Food-grade tube sealing has become a decisive factor in how long mayonnaise stays safe, stable, and appealing. Beyond holding the product in place, the seal determines how effectively oxygen, moisture, and microbes are kept out. Each step of the process — from selecting tube material to applying the final seal — influences the product’s shelf life, taste, and safety during distribution.

In this article, we’ll explore the main challenges that affect mayonnaise preservation, how food-grade tube sealing works to overcome them, and why proper sealing technology is essential for quality and compliance in commercial food production.

Recommended Reading: What Factors Affect the Shelf Life of Mayonnaise? – King Pack Machinery

Challenges in Shelf Life Preservation for Mayonnaise

Oxidation and Rancidity Risks in Oil-Based Foods

Mayonnaise is an emulsion of oil, water, and egg components — all of which are sensitive to oxidation. When air enters the package, oxygen reacts with unsaturated fatty acids in the oil phase, forming peroxides that lead to rancid odor and taste. According to a study published in Food Chemistry (2021), lipid oxidation can increase by up to 35 % when packaging oxygen permeability exceeds 0.5 cm³/m² · day.

| Factor | Effect | Control Method |

| Oxygen Exposure | Causes rancid flavor and odor | Use airtight, low-permeability packaging |

| Headspace Oxygen | Shortens shelf life by weeks | Vacuum or nitrogen flush before sealing |

| Light & Heat | Speeds up oxidation and color change | Store in cool, dark conditions |

| Seal Integrity | Allows oxygen leaks over time | Apply food-grade sealing and inspection |

Even trace oxygen trapped in the headspace can shorten shelf life by weeks. Once oxidation starts, it not only affects flavor but also alters the color and consistency of the product. The result is consumer rejection and costly recalls. Food-grade tube sealing acts as the final oxygen barrier, protecting the product from slow but inevitable degradation during storage.

Microbial Contamination During Storage and Handling

Microbial safety is another defining issue in mayonnaise packaging. Despite containing acid and preservatives, mayonnaise supports microbial growth if environmental spores or bacteria find a way in. Studies on Bacillus cereus and Staphylococcus aureus in emulsified foods show that small contamination levels can multiply rapidly in warm storage conditions.

| Source | Impact on Product | Prevention Method |

| Airborne spores or bacteria | Spoilage, odor, or texture change | Use airtight food-grade seals |

| Unhygienic filling or handling | Rapid microbial growth in warm storage | Maintain clean filling environment |

| Weak or incomplete seal | Allows micro-channel entry | Verify seal integrity with inspection systems |

A weak or partially closed seal becomes an open gateway for airborne contaminants. The filling process may be hygienic, but without a secure closure, the product’s microbial stability cannot be guaranteed. Food-grade tube sealing systems prevent this risk by forming hermetic closures that eliminate possible micro-channels through which microbes might enter after filling.

Leakage and Consumer Safety Concerns in Food Packaging

Physical leakage not only results in product loss but also triggers hygiene and brand trust issues. Even minor seal weaknesses can cause oil separation or liquid weeping under pressure or heat. When this happens, oxygen and moisture penetrate the tube, accelerating spoilage and oxidation.

| Cause | Result | Preventive Action |

| Seal weakness or uneven melting | Product leakage and oil separation | Apply uniform pressure and heat control |

| Temperature or pressure stress | Moisture entry and spoilage | Use flexible, durable laminate materials |

| Mechanical damage in transport | Loss of product and hygiene issues | Strength-test seals and packaging design |

Research on packaged condiments found that leakage accounted for nearly 12 % of consumer complaints in mayonnaise tubes distributed in hot climates. This highlights how crucial seal strength and flexibility are for maintaining integrity throughout logistics and retail storage.

