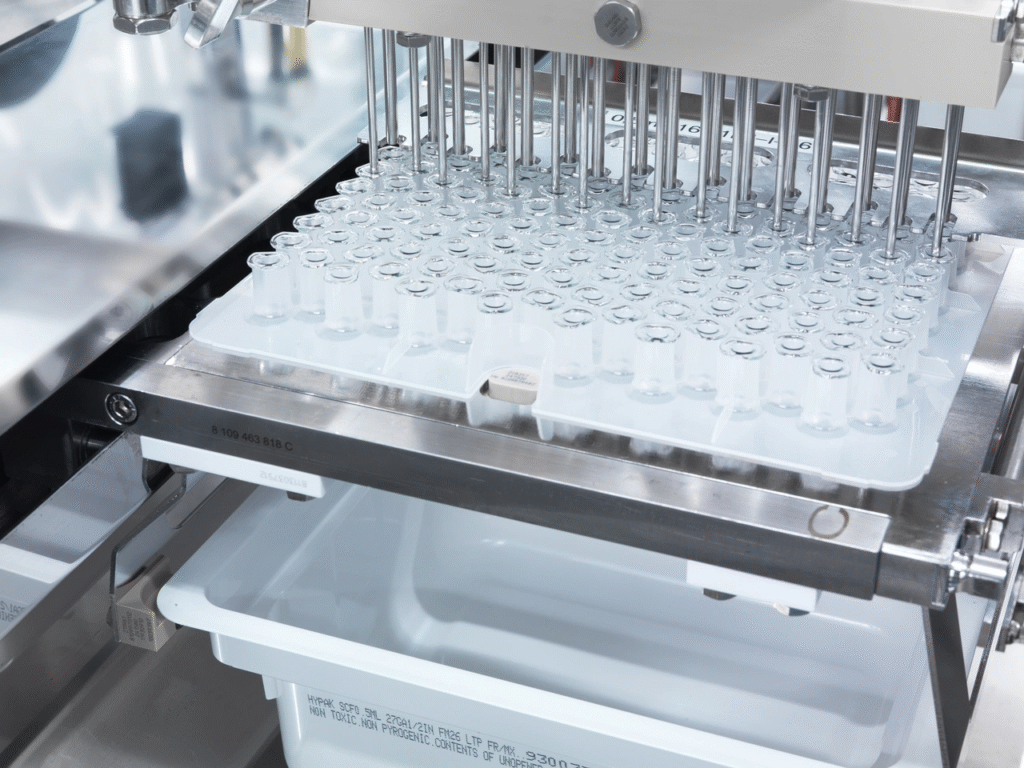

The global pharmaceutical industry increasingly relies on advanced syringe filling machinery to meet growing demands for pre-filled syringes and sterile drug delivery systems. Modern liquid filling technology has changed pharmaceutical manufacturing. It ensures accurate filling, prevents contamination, and adheres to regulations for various medical uses.

Today’s syringe filling process uses advanced automation. It also includes real-time quality control and aseptic handling. These features guarantee product safety and effectiveness. From biologics to vaccines, manufacturers depend on sophisticated filling systems that deliver consistent performance while meeting stringent FDA and EMA standards. The following comprehensive overview examines the top 10 leading manufacturers that continue to drive innovation in syringe filling technology, setting industry benchmarks for precision, reliability, and production efficiency in the competitive pharmaceutical landscape of 2025.

Global Syringe Filling Machine Manufacturers Overview

1. King Pack Filling Machine – China

King Pack, based in Jiangsu Province, China, is a leading manufacturer of syringe filling machines with 20+ years of experience. The company specializes in packaging machinery, including filling, capping, and labeling machines for pharmaceutical, food, chemical, and cosmetic applications. Their ISO 9001-certified facility produces high-precision, engineered products renowned for their durability and reliability. King Pack maintains competitive pricing while ensuring prompt delivery and total client satisfaction. Their state-of-the-art manufacturing combines innovative technology with modern machinery to serve both domestic and international markets effectively. Not just this, but their after sales technical support system is outstanding, serving customers worldwide.

2. Syntegon Technology GmbH – Germany

Syntegon Technology GmbH is a premier provider of advanced syringe filling solutions, recently launching the MLD Advanced filling machine capable of processing up to 400 ready-to-use syringes per minute. Their innovative systems feature automatic bag and tub openers utilizing aseptic, no-touch transfer technology. The Pharma Handling Unit automatically denests syringes while preventing glass-to-glass contact, ensuring product integrity. Syntegon’s unique clip system and circulating transport technology provide smooth handling ideal for RTU syringes, vials, and cartridges, making them a trusted partner in high-value pharmaceutical manufacturing.

