Introduction

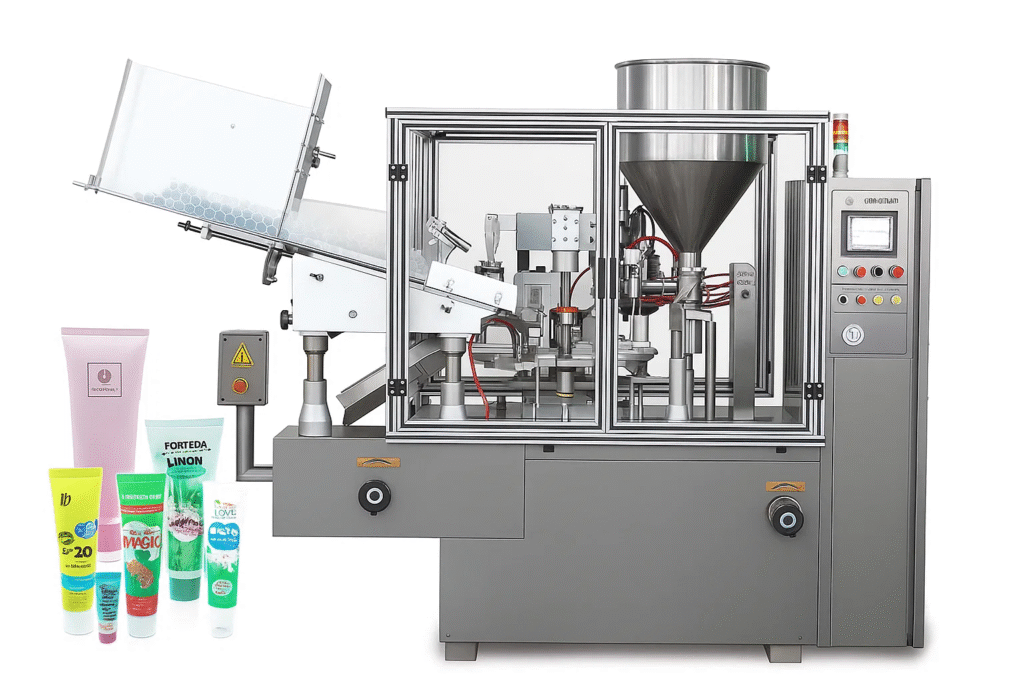

The automatic tube filling and sealing machine form an integral part of today’s packing industry. They operate from free-flowing gels at 100 cP to heavy pastes at 500,000 cP and maintain dosing accuracy to within ±0.5%. This tight tolerance level makes them the perfect match for high-speed production lines, when seal integrity is on the line.

In this article, we will take a look at how these machines work, how and why they outperform manual methods.

Importance of Automatic Tube Filling and Sealing Machines in Cosmetics, Pharmaceuticals, and Food

The tube packaging market has grown rapidly. It was valued at approximately USD 11.35 billion in 2024 and is projected to reach USD 19.99 billion by 2034. These numbers highlight just how central tube filling machines have become in global production.

Pharmaceutical use demands stricter conditions. Equipment must operate in Class 100 cleanrooms and comply with 21 CFR Part 11 standards to guarantee product safety and traceability. For cosmetics and food, consistency in dosing and sealing is just as critical to protect brand quality and consumer trust.

Handling viscous products is another core requirement. Modern systems manage everything from lightweight gels at 50 cP to heavy pastes at 1,000,000 cP. With temperature control maintained within ±2°C, even heat-sensitive formulations stay stable. At KP Filling Machine, we offer equipment designed to cover this entire range, supporting manufacturers across all three industries.

