Introduction – Challenges in Traditional Packaging & Why Upgrades Are Needed

Packaging, no doubt, plays a vital role in the product journey, from the factory to the hands of the consumer. Traditional packaging methods, while tried and tested, often struggle to keep up with the rapidly evolving demands of modern markets. Companies face more pressure to meet market demands. They need fast upgrades like pouch packaging machines. These machines keep the company competitive with flexible packaging. They also meet consumer needs.

Increasing Market Demands for Speed, Hygiene, and Quality

Market competition has pushed packaging from a back‑end function to a core value driver. Retailers and brand owners now require:

- Shorter lead times and faster order turnaround.

- Strict hygiene, especially for food, cosmetics, pet food, chemicals, and pharma.

- Consistent, attractive, and defect‑free pouches on every pallet.

Consumers notice when pouches leak, are under‑filled, or look poorly sealed. Even small visual defects can reduce trust and cause complaints or returns. Many regulatory bodies and large buyers require compliance with standards like GMP and HACCP. These standards need packaging environments that are traceable, clean, and controlled. Under these conditions, relying on fully manual packaging exposes a brand to serious risk in speed, hygiene, and quality.

Problems of Manual or Low-End Packaging

Manual processes and low-end packaging present several drawbacks:

- Slow speed: Manual or low‑end lines move at the pace of human hands, so they quickly become a bottleneck as order volumes increase.

- High labor cost: Hand‑intensive packaging needs many operators plus training and supervision, which drives up unit cost and hurts margins.

- Inconsistent filling accuracy: Human filling is hard to repeat exactly, causing frequent over‑ or under‑fills, waste, and customer complaints.

- Secondary contamination risks: human contact with open pouches and product raises the risk of contamination, spoilage, and non‑compliance.

- Production instability: Output from manual lines changes with fatigue and absenteeism, making planning difficult and threatening on‑time delivery.

Why Automation Is Now a Strategic Investment

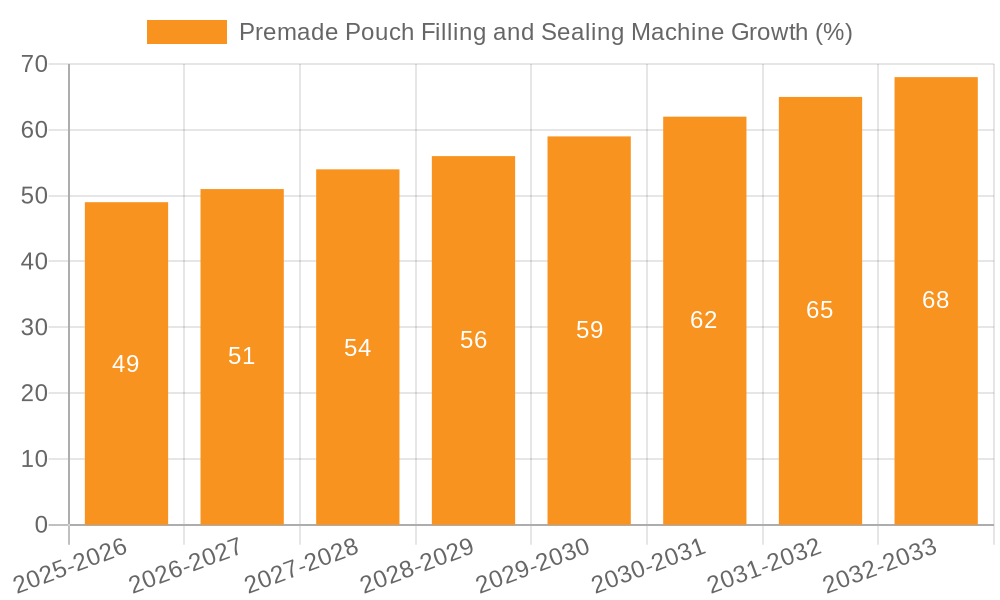

Industries face challenges with manual and traditional packaging. They are choosing to upgrade to more efficient systems. One example is premade pouch filling machines. And that’s why staggering growth has been seen in the premade pouch filling machine market. According to reports, the premade pouch filling and sealing equipment segment is on a strong upward trajectory, with market value expected to reach about 1.02 billion USD by 2025 and then continue expanding at an estimated compound annual growth rate of around 4.6% between 2025 and 2033.

This automated packaging equipment is not just about adding a piece of equipment. It is a strategic investment in speed, quality, hygiene, and brand reputation.

An automated system handles pouch handling, product filling, sealing, and basic inspection. It does this through a series of coordinated, programmable steps. It replaces variable human motions with controlled servo drives, sensors, robotic tools, and feedback loops.

