King Pack has completed the production and factory testing of a six-head linear liquid filling machine for a customer in Russia. The equipment has now successfully passed internal inspection and acceptance testing at the King Pack manufacturing facility.

This machine is designed for filling daily chemical liquid products, including toilet cleaner, shower gel, and similar liquid formulations. The system was developed based on the customer’s production requirements, with a focus on stable operation, consistent filling accuracy, and suitability for long-term industrial use.

Equipment Configuration

The delivered system is a six-head linear liquid filling machine featuring a straightforward and robust structure. It is suitable for medium-output production lines in the daily chemical industry.

Key technical characteristics include:

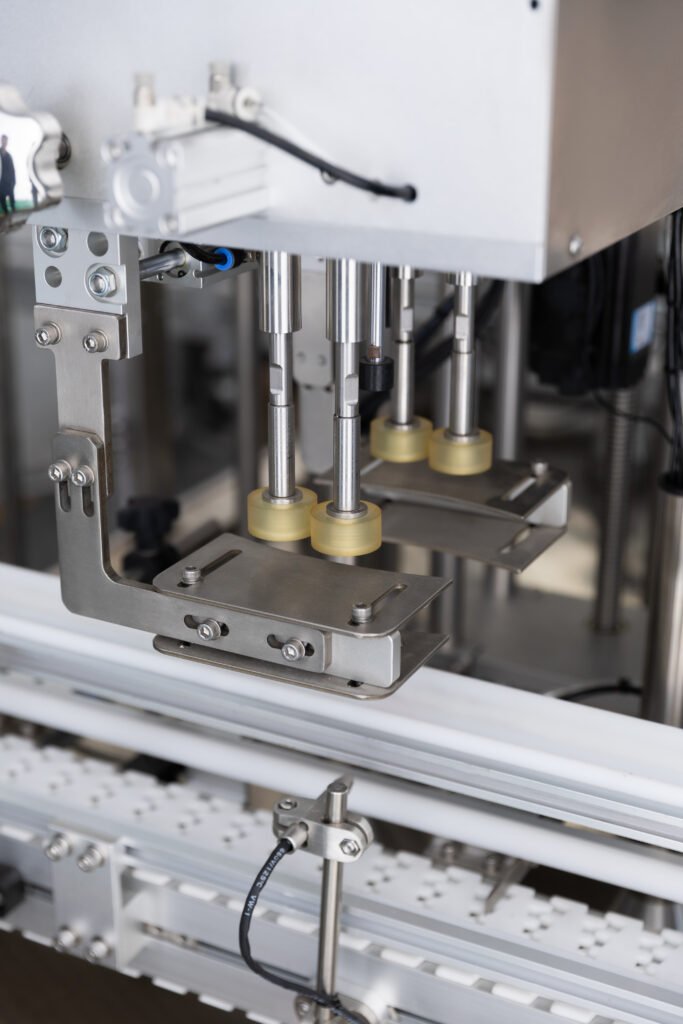

- Six filling heads for continuous and stable operation

- Piston filling system suitable for toilet cleaner and shower gel

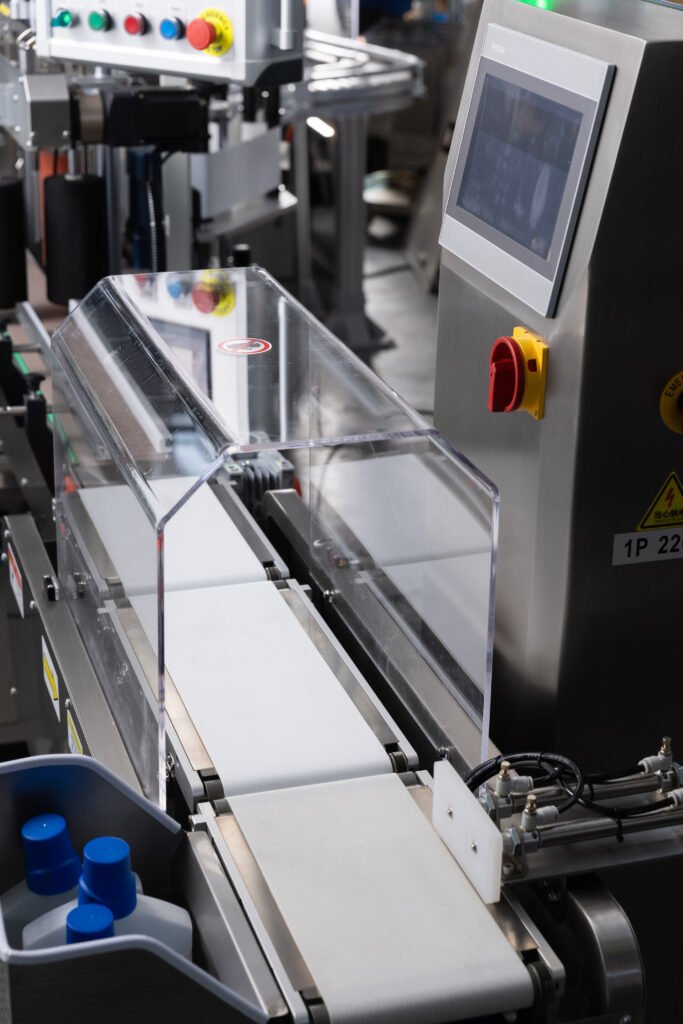

- PLC and touch screen control for parameter setting and monitoring

- Stable filling accuracy with clean and consistent output

- Stainless steel product-contact parts for industrial production environments

During testing, the machine operated smoothly across multiple cycles, maintaining consistent filling volume and reliable bottle handling.

Factory Acceptance Test

After assembly and calibration, the machine underwent a factory acceptance test under normal operating conditions. The test process focused on filling performance, system stability, and overall operational consistency.

A factory test video was recorded to document the equipment’s operating status during the acceptance process. The video reflects the actual performance of the machine during trial operation and serves as a technical reference prior to shipment.

Application Scope

This six-head linear filling machine is suitable for a wide range of daily chemical products, including:

- Toilet cleaner

- Shower gel and body wash

- Liquid detergents

- Other household liquid products

The modular design allows for future integration with capping, labeling, or downstream packaging equipment as production requirements evolve.

Export-Oriented Manufacturing Experience

This project reflects King Pack’s continued involvement in supplying liquid filling equipment for international markets, including Russia and other CIS regions. From individual filling machines to complete production lines, King Pack focuses on delivering practical and reliable equipment solutions based on specific application needs.