The veterinary pharmaceutical market continues to grow at a steady pace. Pet owners expect safer products, accurate dosing, and consistent quality. Regulators now expect the same level of control and documentation seen in human pharmaceuticals. These pressures have reshaped how veterinary liquids are filled and packaged.

At King Pack (KPFilling), we work closely with veterinary drug manufacturers facing this shift. Many are moving away from manual or semi-automatic operations and upgrading to fully automated, GMP-compliant production lines. With the right automation, efficiency improves by more than 30%, while sterility, accuracy, and process control also improve.

In this article, we review how veterinary drop packaging equipment has evolved. We explain the GMP trends driving equipment upgrades, outline core automation technologies, and show how modern filling lines improve speed, accuracy, and compliance.

Recommended Reading: Automatic Case Packaging Machine — Intelligent Transformation of End-of-Line Packaging – King Pack Machinery

The Evolution of Veterinary Drop Packaging

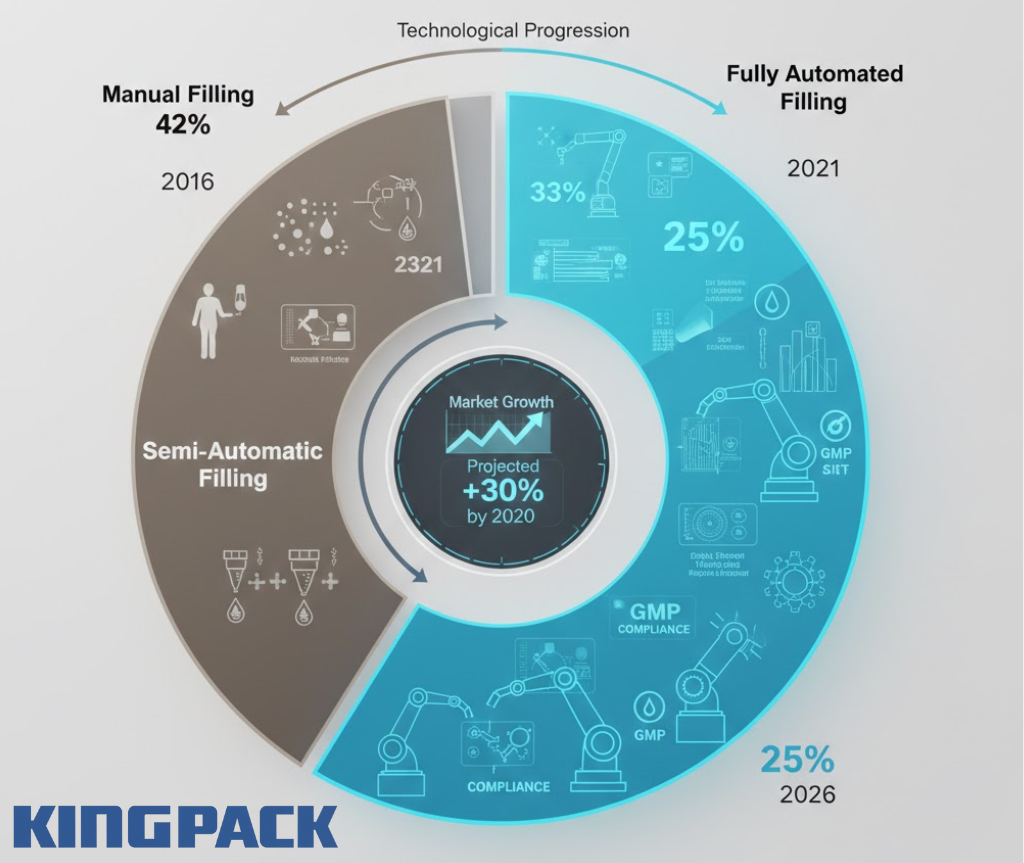

Veterinary drop packaging looked very different ten years ago. Most production relied on manual filling or basic semi-automatic machines. These systems were affordable and simple to operate, but they came with clear limits.

Manual filling depended heavily on operator skill. A small distraction could lead to underfilling, overfilling, or spills. Semi-automatic machines reduced some variation, but they still required constant supervision and manual bottle handling.

As product volumes increased and regulatory scrutiny grew, these methods became harder to justify. Contamination risk, dosing variation, and labor costs all increased with scale.