Recommended Reading: What Is a Prefilled Syringe Filling Machine? – King Pack Machinery

KPGFW-60D drop filling and sealing machine – King Pack Machinery

Benefits of Automation and Precision

Automated systems achieve:

- Fill accuracy: ±0.25% for volumes above 10ml

- Production speeds: 60-200 tubes per minute

- Labor reduction: 70% compared to manual operations

- Waste reduction: 15% through precise volumetric control

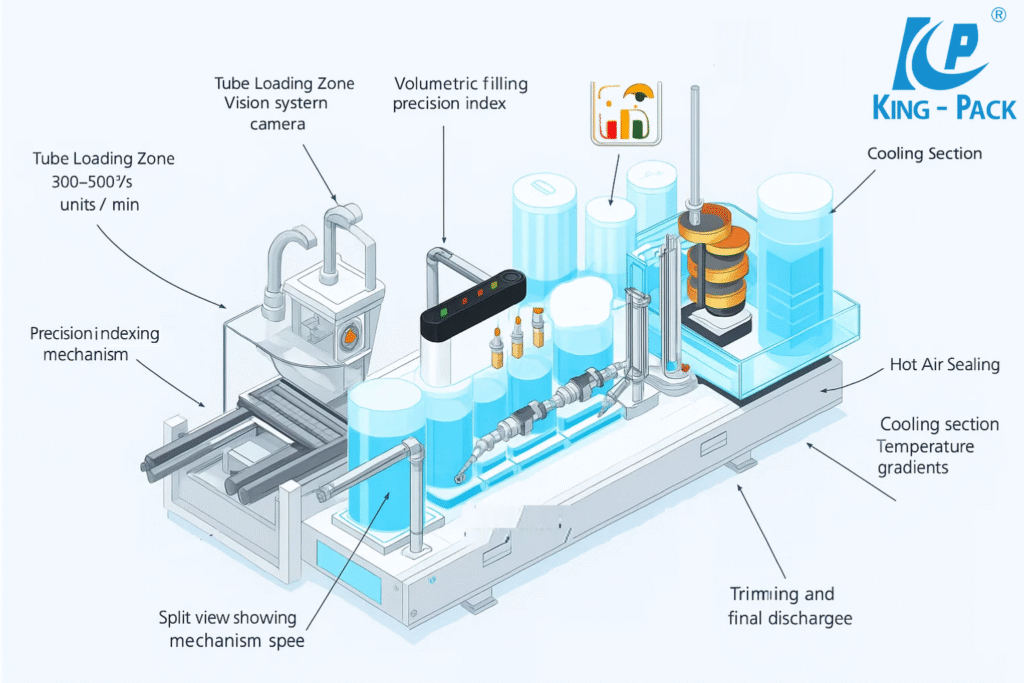

Main Components of a Tube Filling and Sealing Machine

Modern tube packaging equipment consists of several integrated subsystems. Each component performs specific functions while communicating with the central control system. Understanding these components helps operators troubleshoot issues and optimize performance.

The following is a quick rundown of these main components of a tube filling and sealing machine:

| Component | Function | Technical Specifications |

| Feeding System | Tube orientation | 200-500 tubes/min capacity |

| Filling Pump | Product dosing | ±0.5% accuracy, 1-300ml range |

| Sealing Unit | Tube closure | 180-220°C for hot air sealing |

| Control System | Process automation | PLC with HMI interface |

Now, let’s have a detailed look at each of these components:

