Blister packaging machines play a crucial role in pharmaceutical manufacturing—enabling automated production of individual doses, maintaining drug integrity, and meeting regulatory demands. Recent data shows the global pharma blister packaging machines market is projected to grow from approximately USD 2.4 billion in 2025 to USD 3.2 billion by 2035. Meanwhile, the broader blister packaging market (including equipment) was valued around USD 21.7 billion in 2024, with forecasts pointing to a CAGR of ~7.6% through 2034.

In this guide, we cover how blister packaging works, the machines behind it, and their uses across different industries.

What Is Blister Packaging?

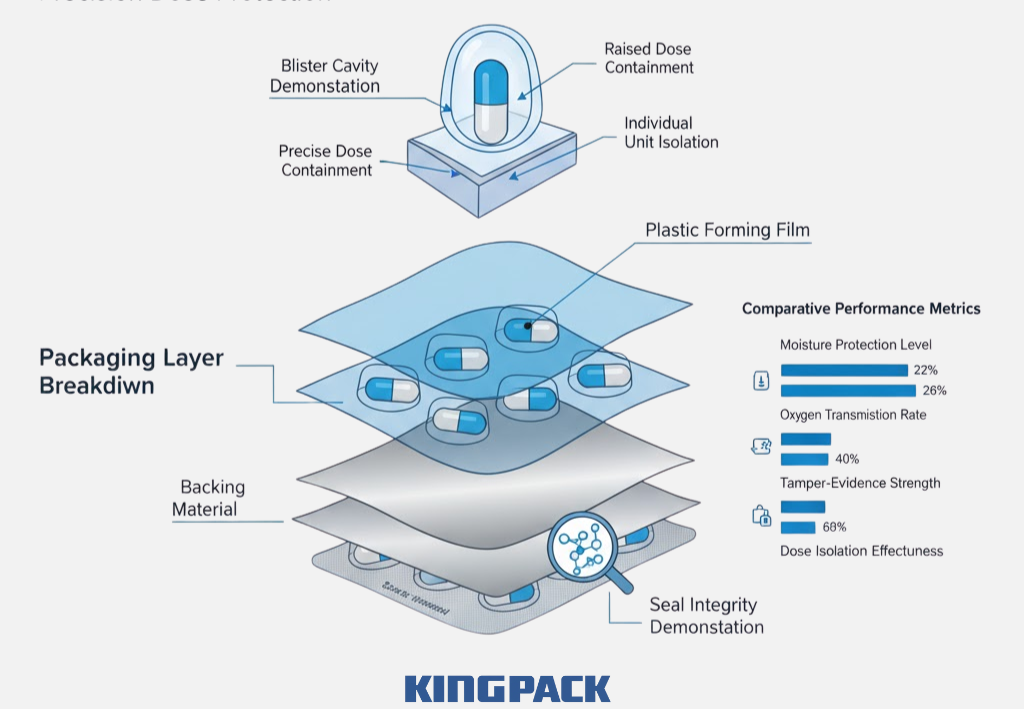

Blister packaging refers to a format where each dose (tablet, capsule, lozenge) is enclosed in a pre-formed cavity (the blister) and sealed by a lidding material. This format offers individual dose protection, tamper evidence, and easy visual inspection.

The term “blister” describes the distinctive raised pocket or cavity that holds each individual unit. Unlike bulk packaging where multiple doses share a common container, blister packaging isolates each dose in its own sealed compartment. This isolation provides multiple advantages that have made blisters the dominant packaging format for solid oral dosage forms worldwide.

Recommended Reading: Cartoning Machine vs Case Packer – King Pack Machinery

How Blister Packaging Works

Blister packaging follows a controlled, multi-step process designed to form, fill, seal, print, and cut dosage units into finished packs. Each step plays a vital role in maintaining product integrity, ensuring sterility, and achieving high production efficiency. Modern machines synchronize these stages automatically, reducing errors and maintaining consistent quality across large production runs.

