Introduction

Secondary packaging plays a vital role in modern manufacturing. It protects products, improves logistics and presents them well to consumers. Two key machines in this stage are cartoning machines and case packers.

Each one serves a distinct purpose in the packaging line. Knowing their differences, their functions and how they fit together helps you select the right solution. This article explores both machines, compares them and shows how KPFillingMachine equipment fits in.

What is a Cartoning Machine?

Definition and Purpose

A cartoning machine is a packaging system that forms cartons, fills them with products, and seals them for retail or transport. It helps manufacturers handle large volumes efficiently while keeping packaging neat and uniform.

This machine is ideal for small or medium-sized products such as bottles, tubes, blister packs, or sachets. It ensures every product is enclosed in a clean, well-shaped carton that protects it and enhances presentation.

The main purpose of a cartoning machine is to automate secondary packaging. It reduces manual labor, increases output, and maintains consistent packaging quality across production batches.

How the Cartoning Machine Works

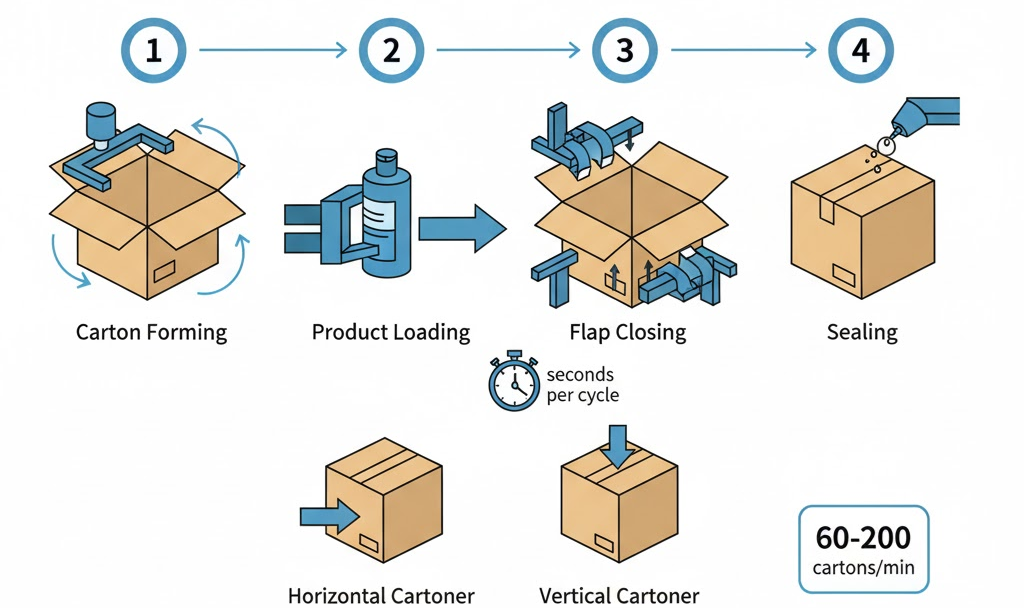

The process typically follows these steps:

- Carton forming – a flat blank is erected into a carton shape.

- Product loading – the product is inserted into the formed carton.

- Flap closing – the carton has flaps or ends which are folded and prepared for sealing.

- Sealing – the carton is sealed via glue, tuck-in flaps or other means.

The system opens the carton from a flat blank and immediately fills it with the product using a feeding unit. Horizontal cartoners feed products from the side. Vertical models drop items from above. After loading, the machine folds the flaps and seals them with glue or tucking mechanisms.

The entire cycle takes seconds. Modern cartoners can process 60 to 200 cartons per minute, depending on complexity.

Applications of the Cartoning Machine

Cartoning equipment is widely used across industries where efficiency, product safety, and presentation are essential. These systems help brands package products quickly while maintaining a consistent and professional appearance. Because modern cartoning systems can handle different shapes and sizes—including rectangular shape products—they are suitable for a wide variety of production lines.

Common industries using cartoning machines include:

- Pharmaceuticals: for packing vials, blister packs, and medical tubes efficiently.

- Cosmetics and personal care: for creams, serums, and skincare products, often using wrap-around cartoners for a premium finish.