Recommended Reading: How Long Do Sealed Sauce Packets Really Last? Shelf Life, Storage & Safety Tips – King Pack Machinery

Functional Role of Food-Grade Tube Sealing

Creating an Oxygen and Moisture Barrier

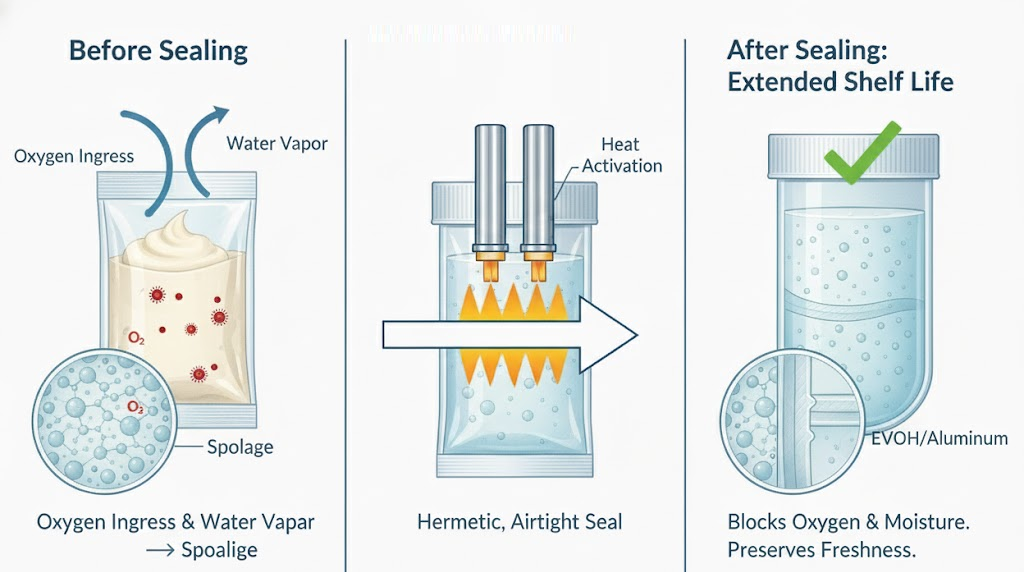

Food-grade tube sealing provides more than just closure — it’s the critical shield protecting mayonnaise from air and humidity throughout storage and distribution. During sealing, heat or ultrasonic energy fuses the inner layers of the tube material to form a continuous, airtight joint.

This prevents gas and vapor from passing through, reducing the chances of oxidation and microbial growth. The goal is to achieve thermal bonding without altering the tube’s food-contact surface, keeping it smooth and hygienic for long-term safety.

Modern laminate tubes used in food packaging are designed with multiple functional layers. Many include EVOH (ethylene-vinyl alcohol) or aluminum as barrier materials, which block both oxygen and moisture transmission.

The sealing process must apply uniform heat and pressure to melt these inner layers evenly. Uneven fusion can create weak points that allow microscopic gas exchange, slowly reducing product quality over time.

When sealing integrity is verified through burst testing or leak detection, the tube becomes an effective oxygen and vapor barrier. Low oxygen-transmission rates (OTR) are a benchmark of quality in condiment packaging.

A properly sealed EVOH or aluminum-laminate tube can maintain an OTR value below 0.1 cm³/m²·day, a level proven to extend product freshness by several weeks under ambient storage. This strong barrier limits rancidity and keeps the flavor, color, and texture of mayonnaise consistent until the point of use.

In large-scale production, maintaining this barrier performance across thousands of tubes daily depends on machine precision, temperature control, and regular seal integrity verification.

Recommended Reading: Types of Food Packaging Machines: Applications, Benefits, and Industry Uses – King Pack Machinery