The following are the main stages of the Blister Packaging process described in detail:

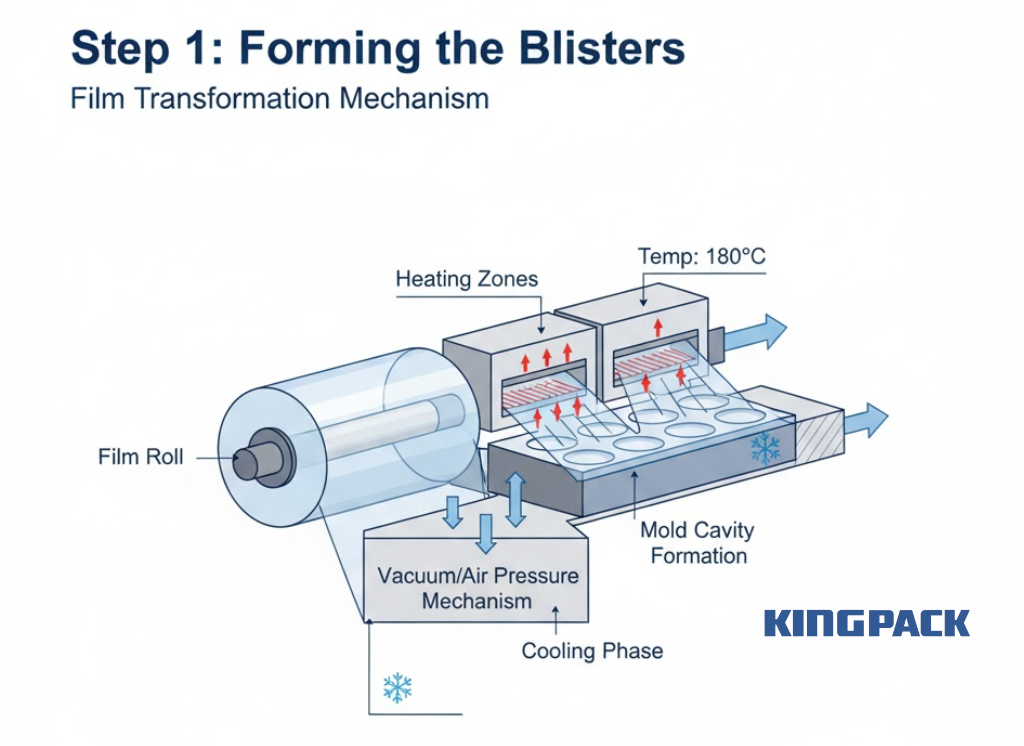

Step 1: Forming the Blisters

The process begins with a flat roll of PVC or PET film that unwinds and passes through a heating station. Controlled heat softens the film just enough to make it pliable without weakening its structure. Once the correct temperature is reached, the film enters the forming station, where vacuum suction or compressed air pushes it into a metal mold to create uniform cavities that will later hold each dosage unit.

After shaping, the film cools briefly to help the cavities retain their form. This cooling phase is important because it prevents distortion or shrinkage before the next operation. A consistent temperature balance during heating and cooling ensures that every cavity has the same thickness and strength, which helps maintain product protection and visual uniformity across the final blister packs.

