Success of every vaccine and critical care medicine depends on a key innovation: the vial packaging machine. These machines ensure pharmaceutical packaging sterility, accuracy, and efficiency. Recent market analyses predict that the robotic vial washing and filling machine segment will reach almost USD 760 million by 2032, growing at a compound annual growth rate (CAGR) of more than 4%.

The growth of this market is being driven by the increased demand for vaccines, customized medications, and injectable biologics. At KP Filling Machine, we offer robust, GMP-compliant vial packaging machines that integrate seamlessly into any pharmaceutical production lines. In this article, we’ll look at everything you need to know about vial packaging machines. We’ll also look at the benefits and features that make KP Filling Machine a top option for pharmaceutical manufacturers worldwide.

What are Vial Packaging Machines? Types Explained

Vial packing machines are automated devices which prepare, fill, seal, label, and pack vials. Their key purpose is to ensure sterility, precision, and efficacy during the packing and packaging process. Percentage-wise, these machines reduce the amount of manual handling and, therefore, the chances of cross-contamination.

There are various types of vial packaging machines, each designed to manage a specific stage of the packaging process. The following section breaks down the main types. Each type is explained with its functions and key features.

1. Vial Filling Machines

Vial filling machines are essential equipment in the pharmaceutical vial filling process. They are made to precisely fill vials with sterile liquids and powders. These devices come in a variety of manual and fully automated models that are designed for accuracy and efficiency. Here is a closer look at the main types of vial filling machines:

- Pharmaceutical vial filling machines: These machines are made in accordance with strict GMP guidelines. They promote aseptic conditions, which are necessary for vaccines and injectable biologics.

- Aseptic vial filling machines: This type of equipment protects product integrity by keeping the environment contaminant-free during filling. Many models also integrate sterilization systems and clean-in-place functions.

- Automatic vial filling machines: These machines increase productivity by automating the entire filling process. They use multi-head nozzles and servo control systems to fill hundreds or even thousands of vials per hour. Waste is kept to a minimum through precise dosing.

At King Pack’s Machinery, we design vial filling machines that exceed FDA and EMA requirements. Each machine is engineered for reliability, precision, and ease of operation.

Our systems can handle a wide range of vial sizes and formulations, from liquid injectables to lyophilized powders. They also integrate seamlessly with other packaging equipment, including stoppering, sealing, and labeling machines, creating a fully automated production line.

Recommended Reading: What is a Vial Filling Machine?

2. Vial Capping & Sealing Machines

Once vials are accurately filled, the next critical step is sealing and capping to maintain sterility and product integrity. Vial capping and sealing machines handle this process, ensuring each vial is securely closed with stoppers or aluminum seals. Here is a detailed overview of each machine:

- Vial Sealing Machines: Vial sealing machines are used to apply aluminum seals to vials, ensuring they are securely closed. These machines are crucial for maintaining the integrity and sterility of the product. They can be designed for various cap types and sizes, offering flexibility in production.

- Vial Stoppering Machines: Vial stoppering machines insert rubber stoppers into vials after filling. This process is vital for preventing contamination and maintaining the sterility of the contents. Advanced models can handle different stopper types and sizes, accommodating a range of vial specifications.

Vial capping and sealing solutions from King Pack’s Machinery are created to maintain precision and consistent quality. Our machines are engineered to work seamlessly with filling systems, ensuring a fully integrated production line. They feature adjustable settings to accommodate various vial sizes and stopper types, while maintaining high-speed operation without compromising sterility.

3. Complete Vial Packaging Lines

A complete vial packaging line brings together all stages of vial handling, from washing and sterilization to filling, stoppering, sealing, and labeling. Integrating these processes into a single line enhances efficiency, reduces contamination risks, and ensures consistent product quality.

Here is a closer look at the components that make up a complete vial packaging line:

- Vial Washing Machines: These machines prepare vials by thoroughly cleaning them before filling. They remove dust, particles, and residues using water jets, air blowers, and sometimes ultrasonic cleaning. Proper washing is essential to maintain sterility and prevent contamination during filling.

