The global tube packaging market reached $9.91 billion in 2020 and is projected to hit $16.11 billion by 2028, growing at a 6.2% CAGR. Within this expanding market, manufacturers face a critical decision: selecting the right tube material and compatible filling technology.

Aluminum tubes and plastic laminated tubes dominate modern packaging across toothpaste, cosmetics, and pharmaceutical applications. Each material demands specific filling and sealing approaches. Understanding these differences guides equipment investment decisions that impact production efficiency, product quality, and long-term profitability.

Why Tube Material Selection Matters in Modern Packaging

Tube material choice affects multiple aspects of manufacturing operations. The wrong selection creates production inefficiencies, product protection failures, and unnecessary equipment costs.

Material properties determine sealing technology requirements. Aluminum tube filling machines use folding mechanisms while plastic laminated tube filling machines employ heat-sealing systems. These technologies cannot interchange without equipment modifications.

Product shelf life depends heavily on barrier properties. Sensitive formulations require protection from oxygen, light, and moisture. Material selection directly impacts how long products maintain stability and efficacy.

Consumer experience varies between materials. Squeeze characteristics, dispensing control, and tube recovery differ significantly. Brand perception connects to packaging quality and functionality.

Recommended Reading: How To Fill Toothpaste Tubes Using Tube Filling Machine? – King Pack Machinery

Overview of Common Tube Materials

Two primary tube materials serve the majority of packaging applications across industries.

What Is an Aluminum Tube?

Aluminum tubes are manufactured through an impact extrusion process using aluminum slugs. This method produces a seamless tube body with uniform wall thickness and no longitudinal seams. The seamless structure allows aluminum tubes to withstand folding and crimping forces without unpredictable deformation.

Aluminum provides a complete barrier to external elements. Light, oxygen, moisture, and gases cannot penetrate the tube wall, which makes aluminum suitable for products that require long shelf life or protection from oxidation. For toothpaste formulations with sensitive active ingredients, this barrier performance remains a key advantage.

From a sustainability perspective, aluminum has a well-established recycling infrastructure. Aluminum can be recycled repeatedly without degrading material quality, and recycled aluminum requires significantly less energy than primary aluminum production. This supports circular economy goals when proper collection systems are in place.

Key characteristics of aluminum tubes:

- Seamless construction from impact extrusion

- Absolute barrier to air, moisture, light, and gases

- High rigidity for reliable folding and crimp sealing

- Long shelf-life protection for sensitive formulations

- Fully recyclable with major energy savings during recycling

What Is a Plastic Laminated Tube?

Plastic laminated tubes are composite tubes created by bonding multiple material layers into a single wall structure. These layers work together to provide strength, barrier protection, sealing compatibility, and surface quality for printing. Most laminated tubes contain between five and eleven layers, depending on the performance requirements.

Laminated tubes differ from aluminum in how they behave during use. They are flexible and recover their shape after squeezing, which improves consumer experience. Their layered structure also allows manufacturers to tailor barrier performance and aesthetics without relying on solid metal walls.

Two laminate formats dominate toothpaste packaging. Aluminum Barrier Laminate (ABL) tubes use a thin aluminum foil layer to enhance protection. Plastic Barrier Laminate (PBL) tubes rely on EVOH or PET layers instead of metal, enabling lighter weight and improved recyclability within plastic streams.

Market adoption of laminated tubes continues to rise due to lower material cost, branding flexibility, and compatibility with high-speed tube filling lines.

Key characteristics of plastic laminated tubes:

- Multi-layer composite structure with functional layers

- Flexible body that rebounds after squeezing

- Available as ABL (foil-based) or PBL (plastic barrier) formats

- Strong print quality for branding and decoration

- Lower weight and material usage compared to aluminum

Key Differences Between Aluminum and Plastic Laminated Tubes

Understanding material distinctions guides appropriate technology selection for tube filling and sealing operations.

