Introduction

The packaging industry has witnessed remarkable transformations in recent decades, with pouch packaging emerging as one of the most dynamic and versatile solutions for modern businesses. As consumer preferences shift toward convenience, sustainability, and portability, manufacturers are turning to flexible packaging solutions that meet these evolving demands while maintaining product integrity and extending shelf life.

In this article, we’ll explore what pouch packaging is, how it works, and why it has become a preferred choice across industries such as food, beverages, pharmaceuticals, and personal care. We’ll also look into the technical aspects of pouch design, the machinery involved in production, and the advantages it offers compared to traditional packaging formats.

Definition of Pouch Packaging

Pouch packaging represents a category of flexible packaging that utilizes various materials and construction methods to create lightweight, durable containers for products across multiple industries.

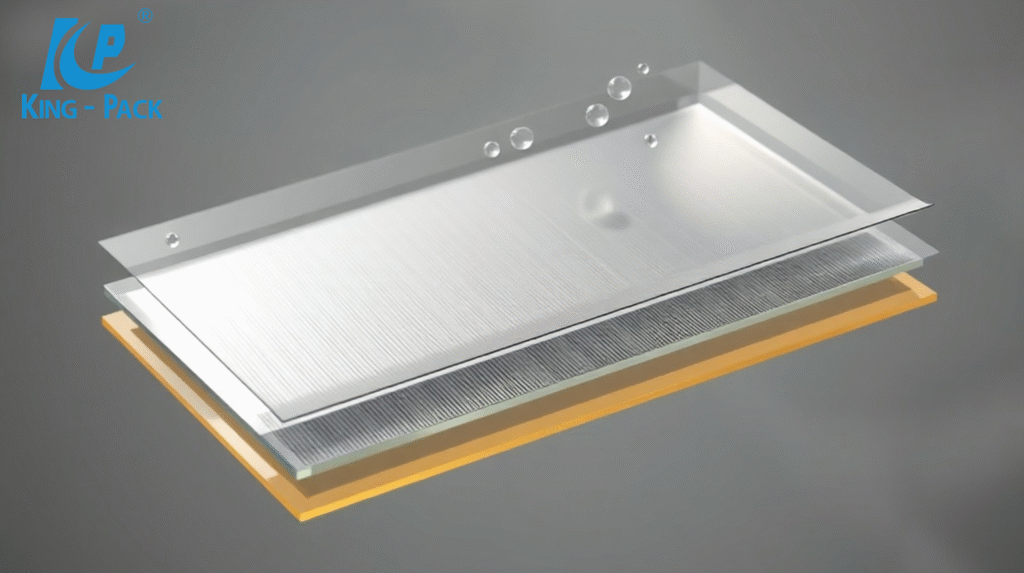

Unlike rigid packaging formats, pouches adapt to their contents while providing excellent barrier properties, making them ideal for liquid, semi-liquid, and solid products. The fundamental design consists of multiple layers of films or foils that are sealed together to form a bag-like container capable of standing upright or lying flat.

Recommended Reading: How Long Do Sealed Sauce Packets Really Last? Shelf Life, Storage & Safety Tips – King Pack Machinery

Importance in Modern Packaging Solutions

The significance of pouch packaging in today’s market cannot be overstated. The pouch packaging market is forecast to grow from USD 43.43 billion to USD 71.02 billion by 2034, with a CAGR of 5.04%. This substantial growth reflects the increasing adoption across diverse sectors, driven by consumer demand for convenient, portable, and sustainable packaging options.

Modern retailers and manufacturers recognize pouch packaging as a solution that bridges the gap between functionality and consumer appeal. The format allows for efficient storage and transportation while offering extensive branding opportunities through high-quality printing capabilities. Companies like King-Pack Machinery have responded to this demand by developing sophisticated pouch packaging machines that deliver precision, efficiency, and reliability for manufacturers seeking to capitalize on this growing market segment.

