Introduction: Importance of Tube Filling Machines

Packaging is not just a container in the cosmetic and pharmaceutical industry. It ensures hygiene, builds trust and protects the product. Because of that, tube filling machines have become essential. They allow you to fill tubes with lotions, creams, gels and ointments with accuracy.

The tube filling machine market is expected to reach $1.2 billion by 2024 and is still growing. Manual filling would be wasteful, slow and uneven without tube filling machines. So companies relying on quality packaging are using advanced pharmaceutical and cosmetic tube filling machines. These machines meet industry standards and are more efficient.

If you want to know how they work and how they can improve your production, this beginner’s guide will take you through all the details. And if you are ready to invest in one, reputable suppliers like KP Filling Machine have high capacity solutions designed for your specific needs.

Applications in Cosmetics and Pharmaceuticals

Cosmetic tube filling machines fill creams, lotions, gels and serums with viscosities between 50 cP and 50,000 cP. Sterility of the product and protection against contamination is largely dependent on these systems in the cosmetic industry.

Pharmaceutical tube filling machines fill ointments, topical drugs and therapeutic gels. These applications require FDA compliant materials and validation functionality. Pharmaceutical products often have active ingredients that require precise dosing accuracy of ±2%.

Recommended Reading: A Detailed Guide to Vial Filling Machine Types – Principles and Selection | King Pack

Benefits of Automated Tube Filling

Automatic tube filling machines give consistent output with filling accuracy within ±1% tolerance. Major benefits are:

- Production rate of up to 600 tubes/minute for automatic machine

- Reducing labor cost by 60-70% compared to manual operation

- Eliminating contamination risk through hermetic processing

- Waste reduction in the product by up to 95%

- Uniform quality meeting regulatory requirements

For small businesses a semi-automatic tube filler may be enough. But with increasing demand it is wiser to invest in a fully automatic tube filling machine. We have both semi and automatic models available at KP Filling Machine depending on your production volume.

Click here to check the range of tube filling machines at KP Filling Machine

Types of Tube Filling Machines

Machine selection depends on production quantity, budget and technical requirements. They have different benefits for different uses. For new companies, a semi-automatic tube filling machine might be sufficient. Large scale operations with high volume tend to go for a fully automatic tube filling machine. Knowing how these two differ will help you choose the best option.

1. Semi-Automatic Tube Filling Machines

Semi-automatic tube fillers process around 30–100 tubes per minute. Operators load tubes manually, while the machine handles filling and sealing. This design reduces human error but still requires hands-on work.

Typical specifications include:

- Fill volume range: 5–500 ml

- Accuracy: ±2%

- Power consumption: 2–5 kW

- Compressed air requirement: 6–8 bar

These systems are affordable, with an initial investment of $15,000–$50,000. The moderate price point makes them ideal for startups, small cosmetic brands, or specialized pharmaceutical packaging machine applications.

Another advantage is flexibility. Semi-automatic tube fillers allow quick product changeovers. Setup time averages 15–30 minutes, so manufacturers can switch between different creams, gels, or ointments without long delays. This makes them a strong choice for companies producing multiple product lines.

