Vertical automatic flour packaging machines sit at the heart of a fast‑growing powder packaging machine market, which is projected to reach about USD 6.3 billion by 2035. The main driver of this tragic growth is increased packaging needs for food products, as food processors worldwide are automating the bagging of flour and other dry ingredients. Within this segment, VFFS vertical form fill seal packing machines are gaining share. They offer compact footprints, high speeds, and flexible bag formats tailored to branded retail and bulk power products such as flour applications.

This article introduces King Pack’s vertical automatic flour packaging machine. It explains what buyers need to know about packaging solutions, their capabilities, hygiene design, and selection criteria. It will focus on helping flour mills, bakery ingredient factories, and food powder manufacturers evaluate whether a VFFS‑based solution is the right choice for their next powder packing investment.

Overview of Vertical Flour Packaging

What is a Vertical Form-Fill-Seal (VFFS) Machine for Flour?

A vertical form fill seal machine or a VFFS flour packaging machine forms bags from a continuous roll of film, fills them with flour or other powders, and then seals and cuts each bag in a fully automatic cycle. The process starts with roll film feeding, shaping the film around a forming collar to create a tube, sealing the back seam, dosing flour from an auger or weighing system, and finally sealing and cutting the finished bags. For food powder packing, typical working ranges for powder VFFS systems are 80–400 mm bag length, 80–250 mm bag width, and up to about 520 mm film width for 1 kg–2 kg retail flour packs.

Why Vertical Packaging Is Ideal for Flour and Fine Powders?

Vertical packaging uses gravity to assist the flow of flour and other powder products into the bag, reducing spillage, dusting, and mechanical complexity compared with horizontal systems. Hermetic vertical seals and top seals protect flour from moisture and oxygen, which slows rancidity and insect infestation, both known shelf‑life risks for milled wheat and grain flours. Modern VFFS flour lines can run from about 15 up to 70 bags per minute. They have a compact footprint. This gives flour millers a good balance of throughput and space efficiency compared to manual or semi-automatic flour packing machine setups.

Typical Industries & Applications

| Category | Typical Users | Main Products Packed | Pack Format / Note |

|---|---|---|---|

| Flour mills & grain processors | Industrial flour mills, grain terminals | Wheat flour, rice flour, corn flour, potato powder | Pillow or gusset pouches, approx. 0.5–5 kg each |

| Bakeries & premix manufacturers | Industrial bakeries, premix plants | Baking flour, cake mixes, bakery premixes, functional blends | Retail and foodservice bags and pouches |

| Food powder factories | Food ingredient and powder processors | Starch, coffee powder, spices, protein and food-grade powders needing accurate dosing and sealed packs | Wide range of sachets, pouches, and bulk bags |

Machine Capabilities & Technical Specifications

Bag Size Range, Packing Speed, and Film Width Compatibility

Dedicated vertical packing machines handle 0.5–2 kg bags. These bags are about 80–400 mm long and 80–250 mm wide. The machines use roll stock film up to 520 mm wide. This setup suits many industrial powder packaging uses with vertical form-fill-seal (VFFS) systems. Representative packing speeds include:

- 5–70 bags/min for compact vertical flour packaging machine designs,

- 20–60 bags/min for 1–5 kg flour bag packaging lines, depending on product flow, film type, and seal time,

- About 15–120 bags/min across the broader VFFS range for different models and products using roll stock film for industrial powder packaging.

For powder‑oriented VFFS platforms equipped with a film-rolling device, common film widths range from about 120 to 520–730 mm for typical food bags. Heavy-duty industrial powder packaging machines with larger film rolling devices that can run large film roll widths in the approximate range of 1,020–1,200 mm for automatic 5–10 kg powder bagger applications.

Filling Accuracy and Servo-Driven Bag Making System

Powder VFFS lines for flour usually include an auger filler or multi-head weigher. They use servo-driven film pulling and sealing. Weighing controllers keep dosing stably for different bag sizes. Many modern systems use an automatic dosing system on the product side. This system can work as a volumetric feeder or as part of a gravimetric system. On the packaging side, servo-driven screw mechanisms feed powder accurately into each bag.