Maintaining Emulsion Stability and Product Integrity

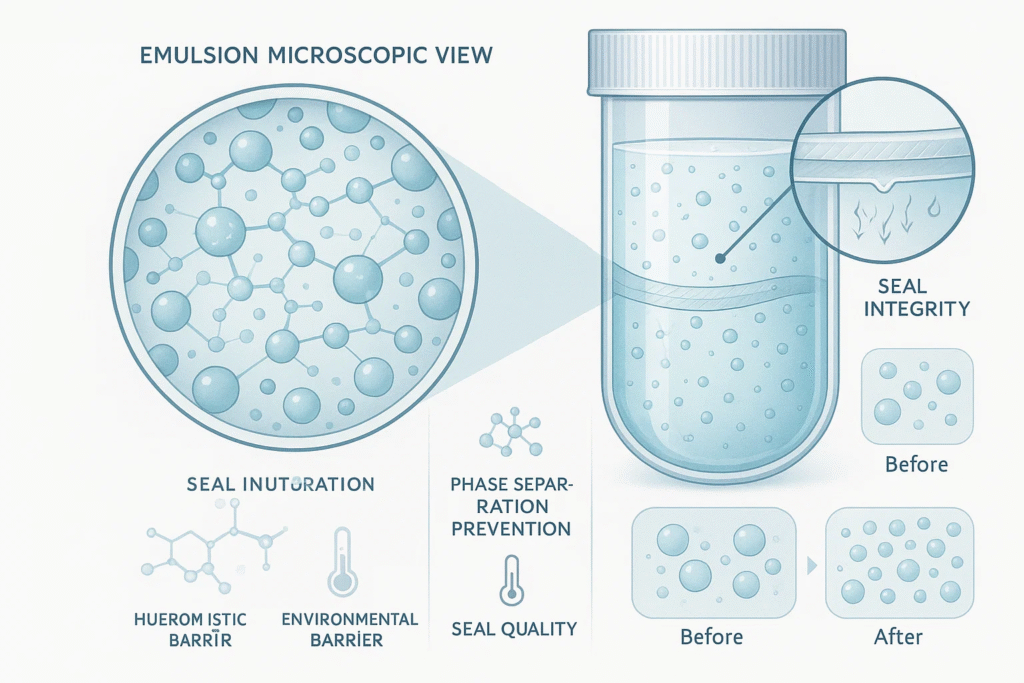

The structure of mayonnaise depends on a stable oil-in-water emulsion where tiny oil droplets are evenly dispersed through an aqueous base. Any external influence — oxygen exposure, temperature fluctuations, or water vapor intrusion — can disturb this delicate balance. The seal acts as the final protective barrier maintaining the controlled internal conditions that preserve this emulsion.

Without a strong seal, even small environmental changes can trigger phase separation, texture breakdown, or oxidation of the oil phase. Food-grade sealing helps preserve the chemical and physical properties of mayonnaise by maintaining a sealed environment with consistent humidity and pressure.

The result is an emulsion that retains its smoothness and spreadability across months of storage. Studies on packaged emulsified foods have shown that samples with fully hermetic seals display up to 30 % lower viscosity loss compared to those with minor sealing defects.

That difference directly translates into a more stable and appealing product for consumers. For manufacturers distributing to multiple regions or export markets, emulsion stability has financial and logistical importance. A small percentage of tubes affected by separation or spoilage can lead to significant losses when scaled across production runs.

By adopting precise hot-air or ultrasonic sealing systems, producers can achieve consistent results across every batch.

Recommended Reading: What Are The Health Benefits Of Mayonnaise, And Why Mayonnaise Making Machines Are Important – King Pack Machinery