- Vial Sterilization: After washing, vials undergo sterilization to eliminate microorganisms and pyrogens. Common methods include autoclaving, dry heat depyrogenation, or chemical sterilization, depending on the product requirements. Sterilization ensures that injectable drugs, vaccines, and biologics remain safe for use.

- Vial Filling Line Integration: A fully integrated line combines washing, sterilization, filling, stoppering, sealing, and labeling into a seamless workflow. Automation and real-time monitoring help maintain consistent quality, reduce errors, and increase throughput. These integrated systems can be customized for different vial sizes and production volumes, making them suitable for both small-scale and large-scale manufacturing.

Manufacturers relying on King Pack’s Machinery benefit from vial packaging lines that combine automation, flexibility, and continuous monitoring. Our systems streamline workflows, reduce risks, and deliver consistent quality for both pharmaceutical and cosmetic applications.

Working Principles of Vial Packaging Machines

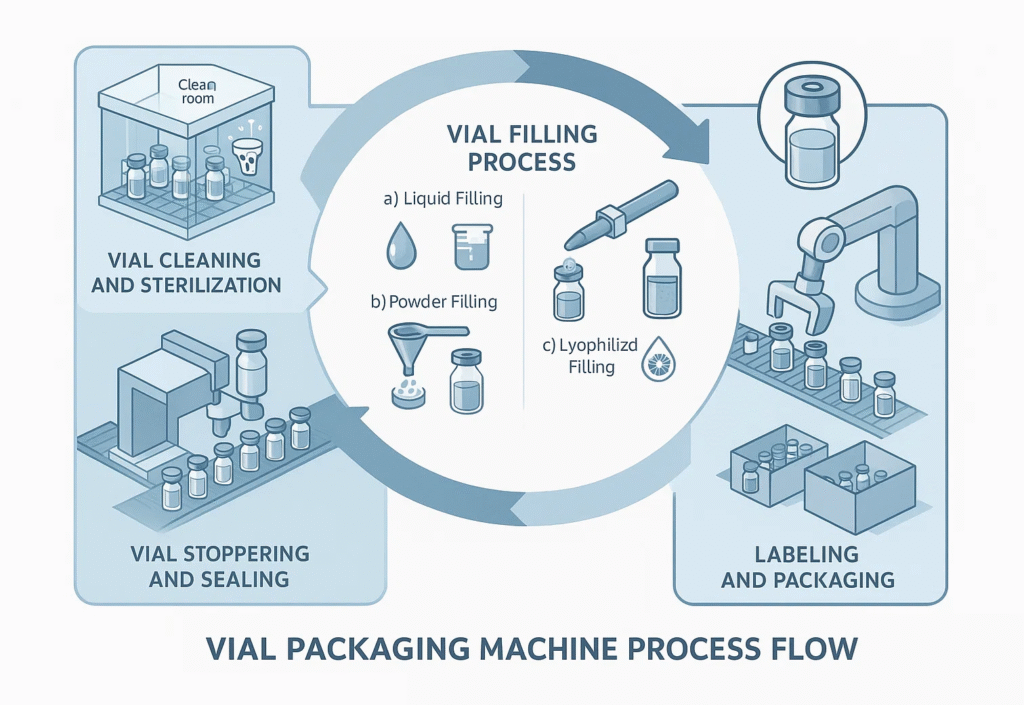

Vial packaging machines work through a series of precise and sterile steps to prepare pharmaceutical vials for safe use. The process begins with cleaning and sterilizing the vials. Empty vials are washed and treated to remove contaminants.

Next comes the filling process, which can involve liquid, powder, or lyophilized filling, depending on the product. Each vial gets the exact dose needed, ensuring accuracy and cutting down waste. After filling, the next steps are stoppering and sealing. Rubber stoppers and aluminum caps secure the contents, maintaining sterility and product integrity.

The last step is labeling and packaging. Vials are marked with batch information and arranged for distribution. At King Pack’s Machinery, these processes are integrated into automated lines that combine efficiency, safety, and reliability, meeting strict industry standards.