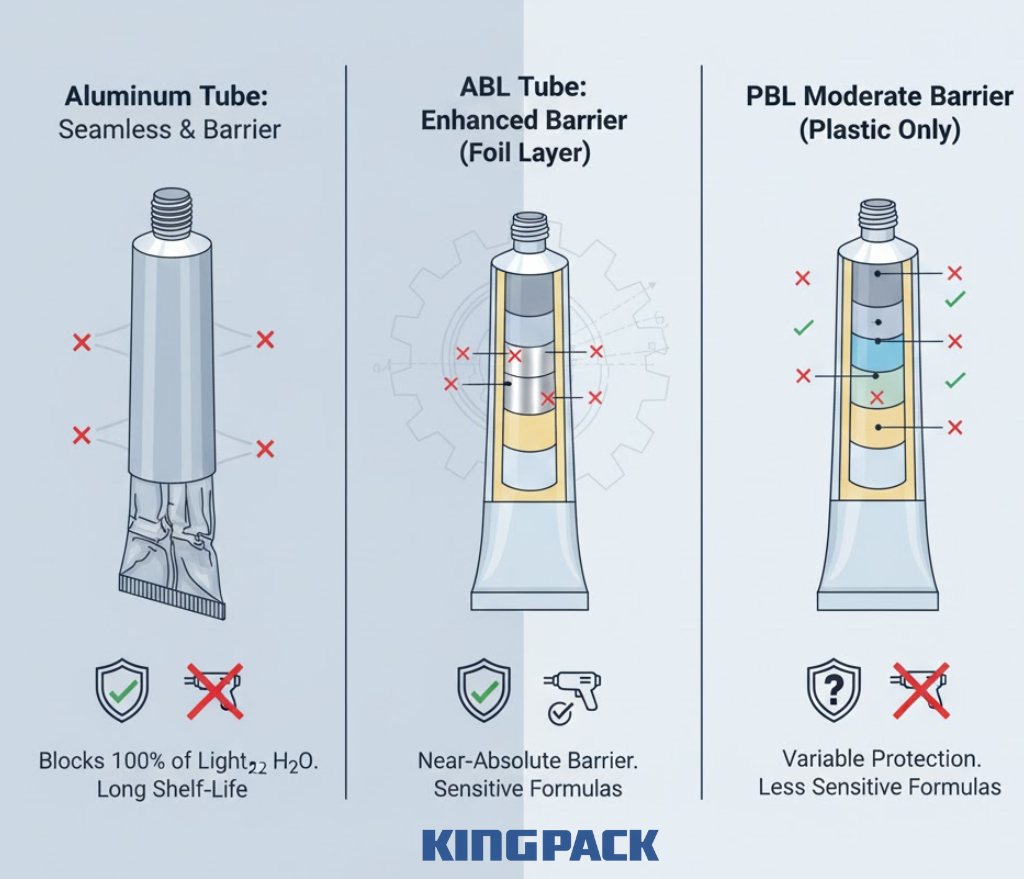

Barrier Properties and Product Protection

Aluminum tubes provide absolute barrier protection. The metal structure blocks 100% of light transmission, oxygen permeation, and moisture transfer. Products inside aluminum tubes maintain stability for extended periods.

Laminated tubes offer variable barrier performance based on construction. ABL tubes with aluminum foil layers approach aluminum tube protection levels. PBL tubes provide moderate barrier properties suitable for less sensitive formulations.

Testing demonstrates that ABL tubes are preferred for highly sensitive formulations requiring enhanced light, oxygen, and vapor protection such as medicated gels and premium skincare products.

Flexibility and Consumer Experience

Plastic laminated tubes exhibit superior flexibility. They squeeze easily and maintain shape throughout use. Consumers appreciate consistent dispensing control from first use to final squeeze.

Aluminum tubes resist deformation initially but crease permanently once bent. This characteristic creates visible use marks. Some consumers prefer this tactile feedback indicating product consumption.

Product evacuation differs between materials. Laminated tubes allow near-complete product removal through flexibility. Aluminum tubes may retain small amounts in corners despite collapsing.

Branding, Printing, and Appearance

Laminated tubes excel in graphics capabilities. The plastic outer layer accepts high-definition printing, vibrant colors, and complex designs. Digital printing allows 360-degree graphics with invisible seam lines.

Aluminum tubes accommodate offset printing, screen printing, and hot stamping. Graphics quality is excellent but substrate limitations exist. The metallic appearance creates premium perception that certain brands desire.

Surface finishing options vary. Laminated tubes offer matte, glossy, soft-touch, and metallic effects. Aluminum tubes provide natural metal appearance or color coating options.

Sustainability and Recycling Considerations

Aluminum tubes are 100% recyclable through established metal recycling streams. The material recycles infinitely without quality degradation. Recycling aluminum requires only 5% of the energy needed for primary production.

Traditional ABL tubes present recycling challenges due to multi-material construction. However, production expenses for laminate tubes are typically 15-20% greater than standard polyethylene tubes. Recent innovations focus on mono-material PBL tubes that improve recyclability while maintaining barrier performance.

Europe produces approximately 35% aluminum tubes, 25% plastic tubes, and 40% laminate tubes. This distribution reflects both material advantages and regional recycling infrastructure capabilities.

