The integrity of a food product—its safety, quality, and consumer appeal—is often secured by the machinery used to package it. For manufacturers operating in the expansive global market, choosing the appropriate food packaging equipment is a foundational business decision, not merely an operational necessity.

In this article, we will explore the key types of food packaging machines offered by King Pack. Understanding each machine type allows manufacturers to select the right solution for their product, ensuring efficiency, consistent quality, and compliance with food safety standards.

Overview of Food Packaging Machinery

Packaging machinery encompasses a spectrum of devices dedicated to enclosing, protecting, and preparing food items for distribution and retail. These machines are engineered to handle varying product formats—liquids, powders, granules, solids, and semi-solids—each requiring a precise and dedicated process.

The industry is experiencing remarkable growth, with the global food packaging market valued around USD 405 billion in 2024 and projected to reach over USD 650 billion by 2033 . This expansion is driven largely by the enhancement of packaging technology designed for improved shelf life and increased food safety.

The essential goal of deploying high-quality food packaging equipment is to ensure that the packaged product maintains its intended quality upon reaching the consumer. This requires machines that deliver both speed and consistency.

Why It’s Critical to Match Packaging Machine to Food Type

Selecting the right packaging machine depends on the food type—whether it’s perishable meats, dry powders, or liquid beverages. Mismatches can lead to inefficiencies or product spoilage. For instance, vacuum machines suit fresh produce, while bagging systems excel with granules.

King Pack emphasizes customization, allowing seamless integration with your existing lines. Our approach ensures that every machine matches your specific needs, reducing waste and improving safety.

How Packaging Machines Improve Shelf Life and Safety

Modern automatic food packaging machine systems play a pivotal role in public health and waste reduction by actively enhancing product longevity and safety.