2. Fully Automatic Tube Filling Machines

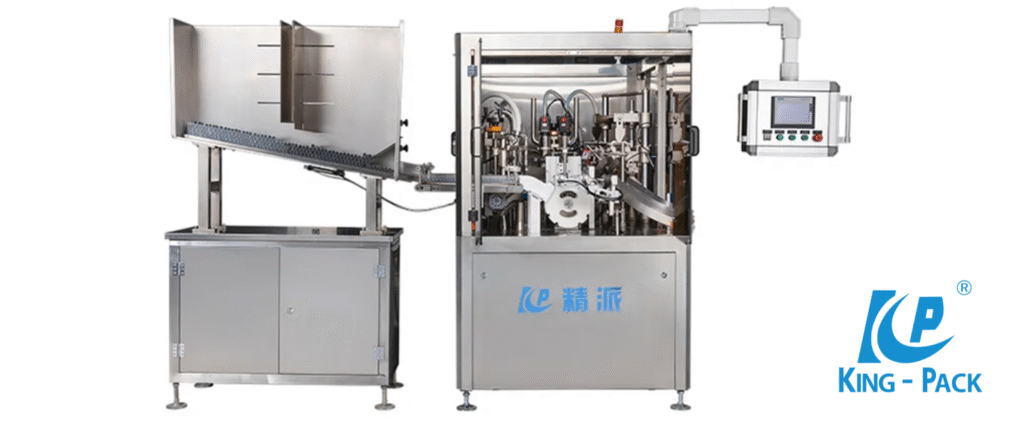

For larger factories, an automatic tube filling machine is the preferred choice. These systems deliver high speed and consistency, processing 200–600 tubes per minute with minimal operator input. The entire process is automated, including tube feeding, filling, sealing, trimming, and coding.

Key performance parameters:

- Fill accuracy: ±1%

- Production capacity: 10,000–35,000 tubes/hour

- Power consumption: 15–25 kW

- Floor space requirement: 15–25 m²

While the upfront cost is higher, the return on investment usually comes within 18–24 months. That’s because automation reduces labor expenses, boosts throughput, and minimizes waste.

Another benefit of automatic tube filling machines is scalability. They support continuous operation, making them suitable for high-demand industries such as cosmetics, pharmaceuticals, and chemical packaging. These machines also integrate with tube sealing machines and advanced systems like ultrasonic tube sealing for superior results.

Leading suppliers such as KP Filling Machine offer advanced automatic solutions. Our machines are designed to meet strict tube filling operation standards while delivering long-term reliability.

Recommended Reading: How to Choose the Right Vial Filling Machine for Your Business – King Pack Machinery

Machine Setup and Installation

You need to know that proper installation directly impacts performance and machine longevity. Every tube filling machine must meet its technical requirements before commissioning. Skipping steps or using incorrect site conditions often leads to breakdowns, reduced accuracy, or even safety risks.

Also, professional installation is always recommended to keep warranties valid and to guarantee reliable operation.

Basic Installation Steps

Before bringing a tube filling machine into production, the site must be prepared. Common requirements include:

- Level concrete floor with a maximum deviation of ±2 mm

- Electrical supply: 380V/50Hz, 3-phase

- Compressed air: 0.6–0.8 MPa, dewpoint –40°C

- Adequate ventilation for cooling and heat dissipation

Automatic systems usually require 3–5 days for full installation and commissioning. This period includes unpacking, positioning, electrical wiring, air connection, and safety checks.

Semi-automatic models are quicker to set up but still benefit from trained technicians to avoid alignment or calibration errors. KP Filling Machine provide on-site setup services, which save time and reduce the risk of early faults. Our team also trains operators during installation so production can start smoothly.

Calibration and Adjustment

Once installation is complete, calibration ensures accurate filling and proper sealing. For tube filling operations, calibration is done under production-like conditions. The most reliable method is gravimetric testing:

- Fill 10 consecutive tubes with the product.

- Weigh each filled tube.

- Calculate the mean deviation from the target fill.

- Adjust servo motor parameters or dosing system settings.

- Repeat until accuracy reaches ±1%.

It’s important to control product conditions during testing. Temperature affects viscosity, which impacts how the machine dispenses material. Product temperature should remain stable within ±2°C during calibration. Otherwise, accuracy may drift during operation.

In addition to volume calibration, sealing units also require adjustment. For ultrasonic tube sealing, vibration power and time are fine-tuned. For heat sealing, operators adjust jaw pressure and temperature settings. Proper calibration in both areas ensures consistent quality and reduces rework.