In 2026, most mid- to large-size veterinary manufacturers are moving toward automated lines. These lines integrate filling, dropper insertion, capping, and labeling into one controlled workflow. Output increases, while operator involvement drops.

The global veterinary pharmaceutical market is projected to reach USD 7.6 billion in 2026, with a CAGR of 6.2%. Liquid dosage forms remain one of the fastest-growing segments, which directly increases demand for reliable drop packaging equipment.

Traditional Manual and Semi-Automatic Filling

Manual and semi-automatic filling still exist in small-scale production. However, their weaknesses become clear once volumes grow or GMP audits become stricter.

Common limitations include:

- High labor dependency and rising operating costs

- Inconsistent dosing, especially below 10 ml

- Frequent product loss due to dripping and spills

- Open exposure to air and operators

- Difficult cleaning and validation

Micro-volume dosing is especially sensitive. Many veterinary drops require exact dosing to avoid under-treatment or irritation. Manual filling lines showed a 3–5% error rate in micro-dosing, while automated systems reduced this to below 0.5%. This gap alone pushes many manufacturers toward automation.

Recommended Reading: Cartoning Machine vs Case Packer – King Pack Machinery

Transition to Automated Production Lines

Automation directly addresses the limits of manual systems. By controlling each step mechanically and electronically, manufacturers gain stability and repeatability.

Automated veterinary drop packaging lines deliver:

- Consistent dosing across long production runs

- Reduced operator contact for better hygiene

- Stable output suitable for growing product portfolios

At KPFilling, our automatic veterinary dropper filling machines are designed for flexible production. A single line can handle bottles from 5 ml to 30 ml, with different shapes and materials. Liquids with varying viscosity run on the same platform using the correct filling technology.

Servo-driven piston systems manage thicker formulations. Peristaltic pumps handle sterile or sensitive liquids. Integrated capping and labeling reduce manual handling and improve line balance. Pet Pharma Insights (2024) reported that manufacturers upgrading to fully automated drop filling lines achieved:

- 32% higher production efficiency

- Over 40% reduction in reject rates

- Shorter validation and cleaning cycles

New Veterinary GMP Requirements Driving Equipment Upgrades

Veterinary GMP standards continue to tighten. Even small producers now face expectations that once applied only to large pharmaceutical plants. Equipment design plays a direct role in compliance. We focus on sterility, accuracy, traceability, and validation from the start.