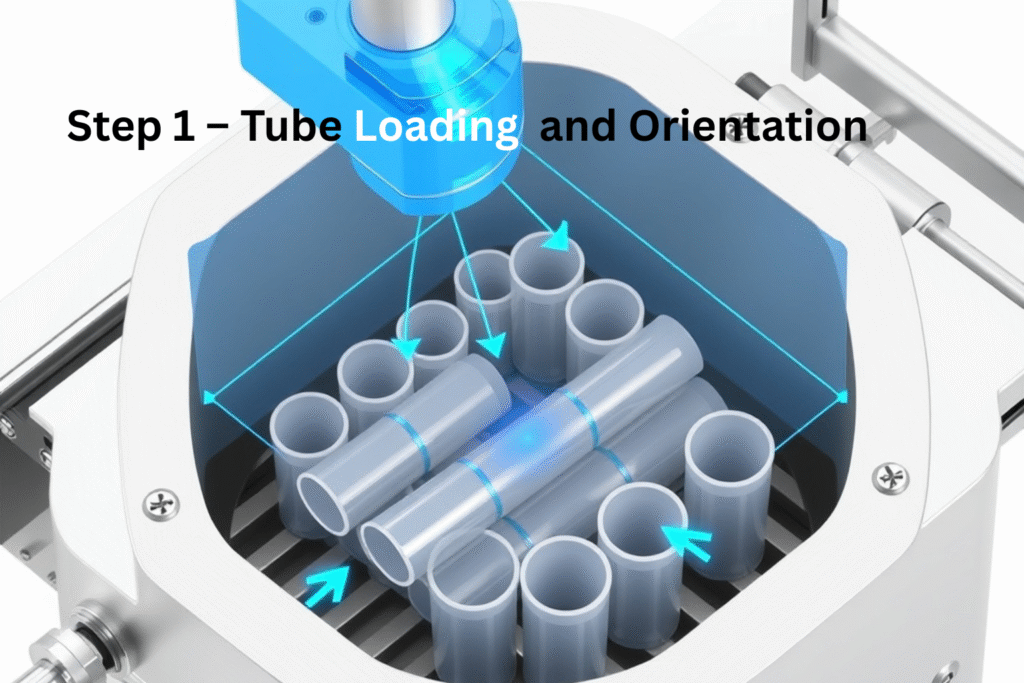

1. Feeding and Orientation Systems

Tube feeding orientation systems automatically position empty tubes for filling. Vibratory bowl feeders sort tubes by size and orient them correctly. Mechanical guides direct tubes into the filling stations with precise alignment.

Sensors verify proper tube positioning before filling begins. Misaligned tubes trigger automatic rejection to prevent equipment damage. The feeding system maintains continuous operation by storing tubes in buffer magazines.

Changeover between tube sizes requires minimal downtime. Quick-change components accommodate different tube diameters and lengths. This flexibility allows manufacturers to run multiple product lines efficiently.

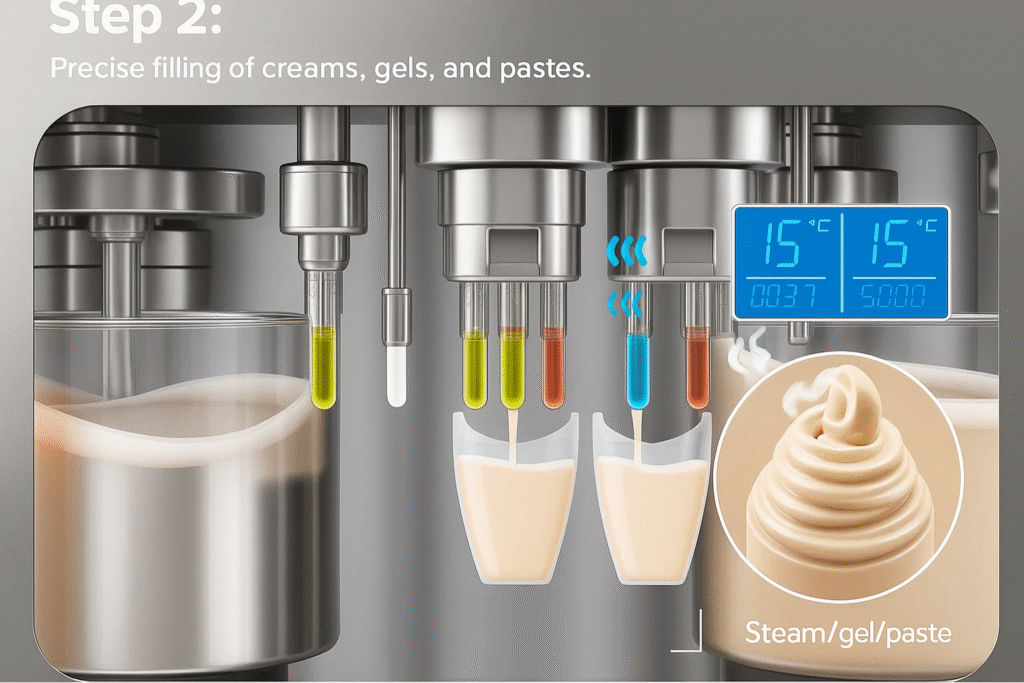

2. Filling Pumps, Valves, and Nozzles

Volumetric filling pumps deliver precise product amounts to each tube. Servo-driven pistons provide accuracy within ±0.5% of target fill weight. Variable speed control adapts to different product viscosities.

Specialized nozzles prevent dripping and contamination. Anti-drip valves seal immediately after filling to maintain clean tube exteriors. Heated nozzles handle temperature-sensitive products without degradation.