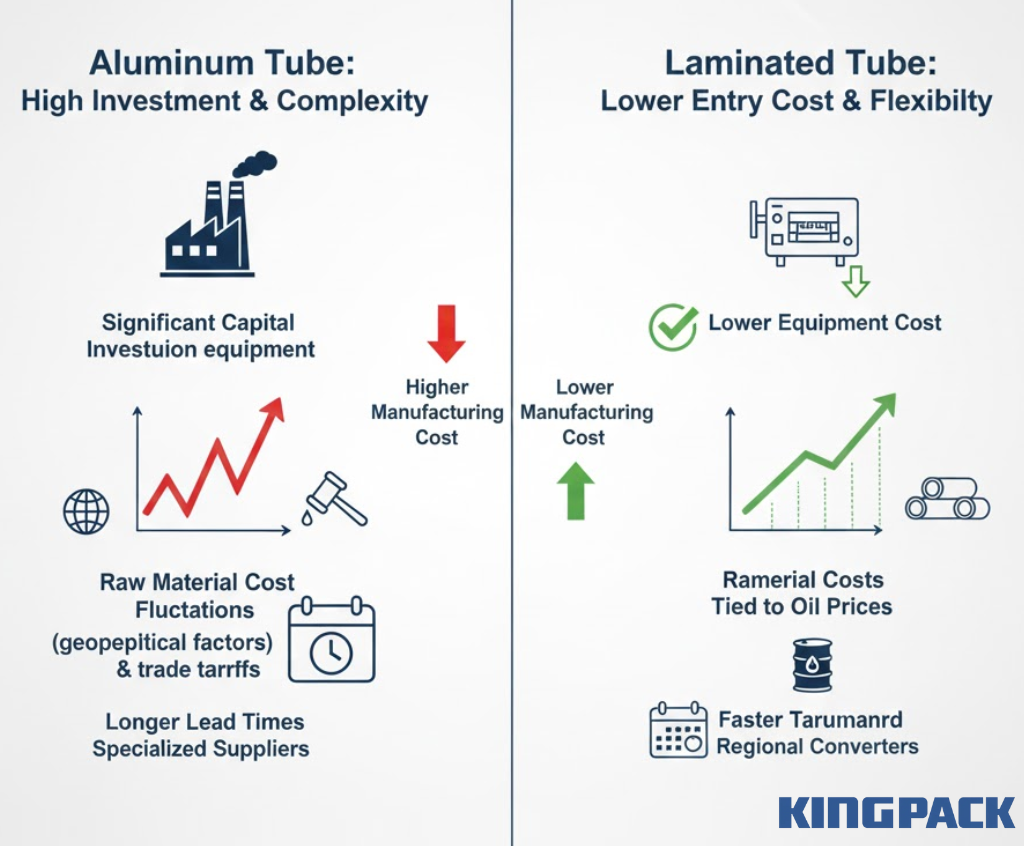

Cost and Supply Chain Factors

Raw material costs fluctuate differently between tube types. Aluminum prices respond to geopolitical events, trade tariffs, and supply chain disruptions. Plastic resin costs correlate directly with crude oil prices.

Manufacturing costs differ substantially. Aluminum tubes require impact extrusion equipment representing significant capital investment. Laminated tube production uses converting machinery with lower entry costs.

Supply chain complexity varies. Aluminum tubes source from specialized suppliers with longer lead times. Laminated tubes often come from regional converters offering faster turnaround and smaller minimum orders.

Recommended Reading: Top 10 Tube Filling Machine Manufacturers Today – Global Leaders in Tube Packaging Technology – King Pack Machinery

Filling Process Considerations for Different Tube Materials

Material properties influence filling accuracy, speed capabilities, and process stability.