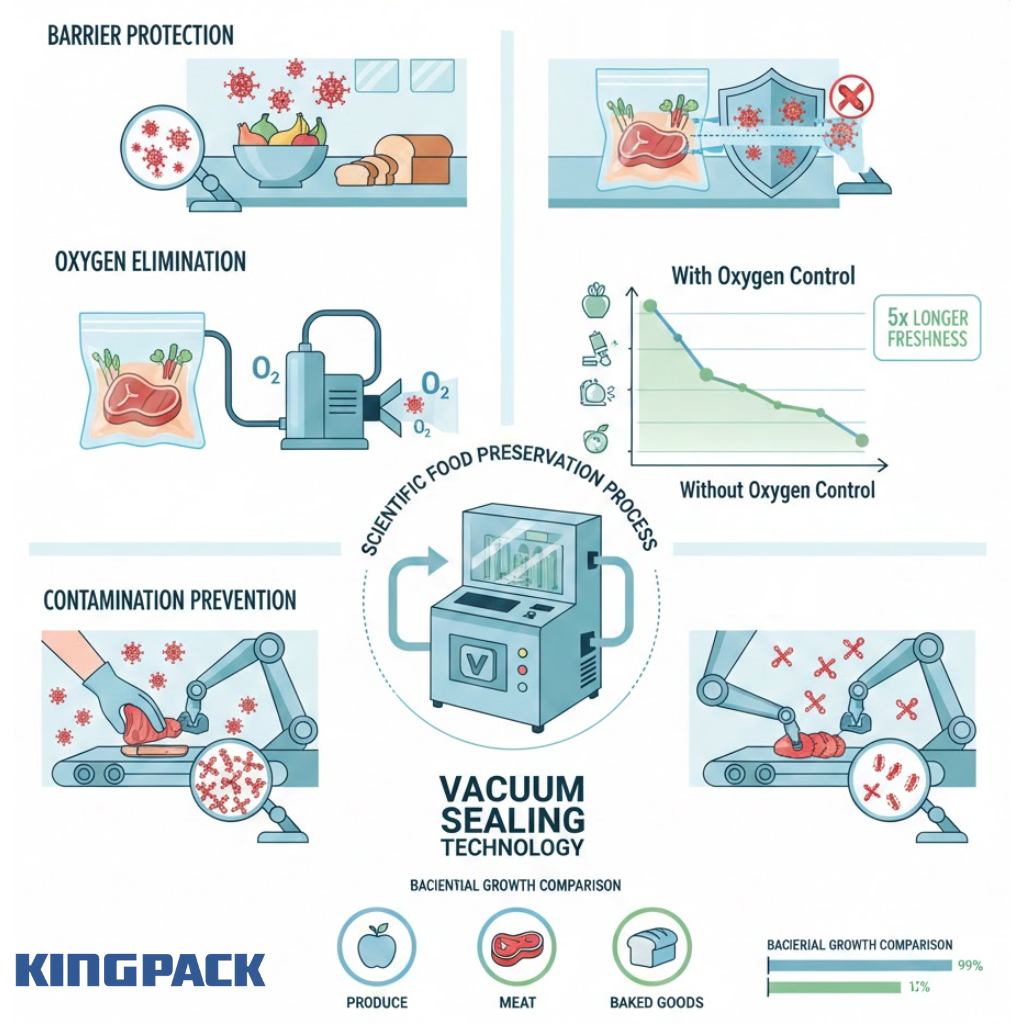

- Barrier Protection: Packaging machinery works with advanced films and containers to create barriers that shield food from external contaminants and damaging elements.

- Oxygen Control: Techniques like gas flushing and vacuum sealing, performed by specialized food packaging equipment, dramatically limit oxygen exposure, which is the primary catalyst for spoilage in many perishable foods.

- Contamination Reduction: Automated lines drastically minimize human contact with the product, significantly reducing the risk of microbial contamination.

Studies confirm the tangible benefits of sophisticated packaging technology. For instance, research on meat products shows that using vacuum food packaging machines can significantly extend shelf life.

Semi-finished meat items can last up to five times longer than with traditional storage methods. This improvement is achieved by slowing oxidative reactions and inhibiting aerobic bacterial growth.

Key Types of Food Packaging Machines

The selection of the appropriate machinery is foundational to operational success. Given the diversity of food products, from sensitive dairy to high-volume snacks, a range of specialized food packaging equipment has been engineered to meet distinct preservation and presentation requirements. The following are the main types of food packaging machines:

1). Vacuum Food Packaging Machines

KPZ-100L vacuum emulsifying machine – King Pack Machinery

Vacuum packaging machines remove air from the package before sealing it tightly. This dramatically slows spoilage, especially for highly perishable products like meat, cheese, and prepared meals, by limiting oxidation and bacterial growth.

The benefits are twofold: product preservation and quality maintenance. By starving aerobic bacteria and slowing oxidation, the vacuum process preserves the food’s sensory qualities, including flavor, color, and texture, which are critical for consumer satisfaction.

This technique can prolong the freshness of perishable goods up to five times longer than conventional storage methods, drastically reducing waste throughout the supply chain.

King Pack’s vacuum emulsifier machines, such as our Vacuum Emulsifier Machine, incorporates similar technology for food processing, ensuring precise control.

| Principle | Primary Function | Ideal Food Types |

| Air Removal | Inhibits aerobic spoilage microorganisms (bacteria, mold). | Meats, poultry, seafood, deli cheeses. |

| Barrier Creation | Prevents moisture escape and freezer burn. | Prepared meals, frozen produce, dry nuts. |

| Reduced Volume | Minimizes package size for efficient storage and transport. | Bulk ingredients, institutional portions. |

2). Biscuit / Bakery Packaging Machines

Food packing machine – King Pack Machinery

Bakery or biscuit packaging machines typically use flow-wrapping or horizontal form-fill-seal (HFFS) technology to wrap individual pieces in film quickly and gently.

These machines are engineered to handle delicate products—like cookies, muffins, or small loaves—without damaging their shape or texture.

Because baked goods often have fragile edges and consistent shapes, flow wrappers provide a reliable, fast, and flexible solution. The machines can adjust speed, film tension, and sealing temperature to match different product sizes, ensuring a clean seal and an attractive final pack.

King Pack’s Food & Beverage Line includes options for such applications, integrating seamlessly with bakery operations.

| Key Feature | Benefit to Bakery Products | Impact on Efficiency |

| Integrated Feeders | Prevents breakage of delicate items (e.g., wafers, cookies). | Ensures continuous flow with minimal stoppage. |

| Heat/Ultrasonic Sealing | Creates airtight package to maintain crispness and flavor. | Rapid closure maintains high cycle speed. |

| Automatic Counting | Places the exact required number of units per pack. | Eliminates labor and human error in portion control. |

3). Food Bundling Machines

Bundling machines group individual food units—such as snack bars, candy sticks, or individual baked items—into a single bundle using a band, sleeve, or film. This is highly useful for promotional packs, multipacks, or retail presentation.