CIP (Clean-in-Place) connections simplify sanitation procedures. Automated cleaning cycles flush product residue from all wetted surfaces. This reduces changeover time between different products.

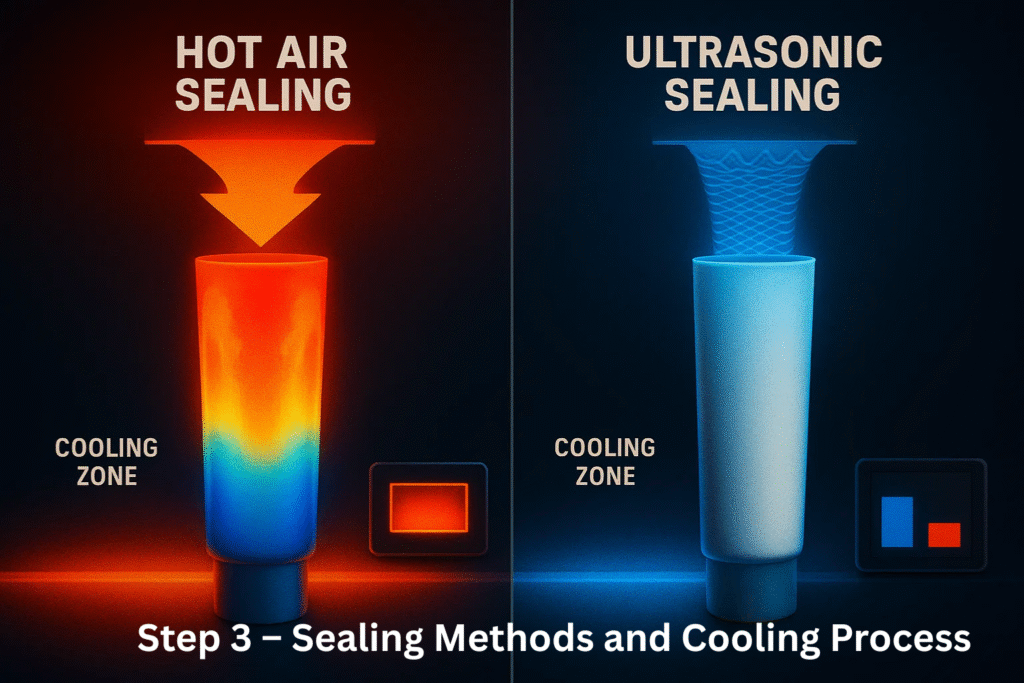

3. Sealing Systems: Hot Air and Ultrasonic

Hot air sealing tube fillers use heated air to melt tube materials together. Temperature control maintains consistent seal integrity across production runs. Cooling stations solidify seals before tubes move to subsequent stations.

Ultrasonic tube sealing technology creates molecular bonds without external heat. Vibrations generate friction that melts plastic materials at the seal point. This method works excellently with heat-sensitive products.

Both sealing methods accommodate various tube materials including plastic, aluminum, and laminates. Seal quality monitoring systems detect weak seals and reject affected tubes automatically.

4. PLC Control and Touchscreen Interfaces

Programmable Logic Controllers coordinate all machine functions automatically. Recipe storage allows quick changeovers between different products and tube sizes. Real-time monitoring displays production statistics and alarm conditions.

Color touchscreens provide intuitive operator interfaces. Parameter adjustments require minimal training while maintaining production security. Password protection prevents unauthorized changes to critical settings.

Data logging capabilities track production metrics for quality analysis. Integration with factory networks enables remote monitoring and diagnostics. Preventive maintenance schedules optimize equipment reliability.

Recommended Reading: Maintenance Tips for Vial Filling Machines to Ensure Longevity – King Pack Machinery

Step-by-Step Operation Process

An automatic tube filling and sealing machine follows a precise cycle designed for speed and accuracy. From tube loading to final discharge, each step is optimized to maintain high throughput and minimize defects. Here is a detailed look at each step of automatic tube filling and sealing machine process:

Step 1 – Tube Loading and Orientation: A vibratory feeder sorts tubes at speeds of 300–500 units per minute. The vision system checks orientation with 99.9% accuracy, while the reject unit removes faulty tubes. The indexing system then positions each tube within ±0.5mm for downstream operations.