3. Groninger Holding GmbH & Co. KG – Germany

Founded in 1980 in Crailsheim, Groninger specializes in high-precision machines for liquid pharmaceutical products. Their DFVN series ranges from the DFVN 1000 for small batches to the DFVN 10000 for high-speed production with 100% In Process Control. The UFVN system processes pre-sterilized syringes with individual weighing and assessment capabilities. Groninger machines offer several filling options. These include rotary piston pumps, peristaltic pumps, and time pressure systems. This ensures flexibility for pharmaceutical uses. Their GMP-compliant systems process pre-sterilized glass and polymer containers from various suppliers.

4. Cozzoli Machine Company – USA

Cozzoli has built a strong pharmaceutical industry for high-precision filling and closing machines. Their VR840 series processes syringes and vials at speeds up to 400 bottles per minute. The company’s simple two-piece filling syringes feature an easy cleaning design with high-precision machining, achieving fill accuracy better than ±0.5% by volume. Their machines offer optional overhead laminar air flow, 4-16 filling heads, and are designed for pharmaceutical applications requiring high performance and complete reliability. Cozzoli’s RM series combines multiple functions while maintaining ease of use and maintenance.

5. Automated Systems of Tacoma (AST) – USA

AST specializes in advanced aseptic processing with its GENiSYS R fully robotic filling machine. This system processes pre-sterilized, ready-to-fill containers on a single platform designed for small to medium-scale aseptic manufacturing under cGMP guidelines. The GENiSYS R combines proven isolator-barrier and automated technologies. It offers flexibility for aseptic, toxic, and cytotoxic drug products. The system uses a Stäubli Stericlean robot in sterile environments. It increases productivity and reduces contamination by limiting operator involvement.

6. Bausch+Ströbel Maschinenfabrik Ilshofen GmbH & Co. KG – Germany

Bausch+Ströbel manufactures sophisticated syringe filling equipment, particularly their SFM series machines featuring volumetric stainless steel rotary piston fillers. Their complete automated systems produce up to 36,000 disposable syringes per hour with infinitely adjustable output. The company’s production lines include tub unpacking, cover removal, filling and sealing machines, and transport systems. Their machines accommodate disposable syringes from 0.5 to 10ml, with all product-contact parts made from stainless steel AISI 316L. Systems are designed for sterile processing under stringent aseptic conditions.

7. Optima Packaging Group GmbH – Germany

Optima offers comprehensive Syringe Filling Machinery through its VSVM series of fully-automatic machines. Their range spans from single-lane VSVM 3000 producing 3,600 syringes per hour to eight-lane VSVM 1800 systems achieving 18,000 syringes per hour. These automated syringe filling machines handle both glass syringes as well as plastic syringes with dosing volumes from 0.1 to 50ml, accommodating syringes up to 21.5mm diameter and 125mm length. Optima uses star-wheel and oval race track transport systems. The choice depends on the configuration. Optima has the skill in handling difficult pharmaceutical uses.

8. IMA Group – Italy

IMA Group’s INJECTA automatic syringe filling system handles pre-sterilized Ready-To-Use containers, including syringes, vials, and pre-capped cartridges. The system provides comprehensive functionality from filling lines to assembly machines and a labeling system in one integrated solution. This flexible machine allows seamless switching between production cycles of different pharmaceutical forms. IMA’s solution works with isolator system technology. This ensures aseptic processing conditions. The company focuses on flexibility and full processing abilities. This makes them preferred for producing many different formats.

9. Marchesini Group – Italy

Marchesini Group stands as a leading Italian manufacturer of pharmaceutical packaging equipment with extensive syringe filling expertise. The company provides new solutions that meet strict pharmaceutical manufacturing rules. It uses advanced technology and easy-to-use operations. Their machines handle various container formats while maintaining high precision and reliability. Marchesini focuses on research and development. This makes them a leader in pharmaceutical packaging technology, especially for aseptic processing. The company emphasizes both efficiency and compliance with pharmaceutical industry standards.

10. Nordson Corporation – USA

Nordson Corporation leverages decades of precision dispensing expertise in pharmaceutical syringe filling markets. Nordson is a global leader in fluid dispensing. It provides high-accuracy filling solutions. These solutions use advanced control technologies for precise fill volumes and product integrity. Their systems follow strict pharmaceutical manufacturing rules. They meet regulatory and validation standards. Nordson’s Atlas™ Syringe Barrel Filling Systems provide consistent volumetric filling with tight accuracy and easy cleaning capabilities. The company’s focus on innovation and reliability establishes it as a trusted supplier for critical pharmaceutical applications requiring the highest accuracy levels.