Key Features & Capabilities

Modern vial packaging machines are designed with advanced features that optimize performance, maintain sterility, and meet strict regulatory requirements. Below are the core capabilities and key features of modern vial packaging machines:

- Precision Dosing Technology – Servo-driven pumps, peristaltic pumps, and piston systems provide accurate fills across a wide range of liquid viscosities and vial sizes. This reduces overfill, cuts down on waste, and ensures consistency.

- Aseptic Operation – Barrier isolators, RABS systems, and HEPA-filtered laminar airflow maintain ISO Class A environments during filling and sealing, reducing the risk of contamination.

- Automation & Modular Design – Automated lines minimize human handling and support scalability. Modular setups allow manufacturers to adapt machines to changing vial sizes, formulations, or production demands.

- Real-Time Monitoring – Integrated sensors and weight-check systems provide continuous in-process control. This ensures compliance with GMP and FDA standards while reducing the need for post-batch inspections.

- Flexibility for Multiple Applications – Machines can handle different vial formats, including glass or plastic vials ranging from 2ml to 100ml. They can process sterile injectables, vaccines, biologics, and oncology drugs with equal precision.

- Compliance & Validation Support – Full IQ/OQ/PQ documentation packages and compliance with 21 CFR Part 11 make integration into validated environments straightforward.

These features not only improve operational efficiency but also help manufacturers stay competitive in a demanding industry. For companies scaling up production of biologics, vaccines, or oncology drugs, these systems provide the flexibility and reliability needed to meet both regulatory and market demands.

Recommended Reading: A Detailed Guide to Vial Filling Machine Types – Principles and Selection | King Pack – King Pack Machinery

Applications of Vial Packaging Machines

Vial packaging machines serve a wide range of industries, with pharmaceuticals leading the market. The global pharmaceutical vials market is estimated at USD 11.03 billion in 2024 and is projected to reach USD 15.85 billion by 2030, growing at a CAGR of 6%. These machines are essential for injectable drugs, vaccines, and IV solutions, where accuracy, sterility, and efficiency are critical. Key applications include:

1. Pharmaceuticals

In the pharmaceutical sector, vial packaging machines are indispensable for filling injectable drugs, vaccines, and IV solutions with precise volumes. Maintaining sterility during this process is vital, as contamination can compromise product safety and lead to regulatory setbacks. Vaccine production, particularly mRNA-based vaccines, has highlighted the importance of vial packaging equipment that can handle ultra-low temperature requirements without sacrificing accuracy.

Automation in pharmaceutical vial filling also addresses scalability challenges. As demand for vaccines, insulin, and oncology drugs continues to rise, automated vial packaging lines allow manufacturers to achieve higher throughput while meeting stringent GMP and FDA standards. By integrating filling, stoppering, sealing, and labeling, these systems streamline operations and reduce production risks.

2. Biotechnology

Biotechnology applications demand specialized vial packaging systems capable of handling sensitive biologics such as protein therapeutics and monoclonal antibodies. These products are highly susceptible to shear stress and contamination, so vial filling machines must incorporate gentle filling technologies that protect product integrity while maintaining dosing accuracy.

Biotech manufacturers benefit from aseptic vial filling equipment that integrates advanced isolation systems and real-time monitoring. This ensures biologics remain stable and sterile throughout the packaging process. As biologic drugs gain a larger share of the global market, biotech firms rely on high-performance vial packaging machines to meet both clinical and commercial-scale production needs.

3. Cosmetics

Vial packaging machines are also widely used in the cosmetics industry, particularly for premium skincare products, serums, and ampoules. Glass vials not only preserve sensitive ingredients from exposure to air and light but also elevate product presentation, making them popular in the luxury beauty segment. Automated filling systems provide the consistency needed to maintain brand reputation in a highly competitive market.

For cosmetics manufacturers, vial packaging machines offer the flexibility to handle different container sizes and materials while maintaining high efficiency. Automated lines with integrated labeling and sealing functions further reduce manual labor, helping brands deliver high-quality, contamination-free products to consumers while keeping production costs under control.

Whether it’s for high-volume pharmaceutical production, delicate biologics, or luxury cosmetics, King Pack’s Machinery combines precision, sterility, and efficiency to ensure consistent, high-quality packaging.