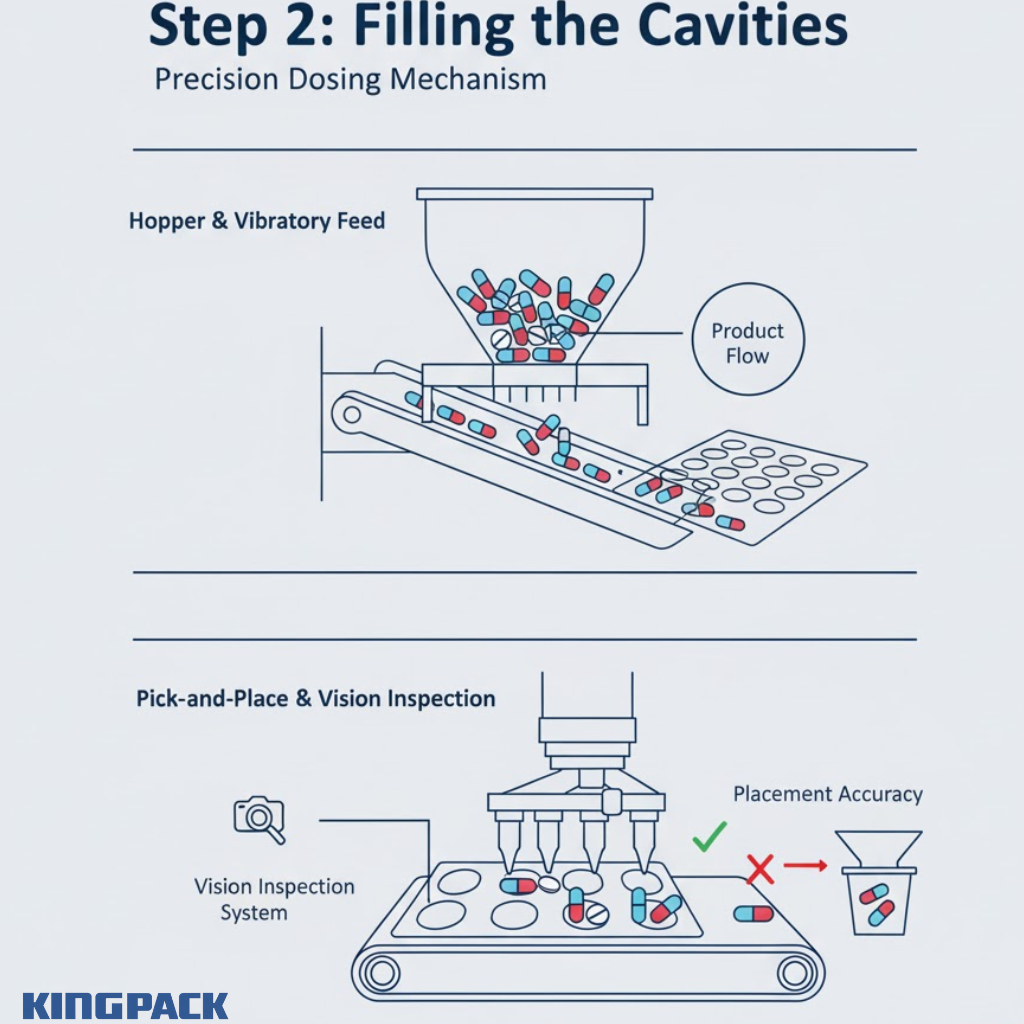

Step 2: Filling the Cavities

Once the blister pockets are formed, the product filling process begins. Tablets, capsules, or lozenges are carefully dropped into each cavity using a system suited to the product type. Gravity-fed hoppers are used for standard tablets that flow freely, while vibratory feeders provide better control for smaller or delicate units.

Pick-and-place systems are ideal for fragile products that need gentle handling to prevent chipping or breakage.

Recommended Reading: Liquid Filling Machine Manufacturer: Top Manufacturers Worldwide – King Pack Machinery

Modern blister packaging lines often include vision inspection systems at this stage. High-resolution cameras check that every cavity has the correct product, positioned properly and free from damage.

Any blister missing a tablet or containing a defective unit is automatically rejected. This step maintains strict quality standards and prevents packaging errors from reaching the sealing station.