Types of Pouch Packaging

The versatility of pouch packaging manifests through various formats, each designed to address specific product requirements and consumer needs. Understanding these different types helps manufacturers select the most appropriate solution and pouching equipment for their applications.

1. Stand-Up Pouches

The stand-up pouches segment is the fastest growing with a CAGR of over 6% between 2025 and 2034. These gusseted pouches feature a gusseted bottom that allows them to maintain an upright position on shelves, making them particularly attractive for retail food and beverage pouch packaging applications. The design maximizes shelf presence while providing excellent stability during filling and packaging, handling, and storage.

Stand-up pouches excel in applications where product visibility, brand presentation, and stand-up resealable pouches are crucial. Their three-dimensional structure provides ample space for branding elements, nutritional information, and marketing messages. The format works exceptionally well for coffee, snacks, OTC powdered products, pet food, and liquid detergents, where independent standing enhances user convenience and retail appeal.

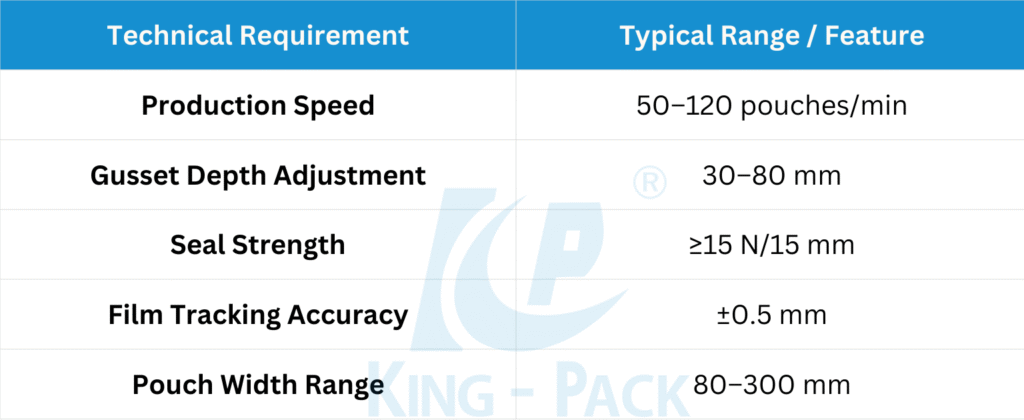

Here are the key technical requirements for stand-up pouch machines:

At King-Pack Machinery, our Pouch Packaging Machines are ideal for producing stand-up pouches. These machines offer high-speed pouch forming and filling with options for custom gusset sizes, strong sealing, and advanced print registration, making them suitable for both food and non-food applications.

2. Spouted Pouches

Spouted pouches incorporate a dispensing spout that allows controlled pouring and portion management. This innovation has transformed liquid pouch packaging and fill and seal premade pouches, offering consumers precise dispensing combined with the space efficiency of flexible packaging systems.

The spout can be integrated during pouch formation or added separately during filling and packaging operations. Materials range from simple plastic spouts to sophisticated valve systems that prevent backflow and maintain product freshness. Industries using spouted pouches include beverages, baby food, condiments, and automotive fluids.

