The global cartoning machines market is projected to grow to over $13.58 billion by 2034 at a compound annual growth rate of around 5.05 %. This growth reflects how manufacturers across industries recognize automated cartoning as essential for competitive operations.

For toothpaste manufacturers, cartoning represents the final critical step before distribution. High-speed cartoning machines transform production efficiency by eliminating manual bottlenecks, reducing labor costs, and improving packaging consistency.

This guide examines how these systems optimize toothpaste factory operations.

The Role of Cartoning in Toothpaste Manufacturing

Cartoning serves as the bridge between primary packaging and distribution. After tubes receive filling and sealing, they require protective cartons that display branding and product information. Manual cartoning limits production capacity and creates quality inconsistencies.

Workers folding cartons by hand, inserting tubes manually, and closing boxes individually cannot match machine speeds. This bottleneck forces filling lines to slow down or accumulate inventory between stages.

Automated cartoning eliminates these constraints. Machines form cartons, insert tubes, add instruction leaflets, and seal boxes continuously at speeds matching upstream equipment. King Pack integrates high-speed cartoning machines with toothpaste production lines, creating seamless material flow from mixing through final packaging.

Recommended Reading: Cartoning Machine vs Case Packer – King Pack Machinery

What Is a High-Speed Cartoning Machine?

A high-speed cartoning machine is automated equipment that forms, loads, and seals cartons at rates exceeding manual capabilities. These systems process 30-200 cartons per minute depending on configuration and product requirements.

Vertical Cartoning Machine – King Pack Machinery

Modern cartoning machines feature servo-driven controls, vision inspection systems, and programmable logic controllers (PLCs). This technology coordination produces consistent results while adapting quickly to different carton sizes and product configurations.

High-speed cartoners integrate with upstream filling equipment and downstream case packing systems. This integration creates continuous production flow that maximizes overall line efficiency. King Pack designs cartoning solutions that synchronize with existing toothpaste manufacturing equipment or as components of complete turnkey systems.

Common Cartoning Challenges in Toothpaste Factories

Traditional cartoning approaches create predictable problems that limit production efficiency.

Bottlenecks After Tube Filling & Sealing

Filling machines typically process 60-120 tubes per minute. Manual cartoning operations handle approximately 20-30 cartons per minute per worker. This speed mismatch creates immediate bottlenecks.

Filled tubes accumulate on conveyors waiting for cartoning. This accumulation requires additional floor space and creates inventory holding costs. Production schedules must accommodate manual cartoning limitations rather than optimizing filling line capacity.

High Labor Dependency

Manual cartoning requires multiple workers per shift. Each operator performs repetitive tasks: picking up pre-folded cartons, inserting tubes, adding leaflets, folding closure flaps, and moving completed cartons. This labor intensity creates several problems.

Labor availability affects production scheduling. Absenteeism directly reduces output. Training new workers takes time and impacts quality during learning periods. Fatigue over shift duration reduces speed and increases errors.

Carton Damage and Incorrect Insertion

Manual handling damages cartons through rough handling or incorrect folding. Bent corners, crushed panels, and poorly formed boxes create retail presentation problems. Customers perceive damaged packaging as product quality issues.

Tube insertion orientation matters for display and barcode scanning. Workers sometimes insert tubes backward or at incorrect angles. These errors require detection and correction, adding inspection labor and material waste.

Inconsistent Packaging Speed

Manual operations vary in speed throughout shifts. Workers start quickly but slow as fatigue increases. Break periods and shift changes interrupt production flow. This variability complicates production planning and capacity forecasting.

Inconsistent speeds create challenges coordinating with upstream and downstream equipment. Filling lines must adjust speeds to match manual cartoning rates, limiting overall throughput.

How High-Speed Cartoning Machines Improve Efficiency

Automated cartoning addresses each challenge systematically through mechanical precision and electronic control.