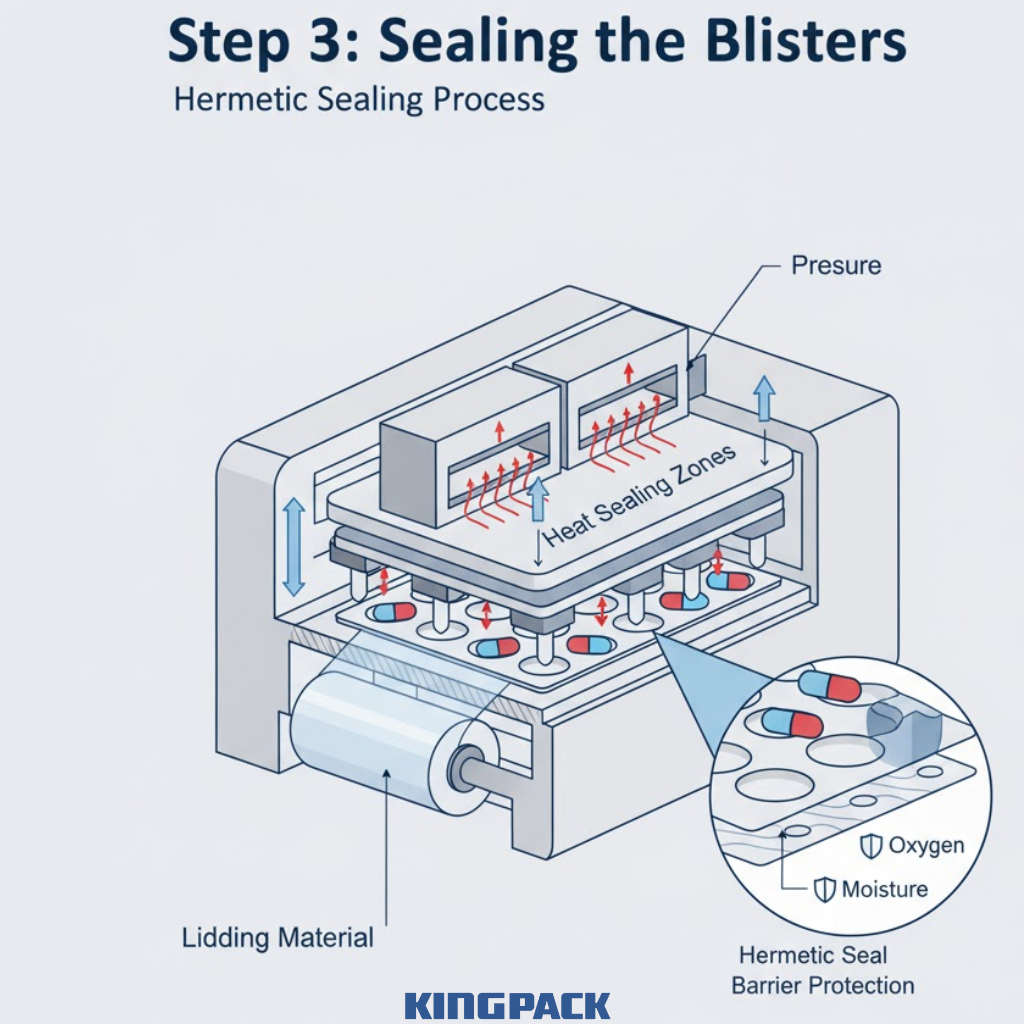

Step 3: Sealing the Blisters

In this stage, a lidding material such as aluminum foil or paper-foil laminate is applied over the filled blisters. The machine uses heat and pressure to bond the lidding layer to the formed film, creating an airtight seal. This sealed layer keeps moisture, oxygen, and light away from the dosage units, ensuring product stability throughout its shelf life.

The sealing operation requires precise calibration of three main factors: temperature, pressure, and dwell time. If the temperature is too low, the seal may be weak and prone to leakage; too high, and it can burn the foil or deform the plastic base. Proper settings achieve consistent, durable seals that protect the contents while maintaining a clean appearance.