For product brands, they offer a superior canvas for marketing, extend shelf life, and optimize logistics. This shift has made automated premade pouch packaging machines a cornerstone of modern production facilities.

Core Advantages of a Premade Pouch Filling Machine

Efficiency Revolution – Massive Capacity Increase

A premade pouch filling machine is designed for high throughput. It can pick, open, fill, and seal pouches at high speeds, reaching several dozen or even hundreds of pouches per minute, depending on the model and product type. This can translate into a 300% or more improvement in effective line capacity compared to manual work or basic semi‑automatic setups. Higher speed has several practical effects:

- You can process larger orders without adding extra shifts.

- You can absorb seasonal demand peaks more easily.

- You can consolidate multiple small manual lines into a single, efficient automated line.

The machine is also built for 24/7 operation, with stable performance across long runs. Continuous operation reduces the impact of shift changes and human fatigue. Downtime is lower because most functions are controlled, monitored, and adjusted through a central system rather than improvised on the line.

Precision and Quality Assurance – Perfect Filling Every Time

Modern premade pouch filling machines are equipped with servo drives, flow meters, multi‑head weighers, or volumetric fillers. These devices accurately control how much product goes into each pouch. It controls product dose within a tight accuracy band (often around ±1–2% of target fill). High precision brings clear business advantages:

- Fewer under‑filled pouches could lead to complaints or legal issues.

- Easier compliance with labeled net weight or volume.,

- Reduction in waste improves margins and supports sustainability objectives.

At the same time, PLC-controlled sealing temperature, pressure, and dwell time generate uniform, reliable heat seals. When combined with options like nitrogen flushing or vacuum sealing, this minimizes leaks, protects sensitive products from oxygen and moisture, and helps extend shelf life.

Hygiene and Safety – Fully Compliant with GMP/HACCP Standards

Premade pouch filling machines use grippers, closed hoppers, pipelines, and nozzles. These parts reduce direct human contact with open products and pouches. This lowers contamination risk and supports food safety rules like GMP and HACCP. Product‑contact and nearby surfaces are typically made from stainless steel and food‑grade materials. They have smooth, easy‑to‑clean geometries, and many designs include quick‑release, tool‑less parts and drain points. Operators can quickly take apart, wash, and put back key parts. This reduces cleaning and changeover time. It also helps plants keep strict hygiene rules and pass audits.

Technical Features and Machine Functions

Compatible with Multiple Premade Pouch Types

Premade pouch fillers can handle many flexible formats. They do this without major mechanical changes. Typical supported pouch types include:

- Stand-Up Pouches (Doypack / SUP)

- Zipper pouches and re‑closable formats

- Three-sided seal or flat pouches

- Gusseted and shaped pouches, depending on the gripper and magazine design

Bag width and length are generally adjustable within defined ranges via the HMI and simple mechanical settings, enabling multiple SKUs to run on the same platform. This flexibility is very useful for contract packers and brand owners. They often have frequent changeovers.

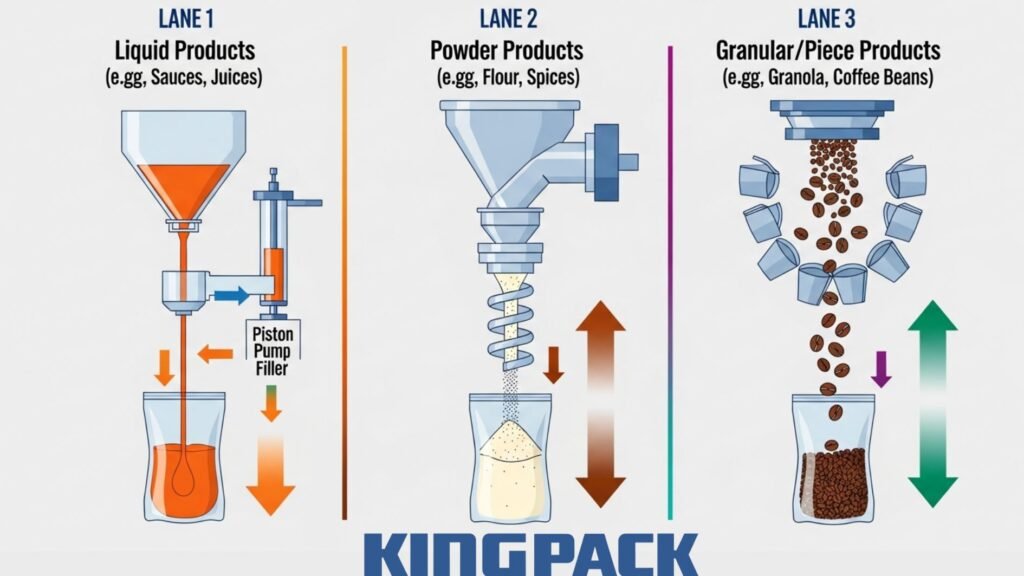

Premade pouch machines can be configured for liquid products, powder, granule, or viscous products by pairing the main frame with the appropriate dosing technologies. This modular approach allows plants to upgrade or reconfigure the filler module as product portfolios evolve.