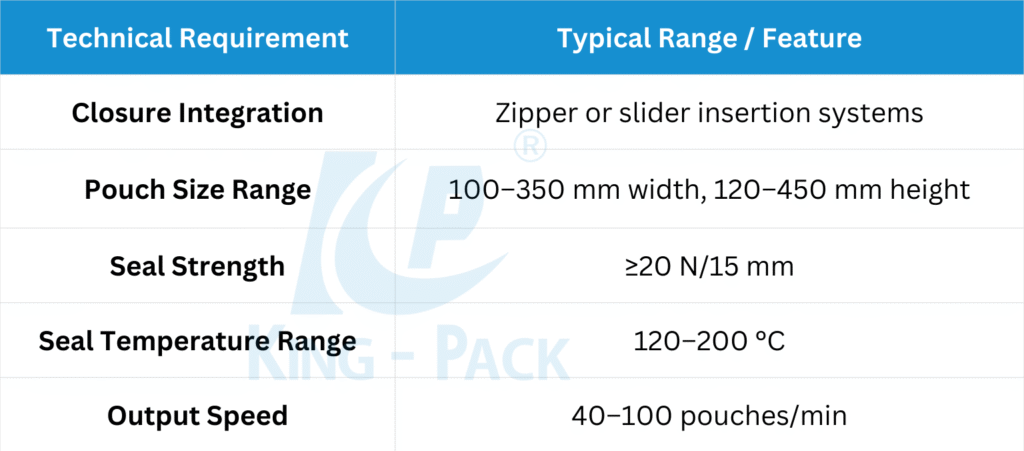

Here are the technical details required for spouted pouch production:

Recommended Reading: A Beginner’s Guide to Tube Filling Machines – King Pack Machinery

3. Flat Pouches

Flat pouches are the simplest format, consisting of two or more layers sealed along the edges to create a simple bag structure. Despite their simplicity, flat pouches offer advantages in material efficiency, storage space, and production speed, making them ideal for powders, granules, and lightweight solids, including OTC powdered products.

Flat pouches are compatible with rigid tray packaging, special shaped pouch formats, packaging film, Auger Fillers, Nitrogen Flush, and retort pouch filling. Their flat configuration maximizes packing density during transportation and storage, reducing logistics costs and environmental impact.

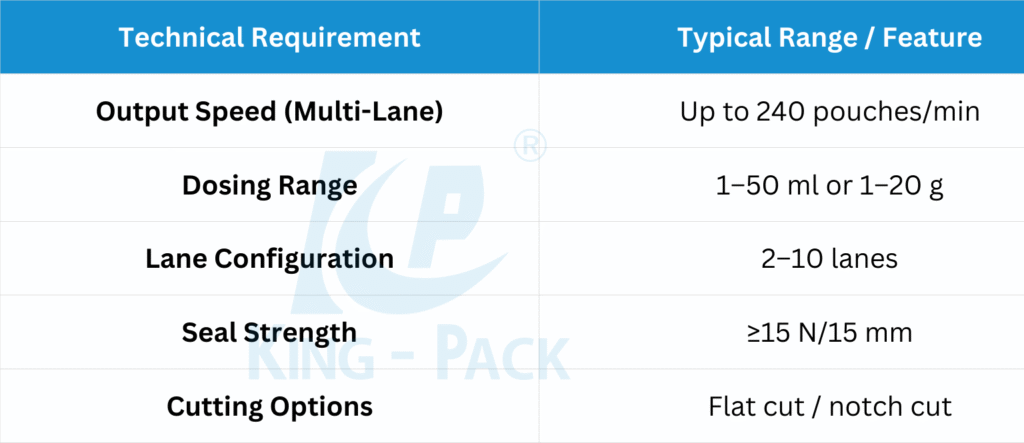

Here are the essential technical requirements for flat pouch machines:

King-Pack Machinery’s Automatic Sachet Packaging Machines are well-suited for flat pouch production. These systems feature high-precision dosing mechanisms, multi-lane designs for parallel output, and reliable sealing technology. Whether it’s ketchup sachets, instant beverage powders, or skincare samples, our machines guarantee consistent quality and efficient throughput.

4. Resealable Pouches

Resealable pouches feature closures that let consumers open and reclose the package multiple times while maintaining product freshness. Options include zip-lock closures, press-to-close seals, and tear-open strips with adhesive resealing capabilities.

Resealable functionality enhances consumer convenience, especially for products consumed over multiple occasions. This format is critical for snack foods, coffee, pharmaceutical products, and personal care items. Pouch cartoning machines, HFFS Single Clamp Flexible Pouch Packaging Machines, and Fill and seal premade pouches ensure that resealable pouches maintain freshness, structure, and brand integrity during filling and packaging processes.

