What Are the Different Types of Salad Dressings? – King Pack Guide

Salad dressings are more than simple condiments; they are carefully engineered emulsions, flavor booster systems, and delivery vehicles for fats, acids, and aromatics. Manufacturers must understand the different types of dressings to compete in a rapidly growing market. This helps them improve flavor, stability, mouthfeel, and nutrition. They also need to match target markets and processing limits. This guide explains the main categories of salad dressings and classic flavor types. It covers key points in pairing, formulation, and commercialization. It is designed for brands and food service operators working with partners like King Pack on custom solutions.

Foundations of Salad Dressings

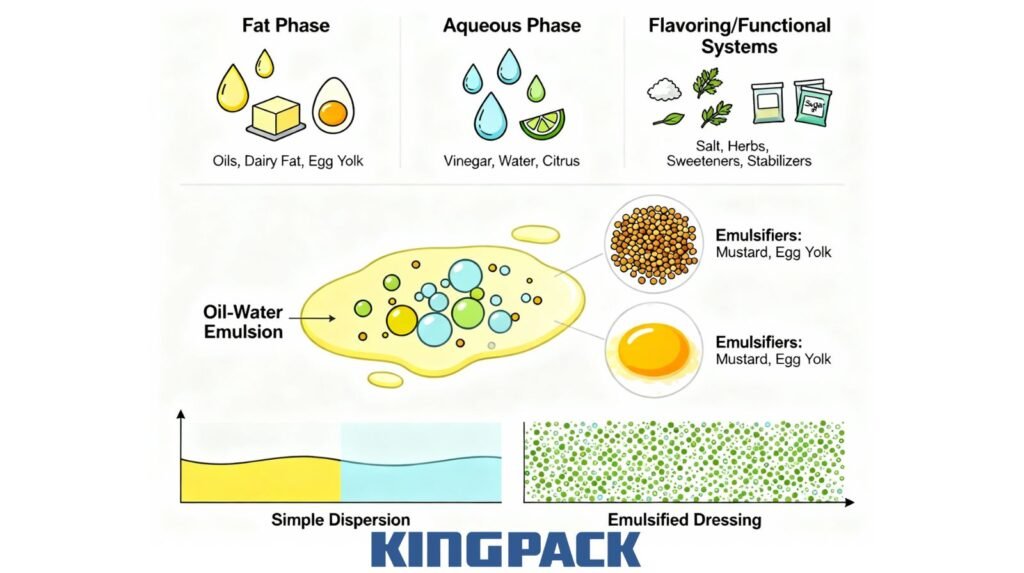

At a technical level, most salad dressings combine three core components:

- A fat phase (typically oils, dairy fat, or egg yolk lipids). Common oils include extra-virgin olive oil, neutral vegetable oils, speciality nut or seed oils, and other heart-healthy oils.

- An aqueous phase (vinegar, water, juices, dairy, or plant-based liquids). Common acids are vinegars (red wine, balsamic, white wine, apple cider vinegars) and citrus juices (lemon, lime).

- Flavoring and functional systems (salt, sweeteners, herbs, spices, stabilizers, and preservatives). These include honey, sugar, maple syrup and other additions like soy sauce or miso build complex flavor profiles.

The critical technological challenge is managing the oil–water interface. Dressings are commonly either:

- Simple dispersions (loosely mixed, separate over time).

- Emulsions (oil-in-water or water-in-oil systems stabilized with emulsifiers such as egg yolk lecithin, mustard, gums, or proteins).

From this foundation emerge three broad families.

Oil-Based Vinaigrettes: Simple & Versatile

Oil-based vinaigrettes are the most straightforward category, typically built on a ratio of approximately 3 parts oil to 1 part acid (such as wine vinegar, apple cider vinegar, or citrus juice). Technically, these are temporary emulsions: when shaken or whisked, oil droplets disperse throughout the aqueous phase, but over time they separate again.