Smart Controls & User-Friendly Interaction

- PLC central control:

- A PLC coordinates all station actions—bag pick‑up, opening, filling, sealing, and discharge—according to defined timing diagrams. Integrated motion control for servo or stepper drives ensures precise positioning and synchronization of grippers, indexes, and seal jaws.

- Large touch‑screen interface: An industrial HMI provides operators with recipe selection, parameter input, alarm lists, and real‑time status of each station. Graphical interfaces and multi‑language support make it easier for operators to understand machine states and make adjustments with minimal training.

- Real‑time monitoring: Sensors monitor bag presence, bag opening, fill level (via checkweigher or feedback signals), jaw temperature, and safety door status. Continuous monitoring enables early detection of misfeeds, film issues, or sealing anomalies, reducing scrap and unplanned stops.

- Self‑diagnosis & alarm functions: Faults are logged with time stamps and descriptive messages on the HMI, guiding operators to the likely root cause. Some systems support remote diagnostics and software updates over secure connections, enabling OEMs to assist with troubleshooting and performance optimization.

Integration Flexibility with Upstream & Downstream Equipment

Premade pouch fillers are usually open platforms. They easily connect with other packaging systems.

Upstream options include:

- Multi‑head weighers for snacks, frozen food products, nuts, and confectionery

- Auger fillers for powders such as flour, spices, coffee, and nutraceuticals

- Piston or gear pumps for liquid and pasty products such as sauces and semi‑viscous products.

Downstream options include:

- Coding machines or printers for best‑before dates, batch codes, or barcodes.

- Metal detectors and checkweighers for foreign‑body control and weight verification.

- Conveyors, case packers, and palletizers to create fully automated end‑of‑line solutions.

Most modern systems are made to grow. You can add more fillers, inspection devices, handling & sterilizing equipment, or packaging modules. This helps when you need more production or different products.

Why This Machine Is a Strategic Upgrade

Transition from Manual to Intelligent Packaging

Migrating from manual or semi‑automatic operations to a premade pouch-filling machine transforms the line into a data‑driven, recipe‑controlled process. Machine parameters, production counts, and alarm histories can be logged and analyzed, feeding continuous improvement initiatives and supporting traceability requirements.

Better Cost Control Through Higher Efficiency

Higher throughput, reduced labor dependency, and lower scrap rates significantly lower unit packaging costs over the machine’s service life. By stabilizing OEE and reducing unexpected stoppages, plants can plan production more accurately and allocate resources more efficiently.

Stronger Brand Image Through Consistent Output Quality

Uniform pouch appearance, accurate fills, and reliable seals directly influence shelf appeal and consumer confidence. Consistent quality across batches helps brands qualify for larger retail listings, export markets, and private-label contracts. These require strict packaging standards.

Conclusion – Upgrade Your Packaging Line Now

Automation as the Key to Competing in Today’s Market

In modern supply chains, speed, hygiene, and repeatable quality are baseline expectations rather than differentiators. Premade pouch filling machines deliver these capabilities in a compact, flexible platform that aligns with GMP/HACCP frameworks and integrates seamlessly into automated filling and inspection lines.

Benefits You Will Gain

- Lower operating costs through reduced labor, waste, and downtime.

- Higher consistency in dosing, sealing, and pouch presentation.

- Better compliance with food safety and quality regulations, supported by hygienic design and documentation.

- Stronger competitiveness in both domestic and export markets through scalable, high‑performance packaging capacity.

Ready to upgrade your packaging line?

Partner with King Pack to turn your packaging line into a high‑performance, fully automated system tailored to your products and budget. With over a decade of specialization in filling, capping, labeling, and complete packaging lines, King Pack delivers CE‑compliant, GMP‑oriented equipment, built with branded electrical components and engineered for 24/7 reliability.

From premade pouch filling systems to final carton sealing and conveying, their engineering team can configure a turnkey solution, provide installation and operator training, and back it with lifetime technical support and readily available spare parts. Visit the King Pack website today to share your product details, output targets, and pouch specifications—King Pack will prepare a personalized proposal and schedule an on‑site or video demonstration so you can see actual machine performance before you invest.