Well-configured flour packing machines usually achieve filling accuracy around ±1% for 100 g–1,000 g ranges. They can reach about ±0.2–0.5% accuracy when optimized weighing and gravimetric control are used for free-flowing powders. Servo drives control the film pull belts and the horizontal sealing jaws to maintain consistent bag length. Sensors or photo-eyes track registration marks to maintain print alignment and bag position. These devices work with weighing controllers and automatic dosing systems. Together, they reduce giveaways and mispacks.

Bag Types Supported

Most vertical flour packaging machine platforms can run multiple bag styles, including:

| Bag style | Description | Typical use in flour lines |

|---|---|---|

| Pillow bags | Flat, three‑seal bags formed from a single film web. | Retail flour packs and small consumer sachets. |

| Gusset bags | Bags with expandable side folds for larger volume and better stacking. | More stable 1–5 kg flour packs for retail or wholesale. |

| Back‑sealed / quad‑seal bags | Bags with a central back seal or four corner seals for a box‑like shape and strong presentation. | Higher shelf‑impact packs or larger flour formats. |

| Hole‑punch / carry‑handle bags | Pillow or gusset bags with punched holes or integrated handles in the header area. | Consumer‑friendly carry packs and display hanging. |

| Valve/degassing options | Bags fitted with valves or one‑way degassing features when required for specific powders. | Powders that release gas or need controlled venting. |

Core Functions & Workflow

Film Feeding and Bag Forming (Roll Film → Forming Collar → Vertical Sealing)

The vertical flour packaging machine unwinds roll film from a reel, maintains tension with a brake or dancer, and feeds it downward over a forming collar. The forming collar wraps the flat film into a tube around the forming pipe, and vertical sealing jaws or bars close the back seam using controlled heat and pressure. Servo‑driven film pull belts synchronize movement with sealing, so the tube advances the correct bag length for each cycle.

Powder Feeding & Metering (Auger Screw / Weighing System → Accurate Dose)

For fine flour and food powders, auger screw fillers are common because they handle low‑bulk‑density, dusty powders with good repeatability. An auger filler doses flour volumetrically, often backed by load cells or periodic weight checks, achieving about ±1% weight accuracy for typical retail pack sizes. Alternative systems, such as linear weighers or multi‑head weighers, may be used for granular or blended products, but for very fine flour, a sealed auger system usually gives better dust control and stability.

Bag Filling → Horizontal Sealing & Cutting → Date/Batch Printing → Discharge

Once the auger or scale releases product, flour drops through the forming tube into the open tube section above the future seal line. Horizontal sealing jaws close to create the top seal of the filled bag and, at the same time, the bottom seal of the next bag; then a knife or hot cutter separates bags for discharge. Built-in thermal transfer or inkjet printers and embossers can mark each bag with the date, batch code, and regulatory information. They do this before the bags move onto a takeaway conveyor or a flour bag packaging line for secondary packaging.