Increased Cartoning Speed and Output Capacity

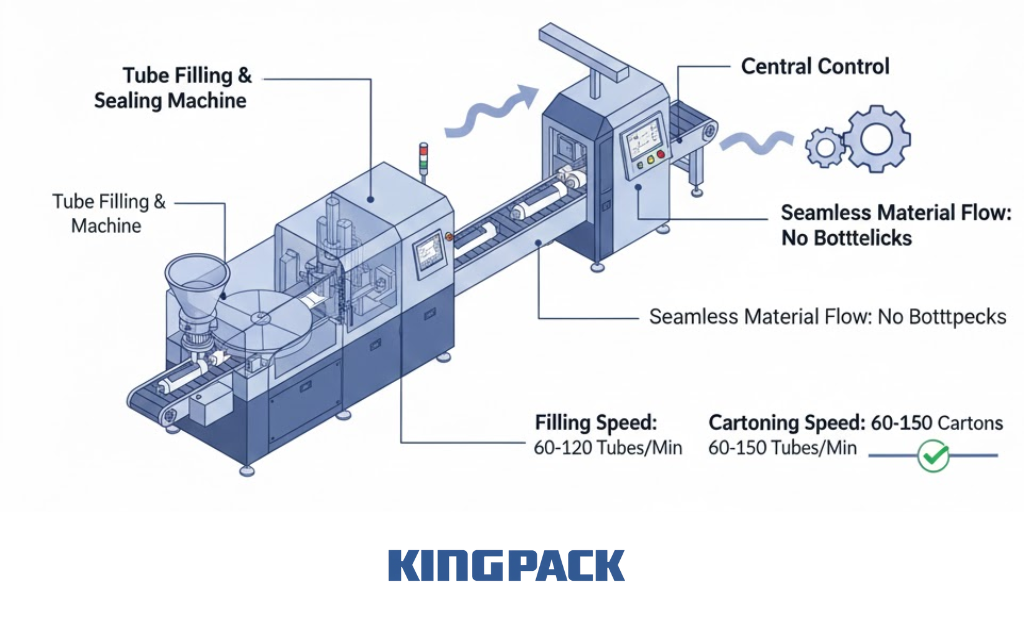

High-speed cartoners process 60-150 cartons per minute consistently. This capacity matches or exceeds filling line speeds, eliminating cartoning bottlenecks.

Production capacity calculations demonstrate dramatic improvements. A factory running two 8-hour shifts produces:The automatic system produces four times manual output with significantly lower labor requirements.

Reduced Manual Labor and Operating Costs

Automation typically reduces direct labor needs by 60-70%. One operator supervises multiple machines compared to multiple workers performing manual cartoning. This reduction creates substantial ongoing cost savings.

Research shows that one robotic system performs work equivalent to 2.6 employees. Beyond direct labor savings, automation eliminates overtime costs during peak production periods. Companies redirect workers to value-added tasks like quality monitoring and maintenance.

Stable, Continuous Operation

Automated systems maintain consistent speeds throughout shifts. Machines do not fatigue or require breaks. This stability simplifies production planning and improves schedule reliability.

Continuous operation capability extends productive time. Lines run through breaks and shift changes with minimal supervision. Only periodic maintenance requires line stops. This maximized uptime multiplies daily output.

Improved Packaging Accuracy and Consistency

Servo-driven motion control positions tubes precisely within cartons. Vision systems verify correct tube orientation before sealing. This precision eliminates insertion errors that manual operations cannot avoid.

Every carton receives identical forming, loading, and sealing. This consistency creates uniform retail presentation that reinforces brand image. Retailers prefer suppliers delivering consistent packaging quality.

Lower Product Rejection Rates

Automated systems detect and reject defective cartons before they enter the supply chain.

Vision inspection identifies:

- Missing or incorrectly positioned tubes

- Damaged cartons

- Missing instruction leaflets

- Improperly sealed closures

Early defect detection prevents shipping errors and customer complaints. Quality consistency improves while waste decreases.

Key Features of High-Speed Cartoning Machines for Toothpaste

Modern cartoning equipment incorporates specialized features that optimize toothpaste packaging operations.