Step 2 – Precise Filling of Creams, Gels, and Pastes: Volumetric filling systems cover a 5–300ml range and maintain ±0.5% accuracy for volumes above 10ml. They handle viscosities from 1–500,000 cP. Heated tanks and nozzles (40–60°C) support smooth dosing of thick products at speeds of 60–120 tubes per minute.

Step 3 – Sealing Methods and Cooling Process: Hot air sealing uses 180–220°C with 1.5–3.0 seconds dwell time, achieving 15–25 N/15mm seal strength. Cooling takes 3–5 seconds. Ultrasonic sealing runs at 20–40 kHz and 800–2000 watts, forming seals in under 2 seconds with 70% greater energy efficiency compared to thermal methods.

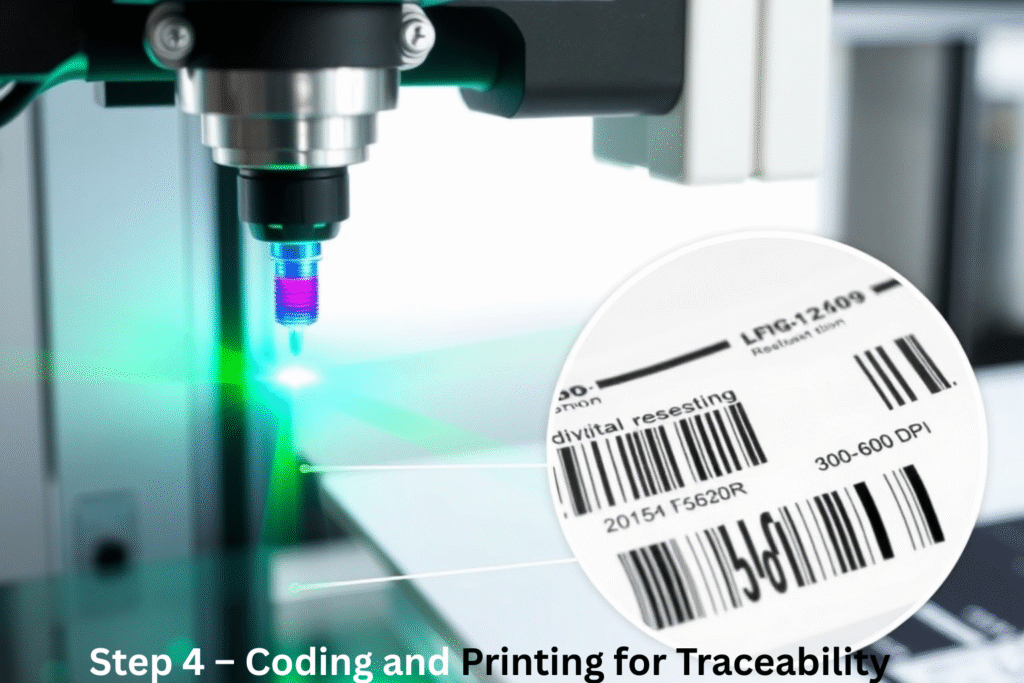

Step 4 – Coding and Printing for Traceability: Coding systems mark tubes at up to 1000 characters per second. Inkjet printers deliver 300–600 DPI resolution for batch and expiry details, while laser coders produce permanent markings that withstand 500+ wash cycles.