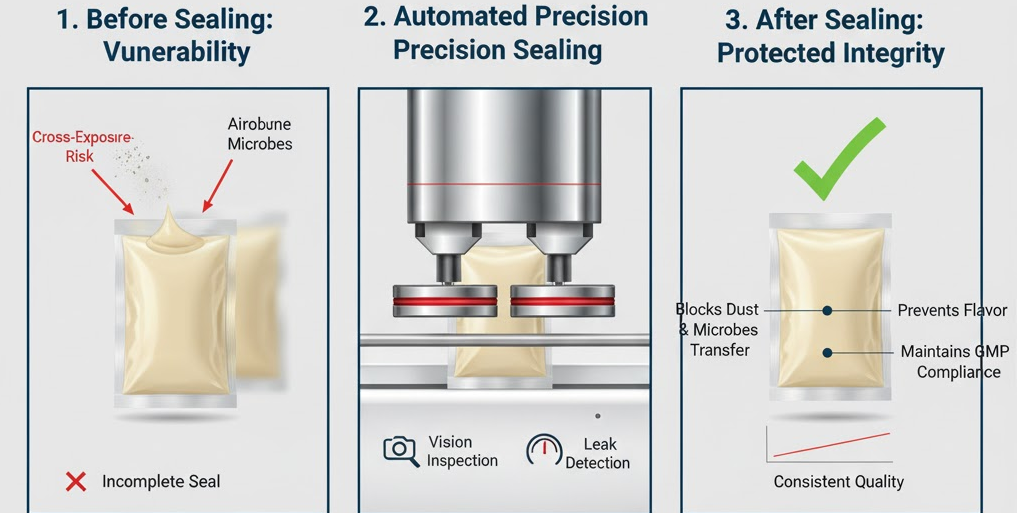

Preventing Post-Filling Contamination and Cross-Exposure

After mayonnaise passes through the bottle filling machine or Mayonnaise packing machine, it moves across several downstream stages—conveyor transfer, capping, labeling, and final packaging. Each transition introduces a chance for contamination if the seal or closure isn’t properly formed. Even a minor gap left by a faulty filling nozzle or filling valve can expose the product to air or microorganisms.

Modern food industry lines use fully automatic sealing systems built with stainless piston measuring pumps and servo motors for stable operation. These systems apply precise pressure and heat to form an airtight seal immediately after filling, keeping the product protected before it reaches open environments.

Every filling station integrates smart inspection tools such as infrared or vision-based systems that monitor filling accuracy and seal quality in real time. Defects like air pockets, uneven sealing, or product residue near the closure zone are detected instantly. The automated system removes defective items from the line, ensuring that only perfect tubes or containers proceed to packaging.

Cross-exposure between different flavors or condiment types can occur on shared lines. Proper sealing and volumetric filling techniques stop flavor or aroma transfer between batches by maintaining separation during and after filling.

When combined with PLC control systems and GMP hygiene protocols, these automated setups deliver a clean, repeatable, and safe filling process. From viscous liquid food products to creamy emulsions like mayonnaise, food-grade sealing keeps every package consistent, contamination-free, and ready for market distribution.

Sealing Technologies Used for Mayonnaise Packaging

Hot Air Sealing for Plastic and Laminate Tubes

Modern Mayonnaise filling machine lines often rely on hot air sealing as part of a fully automatic filling system. In this method, heated air softens the inner layer of the plastic or laminate tube before compression jaws fuse it together. The result is a smooth, durable, and leak-proof seal that protects viscous products like mayonnaise from bacteria contamination during handling and transport.

These systems are built from stainless steel 304 to meet food hygiene quality and GMP requirements. Integrated automatic conveyor systems and bottle position error correction devices help maintain alignment and sealing precision at high speeds. Their flexibility allows the same setup to seal multiple tube diameters and materials without extensive changeover. Regular CIP cleaning cycles keep the equipment sanitary between batches, which is critical for maintaining quality assurance in food production industries.

Recommended Reading: How Are Ketchup Packets Made – King Pack Machinery

Ultrasonic Sealing for Hygienic Applications

Some manufacturers pair the filling unit with servo piston filling machines or piston filler systems, followed by ultrasonic sealing. This technique uses high-frequency vibration to weld the inner layer of the tube without external heat, forming a hermetic seal within milliseconds.

Because no direct heat is applied, food components remain stable, making ultrasonic sealing suitable for sensitive emulsions and condiments.

In high-end packaging setups—like reciprocating packaging machines or airless package formats—ultrasonic sealing aligns with international standards such as CE GMP ISO9001, offering safe, precise, and efficient sealing for the cosmetic industry and food production industries alike.

When integrated into a capping and packaging line, these technologies combine hygiene, automation, and durability to deliver reliable protection and long shelf life for every product.

Vacuum or Nitrogen-Assisted Sealing for Shelf-Life Extension

Oxygen trapped inside the tube shortens mayonnaise shelf life even when external barriers are intact. Vacuum or nitrogen-flushing systems address this problem by removing or displacing internal air before the tube is sealed.

By reducing the headspace oxygen concentration to below 1 %, oxidation reactions slow dramatically, preserving color and taste. This approach is common in export-grade mayonnaise lines where the product may travel through warm climates and long storage periods before sale.

Combining nitrogen-assisted sealing with EVOH-barrier laminate tubes offers one of the longest shelf-life performances currently achievable for food condiments.

