For the production of stable, smooth, and superior creams, lotions, and serums, a cosmetic homogenizer machine is necessary. It prevents separation and guarantees constant product quality by blending and emulsifying materials, such as water and oils, into a homogeneous, fine-textured slurry. Homogenizers, which are widely used in skincare and personal care manufacturing lines, assist producers in producing batches with a luscious texture, extended shelf life, and outcomes of professional caliber.

For the production of stable, smooth, and superior creams, lotions, and serums, a Cosmetic Homogenizer Machine is essential. It ensures constant product quality by blending and emulsifying materials such as water, oils, and natural ingredients into a fine, homogeneous texture. These machines are widely used in hygiene and beauty products, food industry, and pharmaceutical and chemical laboratories, where consistent product stability and longer shelf life are critical. Whether for Body Lotion, Cosmetic Face Cream Lotion, or Haircare Formulas, homogenization ensures every batch meets professional-grade standards.

Why Cosmetic Homogenizer Machines Ensure Skincare Product Quality

Cosmetic manufacturers today must deliver consistent cosmetic formulations that meet both Cosmetic Grade and international standards. To achieve this, they rely on advanced Mixing Equipment such as the vacuum emulsifier homogenizer or Cosmetic Emulsifier Mixer, designed to maintain the perfect balance between texture and uniformity.

From Makeup Cosmetics and liquid lipstick to medical gels and Body Oils, precise homogenization helps achieve the desired viscosity, ensuring customer satisfaction. Equipment like high-pressure homogenizers and Homogeniser emulsifiers play a crucial role in creating fine, stable emulsions.

King Pack, a trusted name in industrial sectors, provides Cosmetic Homogenizers with cutting-edge automation, Programmable controls, and Variable Speed Drives that ensure high production efficiency, safety, and reliable mixing environment.

Why Cosmetic Homogenizer Machines Ensure Skincare Product Quality

Cosmetic manufacturing companies face more pressure. They must produce skincare products that are consistent and high-quality. These products must meet both performance and regulatory standards in today’s fast-changing market conditions. You need advanced equipment to reach that level of precision. This equipment ensures texture stability and visual uniformity. It is where the cosmetic homogenizer machine becomes indispensable.

If you are a startup making new beauty products, investing in the right homogenizer ensures long-term efficiency and reliability. Large manufacturers expanding their cosmetic production equipment line also benefit from the right homogenizer. King Pack, a globally recognized supplier of high-quality mixing and homogenizing systems, helps businesses choose the right solution for their unique formulations. Their team of sales advisors and engineers provides full technical assistance, from consultation to installation, and ensures seamless integration with your production line.

What is a Cosmetic Homogenizer Machine?

A cosmetic homogenizer machine is a piece of high-performance processing equipment used to create stable, uniform mixtures from multiple ingredients. It plays a vital role in the home-buying process, equivalent to the cosmetic world. It ensures that every formulation component blends perfectly. This leaves no separation or uneven texture.

This technology is essential for making creams, serums, lotions, and gels. Emulsification stability defines product quality in these items. The cosmetic cream homogenizer creates micro-emulsions by breaking down oil and water phases into fine particles, ensuring smooth texture, visual consistency, and extended shelf life.

A real estate professional studies market conditions before investing. Similarly, cosmetic manufacturers use precise homogenization to keep product performance consistent in every batch.

How Do Cosmetic Homogenizer Machines Work?

A cosmetic homogenizer machine works in a simple but technical way. It is designed to spread ingredients evenly and keep them stable.

Process Overview:

Ingredient Feeding:

All raw materials, including oils, waxes, and emulsifiers, are added to the main tank.

Mixing:

The emulsifying mixer for cosmetics starts the high-speed blending process using a high shear homogenizer.

- Homogenization: Through mechanical force, particles are reduced and evenly distributed.

- Cooling: The product passes through a cooling jacket or a vacuum homogenizer mixer to maintain stability.

- Packaging: The homogeneous product is discharged and sent for packaging or filling.

Each step mirrors the precision required in a home purchase or mortgage lending process — every stage must be handled correctly to achieve the perfect result.

Laboratory vs. Industrial Homogenizers

King Pack provides cosmetic homogenizer with a vacuum system, lab homogenizers for cosmetics, and industrial homogenizers for cosmetics, designed for scalability and performance.

- Laboratory Models: Perfect for product development and testing small batches. These models are compact, easy to clean, and ideal for R&D operations.