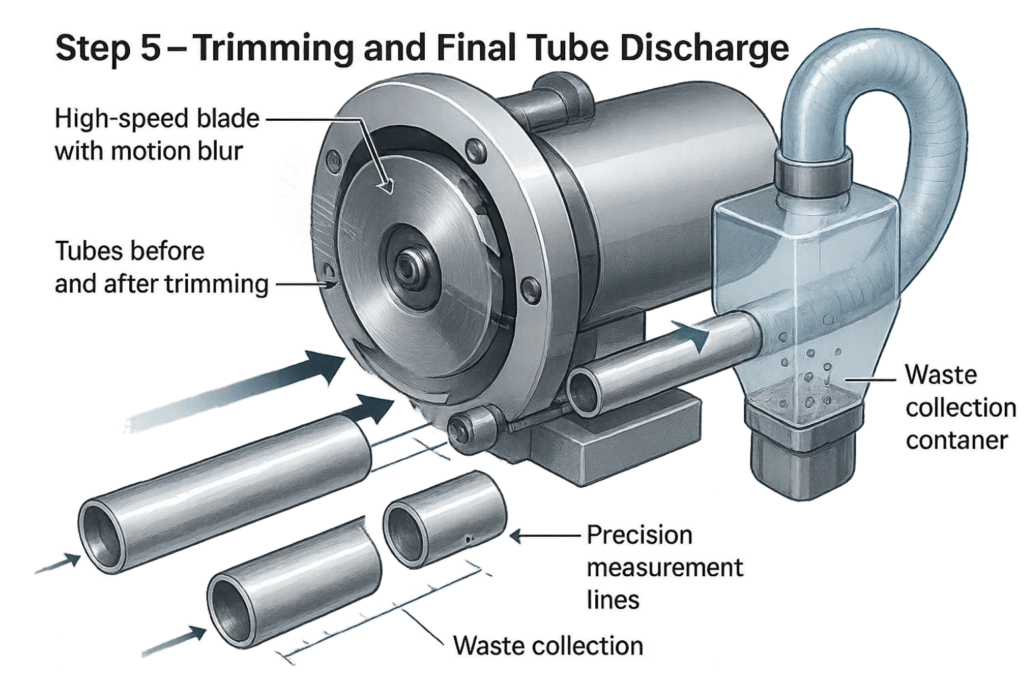

Step 5 – Trimming and Final Tube Discharge: Rotary trimmers operating at 3000 RPM cut tube ends cleanly. Trim length is adjustable between 2mm and 20mm. A vacuum system captures more than 99% of trimmings to maintain a clean working area.

This cycle combines speed, precision, and product safety. By controlling each stage with strict tolerances, automatic tube filling and sealing machines maintain high throughput while keeping rejection rates extremely low.

Recommended Reading: How Vial Filling Machines Improve Efficiency and Accuracy in Liquid Filling – King Pack Machinery

Variants of Tube Filling Machines

Different production environments require different types of tube filling and sealing machines. Variants are usually defined by automation level, motion system, and material compatibility.

Semi-Automatic vs Fully Automatic

KPGZW-60 filling and folding machine – King Pack Machinery

Semi-automatic machines suit smaller operations, while fully automatic systems are built for industrial-scale production. The table below outlines key differences:

| Feature | Semi-Automatic | Fully Automatic |

| Production Rate | 30–60 tubes/min | 80–200 tubes/min |

| Operator Required | 1 per machine | 1 per 2–4 machines |

| Initial Cost | $50,000–150,000 | $200,000–800,000 |

| ROI Period | 18–24 months | 12–18 months |

Semi-automatic machines require more labor but come with lower upfront investment. Fully automatic machines cost more but deliver faster ROI thanks to higher speeds and reduced manpower needs.

Rotary vs Linear Filling Systems

Rotary tube filling machines use a star wheel mechanism with 8–16 stations. They run in continuous motion, reaching up to 200 tubes per minute. With a footprint of 8–12 square meters, they provide high output while saving floor space.

Linear tube filling systems typically feature 4–8 stations arranged in a straight path. They achieve production rates of 60–120 tubes per minute. Their advantage lies in easier maintenance, faster changeovers, and better accessibility for cleaning or adjustments.

Suitable Materials: Plastic, Aluminum, Laminated Tubes

Material compatibility is a critical factor when selecting a tube sealing machine. Studies in packaging performance show:

- Plastic (PE) tubes achieve up to 95% seal integrity at 180°C using hot air sealing.

- Aluminum tubes perform better with ultrasonic or fold sealing, as thermal sealing can weaken the material.

- Laminated tubes require carefully controlled temperature profiles to avoid delamination or incomplete seals.

Choosing the right variant depends on production volume, material type, and long-term cost efficiency. For tailored solutions, KP Filling Machine provides both rotary and linear models designed to handle a wide range of tube materials.