Benefits of Vial Packaging Machines

Automated vial liquid filling machines deliver major efficiency gains compared to manual operations. While an operator may only handle 50–100 vials per hour, systems with multiple filling heads and star wheel indexing can process thousands with minimal supervision. This reduces labor costs and streamlines liquid vial processing.

Product safety also improves with closed-system technology. Automated setups with diving nozzle dosing systems and volumetric principle filling reduce direct human contact. Contamination risks, common in manual handling of pharmaceutical products, are minimized. In large-scale production, even a single contaminated vial can require investigation and revalidation, making prevention essential.

Compliance with GMP standards becomes easier. Modern equipment, built from stainless steel for sterile areas, integrates washing units, sterilization tunnels, and closing machines like the vial capping machine. Automated systems also generate electronic batch records, deviation reports, and trend data, simplifying FDA inspections and accelerating regulatory submissions.

Cost-effectiveness is another advantage. Precise dosing systems cut overfill and underfill errors, while filling and capping systems with automated inspection reject defective units before packaging. This reduces waste, rework, and reliance on manual labor. Customers using King Pack’s injectable vial filling machines have reported packaging cost reductions of 25–30%. These savings come from higher efficiency, better use of packaging materials like flexibles & trays, and minimized downtime.

Choosing the Right Vial Packaging Machine

Selecting the right liquid filling machine starts with understanding throughput needs. Manufacturers must calculate filling ranges, production schedules, and capacity growth. Planning for peak demand avoids future bottlenecks.

Sterility requirements depend on product type. Injectable vial filling machines for biologics or oncology preparations require advanced aseptic processing, while cosmetic or topical lines may only need cleanroom-compatible systems. Matching sterility needs with the right system technology prevents overspending while keeping production safe.

Automation levels also vary. Options range from semi-automatic filling and stoppering machines for small-scale production to fully integrated high-speed systems with decorative labeling and labeling & coding units for traceability. King Pack’s Machinery provides tailored solutions that balance efficiency, sterility, and compliance in the global marketplace.

Budget planning should go beyond initial capital costs. Factors like maintenance, staff training, and validation affect the total cost of ownership. Financing and preowned packaging options can also make advanced equipment accessible across different sales channels.

| Factor | Considerations | King Pack’s Solutions |

| Speed | 100-10,000+ vials/hour | Scalable modular designs |

| Sterility | Clean to aseptic conditions | ISO Class A capabilities |

| Flexibility | Multiple vial sizes | Quick-change tooling |

| Compliance | FDA, EMA, cGMP | Validated systems |

Future Trends in Vial Packaging Technology

The future of vial packaging is shaped by automation, digitalization, and sustainability. Advances in robotics are transforming production floors, with collaborative robots (cobots) now assisting in tasks such as material loading and finished goods palletizing. These systems not only reduce manual labor but also improve workplace safety and consistency in operations.

Artificial intelligence is playing an increasing role in quality control. Modern inspection systems powered by machine learning can detect subtle defects that older technologies might miss. Predictive analytics further enhance efficiency by identifying potential equipment issues before breakdowns occur, minimizing costly downtime.

King Pack’s Machinery continues to invest in smart manufacturing technologies to support these advancements. Our latest equipment integrates IoT connectivity, cloud-based monitoring, and remote diagnostics. These features allow real-time visibility into production, faster troubleshooting, and lower maintenance costs.

Conclusion

Vial packaging machines represent essential equipment for pharmaceutical, biotechnology, and cosmetic manufacturers. And King Pack’s Machinery stands ready to support manufacturers with comprehensive vial packaging solutions.

By combining precision engineering with scalable designs, our machines help companies increase throughput, reduce waste, and maintain sterility across every stage of production. Whether it’s high-volume vaccine filling, delicate biologics, or premium cosmetic packaging, we provide solutions tailored to your industry’s unique challenges.

Ready to upgrade your production line? Contact King Pack’s Machinery today to explore vial packaging machines that improve efficiency, accuracy, and compliance—while future-proofing your operations.