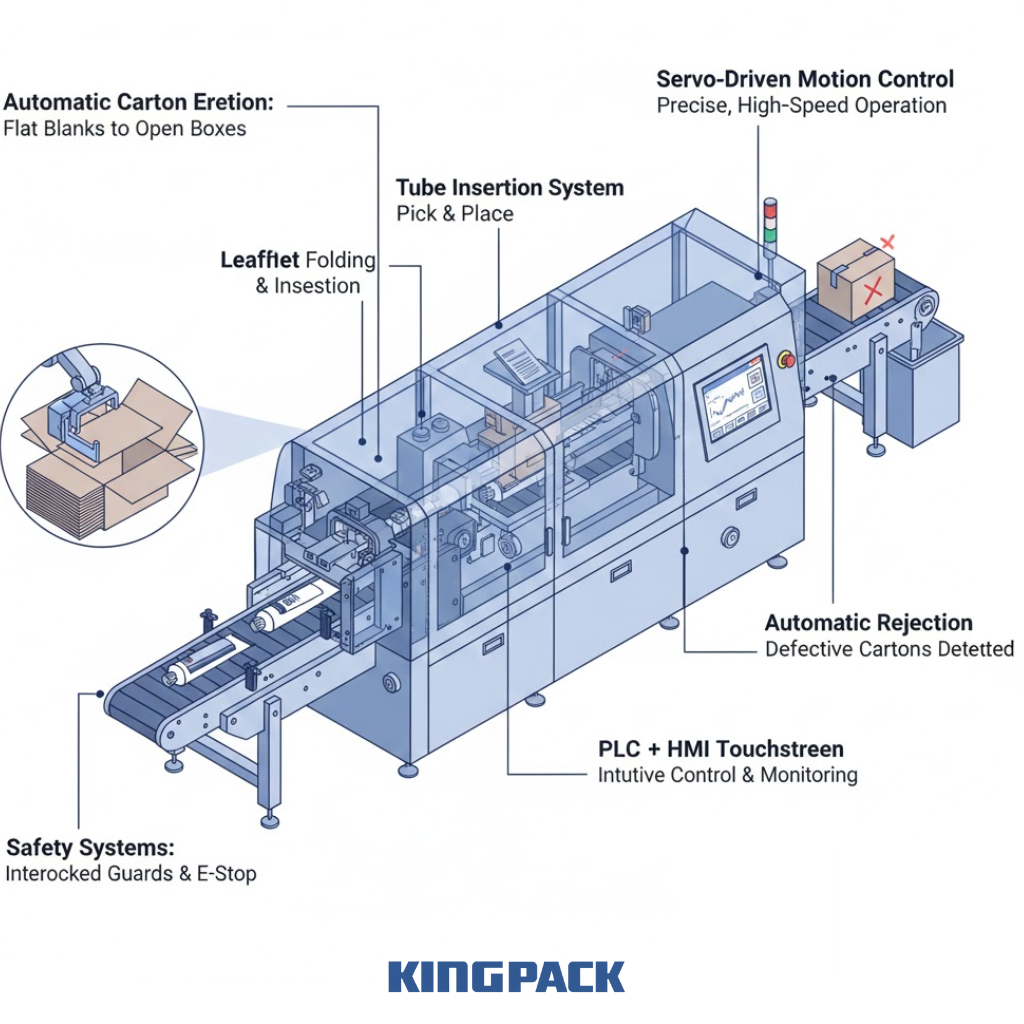

Automatic carton erection forms flat blanks into open boxes ready for loading. Magazine feeds hold carton blanks and dispense them sequentially. Vacuum cups and mechanical formers fold panels into proper configuration. This automation eliminates manual carton preparation labor.

Tube insertion systems use various mechanisms depending on production speed requirements. Pick-and-place robots handle tubes gently while maintaining high speeds. Pusher mechanisms work for simpler applications. Timing screws orient tubes consistently before insertion.

Leaflet folding and insertion integrates instruction sheet placement during cartoning. Automatic feeders fold printed materials and insert them synchronously with tube loading. This eliminates separate manual leaflet insertion operations.

Servo-driven motion control coordinates all machine movements precisely. Servo motors provide exact positioning for carton feeding, tube insertion, and closure operations. This precision maintains quality at maximum speeds.

Automatic rejection of defective cartons removes incomplete or improperly formed packages. Reject mechanisms divert bad cartons to collection bins without stopping the line. Operators address rejects during scheduled breaks rather than interrupting production.

PLC + HMI touchscreen operation simplifies machine control and monitoring. Operators adjust settings, view production statistics, and troubleshoot issues through intuitive interfaces. Recipe storage allows quick changeovers between different product configurations.

Safety guards and alarm systems protect operators while maintaining productivity. Interlocked guards prevent access during operation. Emergency stops halt machines instantly if problems occur. Alarm notifications alert operators to conditions requiring attention.

