintaining sterility barriers.

3. Vial Filling and Stoppering Systems

Integrated filling and stoppering systems combine liquid dosing with primary closure application. These systems eliminate transfer steps that could introduce contamination. Nitrogen blanketing prevents oxidation of oxygen-sensitive products.

Stopper insertion requires precise force control to achieve proper sealing without damage. Vision systems verify stopper position and detect defective closures. Automated rejection mechanisms remove non-conforming vials from the production line.

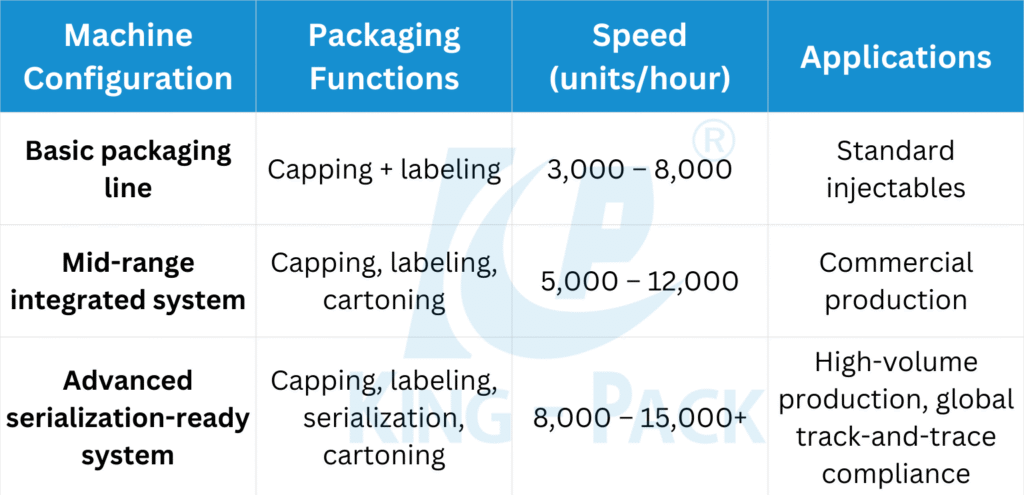

4. Automatic Vial Packaging Machines

Complete vial packaging machines extend beyond filling to include secondary packaging operations. These systems integrate capping, labeling, serialization, and cartoning functions. End-to-end automation reduces labor costs and improves product traceability.

Track-and-trace compliance requires serialization at both unit and case levels. Integrated vision systems verify code quality and database connectivity. King Pack’s systems incorporate advanced serialization capabilities that meet global regulatory requirements.

Applications in the Pharmaceutical Industry

Sterile Injectables and Vaccines

Sterile injectable production represents the largest application for pharmaceutical vial filling machines. These products require the highest levels of sterility assurance and fill accuracy. Vaccine production needs special handling for temperature-sensitive formulations.

mRNA vaccine manufacturing requires ultra-cold chain management and precise fill volumes. King Pack’s aseptic vial filling equipment incorporates temperature control systems that maintain product stability throughout filling operations.

Biologics and Biotech Medicines

Biologic drug manufacturing presents unique challenges for filling equipment design. Protein aggregation sensitivity requires gentle handling during transfer and filling. Specialized pump technologies minimize shear forces that could denature therapeutic proteins.

Monoclonal antibody production volumes keep increasing worldwide. High-concentration formulations need advanced dosing accuracy. This keeps the therapy effective. We offer systems that handle viscous biologics while maintaining precision filling parameters.

Oncology and Critical Drugs

Oncology drug manufacturing requires enhanced containment and operator protection measures. Negative pressure systems prevent product exposure during filling operations. Specialized disposal systems handle contaminated components safely.

Critical care medications demand rapid production capabilities during supply shortages. Flexible vial filling lines enable quick product changeovers to meet urgent medical needs. Emergency production protocols keep the supply available.

Choosing the Right Vial Filling Machine: Factors to Consider

Accuracy and Dosing Technology

Filling accuracy requirements vary by product type and regulatory jurisdiction. Injectable products typically require ±1% accuracy or better. Expensive biologics may demand ±0.5% precision to minimize waste costs.

Dosing technology selection depends on product characteristics and volume requirements. Positive displacement systems offer superior accuracy for most applications. Time-pressure filling provides cost-effective solutions for high-volume production.

Cleanroom Compatibility

Pharmaceutical filling equipment must integrate seamlessly with cleanroom environments. Stainless steel construction with electropolished surfaces prevents bacterial adhesion. CIP (Clean-in-Place) systems reduce manual cleaning requirements.

volumetric principle

Particle generation from equipment operation must remain within cleanroom specifications. Low-maintenance designs minimize interventions that could compromise environmental conditions.