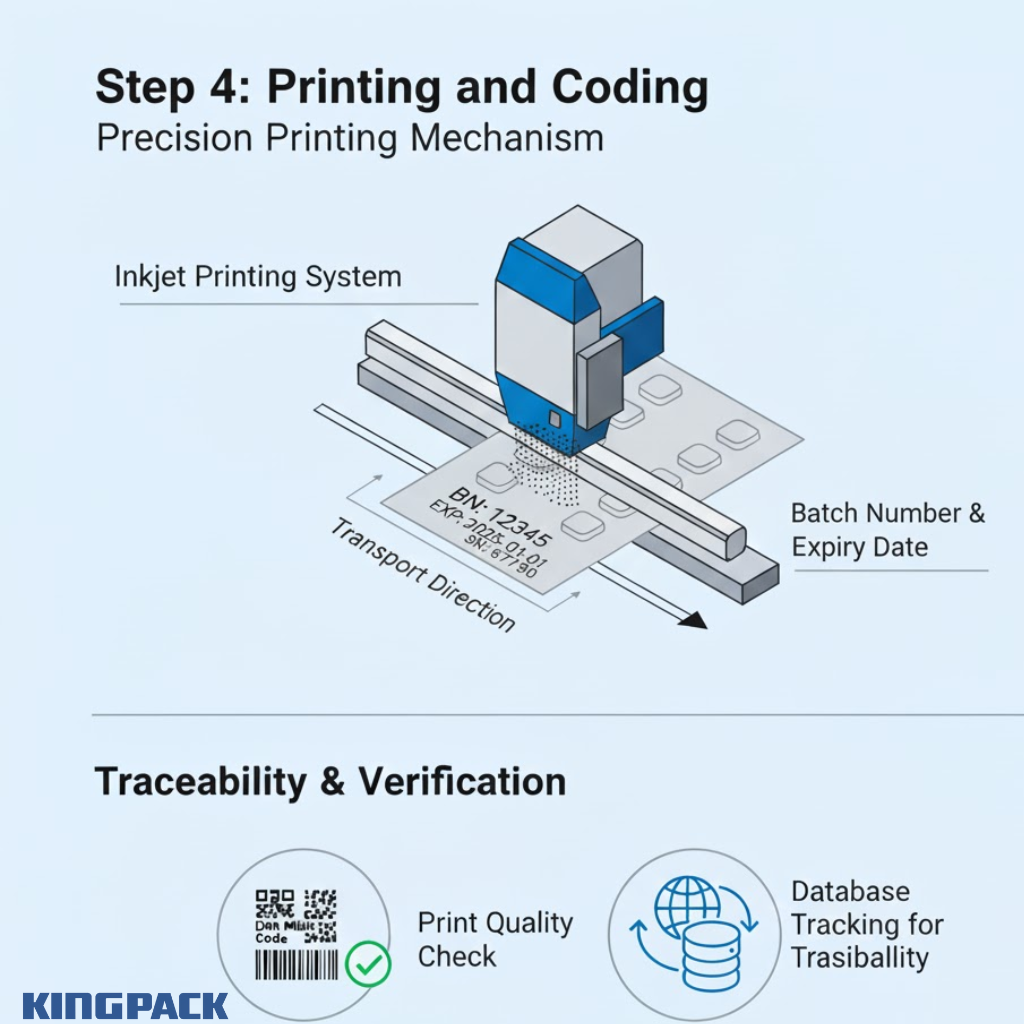

Step 4: Printing and Coding

After sealing, the packaging line prints essential information directly onto the lidding foil. This includes the product name, batch number, expiration date, dosage strength, and sometimes regulatory codes or barcodes. Clear printing is vital for both compliance and traceability, especially in pharmaceutical packaging where identification errors are unacceptable.

Most production lines print on the foil surface rather than on the forming film. The flat surface of the foil allows for sharper text and more accurate color reproduction, which enhances legibility and visual quality. Inkjet or laser systems are commonly used for high-speed printing that keeps up with the production line without sacrificing precision.

Step 5: Punching and Cutting

The final step separates the continuous blister web into individual cards or strips. Precision cutting tools or die-cut systems shape the packs according to product and market requirements—single-dose strips, ten-count packs, or full calendar-style layouts. This customization makes it easy to match packaging formats to dosage schedules or retail presentation needs.