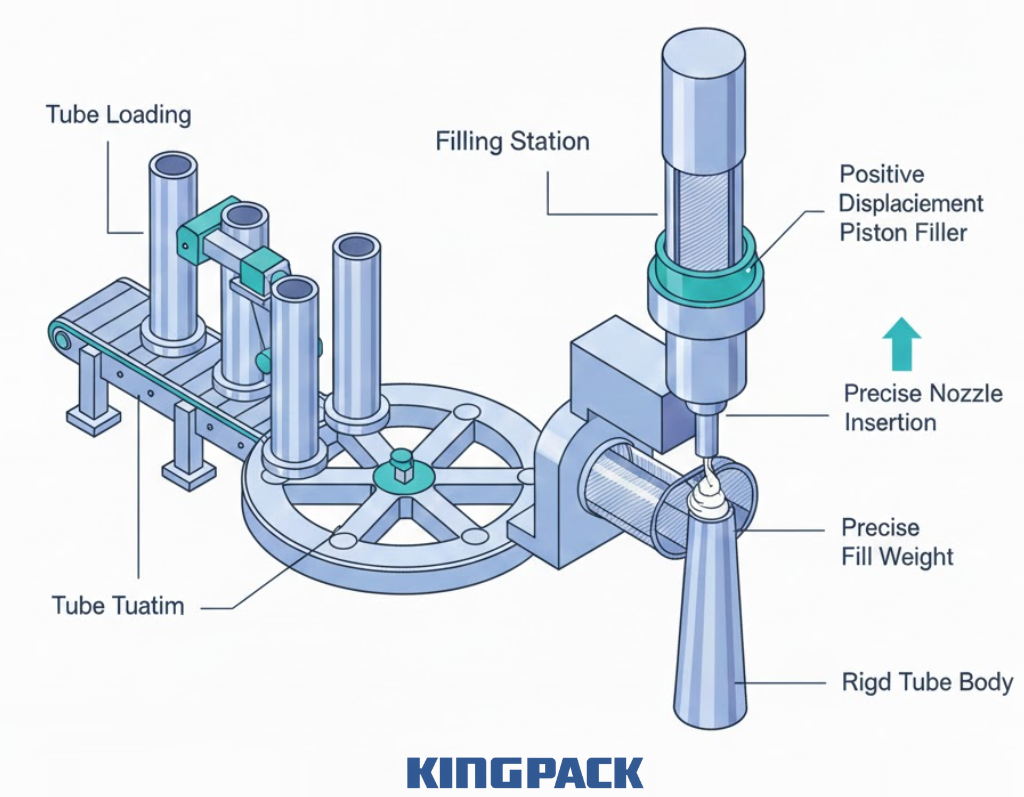

Filling Toothpaste and Ointments into Aluminum Tubes

Aluminum tube filling machines must accommodate rigid tube bodies. Tube loading systems position tubes vertically with openings upward. Filling nozzles insert into tube openings for precise product dispensing.

Viscous products like toothpaste require positive displacement filling systems. Piston fillers or pump fillers deliver accurate doses. Fill weights remain consistent across production runs.

Tube orientation stays fixed during filling. The rigid aluminum structure prevents deformation under filling pressure. This stability simplifies filling control compared to flexible alternatives.

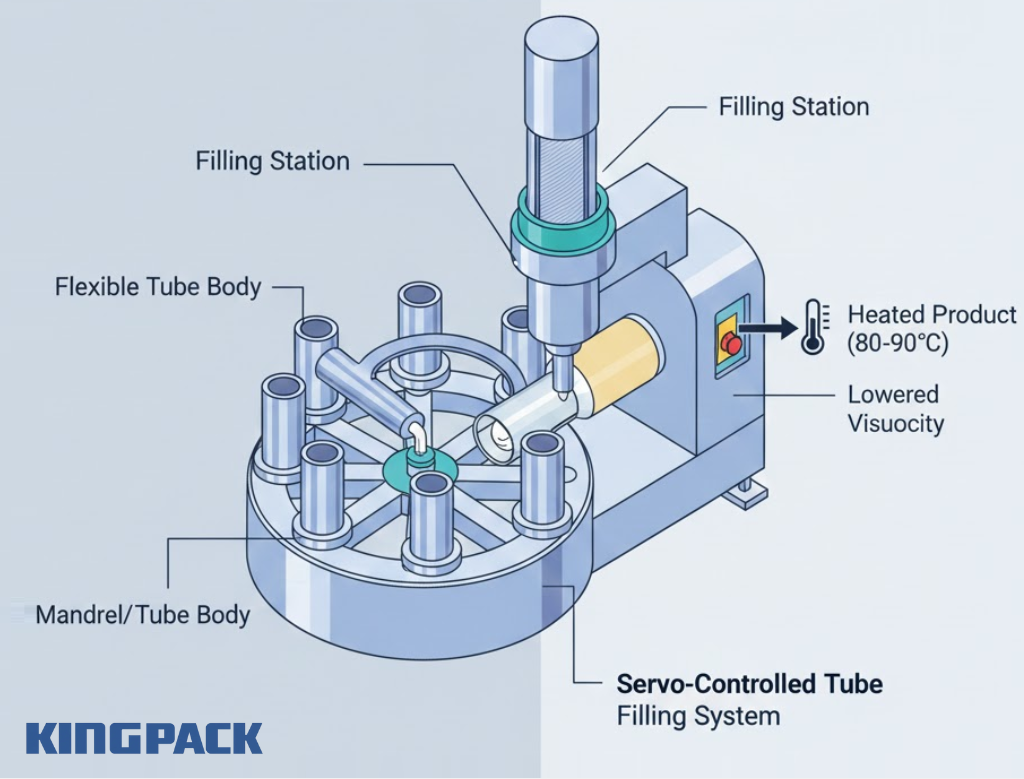

Filling Creams and Gels into Laminated Tubes

Plastic laminated tube filling machines handle flexible tube bodies that require support during filling. Mandrels or tube holders maintain tube shape while nozzles dispense product.

