The global demand for hand sanitizers surged dramatically during the COVID-19 pandemic and continues to remain high across healthcare, commercial, and personal use sectors. As businesses scale up production to meet this demand, investing in specialized filling equipment becomes crucial for maintaining quality, efficiency, and regulatory compliance.

This comprehensive guide covers everything you need to know about hand sanitizer filling machines, from basic operations to advanced selection criteria. You’ll discover how these machines streamline production while maintaining the highest hygiene standards required for sanitizer manufacturing.

What is a Hand Sanitizer Filling Machine?

Definition and Purpose

A hand sanitizer filling machine is specialized packaging equipment designed to accurately dispense liquid or gel sanitizers into containers such as bottles, pouches, or tubes. These machines automate the filling process, replacing manual labor with precise, consistent, and hygienic operations.

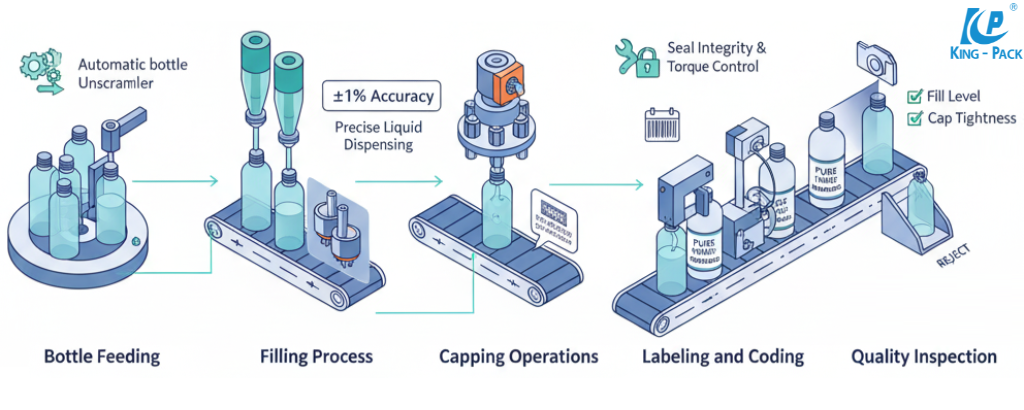

These machines do more than just dispense sanitizer. Many are designed as part of a complete line, handling bottle feeding, precise dosing, capping, and even labeling. By combining these steps, they help manufacturers boost output while maintaining product consistency and meeting strict safety standards.

Importance for Small-Scale and Industrial Production

For small-scale operations, these machines provide the accuracy and speed needed to compete with larger manufacturers while maintaining product quality. Even compact models can fill hundreds of bottles per hour, dramatically outperforming manual processes.

Industrial producers rely on high-speed filling lines capable of processing thousands of units hourly. These systems maintain consistent fill volumes, reduce product waste, and meet strict regulatory requirements for pharmaceutical-grade sanitizers.

Recommended Reading: What You Should Know About Liquid Filling Machines – King Pack Machinery

How Do Hand Sanitizer Filling Machines Work?

Step-by-Step Workflow of a Sanitizer Filling Line

The sanitizer filling process follows a systematic workflow designed for maximum efficiency and contamination prevention. The process generally follows: bottle feeding → filling → capping → labeling → inspection.

In the bottle feeding stage, bottles are placed (manually or automatically) on a conveyor. They move into position under the filling nozzles. The machine doses an exact volume of sanitizer into each container.

Then the capping station applies caps—screw caps, pump tops, or sprays. After capping, labeling adds branding and product info. Finally, inspection ensures correct fill levels, caps sealed, and no defects.

Goals Achieved: Speed, Accuracy, Hygiene

Modern filling systems achieve production speeds ranging from 30 bottles per minute for semi-automatic machines to over 300 bottles per minute for high-speed rotary systems. This speed advantage translates directly to increased profitability and market responsiveness.

Accuracy remains paramount in sanitizer production due to regulatory requirements and consumer safety. Electronic controls maintain consistent fill volumes, while hygienic design prevents cross-contamination between batches.

Semi-Automatic vs Fully Automatic Machines

Semi-automatic machines require operators to load bottles and place caps manually but automate the critical filling process using systems such as overflow fillers and piston filling systems. These machines fit small to medium operations with production needs around 500–2000 bottles per hour. Cap feeding systems, fill-to-level devices, and double-head nozzles can be added to enhance efficiency and versatility.