Automation Level and Output Speed

Production volume requirements drive automation level decisions. Semi-automatic systems suit small-batch or clinical trial production. Fully automated lines optimize high-volume commercial manufacturing.

Speed capabilities must match production planning requirements while maintaining quality standards. King Pack’s vial filling machine manufacturers provide systems ranging from 500 to 15,000+ vials per hour.

Compliance with GMP & FDA Standards

Regulatory compliance represents a fundamental requirement for pharmaceutical equipment. 21 CFR Part 211 defines current Good Manufacturing Practices for finished pharmaceuticals. Equipment design must facilitate validation and ongoing compliance monitoring.

Documentation packages must include Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols. King Pack’s systems include comprehensive validation support services.

Recommended reading: How to Choose the Right Vial Filling Machine for Your Business

Price vs. Performance Considerations

Cost Impact of Aseptic Features

Investing in an aseptic vial liquid filling machine often involves a higher upfront price because of specialized system technology. Features like RABS systems, isolator-based enclosures, UV Light Tunnel, and dehydrogenation tunnel add to capital costs but provide long-term benefits. These advanced designs help pharmaceutical manufacturers protect sterile areas, decontaminate outer surfaces, and reduce contamination risks during liquid formulations and oncology preparations.

A complete Filling and Stoppering Machine with Outside Washing Machine, Rubber Stopper handling, and single-disc sealing can further raise costs. Yet, for high-value pharmaceutical liquids and sensitive products like blood plasma or infusion bottles, this precision is critical. By using dosing methods based on the volumetric principle and diving nozzle systems, modern processing equipment reduces variability and meets global regulatory requirements.

Total Cost of Ownership

When comparing new equipment to preowned packaging machinery available in the global marketplace, the long-term cost difference is in efficiency. Preowned equipment may have a lower entry cost but often lacks predictive maintenance, automation, and energy efficiency.

Modern pharmaceutical vial filling systems reduce unplanned downtime, maintain compliance, and minimize operating costs. Sales channel options such as certified suppliers provide warranty coverage and technical support, which adds further value.

Balancing Investment and Long-Term Savings

Small-scale production facilities may look for budget-friendly options, but lifecycle costs should weigh heavier than initial price tags. A high-quality Filling and Stoppering Machine or aseptic vial liquid filling machine delivers extended service life, consistent performance, and fewer breakdowns. For pharmaceutical manufacturers producing biologics, vaccines, or oncology preparations, avoiding batch losses alone justifies the investment.

King Pack’s system technology supports this balance by offering modular upgrades for filling range flexibility and future-proof design. Financing options such as leasing programs and rental agreements make these solutions more accessible, even for smaller manufacturers. Performance guarantees further protect investments, giving buyers confidence that their equipment can scale with growing demand while meeting strict GMP standards.

Leading Vial Filling Machine Manufacturers

Global Pharma Machine Manufacturers

The vial filling machine manufacturers landscape includes established European companies and emerging Asian suppliers. Traditional leaders maintain strong positions through technological innovation and service capabilities. Market consolidation continues as companies seek global scale advantages.

Quality standards and regulatory expertise differentiate leading suppliers. FDA and EMA pre-approval inspections require demonstrated compliance capabilities. Long-term partnerships provide ongoing technical support and upgrade pathways.

China and European Suppliers Comparison

European pharma machine manufacturers traditionally dominated high-end aseptic filling markets. German and Italian companies established reputations for precision engineering and regulatory expertise. These suppliers continue leading in complex biologics applications.

Chinese manufacturers have expanded capabilities significantly in recent years. Cost advantages and domestic market growth drive international expansion. Quality improvements increase competitiveness. Investments in regulatory compliance also help.

King Pack as a Competitive Solution Provider

King Pack’s Machinery combines competitive pricing with advanced technical capabilities. The company provides comprehensive vial filling equipment solutions from laboratory-scale to high-volume production systems. Our engineering team offers customization services for specialized applications.

Technical support services include installation, validation, training, and ongoing maintenance. King Pack’s global service network provides local support for international customers. Performance guarantees and warranty programs demonstrate confidence in equipment reliability!

Conclusion

Vial filling machines have changed the way pharmaceutical companies meet rising demand. They improve efficiency by cutting manual work, increase accuracy with advanced dosing systems, and protect sterility through barrier technology. On top of that, their scalability and flexibility allow manufacturers to adapt quickly to market shifts without major investment in new lines.

King Pack’s Machinery brings all these advantages together in one place. If you’re exploring ways to upgrade your liquid filling process, we can provide the right solution tailored to your requirements. Get in touch with our team today to discuss how our vial filling machines can help streamline your operations and secure consistent, high-quality output!