Key Characteristics:

- Light viscosity and clean flavor release.

- High perceived freshness due to volatile aromatic compounds in herbs, garlic, and citrus.

- Minimal stabilizer requirement for basic versions, but commercial products often include emulsifiers (e.g., mustard, xanthan gum) to improve stability and shelf life.

Vinaigrettes are highly adaptable and form the basis for many regional variations by adjusting oil type (olive, canola, blended oils), acidity level, and aromatics.

Creamy Dressings: Rich, Emulsified Flavors

Creamy dressings rely on stable oil-in-water emulsions. The fat phase usually includes vegetable oil plus a creamy component such as mayonnaise, sour cream, buttermilk, Greek yogurt, or plant-based alternatives.

Technological hallmarks:

- Use of emulsifiers (egg yolk, modified starches, proteins) and hydrocolloids (xanthan, guar, CMC) to stabilize droplets and deliver smooth, cohesive texture.

- Higher viscosity ranges, from spoonable to thick pourable, tailored to application (salad bar, squeeze bottle, dip).

- Enhanced flavor-carrying capacity for fat-soluble compounds, including aromatics, cheese, and spices.

For manufacturers, process control (shear rate, order of ingredient addition, homogenization) is critical for consistent particle size and long-term physical stability.

Specialty & Cultural Variations

Beyond the classic Western styles, dressing platforms adapt to regional palates:

- Soy-based or miso-based dressings in East Asian cuisine.

- Yogurt–cucumber or tahini–lemon systems in Middle Eastern and Mediterranean markets.

- Fermented ingredients (kimchi brine, fish sauce, gochujang) providing umami and complexity.

These products often include extra challenges. They must manage salt levels, fermentation by-products, and clean-label expectations. They also need to ensure microbiological safety and predictable sensory profiles.

Popular Classic Dressings

Italian Dressing — Zesty Herb Oil–Vinegar Blend

Italian dressing is essentially a vinaigrette enriched with herb and spice systems. A typical formulation includes:

- Oil phase: neutral oil, sometimes blended with olive oil for flavor and cost control.

- Aqueous phase: vinegar (red or white wine vinegar), occasionally with lemon juice.

- Flavor system: dried or fresh herbs (oregano, basil, parsley), garlic, onion, chili flakes, sugar, and salt.

From a technical standpoint, commercial Italian dressings often use an emulsifier (e.g., mustard or xanthan gum) to maintain suspension of herbs and prevent rapid phase separation. Particle size control for herbs and spices is crucial for a uniform, visually appealing product and consistent dosing in industrial or food service settings.

French Dressing — Sweet, Tangy, Tomato-Red Style

French dressing (as known in North America) is an emulsified, sweet-tangy sauce with a characteristic orange-red hue.

Key attributes:

- Oil-in-water emulsion stabilized by egg yolk, modified starches, or gums.

- Sweetness from sugar, HFCS, or alternative sweeteners to balance vinegar acidity.

- Tomato sauce, paprika, or colorants for visual identity.

Formulators must balance viscosity with pourability and ensure color stability over shelf life. Oxidation control (via chelators and antioxidants) is important due to both the oil phase and tomato-based ingredients.

Ranch Dressing — Creamy Buttermilk & Herb Favorite

Ranch is one of the most commercially important dressings in many markets, often functioning as both dressing and dip.

Core components:

- Dairy or dairy analog base (buttermilk, sour cream, yogurt, or non-dairy alternatives).

- Extra-virgin olive oil for richness and mouthfeel.

- Flavor system: garlic, onion, chives, dill, black pepper, and sometimes cheese notes.

Technical considerations include:

- Emulsion stability under cold-chain conditions.

- Microbiological safety in dairy-including variants (pH control, preservatives, thermal treatment).

- Maintaining fresh herb flavor using dried, encapsulated, or natural flavor systems that withstand processing and storage.