- Food and beverage: for grain applications, instant meals, tea bags, and snack boxes, where automatic carton forming machines streamline the packaging process.

- Household and daily-chemical products: for detergents, cleaning tablets, and other retail goods, ready for end-of-line solutions like palletizing or case packing.

Across all industries, cartoning equipment improves productivity, protects delicate products from damage, and ensures uniform packaging. It also prepares items for further processes such as labeling, sealing, and direct placement on store shelves.

What is a Case Packer?

Definition and Function

A case packer is a type of end-of-line packaging machine that collects multiple cartons, bottles, or containers and loads them into corrugated shipping cases. It’s responsible for forming the final layer of protection before products move to storage or shipment.

Unlike machines designed for single-unit packaging, a case packer deals with grouped products. It forms the case, positions products accurately, and seals the box for safe delivery. Most systems can handle various case styles and configurations.

These machines are built for speed and reliability. They can pack dozens of cartons into one case within seconds, maintaining consistent output during high-volume operations. The end result is a clean, stable, and distribution-ready package.

How Case Packer Works

The workflow starts with product grouping. Cartons arrive from upstream equipment and get arranged into specific patterns.

- Product grouping: after cartons or containers, they are grouped or stacked.

- Case forming: empty cases are erected to receive products.

- Loading: multiple units are placed inside the case.

- Sealing: the outer case is sealed with tape, glue or straps.

- Optional labeling or coding may follow.

There are different types: wrap-around case packers, side-load, top-load and robotic case packers. The machine type depends on product geometry and speed requirements.

Applications of Case Packer

Case packers are essential in large-scale production and distribution where speed, consistency, and safety are critical. They help prepare goods for shipment while streamlining inventory management and logistics. By automating bulk packaging, case packers reduce manual handling and maintain smooth operations.

Industries that depend on case packers include:

- Food and beverage: for packing vacuum-packed rice, bottles, cans, and boxed items into transport cases.

- Pharmaceutical applications: for combining medicine cartons, vials, or medical devices into secure shipping boxes.

- Consumer goods: for organizing toiletries, detergents, and other retail products efficiently.

- Cosmetics: for assembling boxed beauty products with flap insertion into master cartons for delivery.

- Electronics and appliances: for safely packaging multiple units using robotic arms, Delta robots, or servo-driven rotary feeders to ensure product integrity.

Modern case packers often feature vision systems, automatic feeding units, and user-friendly controls. Machines with painted or stainless steel washdown frames offer durability and easy maintenance, while hot-melt application systems or Servo-driven systems improve precision and reliability.

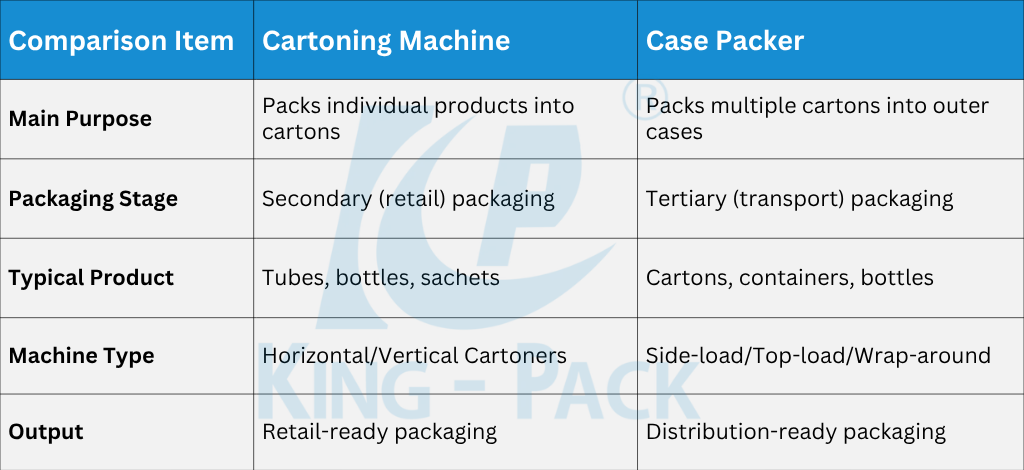

Key Differences Between Cartoning Machine and Case Packer

The distinction comes down to function. Cartoning machines create what customers see on shelves. Case packers create what warehouses and trucks transport.