As cutting takes place, leftover edge material and trimmed sections are collected on take-up rolls for recycling or disposal. Continuous monitoring of scrap levels helps operators identify any upstream problems, such as misalignment or film tension issues. A clean cutting process ensures each blister card maintains its seal integrity and professional appearance before cartoning or final packaging.

Recommended Reading: The Ultimate Guide to Vial Filling Machines for Your Business – King Pack Machinery

Key Methods of Blister Forming

Thermoforming Blister Machines

Thermoforming machines heat a plastic film roll and form cavities using thermoforming or pressure techniques. This is the standard choice for many solid oral dosage lines due to speed and compatibility with PVC/PVDC films. The plastic film is formed, filled, sealed, and punched at high speeds—ideal for large‑volume runs.

Typical Characteristics:

- Roll‑to‑roll operation with continuous motion

- High output (200‑400 blisters/min or more)

- Works well with PVC/PVDC films and lidding foil

- Easier format changes compared to cold‑form foil

Thermoforming machines are widely used when barrier requirements are moderate and volume is high. They deliver excellent productivity while balancing cost and quality.

Cold‑Forming (Alu‑Alu) Blister Machines

In cold‑forming systems, aluminium‑based foils (or laminated aluminium) are mechanically formed into cavities without heating the film. This delivers superior barrier protection (against moisture, oxygen, light) and is necessary for highly sensitive drugs.

Typical Characteristics:

- Aluminum cavities provide maximal barrier

- Often slower than thermoforming (because of forming complexity)

- Higher cost but required when drug stability is critical

- Often used for biologics, moisture‑sensitive tablets and long shelf‑life products

Cold‑form blister machines are selected when the formulation demands the highest protection and when compliance with stringent shelf‑life or moisture control is necessary.

Hybrid & Novel Forming Technologies

Hybrid machines combine the advantages of thermoforming and cold‑forming: for example, a film may form by thermoforming but then sealed with aluminum foil for improved barrier. Novel technologies may include multi‑material forming, smart sensors, vision inspection and interoperability with downstream cartoning.

Typical Characteristics:

- Flexibility to handle multiple materials and formats

- Mid‑ to high‑speeds with enhanced protection

- Better for contract packaging or multi‑SKU lines

- Supports faster changeover and extended capabilities

For manufacturers servicing various product types or who require both high throughput and strong protection, hybrid machines offer a strong compromise.

Applications Across Industries

Blister packaging machines have evolved beyond pharmaceutical use. Their precision, hygiene, and flexibility make them valuable in multiple industries where individual packaging, visibility, and product safety are essential.

The following sectors highlight how this technology adapts to different products, materials, and regulatory demands while maintaining efficiency and protection standards.

Pharmaceutical & Nutraceutical Products (Tablets, Capsules)

In the pharmaceutical and nutraceutical industries, blister packaging remains the gold standard for solid oral dosage forms. Each tablet or capsule is enclosed in its own cavity, protecting it from air, moisture, and cross-contamination. This individual packaging format also simplifies patient dosing and helps manufacturers meet strict regulatory requirements.