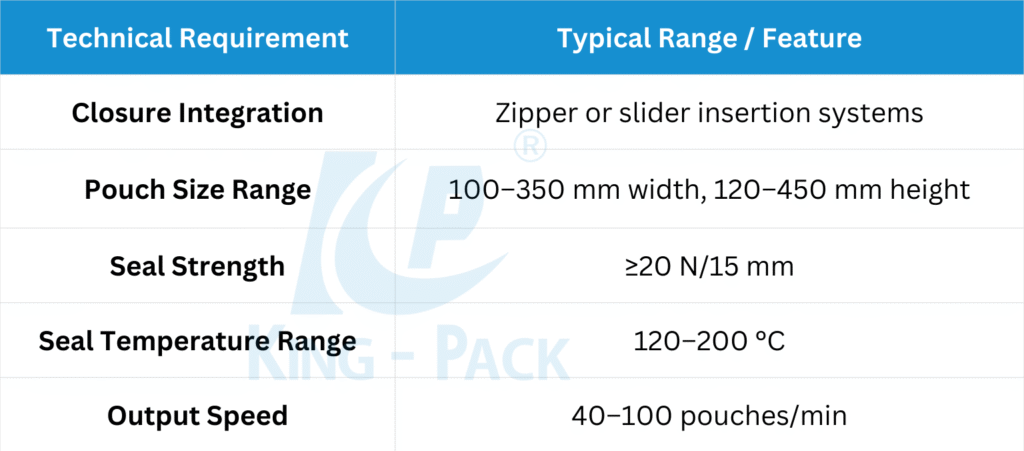

Here are the common technical requirements for resealable pouch production:

Recommended Reading: How an Automatic Tube Filling and Sealing Machine Works – King Pack Machinery

Materials Used in Pouch Packaging

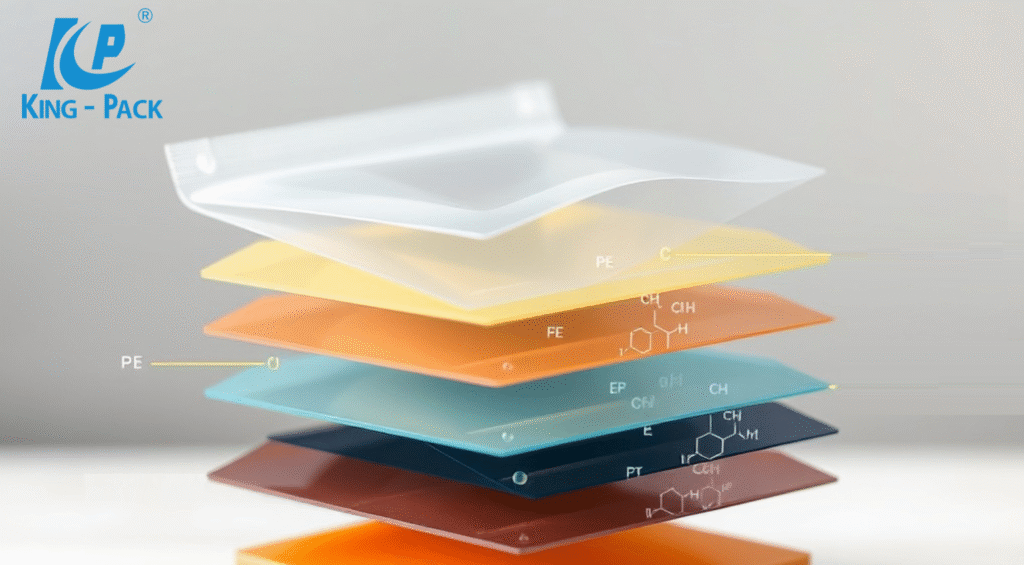

Barrier Films

Barrier films form the foundation of effective pouch packaging, providing protection against moisture, oxygen, light, and other environmental factors that could compromise product quality. The plastic segment is projected to contribute 54.2% of the pouch packaging market revenue in 2025, maintaining its position as the leading material type. Plastic’s flexibility, durability, and cost-effectiveness have made it the material of choice for pouch packaging across various industries.