Filling pressure parameters differ from aluminum tubes. Excessive pressure deforms laminated tubes, affecting fill accuracy. Servo-controlled filling systems adjust pressure dynamically based on product viscosity and tube characteristics.

Product temperature affects filling performance. Heated product reduces viscosity for easier filling. Laminated tubes tolerate filling temperatures up to 80-90°C depending on layer composition.

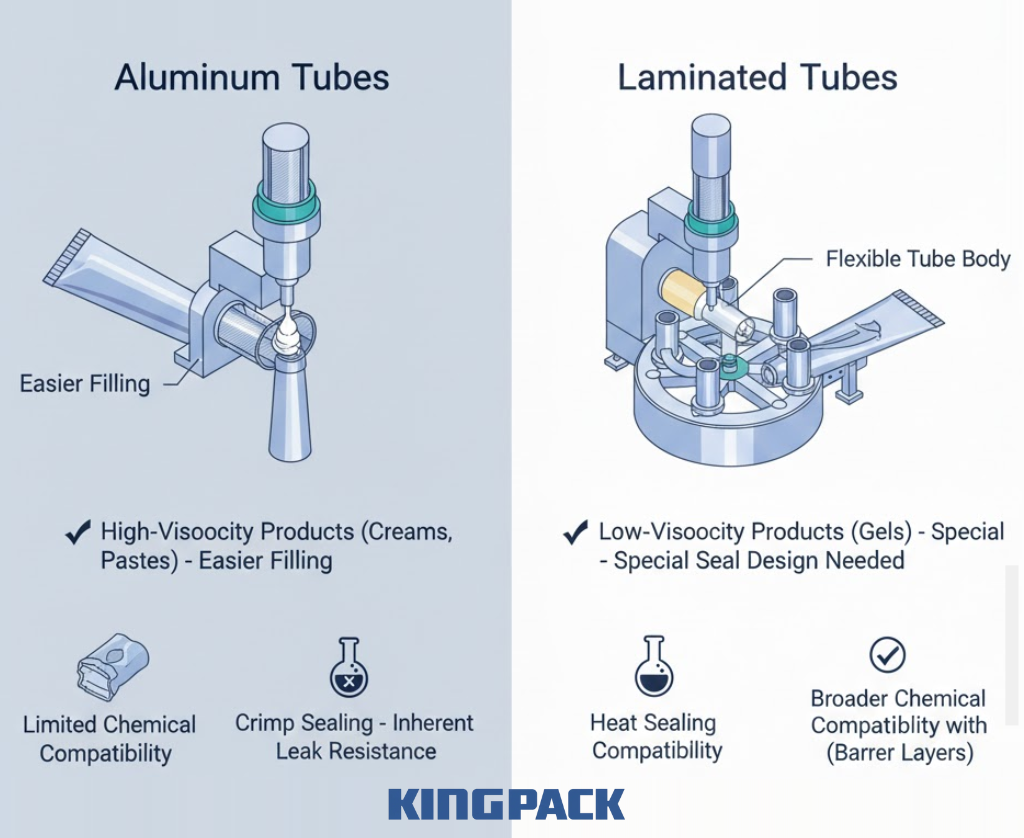

Product Viscosity and Material Compatibility

High-viscosity products (creams, ointments, pastes) fill well into both aluminum and laminated tubes. However, aluminum tube filling and sealing machines typically handle higher viscosity ranges more easily due to rigid tube structure.

Low-viscosity products (gels, serums, liquid formulas) require careful consideration. Laminated tubes with appropriate seal designs prevent leakage. Aluminum tubes provide inherent leak resistance through crimp sealing.

Chemical compatibility varies. Some aggressive formulations react with aluminum. Laminated tubes with barrier layers and protective inner coatings accommodate broader product ranges.

Sealing Technologies for Aluminum Tubes

Aluminum tubes require mechanical sealing methods that work with metal properties.

Folding and Crimping Sealing Technology

Aluminum tube folding machines create hermetic seals through mechanical deformation. The tube end folds repeatedly, compressing layers together. Pressure creates metal-to-metal contact that prevents product leakage.

This sealing method requires no heat or adhesives. The mechanical seal forms purely through force application. Properly executed folds create tamper-evident closures.

Folding equipment operates at high speeds. Production rates reach 60-120 tubes per minute depending on tube size and product characteristics.

Double Fold vs. Triple Fold Sealing

Double fold sealing creates two complete folds at the tube end. This approach provides adequate sealing for most applications. The seal profile remains relatively flat.