Key Technologies and Applications

High-Precision Filling and Capping

High-precision filling machines use volumetric measurement technologies. These include rotary piston pumps and servo-controlled dispensing mechanisms to achieve filling accuracy within ±0.5% tolerance levels for various filling applications. Modern capping systems feature torque-controlled application with automated cap feeding and placing vacuum stoppers for batch filling operations and bulk syringes. Further, the quality verification sensors ensure proper sealing integrity. These integrated systems provide consistent product volumes through real-time monitoring and automated dose adjustment capabilities.

Sterile and GMP-Compliant Operations

Sterile processing environments are maintained through HEPA filtration systems, positive air pressure controls, and isolator barrier technology that eliminates contamination risks during production. GMP compliance is achieved through validated cleaning procedures and pharmaceutical-grade stainless steel construction with electropolished surfaces. Automated cleaning-in-place (CIP) and sterilization-in-place (SIP) functions maintain regulatory standards throughout production cycles.

Automation and PLC Control Systems

PLC control systems provide centralized management of all machine functions. The system includes an intuitive user-friendly touchscreen interface HMI displays with which you can set filling volume, and comes in handy with production data logging capabilities. Advanced automated filling lines include robotic container handling, automated format changeover, and integrated vision systems for real-time quality inspection. Remote monitoring capabilities and predictive maintenance scheduling ensure seamless integration with manufacturing execution systems for complete production traceability.

How to Choose a Syringe Filling Machine?

Production Capacity and Filling Accuracy

Assess your current and projected production volumes. It will determine whether you should choose semi-automatic systems (suitable for small batches) or fully automated filling machines (capable of processing up to 6,000 syringes per hour) that best meet your requirements. Select machines offering high filling accuracy within ±0.5% tolerance levels. They provide consistent dosing. They also ensure regulatory compliance. Precision affects product safety and effectiveness in pharmaceutical uses.

Equipment Compatibility and Flexibility

Ensure the machine accommodates your specific syringe types, including barrel diameter, material composition (glass or plastic), and volume ranging from 1 ml to 50 ml or larger. Choose systems with adjustable settings and customizable components that can handle various syringe formats. They must integrate seamlessly with existing production filling line equipment, such as capping, labeling, and packaging systems.

After-Sales Support and Cost Considerations

Look at the total cost of ownership. This includes the initial investment, maintenance costs, energy use, and possible downtime costs. Do not focus only on the purchase price of the syringe filling machines. Select manufacturers offering comprehensive technical support, readily available spare parts, training programs, and maintenance contracts to ensure uninterrupted operations and maximize equipment longevity.

FAQs About Syringe Filling Machines

What is a syringe filling machine?

A syringe filling machine is a piece of pharmaceutical equipment that automatically fills pre-sterilized syringes with liquid medications. These machines ensure precise dosing and sterile packaging for injectable drugs. They are essential for producing vaccines, biologics, and other pharmaceutical products.

How does a syringe filling machine work?

The machine feeds empty syringes into filling stations where precision pumps dispense exact liquid volumes. After filling, automated systems insert rubber stoppers and seal the syringes. Quality control systems inspect each unit and reject defective syringes automatically.

What is the difference between fully-automatic and semi-automatic syringe filling machines?

Fully-automatic machines operate continuously without operator intervention and can fill over 100 syringes per minute. Semi-automatic machines require manual loading and supervision, making them suitable for smaller production runs. Automatic systems offer higher speeds but cost more than semi-automatic units.

What types of liquids can these machines handle?

Syringe filling machines process water-based solutions, oils, gels, creams, and viscous formulations. Different pump types handle specific liquids – peristaltic pumps work well for sensitive biologics, while piston pumps suit viscous products. The machines accommodate both low and high-viscosity pharmaceutical liquids.

Conclusion

Selecting the right syringe filling machine manufacturer is crucial for pharmaceutical production success. These ten industry leaders offer proven solutions ranging from semi-automatic systems for small batches to high-speed automated lines processing thousands of units per hour. Their advanced technologies ensure precise dosing, sterile operations, and regulatory compliance. Consider production requirements, budget constraints, and long-term support when choosing your equipment partner for optimal manufacturing results.

Contact Manufacturers and Request a Quote

Ready to invest in advanced syringe filling technology? Contact these leading manufacturers directly to request detailed quotations tailored to your production requirements. Provide specific details about your volume needs, product types, and facility specifications to receive accurate pricing and technical proposals that match your operational goals. For more helpful information, contact us.