Compliance and Food-Safety Considerations

FDA and EFSA Requirements for Food-Contact Packaging

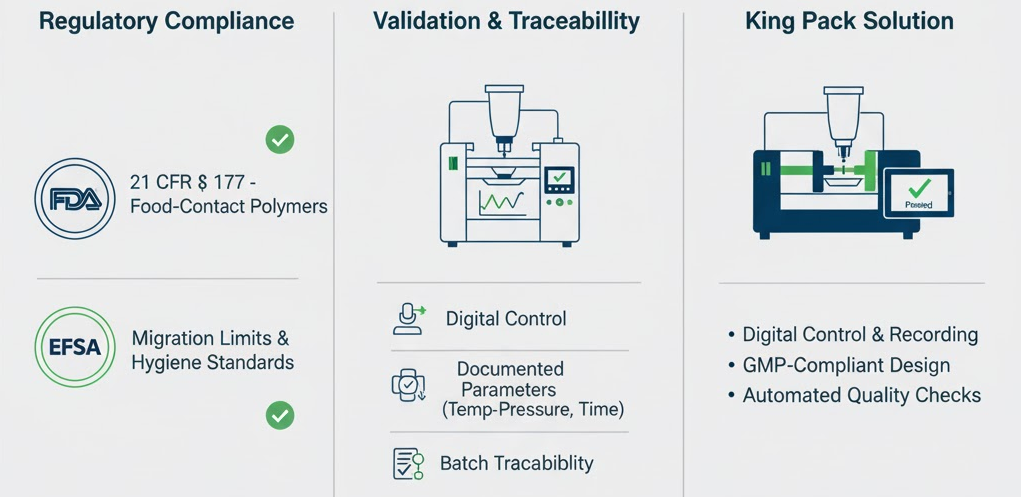

Food packaging must comply with strict safety regulations governing materials, processing, and closure integrity. In the United States, the FDA’s 21 CFR § 177 outlines requirements for polymers in food-contact surfaces. Similarly, the European Food Safety Authority (EFSA) enforces standards on migration limits and hygiene in packaging operations.

Manufacturers are required to validate that sealing processes do not introduce contaminants or compromise material integrity. Each sealing batch must maintain traceability through documented parameters like temperature, pressure, and dwell time. Using food-grade tube sealing machines with digital control and recording functions makes compliance simpler and more transparent.

HACCP and GMP Practices in Sealing Operations

Good Manufacturing Practice (GMP) and Hazard Analysis and Critical Control Points (HACCP) form the backbone of food-grade sealing operations. Each seal represents a critical control point (CCP) — a single failure can render the entire batch unsafe.

Routine inspection of seal strength, burst resistance, and visual uniformity is mandatory. Automated systems can perform inline testing, minimizing operator error. Regular sanitation schedules and operator training further protect against contamination from residual product buildup or airborne particles in the sealing area.

Recommended Reading: Emulsifying Mixer Machine for Cosmetics Production – King Pack Machinery

Traceability and Inline Quality Inspection

Traceability builds accountability throughout production. Modern sealing machines integrate barcode or batch-code printing directly after the sealing step, linking each tube to its production data. Inline camera systems verify code legibility and seal integrity in real time.

Such integrated control allows immediate rejection of defective tubes, improving overall yield and reducing recall risk. It also supports audits and customer confidence, especially in international export markets that demand documented proof of packaging integrity.

Commercial Benefits Beyond Shelf Life

Reduced Product Waste and Return Rates

Defective seals often lead to leaks, microbial spoilage, or texture changes. Each failed package means lost product and additional handling cost. Food-grade sealing significantly cuts this waste by delivering consistent closure strength and stability.

A case study in a large-scale condiment manufacturer found that switching to high-precision ultrasonic sealing lowered leakage-related returns from 1.8 % to 0.4 %, saving nearly 4 tons of product per quarter. Less waste translates into better sustainability scores and lower per-unit packaging cost.