Triple fold sealing adds a third fold for enhanced security. Pharmaceutical applications often specify triple folds. The additional fold increases seal integrity and provides extra tamper evidence.

Fold geometry affects seal appearance and functionality. Precise fold control maintains consistent seal dimensions and appearance across production runs.

End Coding and Finishing for Aluminum Tubes

After sealing, tube ends receive batch coding and date marking. Inkjet or laser systems print required information directly on folded ends.

Trimming operations remove excess material for clean appearance. Cutting blades or trimming wheels create uniform tube lengths.

Final inspection systems verify seal quality, coding legibility, and overall tube appearance. Reject mechanisms remove defective tubes before packaging.

Sealing Technologies for Plastic Laminated Tubes

Laminated tubes require heat-based sealing that bonds plastic layers.

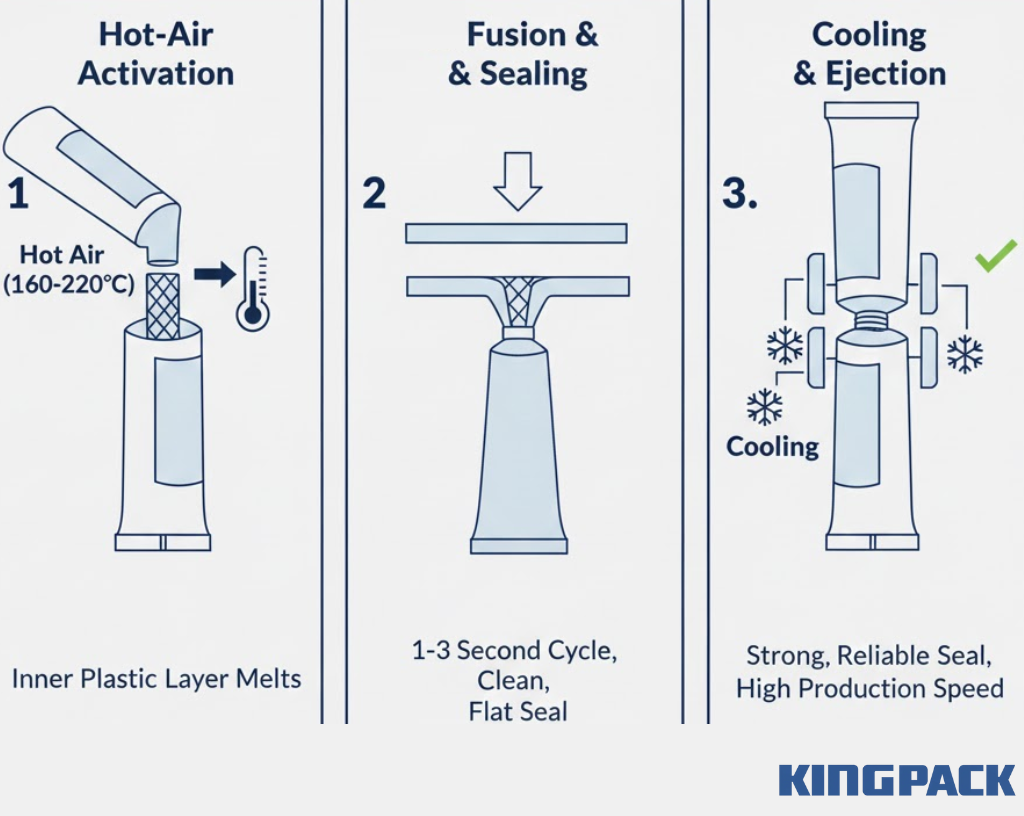

Hot-Air Internal Heating Sealing

Hot air tube sealing machines direct heated air inside tube ends. Temperature typically ranges from 160-220°C depending on laminate composition. The inner plastic layer melts and fuses under pressure.

Sealing time varies from 1-3 seconds. Shorter cycles increase production speed but require precise temperature control. Modern systems use servo-controlled heating and cooling for optimal results.

This method creates clean, flat seals with minimal material distortion. The seal strength withstands normal handling and distribution stresses.