Hygiene, Material Handling & Design Features

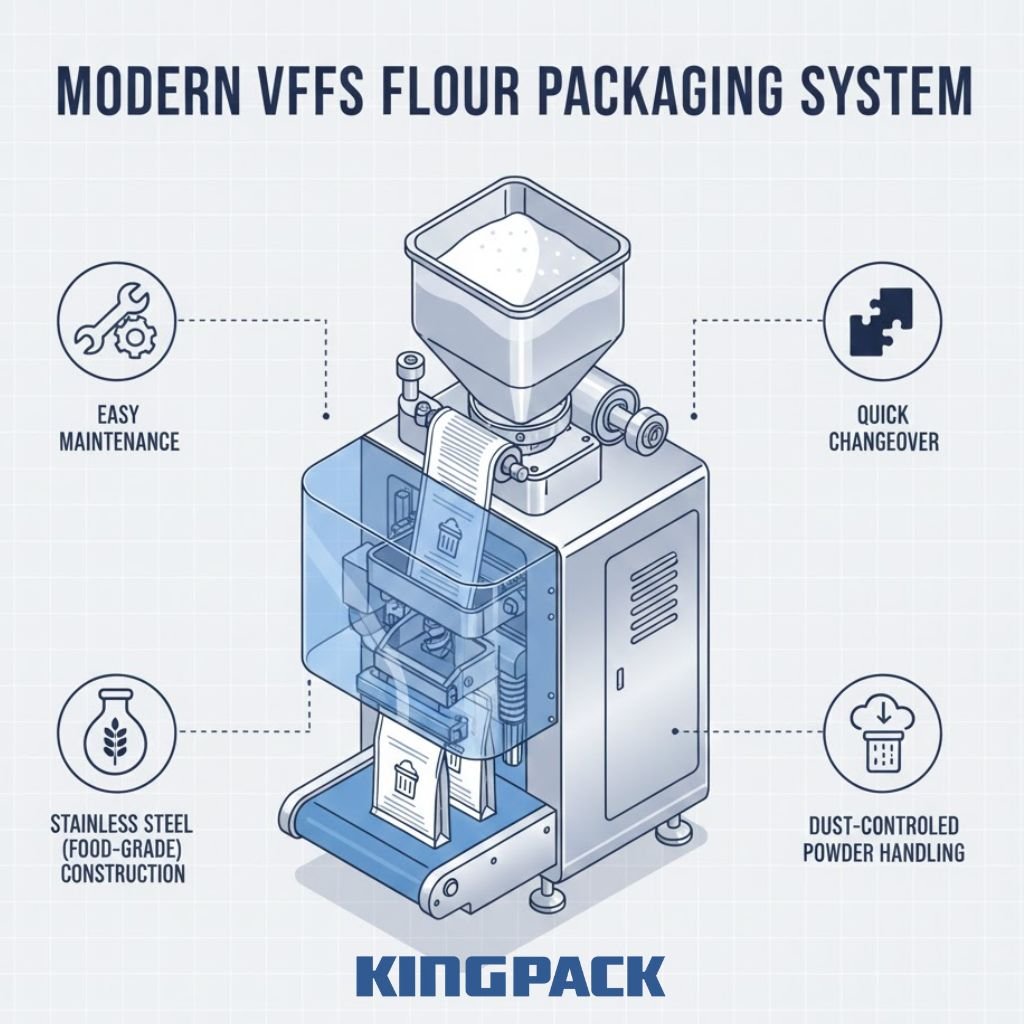

Stainless Steel (Food-Grade) Construction

Food‑grade vertical flour packaging machines typically use 304 stainless steel for frames and covers, with 316 or 316L food-grade stainless steel on product‑contact parts where needed. Smooth welds and rounded corners reduce flour build‑up and make cleaning easier, supporting compliance with food safety schemes such as HACCP and local food codes.

Dust-Controlled Powder Handling

Fine flour is naturally dusty and can create hygiene, explosion, and housekeeping concerns if not contained. Many automatic flour bagging machine encompasses a dust-control design. It incorporates dust hoods, extraction ports at the forming tube, and enclosed product paths from feeder to bag mouth to reduce airborne flour. This not only improves operator safety but also helps keep machine sensors and film surfaces clean, which supports more stable operation.

Easy Maintenance, Quick Changeover

Modern VFFS flour packaging solutions focus on quick format changeovers using modular forming sets and tool‑less adjustments. Typical bag size changeovers on advanced machines may take 15–30 minutes, covering forming tube change, seal position adjustment, and parameter updates on the HMI through PLC control system. Centralized lubrication points, hinged guards, and on‑screen maintenance prompts further reduce downtime and service complexity.