Fully automatic systems handle the entire workflow from bottle feeding through labeling machines, filling nozzles, and final packaging with minimal human intervention. Production capacities range from 2000–15000 bottles per hour, making them ideal for large-scale industries or bulk container operations.

Features like photoelectric sensing, mini pinch or auto pinch mechanisms, and spillage trays reduce errors, maintain hygiene, and optimize workflow.

These systems also accommodate viscous and semi-viscous materials like liquid detergent or hand sanitizer gel, supporting diverse personal care industries.

| Machine Type | Production Capacity | Operator Requirements | Initial Investment | Best For |

| Semi-Automatic | 500-2000 bottles/hour | 1-2 operators | Lower | Small to medium operations |

| Fully Automatic | 2000-15000 bottles/hour | 1 supervisor | Higher | Large-scale production |

Types of Hand Sanitizer Filling Machines

Hand sanitizer filling machines come in different types, designed to match the scale and speed of production. The two most common designs are linear and rotary. Another way to categorize them is by small-scale versus industrial-scale applications.

Linear vs Rotary Machines

Linear filling machines use a straight-line system where bottles move along a conveyor and pass through filling, capping, and labeling stations one by one. They are simple, versatile, and allow quick adjustments for different bottle shapes or sizes. Because of their straightforward design, they are also easier to clean and maintain.

Linear machines’ advantages include:

- Easier to clean and maintain

- Handles many container sizes

- Lower purchase cost

- Simple to train operators

Rotary filling machines, on the other hand, arrange multiple filling heads in a circular pattern. Bottles enter the rotary system and are filled, capped, and processed at the same time across several stations. This design greatly increases speed and efficiency, making it ideal for high-volume runs. However, rotary machines require more complex maintenance and have higher upfront costs.

Rotary machines’ advantages include:

- Faster production speeds

- Saves floor space per unit output

- Continuous operation with fewer pauses

- Best for long, single-product runs

Small-Scale vs Industrial-Scale Machines

Small-scale sanitizer filling machines usually handle bottle sizes between 50 ml and 500 ml. Their production rates fall between 30–100 bottles per minute. Many of these systems require manual bottle loading and use basic controls. This makes them cost-effective for startups or for businesses producing specialty sanitizer products.

Industrial-scale filling machines are built for factories with large output needs. They can fill anything from 50 ml bottles up to 5-liter containers, with speeds of 200+ bottles per minute. These advanced systems often come with automatic changeover functions, PLC-based control panels, and remote monitoring options. Some models also integrate with plant management systems for complete production tracking.

Comparison Table: Types of Hand Sanitizer Filling Machines

Hand Sanitizer Filling Machine Construction and Components

Key Components: Pumps, Nozzles, Conveyors, Capping Heads, Control Panels

Every machine is made up of key parts: pumps or pistons, nozzles, conveyors, capping heads, and control panels.

Pumps or piston systems push sanitizer into containers. Nozzles ensure smooth flow without dripping. Conveyors carry bottles between stations. Capping heads place and tighten caps. The control panel (often PLC + touchscreen) manages timing, volume, and fault detection.

Recommended Reading: How to maintain filling and sealing machine regularly? – King Pack Machinery

Optional Features: Inline Sterilization, Labeling, Inspection

- Inline Sterilization: UV sterilization tunnels or ozone treatment systems eliminate potential contaminants from containers before filling. This feature is essential for pharmaceutical-grade sanitizer production.

- Automated Labeling: Integration with labeling systems allows complete product finishing in a single pass. Options include wrap-around labels, front/back application, and tamper-evident sealing.

- Vision Inspection: Camera-based systems check fill levels, detect foreign particles, and verify proper cap placement. Automatic rejection removes non-conforming products without stopping production.

Materials Used for Hygiene and Durability

All product-contact surfaces use 316L stainless steel or FDA-approved materials resistant to alcohol and other sanitizer ingredients. This construction prevents corrosion and maintains product purity throughout the production process.

Seals and gaskets utilize pharmaceutical-grade silicone or EPDM rubber compounds that resist sanitizer ingredients while maintaining flexibility for proper sealing. These materials also withstand repeated cleaning and sterilization cycles.