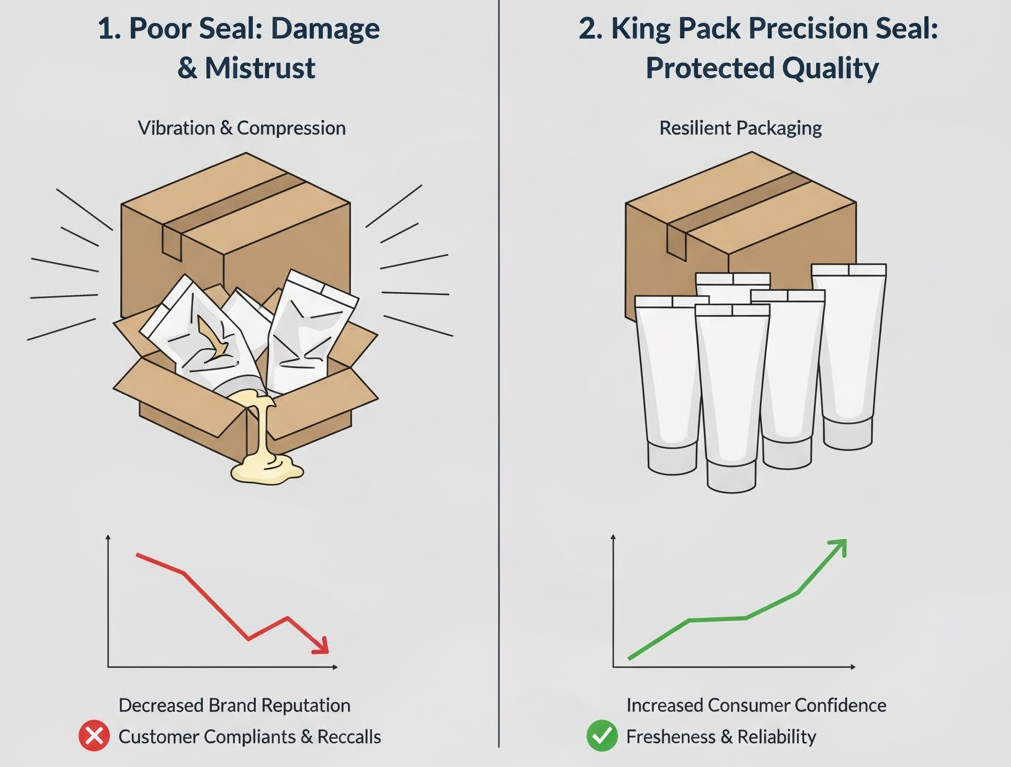

Improved Transport Durability and Brand Perception

Strong seals enhance packaging durability through long distribution chains. Tubes that remain intact under compression, vibration, and temperature fluctuations arrive at retailers in perfect condition. Consistent quality builds brand reputation and consumer confidence.

Consumers associate clean, leak-free packaging with hygiene and freshness — critical selling points for mayonnaise and other emulsified foods. A single leaky tube can affect brand perception far beyond its actual cost. Investing in reliable sealing technology reinforces product credibility and customer loyalty.

Consistency for Mass Production Lines

High-volume food production demands both speed and accuracy. Automated tube sealing machines achieve uniform results at rates exceeding 60 tubes per minute, eliminating the variability found in manual or semi-automatic methods.

Digital control systems store multiple recipes for different tube sizes and materials, ensuring repeatability across product lines. This consistency supports predictable shelf-life performance, simplifies validation, and reduces downtime between runs — all crucial advantages in competitive food manufacturing markets.

Recommended Reading: What is a pouch packaging – King Pack Machinery

Conclusion

Food-grade tube sealing defines how effectively mayonnaise resists oxidation, microbial contamination, and leakage during its journey from plant to consumer. The right sealing technology extends shelf life, enhances safety, and maintains the product’s sensory quality while helping producers meet regulatory and operational goals.

Manufacturers looking to upgrade their packaging lines should evaluate sealing performance with the same rigor as product formulation. Investing in validated sealing solutions improves not only food safety but also brand reliability and operational efficiency.

Contact King Pack to explore high-performance tube filling and sealing systems for mayonnaise and other food products. Our solutions combine hygienic design, traceability, and integrated quality control to help you achieve consistent results and extended shelf life across your entire packaging operation.