Pharmaceutical emulsion mixer machines, especially vacuum emulsifying mixer systems, are now essential for making stable creams, ointments, and injectable emulsions. They provide precise and repeatable quality. The global vacuum emulsifying mixer market is worth about USD 650–700 million in 2024. It is expected to exceed USD 1.1–1.2 billion by the early 2030s. The market grows by 5–6% each year, mainly driven by pharmaceutical and cosmetic uses. This increase shows that regulations require homogeneous, contamination-free formulations. Also, the global growth of high-value pharma and biopharma production drives demand. Advanced vacuum emulsifying mixers are a strategic investment for competitive, GMP-compliant manufacturing.

What is a Pharmaceutical Emulsion Mixer Machine?

A pharmaceutical emulsion mixer machine is a jacketed mixing vessel with an agitator, a high-shear rotor–stator homogenizer, a vacuum system, and a process control unit. It is designed to mix immiscible phases like oil and water into fine, stable emulsions. Typical pharma systems offer working capacities from 5 L for R&D to 5,000 L or more for production, handling viscosities up to 50,000–100,000 cps depending on model.

Key Components of the Emulsion Mixer Machine

- Main emulsification tank (usually SS316L, jacketed for heating and cooling).

- Oil phase and water phase pre‑mix pots for separately melting or dissolving oil‑ and water‑soluble ingredients.

- Anchor or frame agitator with scrapers to move high‑viscosity product and prevent dead zones.

- High‑shear rotor–stator homogenizing head (bottom or inline) operating typically at 2,800–3,500 rpm.

- Vacuum pump and sealed dome to achieve vacuum levels around −0.08 to −0.1 MPa for defoaming and dust‑free powder loading.

- Heating/cooling jacket (steam, electric, or thermal oil), temperature sensors, and control valves.

- PLC control panel and HMI with frequency inverters for variable speed control, recipe storage, and process monitoring.

How Does an Emulsion Mixer Machine Work?

An emulsion mixer machine combines controlled agitation, high-shear mixing, a temperature control system, and often a vacuum homogenizer. These parts create stable emulsions with fine, uniform droplet sizes and reduce particle size effectively. The jacket heating system and cooling circuit keep the product at the right viscosity during emulsification. Internal mixing blades move material through the high-shear zone continuously for consistent homogenization.

The Agitation Process (Anchor Agitator)

The anchor agitator is the low‑speed mixing element that sweeps the vessel wall with attached mixing blades and scrapers, promoting top‑to‑bottom circulation and even heat transfer from the jacket heating system. By keeping the bulk phase uniform in temperature and composition, the anchor agitator pre‑disperses ingredients so the homogenizing mixer can work on a well‑mixed feed, which improves final droplet sizes and emulsion stability.

The Homogenization Process (Rotor‑Stator Homogenizer)

At the heart of the vacuum homogenizer is the rotor-stator assembly, often mounted at the bottom or in‑line with the main vessel. It provides the high‑shear step that defines the emulsification process. The rotor spins at high speed inside the stator, forcing product through narrow gaps where intense shear and turbulence break droplets and agglomerates, driving particle size reduction typically into the micron range. Continuous recirculation through the workhead produces a narrow droplet-size distribution and high homogenization efficiency. The temperature control system keeps the product within the best processing range.

The Contra‑Mixing System

Many production mixers use a contra‑mixing system, where the anchor agitator and internal counter‑flow elements rotate in opposite directions. This creates complex flow paths that eliminate dead zones and constantly feed fresh material into the rotor‑stator zone. The interaction between the contra‑rotating mixing blades and the high‑shear head ensures that all regions of the batch experience a similar shear history, further tightening droplet sizes and improving batch‑to‑batch consistency.

Product Discharge (Transfer Pump Function)

After the emulsification process reaches the target viscosity and droplet‑size profile, the batch is cooled to its final setpoint using the temperature control system, then discharged. In many designs, the rotor‑stator head doubles as a transfer pump, or a separate sanitary transfer pump is connected to the bottom outlet to move product to holding tanks or filling lines. Gentle agitation usually continues during discharge to keep the emulsion homogeneous from the first liter to the last. This preserves the particle size distribution made by the vacuum homogenizer and homogenizing mixer.