Recommended Reading: What is a Vial Filling Machine? – King Pack Machinery

Tube Filling Process

Loading Tubes and Filling Products

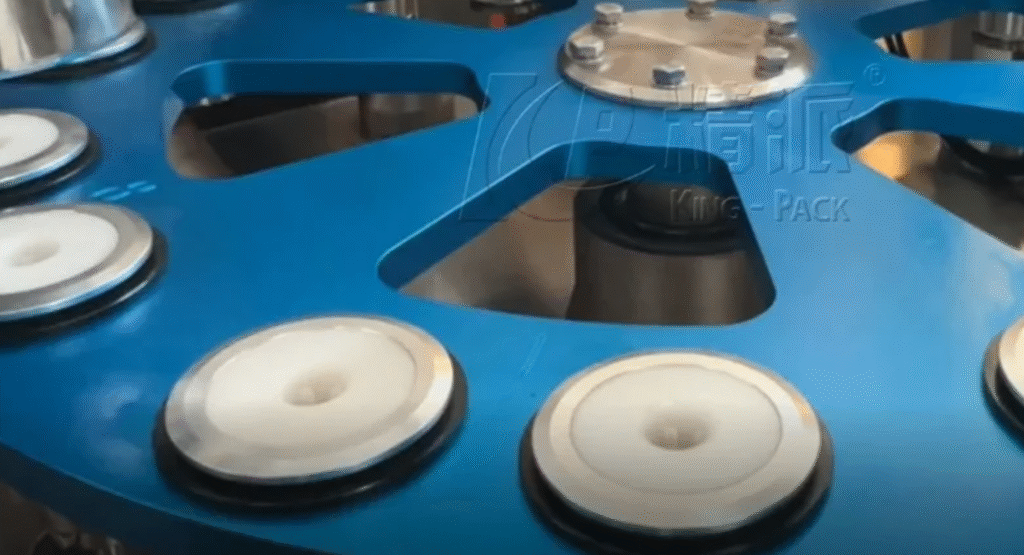

In a typical tube filling operation, tubes are loaded into holders. An automatic indexing system rotates them into position. The filling heads inject the product with precision. After filling, the tubes move forward for sealing.

Filling Different Product Types

Different industries deal with a wide range of viscosities, and a cosmetic tube filling machine may be required to fill lotions, gels, or pastes, while pharmaceutical tube filling equipment often handles ointments or medicated creams.

The dosing system inside the machine adapts to each product type, giving manufacturers the flexibility to switch between products without investing in separate equipment.

Here is a breakdown of how filling parameters change with product type:

You need to know that tube filling operation efficiency depends on the proper tube sealing technique selection. The following section gets into detail about these techniques.

Tube Sealing Techniques

KPGFW-160 Filling and sealing machine – King Pack Machinery

Sealing technology is one of the most critical stages in a tube filling machine operation because it directly impacts both production speed and product integrity. A poor seal can lead to leakage, contamination, or reduced shelf life.

According to a report by MarketsandMarkets, the global tube packaging market is projected to reach USD 4.6 billion by 2029, with pharmaceutical and cosmetic applications driving demand for stronger and more efficient sealing solutions. As product formulations become more complex, sealing methods must adapt to ensure compliance with GMP standards and customer expectations.

The following is a detailed rundown of tube sealing techniques:

| Technique | How It Works | Best For | Pros | Cons |

| Heat Sealing | Heated jaws press and melt the tube end. | PE and laminated tubes. | Reliable, cost-effective, widely used. | Risk of overheating product, less suited for sensitive formulas. |

| Ultrasonic Sealing | High-frequency vibrations generate localized heat. | Sensitive cosmetics and pharmaceuticals. | Strong seals, energy efficient, clean results. | Equipment is more expensive. |

| Hot Air Sealing | Heated air softens inner tube wall, jaws seal. | Automatic systems, laminated tubes. | Smooth finish, consistent sealing. | Needs stable air supply and precise controls. |

| Impulse Sealing | Electric current heats sealing bars only during operation. | Plastic and laminated tubes. | Energy saving, safe. | Slower cycle time compared to ultrasonic. |

| Crimp Sealing | Tube end folded and pressed mechanically. | Metal/aluminum tubes. | Tamper-proof, durable. | Limited to non-plastic tubes, less modern appearance. |

| High-Frequency (RF) | Radio frequency waves melt tube layers internally. | PVC and multilayer tubes. | Strong, uniform seal. | Requires complex, high-cost equipment. |

| Laser Sealing | Focused laser beam melts and bonds tube edges. | High-end pharma applications. | Precise, clean, sterile. | Very costly, still emerging technology. |

Choosing the right sealing method depends on the product formulation, packaging material, and regulatory needs. For example, ultrasonic sealing has grown in popularity for pharmaceutical products because it avoids direct heating, reducing the risk of damaging sensitive ingredients.