Sterility and Hygiene Expectations

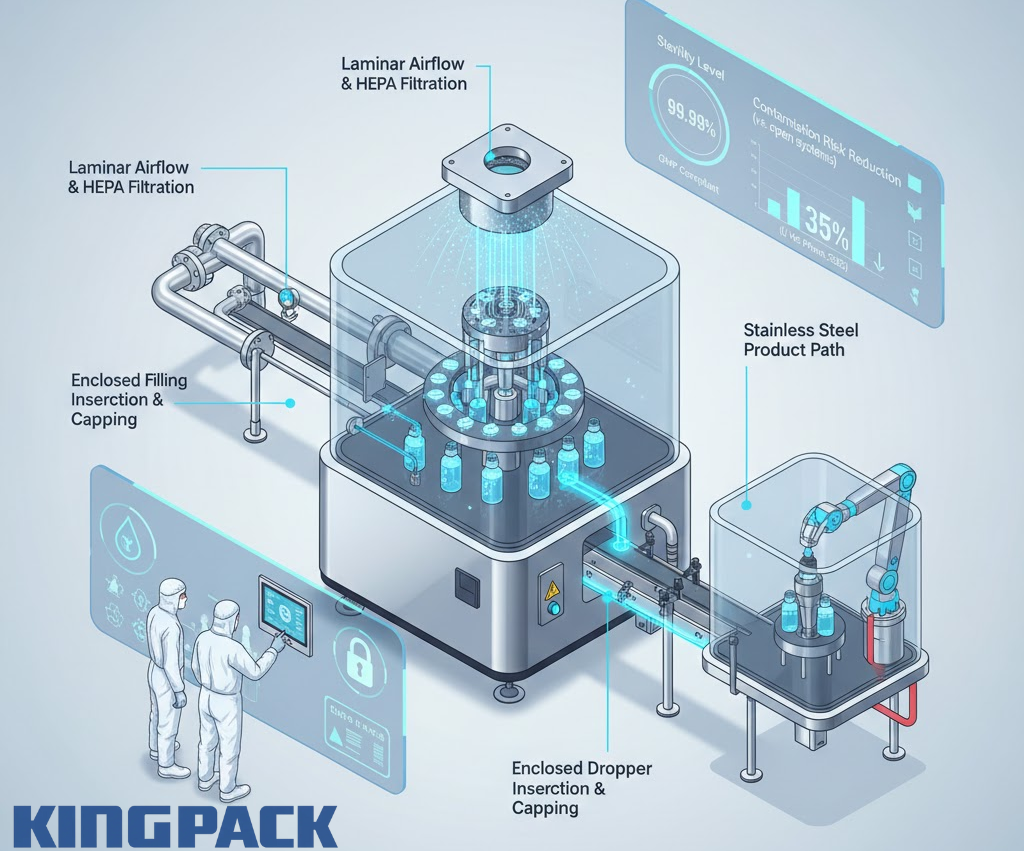

Preventing contamination is a top priority. Modern veterinary GMP guidance emphasizes controlled environments and reduced human contact. Our machines use enclosed filling zones and stainless steel product paths. Optional laminar airflow further protects sensitive liquids.

Key sterility features we apply:

- Closed filling environments

- Minimal operator contact

- Smooth, cleanable surfaces

- CIP- and SIP-ready designs

- Enclosed dropper insertion and capping

Accuracy and Traceability Standards

Dosing accuracy is now measured, recorded, and audited. Traceability is no longer optional.

Our filling systems deliver ±0.3–0.5% dosing accuracy, even at micro volumes. Each bottle links back to its batch through coding and inspection systems.

This supports:

- GMP audits

- Internal quality control

- Efficient recall managemen

A survey found that 68% of veterinary manufacturers upgraded to automated systems specifically to improve micro-volume accuracy and traceability.

Validation and Cleaning Requirements

Downtime affects profit. Validation delays slow launches. Cleaning must be fast and repeatable.

Our veterinary drop packaging equipment supports:

- CIP and SIP readiness

- Tool-free dismantling where needed

- Fast SKU and formula changeover

Recommended Reading: What Is a Planetary Mixer? – King Pack Machinery

Core Technologies in Modern Veterinary Drop Filling Equipment

Reliable automation depends on proven technology. We focus on systems that perform consistently in daily production.

High-Precision Filling Systems

Different liquids require different filling methods.

Peristaltic pump filling

- Best for sterile, low-viscosity liquids

- No product contact with pump components

- Easy tubing replacement

Servo piston filling

- Suitable for higher viscosity products

- Stable repeatability

- Strong control at higher speeds

Filling technology overview:

| Technology | Ideal for | Key benefit |

| Peristaltic pump | Sterile, low-viscosity liquids | Easy cleaning, low contamination |

| Servo piston | Higher viscosity liquids | High precision ±0.3–0.5% |

| Time-pressure | Variable micro volumes | Stable dosing control |

Automatic Plugging and Capping

Dropper placement and cap torque affect both product safety and shelf life. Our automatic systems provide:

- Controlled dropper insertion depth

- Orientation correction

- Torque-controlled capping

- Cap presence detection

According to Packaging Digest, torque-controlled capping reduces leakage complaints by over 40% in liquid pharmaceutical packaging.

Enclosed and Aseptic Filling Zones

Enclosed filling zones protect products from dust and bacteria. Optional laminar airflow adds another protection layer for sensitive veterinary drops. These zones allow higher speeds without sacrificing hygiene. Stainless steel construction supports long-term durability and easy cleaning.

Recommended Reading: How Vial Filling Machines Improve Efficiency and Accuracy in Liquid Filling – King Pack Machinery

Automation Cases That Improve Efficiency by 30%+

Modern veterinary drop packaging lines deliver significant productivity gains. By replacing manual operations with automated filling, capping, and labeling, manufacturers can improve output, reduce labor, and maintain consistent quality.