Integration with Toothpaste Filling and Sealing Lines

Cartoning efficiency depends heavily on integration with upstream and downstream equipment.

Synchronization with Tube Filling Machines

Speed matching prevents bottlenecks and accumulation. Modern cartoners feature variable speed drives that adjust automatically to filling line output. Communication protocols coordinate timing between systems.

King Pack designs integrated production lines where filling machines and cartoners operate as unified systems. Central control coordinates all equipment for optimal material flow.

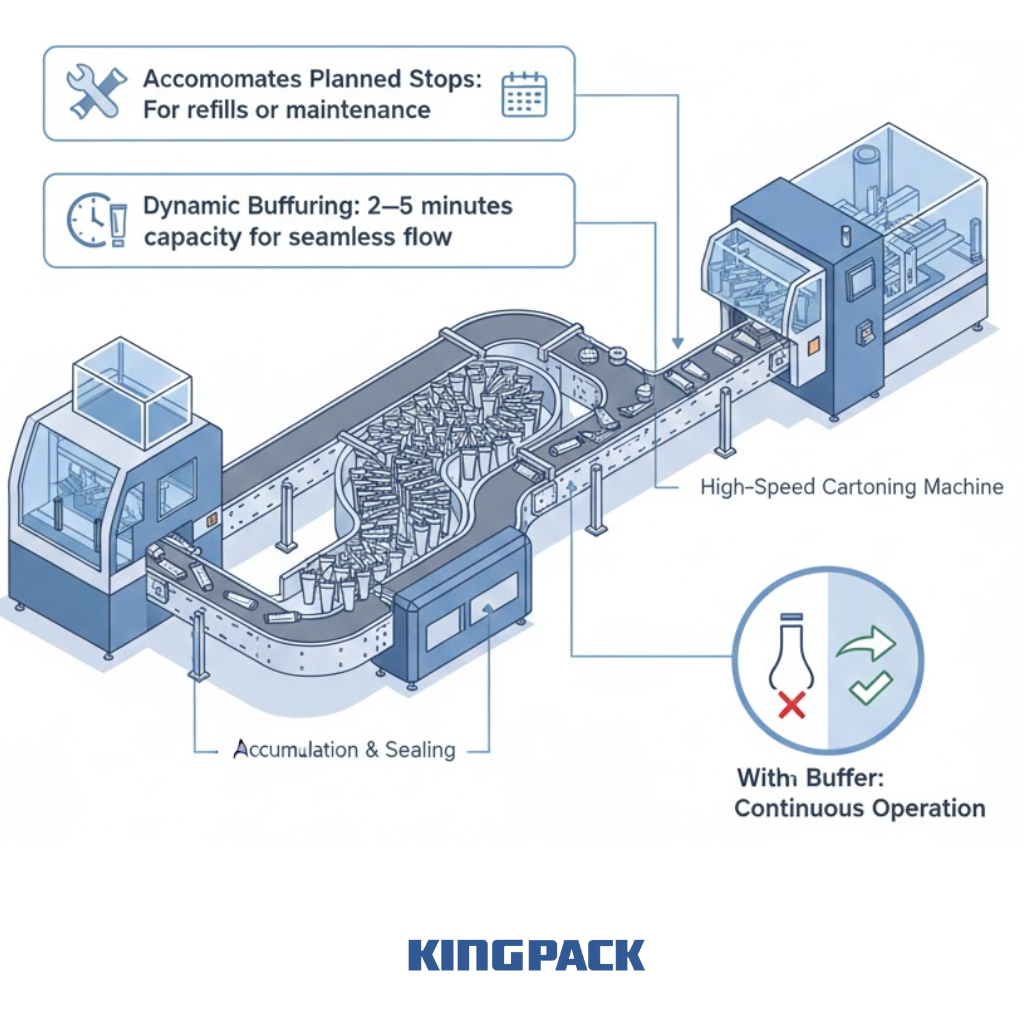

Inline Conveyor and Buffer Systems

Conveyors transport filled tubes from sealing machines to cartoning equipment. Buffer accumulation allows temporary speed differences without stopping either system. Dynamic buffering accommodates planned stops for carton magazine refills or maintenance.

Proper buffer sizing balances flexibility with floor space requirements. Typical systems include 2-5 minutes of buffer capacity.