Recommended Reading: Vial Filling Machines and Processing Solutions – King Pack Aseptic Technology – King Pack Machinery

Key Benefits of Automatic Tube Filling

Modern automatic tube filling machines deliver unmatched accuracy and speed. According to 2023 industrial surveys, average fill accuracy reaches ±0.3%. Compared to manual operations, production speed improves by up to 300%, while changeover times drop by 60%. Overall equipment effectiveness (OEE) consistently falls in the 85–95% range, ensuring stable high-volume output.

Hygiene and compliance are equally important. These machines are designed for cleanroom environments, with Class 100 (ISO 5) air filtration and 316L stainless steel construction. They support CIP/SIP validation protocols and meet FDA 21 CFR Part 11 requirements, making them suitable for regulated pharmaceutical and cosmetic production.

Automation also reduces reliance on labor while improving consistency. Studies show a 60–70% reduction in labor costs and a 95% improvement in product uniformity. Waste levels drop by 12–18%, and quality defects are reduced by as much as 80%, making automated systems both cost-effective and reliable.

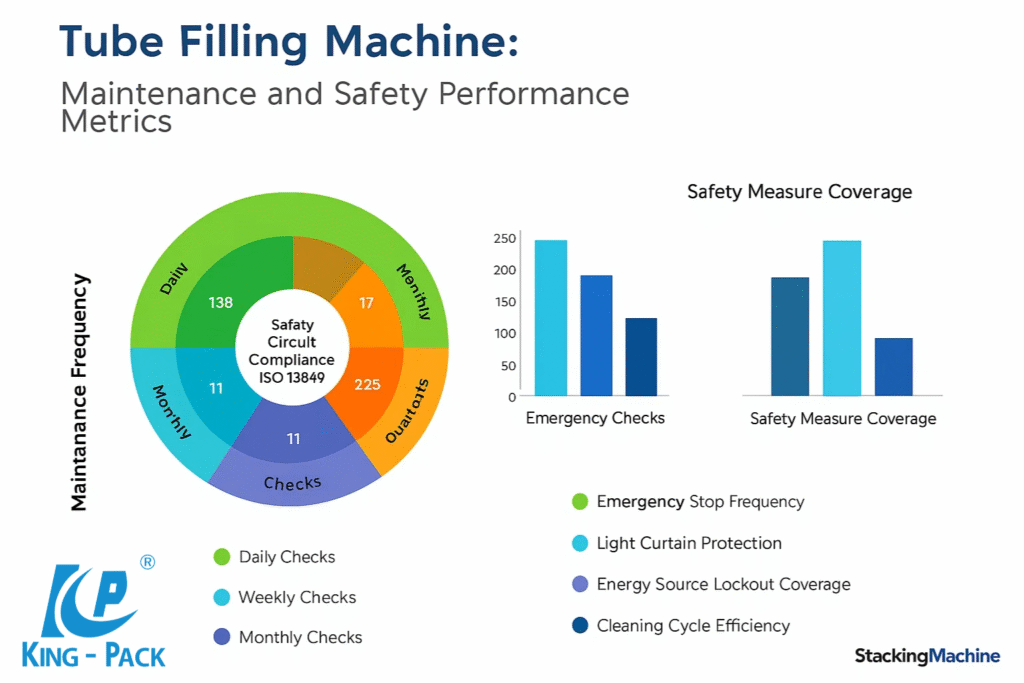

Maintenance and Safety Considerations

Daily Cleaning and Sterilization

Automatic tube filling machines must undergo strict cleaning protocols to maintain product integrity and meet regulatory standards. A typical CIP cycle starts with a pre-rinse using purified water for 2–3 minutes to remove residues. This is followed by a detergent wash at 65°C for about 15 minutes to break down any remaining product. A final rinse with water-for-injection (WFI) takes 5 minutes to ensure pharmaceutical-grade cleanliness. Sanitization is then performed with 70% ethanol for 10 minutes to eliminate microbial risks.

Mechanical and Electrical Checks

Preventive maintenance ensures smooth operation and reduces downtime. Daily tasks include visual inspection of moving parts and lubrication of wear points. Weekly activities focus on torque checks and system calibration for accuracy. On a monthly basis, bearings and alignments are inspected to prevent mechanical failures. Every quarter, a full system validation is carried out, covering both mechanical and electrical performance to verify compliance with production standards.