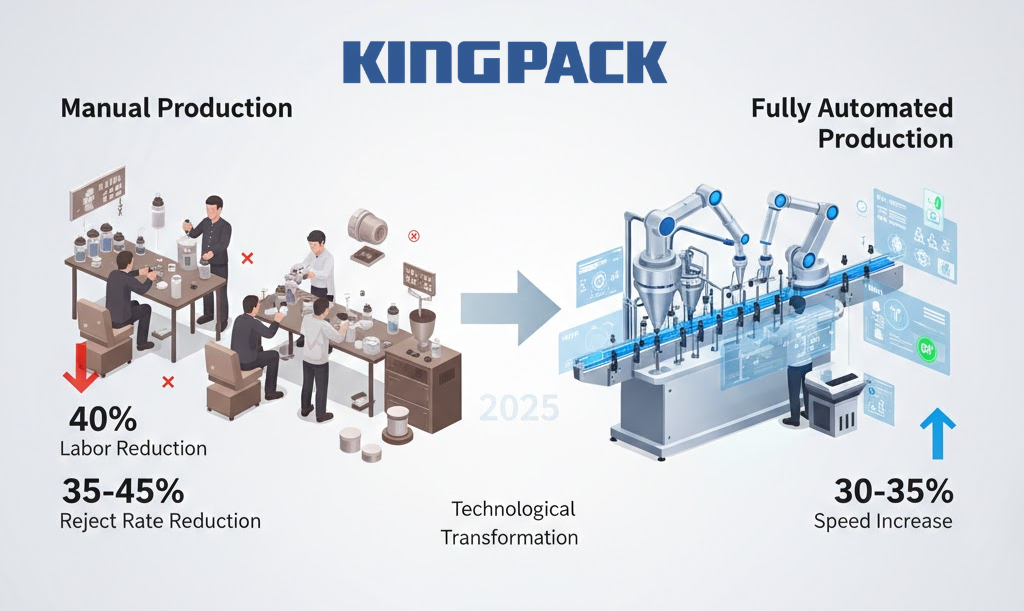

From Manual Filling to Fully Automatic Lines

Manual filling relies heavily on operators, which increases errors, labor costs, and contamination risks. By moving to fully automated lines, production speed rises, and reject rates drop. At King Pack, our fully automatic veterinary dropper filling lines integrate servo or peristaltic filling systems, automatic dropper insertion, torque-controlled capping, and inline labeling. This eliminates repetitive manual tasks, allowing staff to focus on quality monitoring.

Benefits of automation:

- Labor reduction of up to 40%

- Increased production speed by 30–35%

- Reject rate reduction by 35–45%

Integrated Filling + Capping + Labeling

Combining filling, capping, and labeling in a single line improves production rhythm. Our pet medicine packaging lines are designed to handle multi-SKU operations, allowing quick changeovers without compromising dosing accuracy.

Operators can switch between bottle sizes and liquid types seamlessly. Integrated vision inspection systems check fill levels, dropper insertion, and cap torque to ensure every unit meets GMP standards.

Line Speed and ROI Comparison

Efficiency improvements are quantifiable. For example:

| Line Type | Output per Hour | Labor Required | Cost per Unit Reduction |

| Manual Filling | 500–700 bottles | 4–6 operators | Base cost |

| Semi-Automatic Line | 1,000–1,200 bottles | 2–3 operators | 10–15% savings |

| Fully Automatic King Pack Line | 1,500–2,000 bottles | 1 operator | 30–35% savings |

The ROI from automation is not only in labor savings but also in reduced rejects, consistent dosing, and faster production cycles.

Typical Applications of Veterinary Drop Packaging Lines

Typical Applications of Veterinary Drop Packaging Lines

Veterinary drop packaging lines support a wide range of veterinary products used in daily animal care and treatment. Our systems are designed for flexible use across multiple applications:

Pet Deworming Drug Filling Machines

Deworming liquids often require precise micro-dosing in small containers. Our automated filling machines use rotary piston pumps to deliver stable volumes while supporting sterile fill finish processes aligned with cGMP guidelines.

Ear and Eye Drop Production Lines

Eye and ear drops demand strict control during filling and closing. Our eye drop filling and capping machines operate within enclosed zones, using laminar flow systems and integrated capping devices to limit contamination and protect liquid medication.

Oral Veterinary Liquid Packaging

Oral supplements and liquid medications require reliable dosing across different container types. Our filling and closing lines handle various bottle sizes while integrating labeling and sealing for efficient downstream processing.