Compatibility with Different Tube Sizes

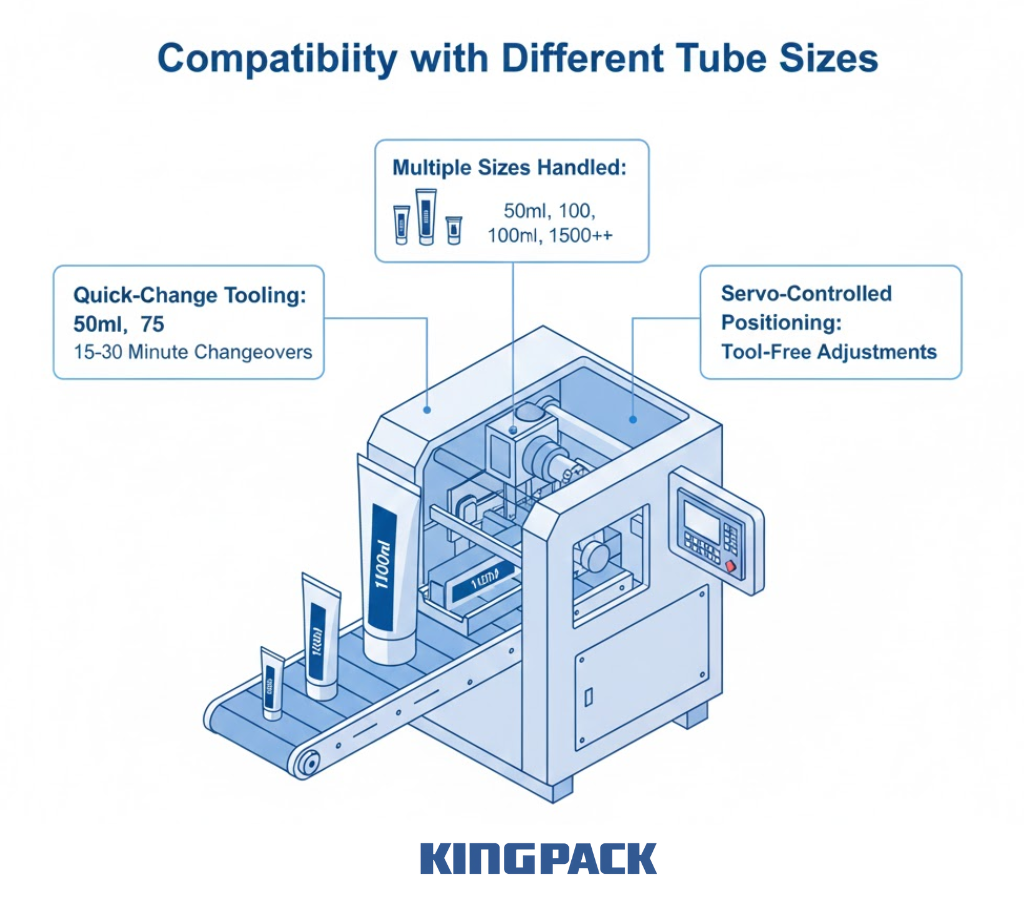

Toothpaste manufacturers produce multiple sizes: 50ml, 75ml, 100ml, 150ml, and family sizes. Quick-change tooling allows rapid conversion between sizes.

Modern cartoners feature tool-free adjustments for common size changes. Servo-controlled positioning eliminates manual measurements. Changeover times reduce from hours to 15-30 minutes.

Integration with Case Packing Systems

Downstream case packing collects multiple cartons into shipping containers. Automated case packers receive cartons from cartoning machines via conveyor. Robotic systems stack cartons in predetermined patterns.

Complete line integration extends automation through warehouse preparation. Palletizing systems build stable loads for distribution. This end-to-end automation maximizes labor efficiency.

Recommended Reading: Packaging Machine Solutions – King Pack Packaging Equipment – King Pack Machinery

Production Efficiency Metrics Improved by High-Speed Cartoners

Quantifiable measurements demonstrate cartoning automation benefits.

Throughput (Tubes per Minute)

Direct output measurement shows immediate capacity improvements. Manual operations typically achieve 20-30 tubes/minute. High-speed automatic cartoners reach 100-150 tubes/minute. This 3-5x throughput increase directly multiplies daily production capacity.