Operator Safety Measures

Operator safety is integrated into machine design through multiple protective systems. The equipment uses Category 3 safety circuits (ISO 13849) for redundancy and reliability. Emergency stop buttons are installed every 3 meters for immediate access during production. Light curtains with a 14 mm resolution safeguard access points, preventing accidental hand entry near moving parts. In addition, lockout/tagout procedures cover more than 15 energy sources, ensuring the machine is fully de-energized before any maintenance or repair work begins.

Recommended Reading: A Detailed Guide to Vial Filling Machine Types – Principles and Selection | King Pack – King Pack Machinery

Applications Across Industries

Cosmetics and Personal Care Products

Cosmetic tube filling machines from KP Filling Machine are designed to process a wide range of viscosities, from lightweight serums at 50–2,000 cP to heavy creams and lotions reaching 50,000 cP, and gels extending up to 100,000 cP. These systems use precision volumetric dosing to achieve ±2% fill accuracy, a critical factor in maintaining consistent packaging for consumer products.

These machines process plastic tubes, laminate tubes, and collapsible aluminum tubes with a filling nozzle diameter matched to product type.

For hygiene, the machines use 316 stainless steel product contact parts, stainless steel tube filler design, and automatic settings that prevent contamination. With touch screen control panels, PLC-based control, and digital temperature control, operators can manage filling accuracy, sealing speed, and date/lot code stamping. This level of precision keeps personal care products consistent in texture, stability, and shelf life.

2. Pharmaceutical Ointments and Creams

In pharmaceuticals, equipment such as the Ointment Tube Filling Machine, Automatic Ointment Filling Machine, and cream and ointment filling and sealing machine meet strict FDA and cGMP standards.

They support batch number and date coding, crimp jaw equipped with date/lot coder systems, and advanced sealing with hot-air sealing or ultrasonic sealing technology.Hygienic construction with double jacket heating hopper, rotary indexing, and operator safety door system allows precise handling of viscous ointments.

Features like safety protection devices, stainless steel contact parts, and automatic tracking electrical control boxes keep dosing accurate while reducing risks of microbial contamination. This ensures reliable tube packaging for antibiotics, corticosteroids, and dermatological creams.

3. Food Pastes and Viscous Products

For food packaging, Tube packaging machines and Paste Tube Filling Machines are designed for sauces, honey, nut butters, and concentrated pastes. They handle viscous and semi-viscous products with the help of vertical screw pumps, piston fillers, and automatic refill pumps.

These machines comply with USDA and HACCP standards, using 316 stainless steel contact parts to prevent cross-contamination. Conveyor belts, electric eyes, and automatic cassette tube feeding support quick product changeovers.

The systems include digital control panels, product output displays, and variable speed drive systems to balance filling speed and accuracy. With heat seal or ultrasonic sealing technology, manufacturers can safely process food products while protecting consumers from allergen carryover.

4. Industrial Adhesives and Chemicals

For chemical industries, Grease Tube Filling Machines, Universal Tube Filling and Sealing Machines, and compact tube crimpers are equipped for aggressive adhesives and solvents.

Built with stainless steel tube fillers, pneumatic cylinders, and diaphragm pumps, these machines handle plastic or metal tube-shaped containers with precision. Safety comes first – features include explosion-proof electrical ratings, pneumatic cutting for cutting excess plastic, and safety protection devices.

With automatic tube sealers, ultrasonic systems, and high response frequency encoders, operators get reliable results without excess waste. Advanced options like product output displays, date coding, and automatic refill pumps improve production efficiency while meeting safety requirements for adhesives and sealants.

Conclusion: Maximizing Efficiency, Precision, and Reliability

Automatic tube filling and sealing machines deliver measurable improvements in productivity, quality, and cost control. Technical specifications show fill accuracies within ±0.5% and production speeds up to 200 tubes/minute. And tube packaging equipment from KP Filling Machine provides comprehensive solutions meeting diverse technical requirements. From handling viscosities up to 1,000,000 cP to integrating FDA- and GMP-compliant systems, their equipment is engineered for both precision and reliability.

If you’re planning to upgrade your production line or need a customized filling solution, now is the time to act. Contact KP Filling Machine today to discuss your requirements and see how our technology can optimize your packaging operations from start to finish!