Disinfectant and Care Solution Filling

Care solutions such as antiseptics and hygiene products run smoothly on our fully automatic solutions. These lines manage different viscosities and support filling and packaging sterile liquids without sacrificing accuracy or production speed.

Recommended Reading: Everything You Need to Know About Vial Packaging Machines – King Pack Machinery

Challenges in Veterinary Drop Packaging and How Automation Solves Them

Automating veterinary drop packaging addresses several key production challenges:

Micro-Dose Accuracy

Small-volume bottles demand ±0.5% dosing accuracy. Our servo and peristaltic systems deliver reliable micro-doses, reducing human error.

Preventing Dripping and Cross-Contamination

Precision nozzles prevent dripping or stringing. Enclosed filling zones and laminar airflow reduce airborne contamination, keeping products safe and clean.

Maintaining Sterility at Higher Speed

High-speed production often risks exposure. Our enclosed aseptic filling systems, stainless steel contact surfaces, and optional airflow solutions maintain sterility even at peak line speeds.

Handling Multi-SKU and Bottle Sizes

Switching between formulas or bottle sizes can be challenging. King Pack lines feature modular designs and quick-changeover mechanisms. Operators can adjust bottles and liquid types without disrupting production or reducing accuracy.

How King Pack Supports Veterinary Packaging Automation

We provide turnkey solutions for veterinary manufacturers, combining precision, hygiene, and efficiency.

GMP-Oriented Equipment Design

All product-contact parts are stainless steel. Enclosed chambers and smooth surfaces make cleaning fast and simple. CIP/SIP readiness ensures compliance with veterinary GMP standards.

High-Precision Filling Control

Our machines use servo and peristaltic technology to achieve ±0.3–0.5% dosing accuracy. Integrated monitoring ensures consistent fill levels, dropper insertion, and cap torque.

Turnkey Veterinary Production Lines

We offer fully integrated lines that include filling, dropper insertion, capping, labeling, and cartoning. Lines can be customized for small or large batch production and accommodate multiple bottle sizes and formulations.

Benefits for our clients:

- Faster production with fewer operators

- Consistent micro-dosing accuracy

- Reduced contamination risk

- Flexible lines for multi-SKU production

Automatic Liquid Filling Machine – King Pack Machinery

Future Trends in Veterinary Drop Packaging Equipment

Several trends are shaping the next generation of veterinary drop lines:

Higher Automation and Smart Control

Machines with digital monitoring and remote control allow operators to track production in real time. Predictive maintenance reduces downtime and improves line reliability.

Compact Sterile Line Design

Smaller, more efficient lines reduce contamination risk and save space, making it easier to implement GMP-compliant production in limited facilities.

Flexible Manufacturing for Multiple Products

Modular designs allow manufacturers to handle multiple bottle sizes, liquid types, and viscosities without complex adjustments.

Digital Monitoring and Traceability

Integration with enterprise systems enables batch-level traceability, digital documentation, and automated reporting, simplifying audits and regulatory compliance.

Frequently Asked Questions (FAQ)

What are new GMP requirements for veterinary drop filling?

GMP standards now emphasize enclosed filling, micro-volume dosing accuracy, cleanable surfaces, and batch traceability.

How much efficiency improvement can automation bring?

Fully automated lines can improve efficiency by 30–35%, reduce labor, and lower reject rates.

Which filling technology suits pet deworming drugs?

Peristaltic pump systems are ideal for low-viscosity solutions, while servo piston systems are better for viscous or sensitive liquids.

Can one line handle multiple bottle sizes?

Yes. King Pack lines are designed for multi-SKU production with quick changeovers between bottle sizes and formulations.

How to maintain sterility in automated veterinary filling?

Enclosed filling zones, stainless steel product paths, CIP/SIP-ready systems, and optional laminar airflow help maintain sterility at high speed.

Closing Perspective

Veterinary drop packaging continues to move toward higher automation, stricter GMP compliance, and smarter production control. Manual systems no longer support the scale, accuracy, or hygiene the market expects. At King Pack, we design veterinary drop packaging equipment that supports this shift. Our automated filling lines improve efficiency, protect product quality, and help manufacturers grow with confidence.