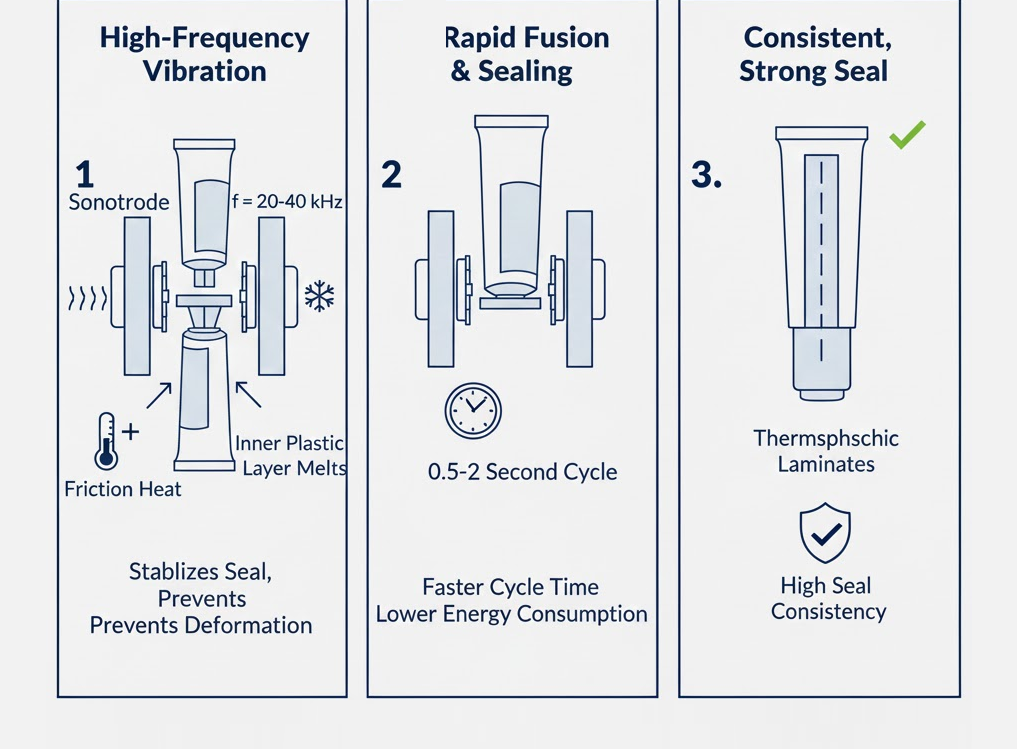

Ultrasonic Tube Sealing Technology

Ultrasonic sealing generates heat through high-frequency vibration rather than external heating. Ultrasonic energy (20-40 kHz) causes plastic molecules to vibrate and generate friction heat.

This technology offers faster cycle times than hot air sealing. Seal formation occurs in 0.5-2 seconds. Energy consumption decreases compared to resistance heating methods.

Recommended Reading: What Differentiates Tube Filling and Sealing Machine from Ultrasonic Tube Sealing Machine? – King Pack Machinery

Ultrasonic systems work exceptionally well with thermoplastic laminate structures. Seal consistency remains high across varying production conditions.