Caesar Dressing — Bold, Garlicky, Parmesan-Infused

Traditional Caesar dressing is an intense, umami-rich emulsion that historically includes raw egg yolks and anchovies. Commercial formulations may adapt for safety and labeling.

Typical structure:

- Oil-in-water emulsion supported by egg or egg-free emulsifiers.

- Acid phase from lemon juice and vinegar for brightness.

- Flavor system: Parmesan cheese, anchovy or fish sauce analogs, garlic, black pepper, and sometimes mustard.

Manufacturers must manage:

- Protein and fat interactions from cheese and egg.

- Heat sensitivity of cheese flavors during processing.

- Clean-label anchovy substitutes where allergen or consumer perception is a concern.

Rich & Decadent Dressings

Blue Cheese Dressing — Sharp Cheese Cream Base

Blue cheese dressing relies on a combination of crumbled blue cheese and a creamy emulsion base (mayonnaise, sour cream, yogurt, or blends).

Technical aspects:

- Chunky vs smooth variants: chunk size and distribution are critical for sensory consistency.

- Emulsion integrity despite particulate load from cheese.

- Control of strong flavor intensity and salt content to appeal to varied palates.

Stability challenges include preventing oiling-off around cheese particles and maintaining texture over shelf life. Modified starches and hydrocolloids frequently support structure.

Thousand Island Dressing — Sweet & Tangy Mayonnaise Blend

Thousand Island is a mayonnaise-style emulsion with inclusions such as chopped pickles, pimentos, or relish, and often ketchup or tomato for sweetness and color.

Key formulation points:

- Oil-in-water emulsion similar to mayonnaise but with lower viscosity and higher sugar/acid levels.

- Inclusions that require careful particle size control and dispersion.

- Water activity and pH management to keep inclusions microbiologically safe.

Because of visible particulates, filling and pumping equipment must be selected and calibrated to avoid shear damage while maintaining homogeneous distribution.

Vinegar-Based & Emulsified Vinaigrettes

Balsamic Vinaigrette — Bold, Dark, and Sweet

Balsamic vinaigrette combines the depth of balsamic vinegar with a neutral or olive oil base.

Characteristics:

- Higher perceived sweetness and complexity from balsamic, sometimes supplemented with additional sweeteners.

- Dark color that influences salad appearance and plating.

- Often positioned as premium, requiring careful sourcing and standardization of vinegar to maintain consistent flavor and acidity.

Technologically, the higher sugar content can modify viscosity and phase behavior, and color stability must be managed with respect to light, oxygen, and storage conditions.

Emulsified Vinaigrettes — Stable Dressings That Don’t Separate

Emulsified vinaigrettes bridge the gap between classic vinaigrettes and creamy dressings by using emulsifiers to create a more stable, slightly thicker product that resists separation.

Typical elements:

- Oil and vinegar balanced to desired acidity and fat content.

- Emulsifiers (e.g., mustard, egg yolk, lecithin, or plant-based fibers) to reduce interfacial tension.

- Hydrocolloids to increase viscosity and slow creaming and coalescence.

For processors, these systems allow improved shelf stability, better consumer experience (no need to shake vigorously), and more consistent dosing in industrial or food service formats.

Japanese “Wafu” Dressing — Soy, Vinegar, and Oil Fusion

Wafu dressings are Japanese-style vinaigrettes that integrate soy sauce and sometimes dashi, ginger, or sesame oil.

Key features:

- Combination of oil, vinegar, and soy sauce for a salty-umami-acidic profile.

- Often enhanced with aromatics (ginger, garlic, onion) and sesame.

- Elevated sodium and umami profiles, requiring thoughtful balance with acid and sweetness.

Formulation must consider protein content from soy sauce and any stock components, which can affect emulsion behavior. For clean-label markets, natural stabilizers like mustard, fiber, or gums are often used instead of synthetic emulsifiers.