Applications of the Vacuum Emulsifying Mixer

Pharmaceuticals (ointments, dental composites, syrups, injections)

Vacuum emulsifying mixers are widely used to manufacture dermatological ointments, gels, and creams, as well as ophthalmic and dental pastes, syrups, and certain injectable suspensions. The vacuum function removes trapped air, which improves sterility, dosing accuracy, and patient comfort. High-shear mixing ensures even distribution of active pharmaceutical ingredients.

Food Applications (mayonnaise, dressing, jam, butter, margarine)

In the food industry, these mixers process high‑viscosity emulsions such as mayonnaise, salad dressings, sauces, jams, spreads, and margarine. Controlled shear and temperature help achieve consistent texture, flavor release, and microbial stability while vacuum degassing limits oxidation and foaming.

Toiletries and Cosmetics (cream, lotion, wax, mascara, gel, toothpaste)

Cosmetic and personal‑care plants use vacuum emulsifying mixers for lip gloss, facial creams, liquid soap, body lotions, sunscreens, hair masks, waxes, mascaras, gels, and toothpaste. These systems deliver smooth, glossy, air‑free products with reproducible rheology, which is critical for application feel, packaging performance, and shelf life.

Chemical Products (polyester, synthetic fiber, shoe cream)

In the chemical industry, mixers handle waxes, lubricants, shoe creams, polyester additives, and synthetic‑fiber finishes that require high‑shear dispersion under controlled conditions. The ability to work under vacuum and at elevated temperatures makes them suitable for reactive systems or sensitive ingredients.

Emulsifier Mixer Machine Advantages

Effective Heating

Jackets with two layers allow precise heating and cooling using steam, hot water, or thermal oil, often with temperature control within ±1–2 °C. Efficient heat transfer across the scraped wall minimizes hot or cold spots, reducing process time and ensuring consistent physical properties.

High‑Performance Homogenizer & Mixer

Triple‑action systems (anchor plus high‑shear head, sometimes with inline recirculation) can process materials with viscosities up to about 50,000 cps and, in some designs, 100,000 cps. Emulsification speeds up to about 3,500 rpm, enabling rapid droplet size reduction and short batch times, improving throughput and energy efficiency.

Hydraulic Lifting System

Many production‑scale machines include a hydraulic lift to raise the vessel lid for cleaning, inspection, and tool change, improving ergonomics and safety. This feature also facilitates maintenance on the agitator and homogenizer without full disassembly of the tank.

Advanced Control System

Modern vacuum emulsifying mixers use Siemens PLC Touch Screen and HMI panels with frequency inverters to adjust agitator and homogenizer speeds, process time, temperature, and vacuum level. Recipe management, batch data logging, and alarm functions support cGMP documentation and reproducible scale‑up from lab to production.