One focuses on presentation and product information. The other prioritizes protection and efficient handling during logistics.

Speed differs too. Cartoners often run faster because they handle lighter, smaller items. Case packers work with heavier loads and need more time per cycle.

Recommended Reading:

How to Choose Between a Cartoning Machine and a Case Packer

Selecting the right packaging equipment goes beyond budget considerations—it’s about finding a cartoning system or case packing solution that matches your production goals, available space, and long-term growth strategy.

Both cartoning machines and case packers have distinct roles within a packaging line. Choosing the right option depends on your workflow, output requirements, and the level of automation you need.

Production Requirements

The scale and type of your production line largely determine whether a vertical cartoner, horizontal cartoning machine, or case packer is the best fit. For small-batch retail packaging of items such as sachets, tubes, jars, or bottles, a cartoning machine provides precision, speed, and reliability.

Vertical cartoning machines are particularly effective for fragile or small products, offering gentle handling and consistent accuracy, while horizontal cartoning machines handle bulkier items with higher speeds and versatile carton sizes.

Automatic cartoning machines and intermittent motion cartoners are designed to integrate seamlessly with filling, sealing, and labeling systems, making them ideal for complex workflows. Case packers, on the other hand, are optimized for high-volume production where multiple cartons, pallet boxes, or tray packs need to be grouped together for shipping.

These machines streamline bulk packaging, reduce manual handling, and are especially useful for industries like chemical industries, baking mix production, beverage, or consumer goods distribution. Multipacking machines, wraparound packers, and Triangle bag-in-box cartoners further enhance case packing applications, improving throughput and overall line efficiency.

Packaging Format

Understanding your packaging format is crucial to avoiding bottlenecks later. Retail-ready packaging generally requires a vertical cartoner, horizontal cartoning machines, or wrap-around cartoners, which organize products neatly for display.

If your business also involves grouping finished cartons into larger shipping cases, an automatic carton forming machine or a dedicated case packing solution becomes essential. Some facilities implement both, using cartoning equipment for primary packaging and case packers for end-of-line operations.

This dual setup ensures smooth handling across the entire packaging line and preserves product integrity while moving items directly from production to palletizing.

Space and Layout

Floor space and layout are important when integrating a cartoning system. Cartoning machines, including automatic carton filling machines and intermittent motion cartoners, often sit mid-line and work seamlessly with filling, sealing, and labeling equipment. Their relatively compact footprint makes them suitable for facilities with space constraints.

Case packers, by contrast, require more room due to larger components for handling multiple cartons or pallet boxes. They are usually installed at the end of the packaging line, near palletizing stations or stretch-wrapping systems. Planning equipment placement carefully ensures smooth workflow, efficient product flow, and minimal interference with other operations.

Budget and ROI

While cartoning machines typically involve lower initial investment compared to high-speed case packers, total value depends on the machine’s contribution to time savings, labor reduction, and waste minimization. Factors such as machine speed, flexibility, and maintenance requirements directly affect return on investment.

For example, KPFillingMachine offers horizontal cartoning machines with multiple carton size options, variable speed ranges, and advanced inspection systems. These automatic cartoning machines allow fast product changeovers without significant downtime.

Choosing equipment that integrates easily with existing packaging lines—including primary packaging, hot melt glue sealing, and multipacking machines—can substantially improve long-term ROI by minimizing disruptions and boosting overall efficiency.

Integration Possibility

Seamless integration with other packaging lines is essential for continuous, automated operations. Vertical cartoning machines, horizontal cartoning machines, automatic carton forming machines, and wrap-around cartoners are engineered to connect smoothly with filling, capping, and labeling equipment.

Case packers, pallet box handling systems, and wraparound packers link effectively to end-of-line palletizers and shrink-wrapping stations. Facilities using KPFillingMachine filling, sealing, or packaging systems can synchronize these operations with our cartoning and case packing equipment, creating a fully automated, highly efficient packaging workflow.

Properly integrated systems maintain product integrity, ensure gentle handling, and maximize throughput across all stages, from primary packaging to final palletized loads.