Overall Equipment Effectiveness (OEE)

OEE measures manufacturing productivity combining availability, performance, and quality. According to industry standards, 85% OEE is considered world-class for discrete manufacturers. Pharmaceutical packaging lines average around 30-48% OEE, with realistic targets in the 40-60% range.

High-speed cartoning improves OEE through multiple mechanisms:

| OEE Component | Manual Impact | Automated Impact |

| Availability | Reduced by breaks, absenteeism | Continuous operation capability |

| Performance | Variable speed, fatigue | Consistent maximum speed |

| Quality | Insertion errors, damage | Vision verification, precision |

Companies implementing automated cartoning typically see OEE improvements of 15-25 percentage points.

Labor Utilization

Labor metrics track worker deployment efficiency. Manual cartoning assigns 3-4 workers per line performing repetitive tasks. Automated systems require one supervisor monitoring multiple machines.

This shift allows worker redeployment to value-added activities. Quality inspection, maintenance, and process improvement receive dedicated attention. Labor costs decrease while remaining staff perform higher-value functions.

Downtime Reduction

Unplanned stops disrupt production schedules and reduce output. Manual operations experience downtime from worker breaks, material replenishment, and coordination delays. Automated systems minimize these interruptions.

According to the U.S. Bureau of Labor Statistics, the packaging industry shows approximately 3.2% annual growth through 2026, driven by automation adoption. Modern cartoners feature quick-change capabilities and predictive maintenance that reduce unplanned stops. Scheduled maintenance occurs during planned downtime rather than interrupting production.

Applications in Toothpaste & Oral Care Packaging

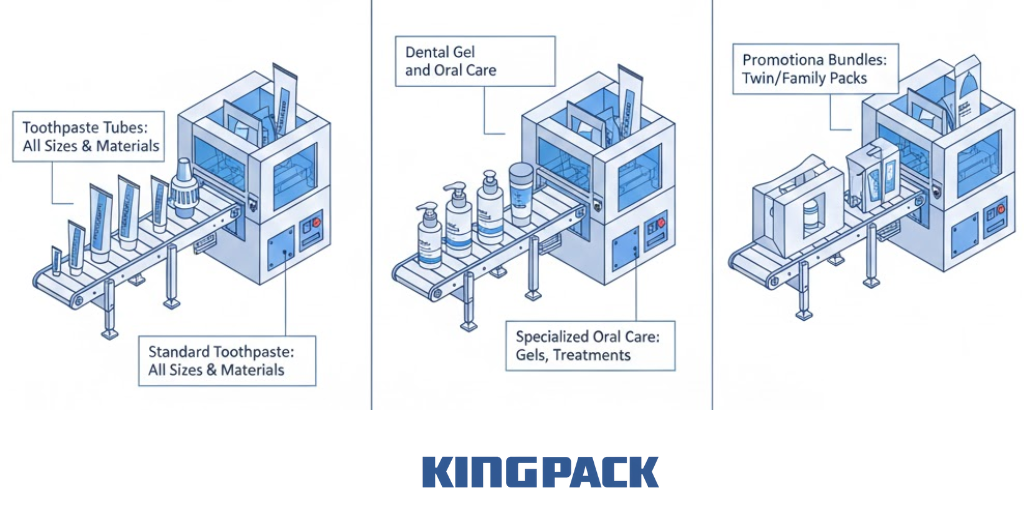

Cartoning machines serve diverse oral care product lines beyond standard toothpaste tubes.

Toothpaste Tubes

Standard toothpaste represents the primary application. Cartoners handle laminate tubes, plastic tubes, and aluminum tubes across all size ranges. Flexibility accommodates various tube materials and closures.

Dental Gel and Oral Care Products

Specialized oral care items require similar cartoning. Dental gels, desensitizing treatments, and prescription fluoride products use identical cartoning processes. Equipment versatility reduces capital investment needs.

Multi-Pack and Promotional Packaging

Promotional offerings often bundle multiple tubes. Cartoning systems accommodate twin-packs, family packs, and promotional bundles. Adjustable tooling handles various bundle configurations without dedicated equipment.