- Industrial Models: Built for continuous operation and large-scale production, offering automation features and better control.

Like selecting between a small credit union and a large lending institution, the choice depends on production volume, formulation type, and budget.

Types of Cosmetic Homogenizer Machines

Choosing the right homogenizer is similar to evaluating the real estate market — every option has its own strengths, depending on the formulation’s needs and budget.

1. Rotor-Stator Homogenizers

These use mechanical shear to break particles, ideal for creams and lotions.

2. High-Pressure Homogenizers

A high-pressure homogenizer is best suited for serums and emulsions requiring ultra-fine particle sizes.

3. Ultrasonic Homogenizers

An ultrasonic homogenizer uses sound energy to create microscopic cavitation, and it also reduces heat stress on sensitive ingredients.

4. Vacuum Emulsifying Machines

A vacuum emulsifying machine or vacuum homogenizer mixer uses vacuum technology to remove trapped air bubbles during homogenization. This improves the visual clarity and density of products.

King Pack designs cosmetic mixing and homogenizing equipment for quality, reliability, and GMP compliance. It applies to both batch and continuous operations, and it is similar to how a well-structured home loan process ensures stability and long-term satisfaction.

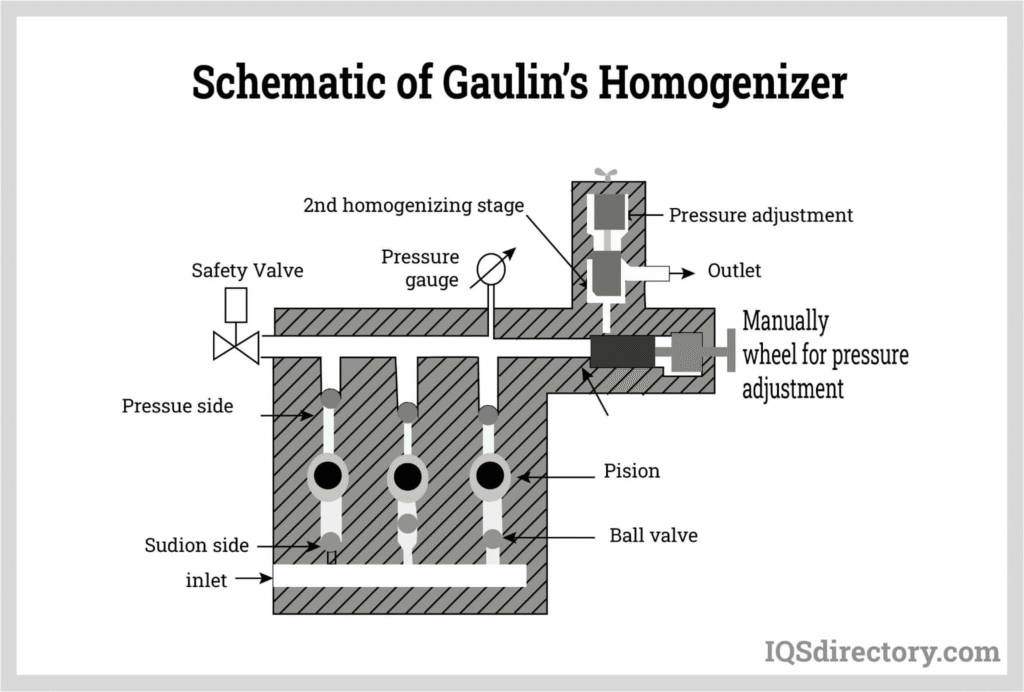

Construction and Components of Cosmetic Homogenizer Machines

Each cosmetic homogenizing system is designed with precision and built for durability:

- Mixing Tank: Made from stainless steel 316L, resistant to corrosion and contamination.

- Rotor-Stator Assembly: Ensures uniform shear forces and even emulsification.

- Motor and Drive Unit: Provides power and speed control.

- Control Panel: Offers automated operation, error detection, and data monitoring.

- Vacuum and Cooling System: Prevents air entrapment and temperature fluctuations.

- Safety Systems: Integrated with alarms, interlocks, and insurance companies-approved safety standards.

A good exit strategy in equipment investment includes:

- Reliable construction

- Easy maintenance

- Guaranteed performance

All features that King Pack ensures with its homogenizing systems.