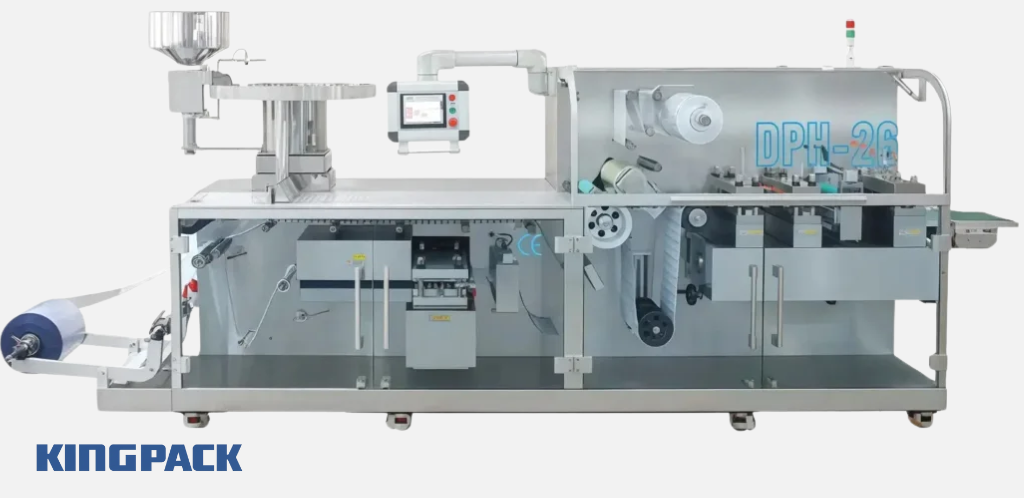

Blister machines like DPH-260 High-Speed Blister Packaging Machine used in this sector operate under GMP conditions, supporting full traceability and automated inspection. They can integrate desiccant layers or child-resistant designs for extra safety. Nutraceutical companies also rely on blister packaging to present vitamins and supplements attractively while maintaining freshness and integrity.

| Aspect | Pharmaceutical Blisters | Nutraceutical Blisters |

| Purpose | Accurate, protected dosage | Appealing, hygienic packaging |

| Materials | PVC, PVDC, Aluminum Foil | PET, Paper-Foil Laminate |

| Main Benefit | Dose control and safety | Shelf appeal with protection |

Food, Snacks & Confectionery

Blister packaging plays a growing role in the food and confectionery sectors. It’s used for chocolates, lozenges, gums, and other bite-sized snacks that need clear visibility and hygiene. Transparent films allow customers to view the product, while sealed compartments maintain freshness and prevent contamination.

These machines can process food-safe films such as PET or PLA, supporting recyclable or biodegradable options. Retailers value blister packs for their easy stacking and portion control, while consumers appreciate their convenience and attractive presentation.

| Aspect | Food Blisters | Confectionery Blisters |

| Common Products | Snack bites, lozenges | Chocolates, candies |

| Material Type | PET, PLA, Paper-Foil | PVC, PET |

| Key Benefit | Portion control, freshness | Shelf appeal, tamper resistance |

Electronics, Personal Care & Small Hardware

Blister machines are widely used to package small consumer goods like batteries, cables, razors, toothbrushes, and screws. The combination of rigid cavities and transparent covers provides both visibility and durability. These packs protect delicate or sharp items during shipping and prevent product loss or damage.

Manufacturers also value blister packs for their retail display benefits. The sealed packaging discourages tampering and theft while allowing for branding through printed backing cards. This makes them ideal for mass-produced consumer products that must stand out on store shelves.

| Aspect | Pharmaceutical Blisters | Nutraceutical Blisters |

| Purpose | Accurate, protected dosage | Appealing, hygienic packaging |

| Materials | PVC, PVDC, Aluminum Foil | PET, Paper-Foil Laminate |

| Main Benefit | Dose control and safety | Shelf appeal with protection |

Food, Snacks & Confectionery

Blister packaging plays a growing role in the food and confectionery sectors. It’s used for chocolates, lozenges, gums, and other bite-sized snacks that need clear visibility and hygiene. Transparent films allow customers to view the product, while sealed compartments maintain freshness and prevent contamination.

These machines can process food-safe films such as PET or PLA, supporting recyclable or biodegradable options. Retailers value blister packs for their easy stacking and portion control, while consumers appreciate their convenience and attractive presentation.

| Aspect | Food Blisters | Confectionery Blisters |

| Common Products | Snack bites, lozenges | Chocolates, candies |

| Material Type | PET, PLA, Paper-Foil | PVC, PET |

| Key Benefit | Portion control, freshness | Shelf appeal, tamper resistance |

Electronics, Personal Care & Small Hardware

Blister machines are widely used to package small consumer goods like batteries, cables, razors, toothbrushes, and screws. The combination of rigid cavities and transparent covers provides both visibility and durability. These packs protect delicate or sharp items during shipping and prevent product loss or damage.