Combining Both Machines in One Packaging Line

Modern packaging lines often combine multiple machines to maximize efficiency, especially when handling diverse products like food products, pouch/bagged snacks, blister packs, or medical devices. A typical setup looks like this:

- Filling machine → 2. Capping/Sealing machine → 3. Vertical cartoner or cartoner 100 intermittent motion cartoning machine → 4. Case packer → 5. Palletizer

Using modular cartoning machinery and automatic carton forming machines allows smooth integration with upstream filling units. Companies like the paxiom group provide solutions that can handle pharmaceutical applications, medical devices, and general consumer products with high precision.

Key advantages of a combined layout include:

- Streamlined workflow with fewer manual transfers

- Higher automation rates and lower labor costs

- Consistent packaging quality and minimal waste

- Easier line monitoring and reduced downtime

Many systems include intuitive controls and printing systems for product information or batch coding. Before full deployment, manufacturers perform trial runs and factory acceptance testing to ensure the line operates efficiently.

Tools like a machine finder can help select the right cartoning equipment for your specific product type, whether it’s food products, blister packs, or pouch/bagged snacks.

In operation, the cartoner receives filled units, passes cartons to a conveyor, and feeds the case packer for automatic case forming and loading. This setup ensures a smooth, fully integrated packaging line that supports both high-speed production and reliable pharmaceutical applications or consumer goods packaging.

Recommended Reading: What is a Vial Filling Machine? – King Pack Machinery

Best Cartoning Machines from KPFillingMachine

1. Horizontal Cartoning Machine

KPFillinge’s horizontal cartoning machines are built for high-speed, fully automatic operation. They form, fill, and close cartons efficiently, making them perfect for items like bottles, tubes, or sachets. With a packing speed of up to 100 boxes per minute, this machine delivers stable performance through its PLC (Programmable Logic Controller) and HMI control system.

Supporting multiple carton sizes, these machines offer flexibility for manufacturers handling different packaging formats. Their compact design and efficient air consumption reduce operating costs while maintaining smooth performance.

Key Highlights:

- Handles multiple carton sizes automatically

- Fault detection and product rejection system

- Stable PLC + HMI control with adjustable speed

- Compact, low-maintenance design suitable for continuous production

2. Vertical Cartoning Machine

This model suits products that are better loaded vertically, such as vials, jars, or small bottles. Like the horizontal type, it features a fully automatic process from carton opening to closing, making it suitable for medium to large-scale production.

It delivers speeds of 40–70 boxes per minute, balancing precision and efficiency. The machine is built for consistent accuracy when loading fragile or small products, reducing waste and rework.

Key Highlights:

- Supports various product dimensions

- Smooth vertical loading system ideal for bottles and jars

- PLC and HMI for consistent performance

- Quick size adjustment for product changeovers

3. KPFQ-300 3D Packing Machine

The KPFQ-300 is a versatile 3D wrapping system designed for premium packaging needs. It uses BOPP cigarette film with a gold pull line, delivering a high-end look suitable for boxed cosmetics, electronics, and gift sets.

It runs at 40–60 packs per minute, combining both precision and aesthetics. The quick mold change design cuts downtime from hours to minutes, while the dual-safety mechanism protects components without interrupting production.

This model also includes a fully enclosed acrylic cover that keeps the work area clean and safe. Its stainless-steel worktable resists scratches and maintains the quality of each pack. Ideal for brands that need both protection and presentation in their packaging.

Key Highlights:

- Quick mold and film roll change system

- Dust-proof, transparent safety cover

- Advanced static-free film feeding system

- Dual-safety design to prevent mechanical damage

Conclusion

To sum up: a cartoning machine handles individual retail packages; a case packer handles grouped cartons for transport. They are not rivals; they are complementary. Selecting the right machine (or the right combination) depends on your production volume, packaging format, space, budget and integration needs.

And when you need a trusted partner for your packaging line, exploring the cartoning machine options offered by KPFillingMachine is a smart move. Our machines are built for reliability, precision, and long-term efficiency.

Each model is designed to match real production demands, from small-batch manual setups to fully automatic, high-speed systems. Contact us today to discuss your production goals and get expert guidance on building a packaging system that performs consistently, scales easily, and delivers strong ROI.

Recommended Reading:

.jpg)