Common barrier materials include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and specialized barrier films incorporating ethylene vinyl alcohol (EVOH) or metallized layers. Each material contributes specific properties: PE provides excellent moisture barriers and heat sealability, PP offers clarity and chemical resistance, while PET contributes strength and temperature stability.

The selection of barrier materials directly impacts shelf life, product compatibility, and processing requirements. King-Pack Machinery’s equipment is designed to handle a wide range of barrier materials, accommodating different thickness combinations and sealing requirements to meet specific product protection needs.

Foil Laminates

Aluminum foil laminates provide superior barrier properties, particularly against light, moisture, and gases. These materials excel in applications requiring extended shelf life or protection of light-sensitive products. The metallic layer creates an impermeable barrier while contributing to the package’s structural integrity.

Foil laminates typically combine aluminum foil with polymer films to achieve optimal performance characteristics. The polymer layers provide flexibility and heat sealability, while the foil contributes barrier properties and puncture resistance. This combination makes foil laminates ideal for pharmaceutical products, coffee, ready-to-eat meals, and other products requiring maximum protection.

Processing foil laminates requires specialized equipment capable of handling the material’s unique characteristics. King-Pack Machinery’s systems incorporate temperature and pressure controls specifically calibrated for foil laminate processing, delivering consistent seals while preventing material damage during production.

Sustainable Materials

The packaging industry faces increasing pressure to adopt environmentally responsible materials, driving innovation in sustainable pouch packaging options. These developments include biodegradable films, compostable materials, and recyclable multi-layer structures that maintain performance while reducing environmental impact.

Bio-based polymers derived from renewable resources offer alternatives to traditional petroleum-based materials. These materials can provide comparable barrier properties while supporting circular economy principles. Recyclable laminates use compatible polymer layers that can be processed through existing recycling infrastructure.

King-Pack Machinery recognizes the importance of sustainable packaging and has developed equipment capable of processing next-generation sustainable materials. Their systems accommodate the unique processing requirements of bio-based and recyclable materials while maintaining the precision and efficiency demanded by modern production environments.

Advantages of Pouch Packaging

Pouch packaging offers several advantages:

- Space Efficiency: Flexible pouches take up less storage space during shipping and less shelf space. They also weigh less, which lowers transportation costs. Flexible packaging often uses significantly less material compared to rigid alternatives.

- Lightweight & Cost-Effective: Because flexible materials are lighter and consume less substrate, cost of raw material and logistics is reduced.

- Customization & Branding: Pouches support high quality printing (flexographic, rotogravure, digital), custom shapes, resealable closures, spouts—all help brands stand out. King-Pack Machinery provides pouch packaging machines with customizable width, sealing options, and printing/labeling integrations.

- Extended Shelf Life: Barrier films and foil laminates help protect products against moisture, oxygen, heat, preserving freshness and extending shelf life — especially for food and beverage items.

Applications of Pouch Packaging

Food & Beverages

Pouch packaging is transforming the food and beverage sector. According to Grand View Research, the global pouches market was valued at USD 42.19 billion in 2023 and is projected to reach USD 63.14 billion by 2030, growing at a CAGR of ~5.9%.

Stand-up, spouted, and retort pouches are widely used for snacks, sauces, drinks, ready-to-eat meals, and condiments. Retort pouches offer shelf stability and can replace cans for many applications, reducing weight and improving transportation efficiency. Technical requirements include good barrier film (to protect against oxygen and moisture), precise fill systems for liquids or semi-liquids, and strong seals to avoid leakage.

King-Pack Machinery offers pouch packaging machines that are built for food and beverage: our machines support various pouch formats (stand-up, spout, retort), use food-grade stainless steel contact parts, and incorporate high-precision filling heads.