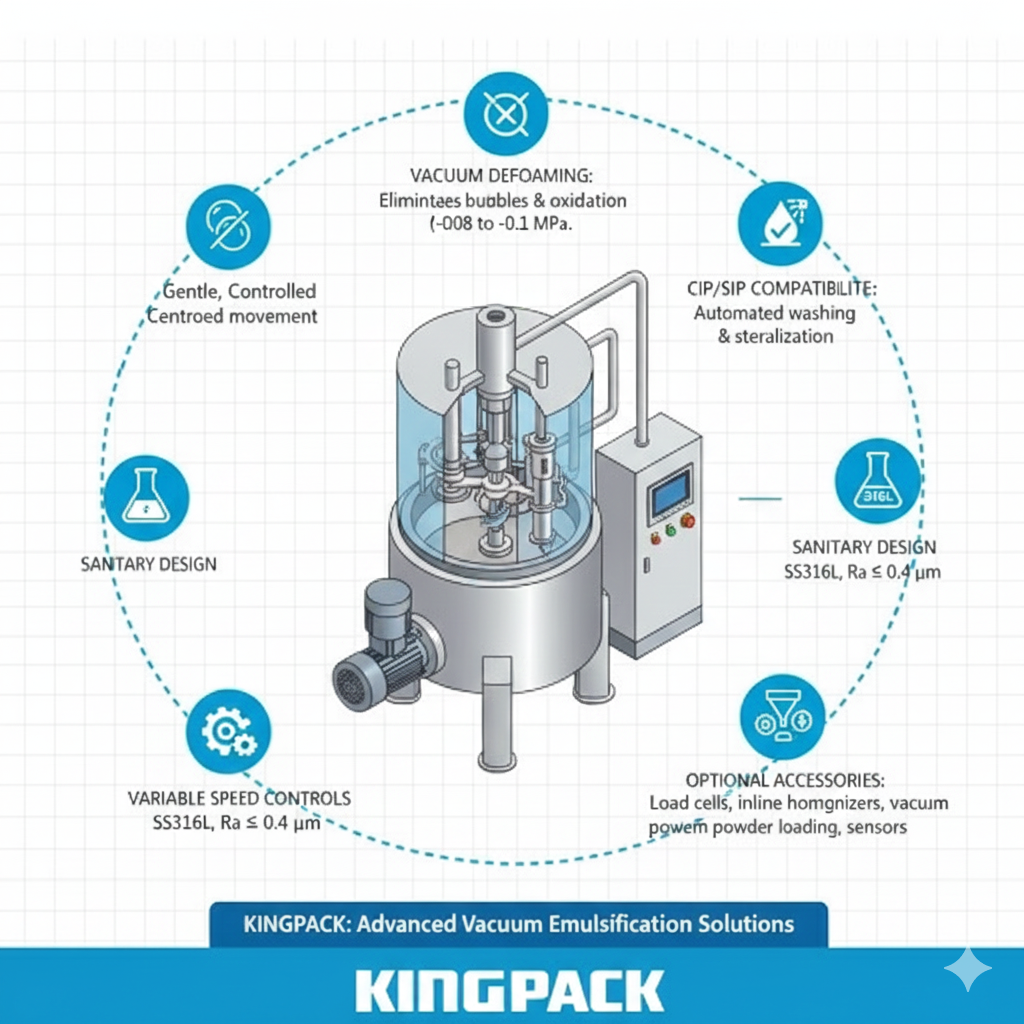

Vacuum Emulsifying Mixer Machine Features

Key features that support pharmaceutical and cosmetic GMP requirements include:

- Full vacuum defoaming (typical vacuum −0.08 to −0.1 MPa) to eliminate bubbles and reduce oxidation.

- CIP/SIP compatibility, with spray balls and validated cleaning cycles to automate washing and sterilization.

- Sanitary stainless steel design, often SS316L for product contact surfaces with internal roughness around Ra ≤ 0.4 μm.

- Variable speed controls for both agitator and homogenizer to adapt shear rate and mixing intensity to different formulations.

- Optional accessories such as load cells for batch weighing, inline homogenizers for continuous processing, vacuum powder loading systems, and integrated temperature and pressure sensors.

Full Vacuum Homogenizing Emulsifier Production Line

In integrated plants, the vacuum emulsifying mixer forms part of a complete production line that covers raw material charging through to filling.

Key elements include:

- Oil phase vessel, water phase vessel, and main emulsifying pot mounted on a common platform or skid with stairs and guard rails for operator access.

- Vacuum pipeline connecting the vessels and main dome, enabling powder suction and degassing during mixing.

- CIP cleaning loop with dedicated pump, valves, and spray devices to clean all tanks and pipelines in place.

- Optional inline homogenizer and transfer lines to feed downstream holding tanks, filters, or filling and packaging systems for automatic, continuous operation.