Advantages of Using Vertical Flour Packaging Machine

High Efficiency: Fast Output & Stable Production

When comparing an automatic vertical flour packaging machine to manual bagging, the difference in throughput is substantial. A typical semi-automatic flour packing setup manages 8–12 bags per minute per operator. A single vertical automatic flour packaging machine can run 20–70 bags per minute. The speed depends on the product and film. The higher packing rate and automated functions let one operator supervise many machines. This reduces labor cost per packed kilogram. It also stabilizes output.

Consistent Weight & Accurate Filling

Accurate filling in powder production lines is fundamental for compliance and cost control. If auger or weighing systems are calibrated correctly, a vertical flour packaging machine can keep about ±1% net weight tolerance for 0.5–2 kg flour bags. This greatly reduces overfill compared to manual scoop or volumetric filling. Across thousands of bags, even a 1–2% reduction in average overfill can translate into substantial flour savings and more predictable inventory planning.

Extended Shelf Life & Powder Quality

Tight vertical and horizontal seals protect flour from ambient humidity and oxygen, two main drivers of quality decline and shelf‑life reduction. The correct sealing mechanisms, temperature, and control use multiple temperature zones and up to four independent temperature controllers. This helps keep seal quality without burning or deforming the film. In some configurations, nitrogen flushing or air evacuation devices can be integrated to support extended shelf life for sensitive powders further.

Scalability for Small to Large Batches

Entry‑level vertical flour packaging machine models handle low to medium capacities suitable for local mills or brand start‑ups, while larger VFFS frames and film widths handle 5–10 kg bags and higher tonnage lines. Because the core technology scales mainly by film width, jaw size, and weighing capacity, manufacturers can standardize across plants and select models matching line speed and SKU mix.