Manufacturers also value blister packs for their retail display benefits. The sealed packaging discourages tampering and theft while allowing for branding through printed backing cards. This makes them ideal for mass-produced consumer products that must stand out on store shelves.

| Aspect | Electronics | Personal Care & Hardware |

| Typical Items | Batteries, adapters, earbuds | Razors, screws, toothbrushes |

| Sealing Type | Plastic-to-card or foil | Plastic-to-paper or foil |

| Benefit | Product visibility, protection | Tamper resistance, strength |

Medical Devices & Diagnostics

In the medical field, blister packaging ensures sterile protection for items such as syringes, catheters, diagnostic test kits, and single-use instruments. The sealed environment safeguards against contamination and allows hospitals or clinics to use items straight from the package without further sterilization.

DPP-250 Flat Blister Packaging Machine – King Pack Machinery

Medical blister machines often use medical-grade PVC or PETG films paired with Tyvek® or foil lids. These materials maintain sterility while allowing for easy peel-opening. With barcodes and UDI (Unique Device Identification) integration, manufacturers can also improve traceability and inventory control.

| Aspect | Medical Devices | Diagnostics |

| Common Products | Syringes, catheters | Test kits, swabs |

| Lidding Material | Tyvek®, Foil | Foil, Paper |

| Main Benefit | Sterile barrier protection | Secure and traceable packaging |

Consumer Goods & Retail Promotions

Blister packaging also serves promotional and retail purposes across cosmetics, toys, and gift items. Its clean look and clear visibility enhance presentation while maintaining affordability. Brands often use shaped cavities and colorful backing cards to attract consumer attention in competitive markets.

This type of packaging allows easy customization in size, color, and shape, supporting both limited-edition and regular retail products. It’s a practical balance between cost efficiency, protection, and marketing appeal.

| Aspect | Cosmetics & Gifts | Retail Promotions |

| Typical Items | Lip balms, perfumes, jewelry | Collectibles, toys |

| Material Used | PET, PVC | PET, Cardboard |

| Key Benefit | Elegant presentation | Branding and shelf impact |

Selecting the right blister packaging machine involves evaluating several important factors:

Key Selection Factors:

- Supplier Experience & Technical Capability: Look for proven expertise, GMP-compatible turntable machines, monobloc blister packaging, and customization options. Strong technical support and validation capabilities are essential.

- Customization, Format Change-Over & Machine Speed: Machines should handle different blister sizes, thermoform blisters or cold forming designs, and support fast changeovers for Small Batch production. Features like automatic blister feeders, cam index rotary table drives, and color touch screen HMI improve efficiency and ease of operation.

- Compliance, Service Support & Global After-Sales: Ensure GMP/FDA/CE compliance, availability of spare parts, and a reliable service network to maintain production continuity.

Why Partner with King Pack?

King Pack provides complete packaging solutions for the pharmaceutical industry, combining in-line blister packaging, forming, filling, sealing, and inspection modules. Our systems support both thermoform blisters and cold-forming designs, as well as roller sealing and inline designs for high-throughput or flexible production needs.

With global support, customized engineering, and integration capabilities across entire production lines, King Pack helps manufacturers scale operations efficiently while maintaining compliance and high line competence.

Conclusion

Blister packaging machines form a critical backbone of modern dose‑packaging lines. Whether you focus on high‑volume tablet production, specialised cold‑form formats, or multi‑SKU runs, choosing the right machine type—and the right vendor—matters. With blister machine markets expanding and regulatory pressure increasing, aligning your line with a partner like King Pack ensures you stay ahead. Contact King Pack for your fully integrated blister packaging line and build a system designed for performance, protection and flexibility.