Benefits of Using a Cosmetic Homogenizer Machine

- Enhanced Product Uniformity: A cosmetic lotion homogenizer ensures perfectly blended textures without phase separation.

- Improved Efficiency: Reduces processing time and minimizes waste.

- Versatility: Can handle various viscosities, from lightweight serums to dense creams.

- Product Stability: Prevents air bubbles and ensures consistent viscosity.

- Cost-Effectiveness: Like monitoring moving costs in relocation, a well-maintained homogenizer minimizes long-term operational expenses.

Businesses that partner with King Pack get tailored solutions, after-sales support, and a high-performance and reasonable cosmetic homogenizer machine price. These machines meet global manufacturing standards.

What to Consider Before Buying a Cosmetic Homogenizer Machine

Before finalizing your investment, analyze factors similar to assessing a home sale or property value — where details matter most.

- Production Capacity: You can choose between batch homogenizers and continuous systems based on expected volume.

- Viscosity and Formula Type: Ensure compatibility with your product range.

- Compliance: Opt for GMP cosmetic processing equipment that meets international standards.

- Automation Features: Programmable control systems and other features of the homogenizer machine improve consistency and reduce operator error.

- Service and Support: Expert advice, custom configurations, or maintenance plans.

- Financial Consideration: Understand operational costs, ROI, and maintenance budgets — your “monthly payment” in equipment terms.

Smart buying choice also entails the performance of the machine. It also entails long-term service, warranty, and supply reliability. These are some of the main components in any professional home buying procedure or industrial acquisition.

Maintenance and Troubleshooting Tips

Routine maintenance ensures optimal performance and longevity of your cosmetic cream homogenizer:

- Clean thoroughly after each batch to prevent contamination.

- Check seals, bearings, and rotor clearance regularly.

- Monitor temperature and pressure settings.

- Replace worn-out parts as per the manufacturer’s schedule.

Proper calibration and inspection can fix common problems like overheating, uneven emulsification, or air incorporation. King Pack’s mortgage broker-like precision in after-sales support ensures consistent operation and minimal downtime.

In case of performance drops, their sales advisors can guide maintenance teams remotely or on-site, helping you preserve efficiency while avoiding unexpected “closing costs.”

Choosing Right Homogenizer For Cosmetic Success

A cosmetic homogenizer machine is essential to contemporary skincare and cosmetic manufacturing, and its cost must be taken into account. Long-term market success, texture consistency, and product quality are all influenced by it. Manufacturers and brands aim for perfection. They need to pick the best high shear homogenizer, vacuum homogenizer mixer, or homogenizer for cosmetic lotion.

With King Pack as your reliable partner, you enjoy access to cutting-edge cosmetic production machinery. This machinery is backed by expert engineering, technical guidance, and staunch customer service. Their professionals ensure all systems are designed according to your requirements — from R&D to mass production — while being in line with market conditions and industry requirements.

To explore your next investment in efficient and scalable homogenizing technology, Contact Us today and speak with King Pack’s expert sales advisors. Together, you can build a more productive, profitable, and sustainable future for your cosmetic manufacturing business.

FAQs

What is a cosmetic homogenizer machine used for?

A cosmetic homogenizer machine is used to blend, emulsify, and stabilize formulations in skincare and personal care products. It ensures smooth, uniform textures for creams, lotions, and gels. Manufacturers like King Pack-one of the best cosmetic homogenizer suppliers, design these machines to enhance product quality and production efficiency.

What are the main types of cosmetic homogenizers?

The main types include:

- Rotor-stator

- High-pressure

- Ultrasonic

- Vacuum emulsifying machines

Each type of cosmetic homogenizer serves specific production needs from small lab testing to large-scale industrial manufacturing.

Why is a vacuum homogenizer mixer important in cosmetic manufacturing?

A vacuum homogenizer mixer removes air bubbles and improves product density, creating professional-grade emulsions. It is essential for achieving premium-quality skincare and pharmaceutical products.

What should manufacturers consider before buying a cosmetic homogenizer?

Buyers should consider all the main factors before purchasing, such as:

- Capacity

- Viscosity range

- Automation

- GMP compliance

After-sales support. King Pack provides consultation through experienced sales advisors to help clients choose the best machine for their application.

How does King Pack support cosmetic manufacturers?

King Pack offers end-to-end service, and its services will be from product consultation and design to installation and after-sales maintenance. Their cosmetic homogenizer machines meet global standards and are customized for different production scales.