On the other hand, heat sealing remains dominant in cosmetics due to its affordability and proven reliability. For long-term reliability, at KP Filling Machine, we provide both standard and advanced sealing solutions tailored to industry requirements.

Recommended Reading: How Does a Tube Filling Machine Work? – King Pack Machinery

Safety Considerations

Operating a tube filling and sealing machine, whether it’s a plastic tube filling and sealing machine or an automatic tube filling and sealing machine for pharma & healthcare, requires strict safety protocols. Operators in cosmetics, liquid soaps, hair care, and chemical industries should wear protective gear during every production shift.

Operator safety gear includes:

- Safety glasses/goggles: protection from splashes during automated filling

- Chemical-resistant gloves: nitrile for skin & sun care, butyl for solvents in home care or chemical industries

- Protective clothing: antistatic coats or aprons for clean room production

- Respiratory masks: when handling volatile formulations or unit dose squeeze tubes

- Safety shoes: non-slip, chemical-resistant for ergonomic design workplaces

- Ear protection: necessary when cartoning machines, labeling machines, or tube elevator machines are running above 85 dB

Pre-operation checks are just as critical. For rotary indexing systems or FP tube filling machines, verify:

- Emergency stop: responds in less than 0.5 seconds

- Safety guards: enclosure panels, closure stations, and operator safety doors in place

- Electrical system: servo drives, touch screen PLC, and control and drive technology free of faults

- Pneumatic system: pneumatic cylinders at correct pressure for pneumatic cutting and crimping machine operations

- Safety signage: date/lot code, batch coding, and barcode generation labels visible on the equipment

Lock-out/tag-out procedures must always be followed during maintenance to isolate servo technology, pneumatic systems, or hot air tool leister modules for safe handling.

Troubleshooting Common Problems

Even with advanced automatic tube filling machines, issues can occur. Below are common problems and quick fixes:

Regular troubleshooting prevents small problems from escalating into major downtime.

Maintenance and Care

When it comes to maintenance and care of tube filling machines, you need to know that consistent upkeep is what keeps the equipment reliable and productive. Proper tube filling maintenance increases reliability and extends machine life. Routine cleaning should be done after every production run.

Product residues inside hoppers, filling nozzles, and sealing units must be removed to prevent blockages and cross-contamination. Using approved cleaning agents is important, especially in pharmaceutical packaging machines where GMP standards apply. Always document cleaning cycles in logs for full traceability.

Preventive maintenance is just as critical because it reduces unplanned downtime. A typical schedule should be like that:

Well-maintained equipment not only delivers accurate results but also saves costs over the long term. Reliable suppliers like KP Filling Machine provide spare parts and after-sales support, making preventive maintenance easier to manage.

Conclusion: Optimizing Tube Filling Efficiency

A tube filling machine is no longer optional in cosmetics and pharmaceuticals. From small brands using a semi-automatic tube filler to large firms running a fully automatic tube filling machine, the benefits are clear – accuracy, speed, and professional packaging.

By learning setup, sealing methods, safety checks, and tube filling troubleshooting, operators can maximize efficiency. Regular tube filling maintenance extends machine life and keeps production smooth.

If you are planning to upgrade your cosmetic or pharmaceutical packaging, investing in a reliable filling and sealing machine from KP Filling Machine is a smart move. Our wide range of solutions ensures you get the right machine for your production scale. Contact us today to discuss your requirements, get expert guidance, and request a tailored quote. The right machine can transform your production efficiency—let us help you achieve it!