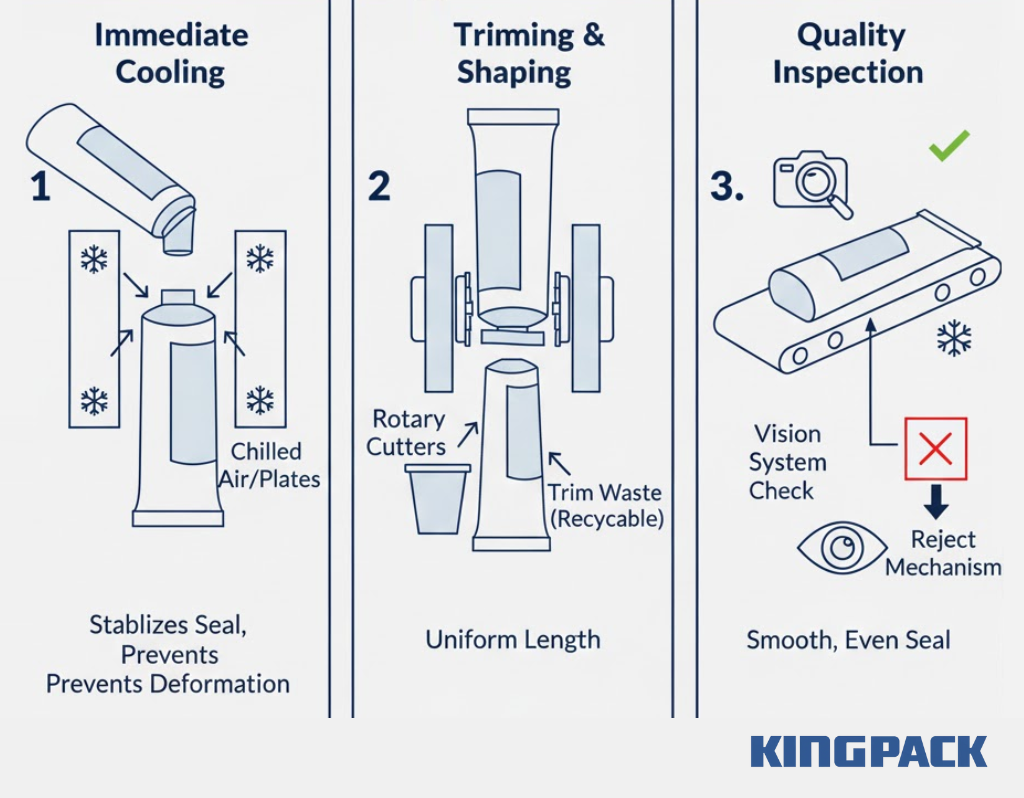

Cooling, Trimming, and Sealing Appearance Control

Immediate cooling stabilizes seals after heat application. Cooling stations use ambient air or chilled plates. This step prevents seal deformation and improves appearance.

Trimming removes excess material creating clean tube ends. Rotary cutters or guillotine blades produce uniform results. Trim waste collects for recycling when possible.

Seal appearance affects consumer perception. Smooth, even seals with consistent dimensions create quality impressions. Vision systems inspect seal quality automatically.

Equipment Differences in Tube Filling and Sealing Machines

Applications by Industry

In toothpaste and oral care, laminate tubes are the most common, while premium brands often prefer aluminum for perceived quality. King Pack’s equipment supports both materials efficiently.

In cosmetics and personal care, laminated tubes dominate for lotions, creams, and body products, while aluminum is used for luxury or specialty items. Both tube types coexist across cosmetic portfolios.

Pharmaceutical ointments and medical gels mostly use aluminum tubes to provide maximum barrier protection and tamper evidence.

King Pack’s machines meet pharmaceutical-grade standards. Industrial and chemical products like adhesives and sealants use both aluminum and laminated tubes, with material choice based on chemical compatibility and formulation needs.

How to Choose the Right Filling and Sealing Technology

Products with long shelf life typically require aluminum or ABL tubes, while laminated tubes suit moderate stability formulas. Here is how to choose the right filling and sealing technology:

- Product characteristics & shelf life: Aluminum tubes or ABL tubes for long shelf life; laminated tubes for moderate stability.

- Tube material strategy: Dedicated machines for single materials; dual-purpose machines for multi-material production.

- Production speed & automation: High-volume lines need fully automatic high-speed machines; medium-volume lines use standard automation.

- Budget, changeovers, expansion: Quick-change systems save downtime; modular designs allow future scaling.

Why King Pack Tube Filling and Sealing Solutions

King Pack’s dual-purpose machines accommodate both aluminum and laminated tubes through modular sealing units, eliminating duplicate investments. Changeovers take only 15–30 minutes with servo-controlled recipe recall, reducing errors and downtime.

Custom engineering and turnkey integration ensure smooth production, covering mixing, storage, filling, sealing, and downstream packaging. Global support includes installation, training, spare parts, and remote diagnostics.

King Pack’s solutions simplify tube production, improve efficiency, and reduce operational costs. Contact King Pack today to design a production line tailored to your specific toothpaste, cosmetic, pharmaceutical, or industrial product requirements.

Frequently Asked Questions (FAQ)

1. Can one machine handle both aluminum and plastic laminated tubes?

Yes, King Pack’s dual-purpose machines handle both tube types. Modular sealing units adapt to material requirements, giving flexibility without separate machines.

2. How long does changeover between tube materials take?

Quick-change systems complete changeovers in 15–30 minutes. Stored recipes and servo controls reduce manual adjustments and errors.

3. Which sealing technology is best for toothpaste?

Both hot air (laminated) and mechanical folding (aluminum) work effectively. King Pack machines manage paste viscosity reliably for either type.

4. Does sealing quality stay consistent after changeovers?

Yes. Verification protocols and vision inspection ensure seal integrity and consistent quality immediately after changeovers.

5. Can the machine integrate into a full production line?

Absolutely. King Pack systems connect with mixers, aging tanks, cartoning, and case packing equipment, coordinating material flow and production efficiency.

Conclusion

King Pack’s dual-purpose tube filling and sealing machines handle both aluminum and laminated tubes on a single platform. This reduces equipment duplication, lowers capital spend, and simplifies production planning across multiple SKUs. Modular sealing units, fast changeover, and automation support consistent filling accuracy and stable sealing with minimal downtime.

Turnkey lines integrate smoothly from mixing and storage through filling, sealing, and cartoning. With global installation support, operator training, and maintenance services, manufacturers maintain reliable operation and consistent product quality at scale.

Contact King Pack to improve packaging efficiency, increase throughput, and achieve stable, defect-free tube production tailored to your product range.