Suitable Products & Use Cases

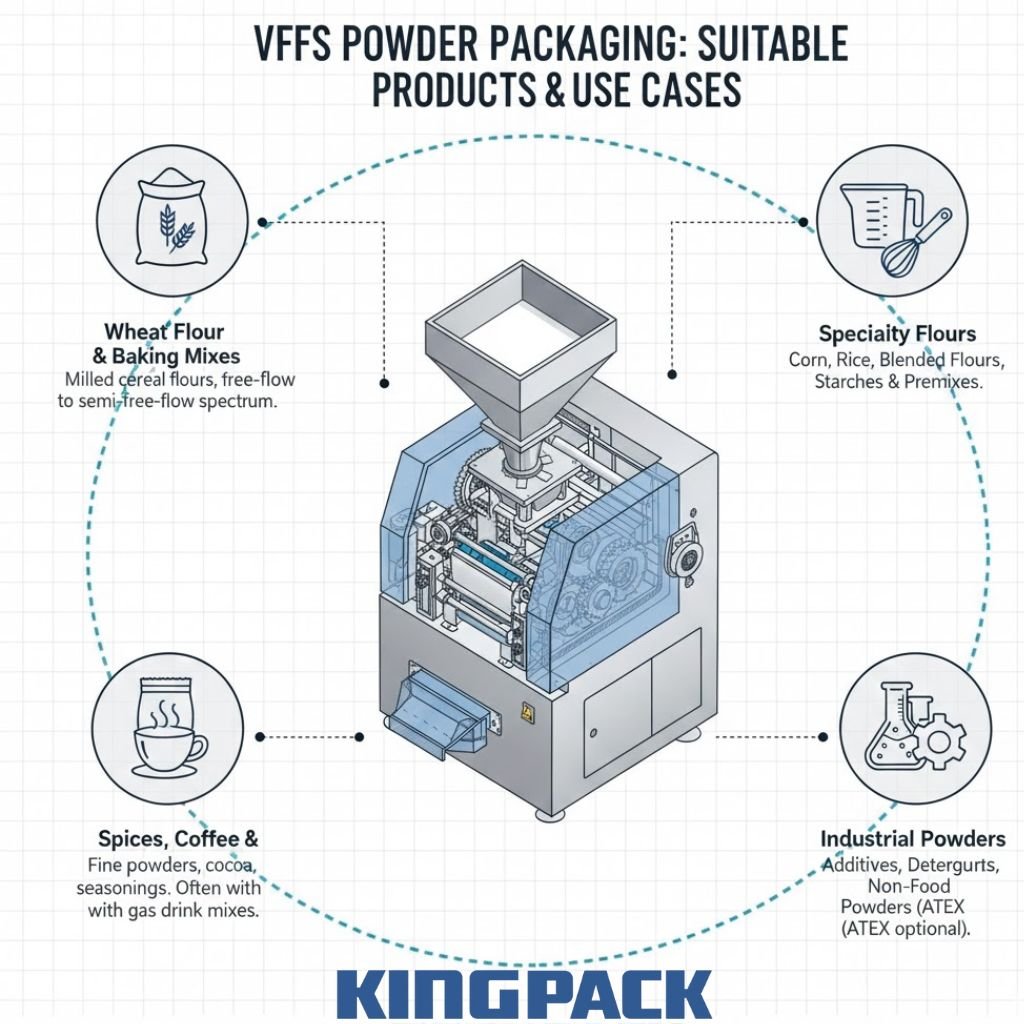

Wheat Flour, Corn Flour, Rice Flour, Baking Flour, Powdered Ingredients

Any milled cereal flour or bakery powder within the free‑flow to semi‑free‑flow spectrum can be run on a flour packing machine configured with an appropriate auger design and venting. This includes straight wheat flour, blended baking flours, corn flour, rice flour, starches, and functional bakery premixes.

Spices, Starch, Coffee Powder, Protein Powder

Beyond flour, VFFS powder packaging machines are widely used for spices, powdered coffee, cocoa, seasoning blends, and protein powders, using dust‑tight auger fillers and sometimes gas flushing for oxidation‑sensitive products. Bag sizes and films vary according to product value and distribution channel.

Industrial Powders, Seasonings, Additives

Industrial powders like food additives, premix ingredients, or non-food powders such as detergent bases and building materials can also be packed on similar machines. These machines have suitable material contact finishes. They include safety features like ATEX or similar when needed.

How to Choose the Right Vertical Flour Packaging Machine?

Consider Powder Type, Particle Size, Moisture Sensitivity, and Flowability

Flow properties influence the choice between auger, cup filler, or scale, as well as hopper geometry, agitation, and venting. Very fine, sticky, or fat-rich flours need agitators and well-sealed auger systems. These prevent bridging and dust emissions. Moisture-sensitive powders may benefit from gas flushing or better barrier films.

Define Desired Bag Size, Output Speed, Accuracy & Batch Size

The required bag dimensions, target output (bags/min), and tolerance determine film width, machine frame size, and filler capacity. For example, a small mill that wants 20–25 bags per minute of 1 kg flour may pick a compact automatic flour bagging machine. A larger plant aiming for 50–70 bags per minute and multiple SKUs will choose higher-spec VFFS flour packaging with servo axes and recipe storage.

Evaluate Support Services, Spares, Maintenance & Cleaning

Flour and food powder packing is usually continuous, so service and spare parts support are crucial. When choosing flour packaging machine makers, decision makers should check local technician availability. They should also check response times, spare parts stock, operator training, and documentation. They should consider these factors along with the machine price. Machines with clear access for cleaning, dust‑tight covers, and robust stainless steel construction will reduce lifetime maintenance costs and downtime.

Conclusion & Call to Action

A well-designed vertical flour packaging machine uses VFFS technology. These packing lines provide various benefits to flour mills, bakeries, and food powder producers, offering a reliable, efficient, and clean way to bag flour and fine powders. They can be easily integrated into the food industry, the manufacturing and industrial powder industry, and food processing plants. These automatic powder filling machines combine accurate auger or weighing systems with servo-driven bag forming and strong sealing. Automatic flour bagging machine lines optimize bag sizes, speeds, and filling tolerances. They help reduce product giveaway, limit labor needs, cut dust emissions, and protect flour quality during its shelf life.

Contact King Pack today to define a custom vertical flour packaging line and receive a detailed quotation tailored to your target bag sizes, throughput, and powder characteristics.