These machines help brands reduce manual labor and boost efficiency by automating the grouping process. They also play an important role in secondary packaging, preparing products for shipping or retail-ready bundling with consistent tightness and alignment.

King Pack provides bundling solutions within our Bag Packaging Machine range, tailored for food bundling needs.

| Bundling Method | Packaging Material | Advantages |

| Shrink Wrapping | Thin, high-strength thermoplastic film. | High visibility, tamper evidence, product stability. |

| Banding/Taping | Wide adhesive band or tie material. | Quick application, minimal material use, easy opening. |

| Cartoning/Sleeving | Printed cardboard sleeves or trays. | High branding area, structural support, premium feel. |

4). Bagging Machines (Formed and Pre-made Bags)

Paging machine & Premade pouch packaing machine – King Pack Machinery

Bagging machine for food technology is highly versatile, accommodating both pre-made pouches and film formed in-line. The two primary food packaging machine types in this category are the Vertical Form-Fill-Seal (VFFS) and open-mouth baggers.

VFFS machines are the core of flexible packaging for products like snacks, powders, and frozen foods, forming the bag from a roll of film, filling it via gravity or an auger, and sealing it in one continuous, high-speed, vertical motion.

Open-mouth baggers, conversely, handle large volumes (typically 5 kg to 50 kg) of bulk granules and powders, like flour and rice, filling pre-made bags with high-precision weighing systems before sealing them via heat or stitching. Explore King Pack’s Pouch Packaging Machine for pre-made bag options in food applications.

| Machine Type | Formation Method | Typical Products |

| VFFS | Forms bag from film roll, fills vertically. | Chips, coffee, nuts, candies, powder mixes. |

| Open-Mouth Bagger | Fills pre-made bags from the top. | Flour, sugar, grains, seeds, pet food. |

| Pre-made Pouch Filler | Fills already-formed stand-up pouches. | Sauces, purees, juice, small snack portions. |

5). Closing / Sealing Machines

KPSCF-500 Automatic folding and sealing machine – King Pack Machinery

Closing or sealing machines are responsible for applying the final seal to a package—whether that’s a heat seal, induction seal, or mechanical clip. They are crucial to preserving product integrity, controlling contamination, and ensuring tamper evidence.

For flexible packaging (pouches and bags), the process relies on heat-sealing, where precise temperature and pressure fuse the material layers. For other container formats, the closing machine may stitch, tie, or apply complex heat-induced seals (like induction seals for jars).

King Pack’s expertise in sealing technology ensures that the package maintains its barrier properties, supporting HACCP compliance throughout the distribution chain. King Pack’s sealing technology supports various food types, aligning with our Cartoning Machines for small portions.

| Sealing Method | Application | Resulting Seal Characteristic |

| Heat Sealing | Films, bags, and pouches (thermal plastics). | Hermetic, air-tight, moisture-proof barrier. |

| Induction Sealing | Lids of bottles and jars (foil liner). | Tamper-evident, high security against leakage. |

| Stitching/Sewing | Heavy-duty paper or woven bulk bags (e.g., rice, feed). | Durable, strong closure for large volumes. |

6). Capping Machines for Bottled Foods

Three-in-One Liquid Filling and Capping Machine – King Pack Machinery

The food capping machine is essential for liquid, semi-liquid, and bottled solid food products (sauces, oils, beverages). These machines must operate with speed and precision, applying closures ranging from simple screw caps to complex tamper-evident seals. King Pack specializes in Filling and Capping Line solutions that ensure this process is flawless.

Integration with filling lines is paramount for efficiency. Automatic cappers are synchronized with the upstream filling machine, ensuring that a filled bottle immediately receives its cap. This quick turnaround minimizes product exposure to air, maintaining the sterility and quality established during the filling process, and maximizing the line’s overall output.

King Pack’s Oral Liquid Filling and Capping Machine exemplifies this for food beverages.

| Capping Type | Mechanism | Closure Format |

| Screw Capper | Applies rotational torque to threaded caps. | Plastic or metal screw caps (e.g., sodas, water). |

| R.O.P.P. Capper | Forms threads onto the cap while applying it. | Aluminum caps with pilfer-proof band (e.g., oils, wines). |

| Snap Capper | Applies vertical pressure to snap-on lids. | Plastic snap-on lids (e.g., certain dairy, seasoning jars). |

Accumulation Devices & Line Feeders

The food accumulation device acts as a crucial buffer within the production line, preventing costly full-line shutdowns. These systems are strategically positioned between different packaging stations that may operate at slightly varied speeds or experience momentary pauses.