Recommended Reading: Types of Food Packaging Machines: Applications, Benefits, and Industry Uses – King Pack Machinery

Cosmetics & Personal Care

In cosmetics and personal care, pouches are used for lotions, creams, shampoos, masks, facial cleansers, and travel-size or sample packs. These sectors demand not just good packaging, but packaging that protects product integrity (fragrance, consistency, color), ensures hygienic dispensing, and presents visually appealing branding. Pouch Packing Machines with PLC controlled functionality, servo motor-driven operations, and digital temperature controllers are often used to maintain precise dosing and product stability.

Technical details often include soft touch laminates, barcode scanners for traceability, UV protection, and compatibility with fragrance oils or active ingredients. Vacuum generator systems and nitrogen gas flushing help reduce oxidation and maintain product quality, while multi-component blends require machines capable of consistent handling and mixing. Washdown structure and Streamline operations ensure hygienic production and easy maintenance.

King-Pack Machinery’s flat and resealable pouch machines are well suited here. Flat pouch machines can produce sample sachets with fine print detail, while stand-up resealable pouches can be fitted with sliders or zippers. These machines maintain seal strength, precise dosing, and can adapt to aesthetic finishes that matter in personal care, including bottom pouch support for stability during filling and packaging.

Pharmaceuticals

Pharmaceutical applications put even stricter demands on packaging. Single-dose pouches for powders, liquids, or tablets must comply with regulatory standards such as ISO 11607 for sterile barrier systems when terminal sterilization is involved. Pouch Packing Machines used in this sector often include vacuum packaging machine capability, digital temperature controllers, and PLC controlled functionality to maintain precision.

The packaging has to protect against moisture, oxygen, contamination, and sometimes light. Fill processes must be validated, fill volume highly precise, and materials compatible with pharmaceutical contents. Barcode scanners, pouch deflator systems, and vibratory settler devices are commonly integrated to ensure quality and minimize errors.

King-Pack Machinery’s pharmaceutical-grade pouching equipment handles single-dose liquid sachets or powders with strict hygienic design, nitrogen gas flushing for stability, and multi-component blends without compromising safety or consistency.

Household Products

Household products like detergents, cleaning liquids, insecticides, pet foods, and refill packs are increasingly shifting to pouch packaging. In the U.S., demand for pouches was over USD 13 billion in 2024, and nonfood markets (including household care) are growing.

These pouches reduce material waste, are lighter, and often use spouts or reseal features for liquids. Technical needs include chemical compatibility of materials (resistance to caustics or surfactants), strong seals under variable conditions, reliable spouts or closures, and machines that can fill thicker liquids without clogging.

King-Pack Machinery makes machines that serve this sector include liquid-fill spout pouch machines and resealable pouch machines suited to household liquids and pet food refills. They ensure strong chemical compatibility, support on-machine cleaning protocols, and maintain consistent fill rates even with viscous or foaming products.

Environmental Considerations

Recyclability of Pouch Materials

One challenge is that many pouches combine multiple materials (plastic + foil + adhesives), which makes recycling difficult. Separating layers during recycling is costly and often not fully effective. Some regions report low recycling rates for flexible packaging.

Innovations in Sustainable Pouch Packaging

Innovation is underway: compostable paper pouches, mono-material plastics, and pouches designed to be recyclable in existing systems. The market growth in sustainable pouches is significant. And King-Pack Machinery supports this shift by designing machines with flexibility: adjustable sealing temperatures, compatibility with sustainable films, and modular features that allow manufacturers to adopt greener materials without large retooling.

Click here to check our products

Conclusion

Pouch packaging has become a leading format in flexible, efficient packaging. Its ability to save space, support lightweight materials, offer strong branding options, and extend shelf life makes it attractive across industries. With growing concern over sustainability, the move toward recyclable and compostable pouches is accelerating.

King-Pack Machinery is ready for the future: our machines are built for versatility, compatibility with sustainable materials, and customization. For companies seeking to adopt pouch packaging or upgrade existing lines, King-Pack offers reliable pouch packaging machines that deliver performance, flexibility, and long-term value.

Get in touch with King-Pack Machinery today to discuss your packaging needs and find the right solution to keep your production ahead of the curve.