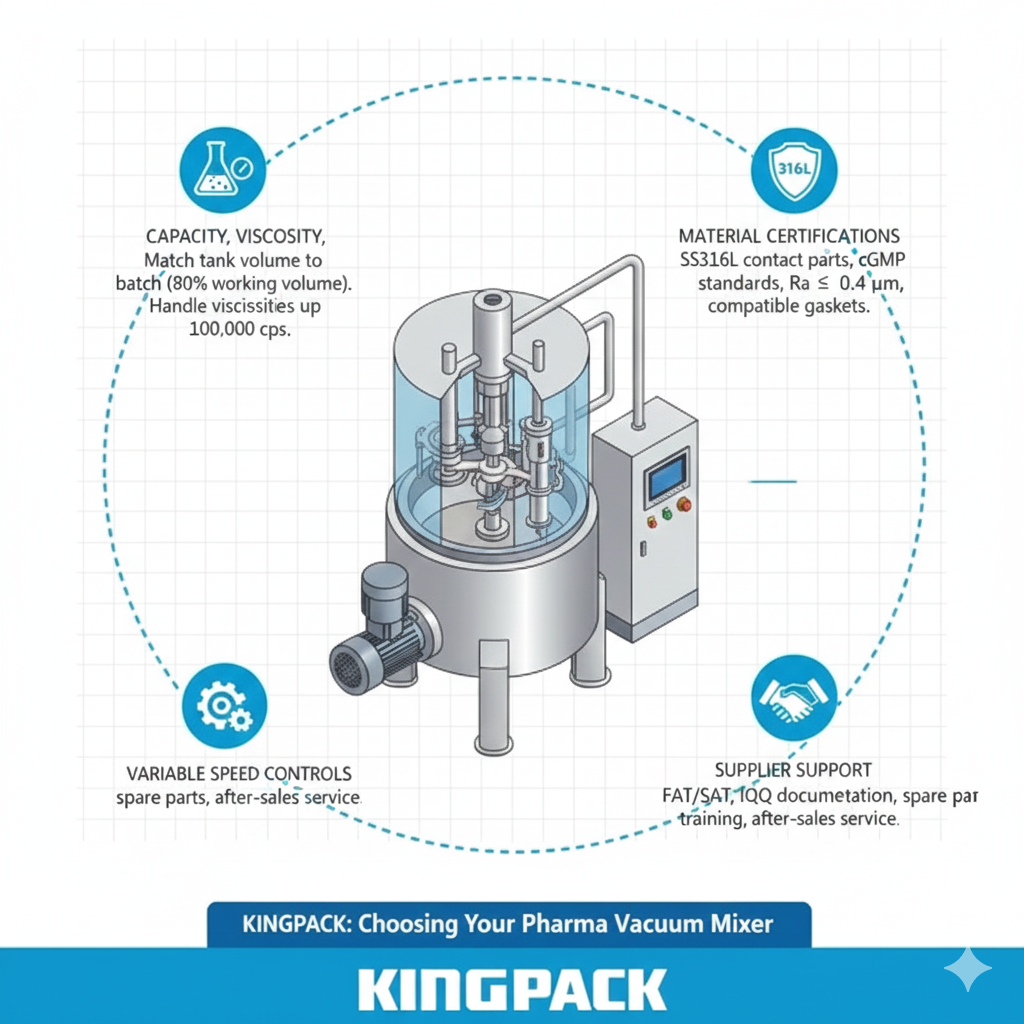

How to Choose the Right Pharma Vacuum Mixer

When selecting a pharmaceutical emulsion mixer machine, key considerations include:

- Capacity, viscosity, and batch size: Match mixing tanks’ volume to the typical batch size (often 70–80% working volume) and confirm the mixer can handle expected viscosities (for example, up to 100,000 cps for ointment mixer applications).

- Material certifications: Specify that SS316L contact parts comply with cGMP standards, appropriate surface finishes (for example, Ra ≤ 0.4 µm), gasket materials compatible with the product and cleaning agents, and cGMP requirements.

- Supplier support: Evaluate availability of FAT/SAT, IQ/OQ documentation, spare parts, training, after-sales service and local service for installation and lifecycle support.

Maintenance and Operation Best Practices

- Daily cleaning and sterilization: Follow validated CIP/SIP cycles or manual cleaning SOPs to avoid cross‑contamination and maintain hygiene and safety.

- Troubleshooting foaming and emulsion break: Adjust vacuum level, homogenizer speed, and addition rate of emulsifiers; verify droplet size targets and temperature profiles to prevent instability.

- Safety features and operator training: Ensure pressure/vacuum relief valves, emergency stops, lid interlocks, and overload protection are functional, and train operators in safe startup, shutdown, and cleaning procedures.

Conclusion & Call to Action

A pharmaceutical emulsion mixer machine, especially a vacuum emulsifying mixer, provides a complete solution for making high-quality emulsions in pharmaceuticals, cosmetics, food, and specialty chemicals. It combines oil-and-water phase mixers, a vacuum mixer-homogenizer, precise temperature control, and a hygienic design. These vacuum mixer homogenizer systems improve batch consistency, reduce processing time, support cGMP compliance, and enable flexible production across ointments, creams, lotions, gels, syrups, and more.

Contact King Pack today to design a custom vacuum emulsifying mixer line tailored to your formulation, capacity, and regulatory requirements, and request a detailed quotation for your next emulsion mixer project.