The primary purpose of accumulation is to smooth the flow and synchronize operations. By temporarily holding products—from bottles to finished cartons—these devices ensure that a temporary stop at a labeler, for instance, does not halt the entire upstream filler or capper.

This buffering capability is essential for sustaining high operational efficiency and maximizing the total throughput of any sophisticated automatic food packaging machine setup. At King Pack, we incorporate these in our Filling and Capping Line, optimizing food production.

| Device Type | Primary Function | Operational Benefit |

| Accumulation Table | Creates a temporary buffer zone for products. | Prevents line stoppage from minor downstream issues. |

| Line Feeder | Organizes and separates products entering a machine. | Ensures consistent spacing and orientation for precise machine timing. |

| Zero-Pressure Conveyor | Controls product flow to prevent contact and collision. | Minimizes damage to fragile or unstable containers/packages. |

Other Essential Packaging Equipment

A complete, functioning food packaging line requires more than just the primary enclosure machine. It necessitates a range of complementary devices that handle product preparation, secondary containment, and final logistics.

Complementary Machines You Might Need

For many clients, particularly those utilizing the comprehensive King Pack food packaging solutions for liquid and viscous products, the following machines are essential for a complete turnkey system:

- Filling Machines (Liquid, Powder): These primary machines measure and dispense the product into the container. King Pack offers specialized equipment, including piston, gravity, or auger fillers, that are integral to their liquid and powder processing lines.

- Heat Sealing Machines: Beyond basic heat sealing on VFFS machines, standalone heat sealers are used to seal trays, cups, or pre-made pouches (such as the sachet and pouch packaging machine types offered by King Pack). These ensure a perfect barrier integrity.

- Labeling, Case Packing, Strapping Machines: These handle the end-of-line logistics:

- Labeling: Applying required information, barcodes, and branding.

- Case Packing: Mechanically inserting finished, labeled units into shipping boxes.

- Strapping: Applying durable plastic or metal bands around cases or pallets for stability during transit.

How to Select the Right Packaging Machine for Food

Choosing the right machine involves evaluating multiple factors to align with your operations.

Choosing the Right Machine for Your Operations

Selecting the right packaging machine involves evaluating multiple factors to align with your operations.

Key Considerations — Product, Volume, and Shelf Life

Start by assessing your product type—frozen processed foods, meat alternatives, or other items in the food and beverages industry. Production volume matters: high-volume runs need fast, efficient machines, while smaller runs may prioritize flexibility.

Shelf-life goals affect choices too—machines that support vacuum sealing or moisture-resistant coatings help maintain food freshness and reduce food spoilage or microbial growth. Testing product samples with your packaging products, including folding cartons, barrier-lined paperboard, or FibreForm trays, can guide customization.

Evaluating Automation Level and Line Integration

Automation ranges from semi-automatic to fully robotic, fitting different food chains, grocery stores, and food distributors. High automation supports large-scale operations and integrates with mechanical packaging systems for real-time monitoring.

Features like Pre-Applied Closures, Daisy Chain lines, and customer portals make managing delivery events and packaging solutions easier. Recyclable rollstock, paper-based solutions, cellulose derivatives, and polyethylene resins allow for recycle-ready solutions, reducing your packaging footprint and environmental concerns.

Balancing Cost, Maintenance, and Throughput

Factor upfront cost against long-term savings: efficient machines lower waste and improve product availability. Retail-ready packaging and durable frozen-food packaging benefit from consistent throughput and minimal downtime.

After-sales support, combined with insights from Consumer Insights, Pulse Packaging Survey, and Packaging Innovation Award trends, helps maintain optimal performance. Using machines compatible with your packaging recyclability goals ensures your operations align with sustainability and industry standards.

Upgrade Your Food Packaging Line Now

Choosing the right food packaging machinery is a strategic step that directly impacts product quality, safety, and operational efficiency. King Pack provides robust, high-performance solutions—from vacuum packaging and high-speed bagging to liquid filling and capping—designed to optimize your production line, reduce waste, and protect your brand reputation.

With decades of engineering expertise, King Pack delivers fully integrated, customizable systems that meet the highest standards of hygiene and precision. By partnering with us, manufacturers can achieve higher throughput, seamless line integration, and reliable product protection. Contact King Pack today to design a tailored packaging solution that elevates your production and secures your product’s future.