Recommended Reading: What Differentiates Tube Filling and Sealing Machine from Ultrasonic Tube Sealing Machine? – King Pack Machinery

How to Choose the Right Cartoning Machine for a Toothpaste Factory

Proper equipment selection matches machine capabilities to production requirements.

Matching Speed with Filling Line Capacity

Cartoning speed must meet or exceed filling machine output. Undersized cartoners recreate manual bottlenecks despite automation. King Pack analyzes complete production line capacity during equipment specification.

Buffer systems accommodate temporary speed differences. Plan cartoning capacity 10-15% above filling line output for optimal flow.

Carton Size Flexibility

Product line diversity requires handling multiple carton sizes. Evaluate changeover requirements between sizes. Quick-change tooling reduces conversion downtime from hours to minutes.

Consider future product development. Equipment capable of handling larger cartons than currently needed provides expansion flexibility.

Automation Level and Expansion Capability

Automation levels range from semi-automatic to fully automatic with integrated robotics. Initial investment scales with automation degree. Balance capital costs against labor savings and production requirements.

Modular designs allow future capability additions. Start with core automation and add features like case packing or palletizing as production grows.

Compliance with GMP and Safety Standards

Toothpaste falls under cosmetic or OTC drug regulations depending on formulation. Equipment must meet applicable Good Manufacturing Practice standards. Stainless steel construction, sanitary design, and documentation packages support regulatory compliance.

Safety certifications (CE marking, UL approval) validate proper design. Interlocked guards, emergency stops, and safety circuits protect operators.

Why Choose King Pack High-Speed Cartoning Machines

King Pack brings specialized expertise to toothpaste packaging with proven cartoning solutions.

Proven Integration with Toothpaste Production Lines

King Pack supplies complete toothpaste manufacturing systems including mixing, filling, sealing, and cartoning equipment. This comprehensive approach guarantees equipment compatibility.

System integration experience translates to seamless installation and startup. All equipment operates as unified production lines rather than disconnected machines.

Custom Engineering and Turnkey Solutions

Every toothpaste manufacturer has unique requirements. King Pack provides custom engineering that matches specific production needs. Capacity sizing, product handling, and facility layout receive individual attention.

Turnkey delivery includes equipment design, manufacturing, installation, and commissioning. Single-source responsibility simplifies project management and accelerates implementation.

Reliable After-Sales Service and Global Support

Equipment performance depends on ongoing support. King Pack maintains service networks across major manufacturing regions. Installation teams handle setup and operator training.

Long-term support includes spare parts supply, remote diagnostics, and periodic maintenance visits. Technical teams remain available throughout equipment lifetime.

Frequently Asked Questions (FAQ)

1. What is the maximum cartoning speed?

King Pack cartoning machines handle 30–150 cartons per minute depending on configuration, carton size, and tube dimensions. Custom high-speed systems can exceed 200 cartons per minute for large-scale operations.

2. How long do changeovers take?

Tool-free quick-change systems allow changeovers in 15–30 minutes using stored PLC recipes. Initial setup for new products may take 1–2 hours, but subsequent changes are much faster.

3. Can cartoners integrate with existing filling lines?

Yes, King Pack designs systems to work with most filling and sealing machines. Conveyor interfaces, speed matching, and control communication ensure seamless integration with existing lines.

4. What maintenance and spare parts support is available?

Preventive maintenance includes daily inspections, weekly lubrication, and quarterly servicing. Comprehensive spare parts kits are supplied, and critical components ship quickly from regional warehouses. Service contracts provide scheduled maintenance visits and priority technical support.

5. How is operator training handled?

Training is provided during installation and commissioning, covering machine operation, routine maintenance, troubleshooting, and safety. Hands-on sessions continue until operators demonstrate full competency, with follow-up training available as needed.

Conclusion

High-speed cartoning significantly boosts toothpaste production efficiency, reduces labor requirements, and ensures consistent, high-quality packaging. King Pack’s turnkey solutions combine precision engineering, seamless integration with existing filling lines, and robust automation to maximize throughput while minimizing downtime.

Our global support network, comprehensive training programs, and readily available spare parts ensure reliable operation over the long term. Choosing King Pack means gaining a partner that helps optimize your production workflow, maintain regulatory compliance, and scale efficiently as demand grows.

Contact King Pack today to upgrade your toothpaste production line and achieve consistent, defect-free results at every stage.