Benefits of Using a Hand Sanitizer Filling Machine

Automated filling machines boost output far beyond manual methods, often increasing production by 300–500%. They maintain precise fill levels within ±0.5%, cutting waste and keeping alcohol concentrations within compliance standards. This accuracy ensures every batch looks uniform, strengthening consumer trust and brand reputation.

Closed-system designs protect operators from sanitizer vapors and reduce contamination risks. Features like batch tracking, automated quality checks, and CIP cleaning systems simplify regulatory compliance. These safeguards are especially important for FDA approval and international distribution.

Modern machines handle both thin liquids and thick gels by using different pump types, nozzle designs, and temperature controls. Heated hoppers and anti-foam systems help maintain consistency and appearance, even with challenging gel or surfactant-based formulations.

Click here to check our products

What to Consider Before Buying a Hand Sanitizer Filling Machine

Production Capacity and Speed

Accurately assess your current and projected production needs before selecting equipment. Consider peak demand periods and allow for growth when specifying machine capacity.

Capacity Planning Guidelines:

- Small operations: 1,000-5,000 bottles per day

- Medium operations: 5,000-25,000 bottles per day

- Large operations: 25,000+ bottles per day

Match machine speed to your downstream equipment capabilities including capping, labeling, and packaging systems. A filling bottleneck can limit overall production efficiency.

Recommended Reading: How an Automatic Tube Filling and Sealing Machine Works – King Pack Machinery

Budget and ROI

Calculate the total cost of ownership including initial purchase price, installation, training, and ongoing maintenance costs. Factor in the labor savings and increased production capacity when determining payback period.

Financing options may be available for qualified buyers, spreading the investment cost over multiple years while immediately realizing production benefits. Leasing arrangements can also provide tax advantages for some businesses.

Consider the opportunity cost of not investing in automation. Manual production limitations may prevent you from capturing market opportunities or meeting customer delivery requirements.

After-Sales Support and Maintenance

Evaluate the manufacturer’s service network and response capabilities in your region. Local service availability reduces downtime and maintenance costs over the machine’s operational life.

Training programs for operators and maintenance staff are crucial for maximizing equipment performance. Look for manufacturers that provide comprehensive training as part of the purchase package.

Spare parts availability and pricing significantly impact long-term operating costs. Establish parts stocking agreements and maintenance contracts to minimize unexpected expenses.

King Pack provides comprehensive after-sales support with our global service network, addressing the critical need for reliable equipment maintenance and technical assistance.

Compliance and Certifications

Verify that the filling machine meets relevant regulatory requirements for your target markets. FDA compliance is mandatory for US sales, while CE marking is required for European markets.

Documentation packages should include IQ/OQ protocols (Installation Qualification/Operational Qualification) required for pharmaceutical applications. These protocols demonstrate that the equipment operates according to specifications.

Material certifications for product-contact surfaces are essential for regulatory submissions and customer audits. Request certificates of conformance for all stainless steel and polymer components.

Energy Consumption and Efficiency

Modern filling machines incorporate energy-efficient components that reduce operating costs while supporting sustainability initiatives. Variable frequency drives on motors and efficient heating systems can significantly impact energy consumption.

Compare power requirements and compressed air consumption between different machine options. These operating costs accumulate significantly over the equipment’s operational life.

Look for machines with standby modes and automatic shutdown features that reduce energy consumption during production breaks and maintenance periods.

Maintenance and Troubleshooting Tips

Daily Cleaning and Calibration

Establish standardized cleaning procedures that address all product-contact surfaces while protecting sensitive electronic components. Use cleaning agents compatible with stainless steel and sealing materials.

Daily Maintenance Checklist:

- Clean filling nozzles and product pathways

- Check and adjust fill volumes

- Inspect conveyor alignment and belt condition

- Verify capping torque settings

- Document production parameters and any issues

Calibration checks with test fills using water or sanitizer maintain accuracy over time. Record fill weights and adjust pump settings as needed to maintain target volumes.

Conclusion

A well-chosen hand sanitizer filling machine can perfectly boost your production line while maintaining hygiene and reducing errors. At KP Filling Machines, we provide solutions tailored to your production scale—whether you’re a small business looking for compact semi-automatic units or a large facility requiring fully automated high-speed systems.

With our advanced technology, durable components, and global support network, you gain the reliability and performance needed to stay competitive in a demanding market. Don’t let outdated or manual processes hold back your growth.

Contact KP Filling Machines today to explore our range of sanitizer filling equipment and find the right solution for your business.