How to Choose the Right Dressing for Your Salad

Pairing Dressing with Greens, Proteins & Add‑Ins

From a product development and culinary standpoint, dressing choice should align with:

- Leaf type and structure: Delicate greens (butter lettuce, baby spinach) pair better with lighter vinaigrettes, while robust greens (kale, romaine, cabbage) can support thicker, assertive dressings.

- Protein inclusions: Creamy and umami-rich dressings pair well with grilled meats, fried proteins, and hearty legumes, while citrus or herb vinaigrettes lift seafood and lighter proteins.

- Add-ins and textures: Ingredients like nuts, seeds, fruits, and cheeses influence whether a sweet-tart vinaigrette or a savory creamy base is more appropriate.

For manufacturers, understanding these use-cases helps position products in portfolios (e.g., “for grain bowls,” “for grilled chicken salads”).

Balancing Flavor, Consistency & Nutritional Profile

Technical formulation involves trade-offs among:

- Flavor intensity: Acid level, salt, and umami must balance with sweetness and fat to avoid harshness or flatness.

- Consistency: Target viscosity should match packaging format (pourable bottle vs dip cup) and end-use (topping vs marinating).

- Nutrition: Reduced-fat, low-sodium, sugar-reduced, or plant-based objectives require careful redesign of the emulsion system, often leveraging fibers, starches, and protein concentrates to mimic full-fat mouthfeel.

Sensory testing and rheological measurements are critical tools for optimizing these parameters.

Making or Using Store-Bought: What to Consider

For end users and food service operators, key decision points include:

- Ingredient list and labeling: Preference for clean-label emulsifiers and recognizable ingredients.

- Storage and shelf life: Ambient-stable vs refrigerated requirements, impact on logistics and waste.

- Versatility: Dressings that can double as marinades, sandwich sauces, and dips increase value and simplify inventory.

For brands, partnering with a development and packing specialist enables tailoring formats (pouches, PET, glass, bulk) and performance (heat stability, freeze–thaw tolerance) to specific channels.

Trends & Health-Conscious Variations

Low-Fat or Oil-Free Dressings (Greek Yogurt, Tahini, etc.)

Health-driven reformulation is reshaping the dressing category:

- Greek yogurt–based dressings reduce oil content while maintaining creaminess through milk proteins and natural thickness.

- Herbed Tahini dressing or nut-butter bases provide plant-based fats, protein, and fiber, appealing to vegan and Mediterranean-inspired concepts.

- Oil-free systems rely on purees (vegetables, fruits, legumes) and hydrocolloids for body, with acids and spices providing flavor.

Technically, these systems often act differently from classic emulsions. Their viscosity may be more shear-thinning. Stability can depend more on particle size control and water-binding ability.

Flavor Innovations — Berry Vinaigrettes, Citrus, Sweet & Spicy Blends

Innovation focuses not only on nutrition but also on flavor differentiation:

- Fruit-based vinaigrettes (strawberry, raspberry, mango) use purees and juices to introduce color, aroma, and natural sweetness.

- Citrus-forward dressings (yuzu, lime, blood orange) highlight volatile aromatics and high acidity, requiring careful pH and oxidation management.

- Sweet–spicy blends (honey–sriracha, chili–lime) respond to global flavor trends and snacking behavior, often designed to cross-function as glazes or dips.

These concepts demand more nuanced control of flavor balance, color stability, and potential flavor interactions over shelf life.

Conclusion

Choosing the right salad dressing style is not just a culinary decision; it is a technical one that shapes flavor delivery, eating experience, nutritional profile, and product performance across applications. Dressings range from simple oil–vinegar blends to complex emulsified, cheese- or yogurt-based systems. Each type has a unique function and sensory profile. These must fit target consumers, menu ideas, and operational limits.

Get in touch to design custom dressing formulations with King Pack!

King Pack specializes in translating these principles into robust, scalable formulations tailored to your brand and market. Explore King Pack’s flavor development services or get in touch to design custom dressing formulations that balance taste, texture, nutrition, and shelf stability for your next product launch.