and integrated final packaging lines. This guide provides essential knowledge you need about these Multilane packing machines. So, let’s dive in and get started.

Introduction to Multilane Packing Machines

What Is a Multilane Packing Machine?

(VFFS)A multilane packing machine is a sophisticated piece of automated equipment that operates on the VFFS form fill and seal, principle, but with a significant enhancement. So, it forms a seal on different-shaped sachets.

Instead of a single production line, these machines use a wide roll of film that is split and formed into multiple parallel tubes, or lanes. Each lane functions as an individual packaging channel, receiving product, sealing it, and cutting it into a finished sachet or stickpack. This multichannel approach dramatically increases the machine’s overall output, allowing for the rapid production of thousands of units per hour.

Why Multilane Machines Are Important for High-Speed Production

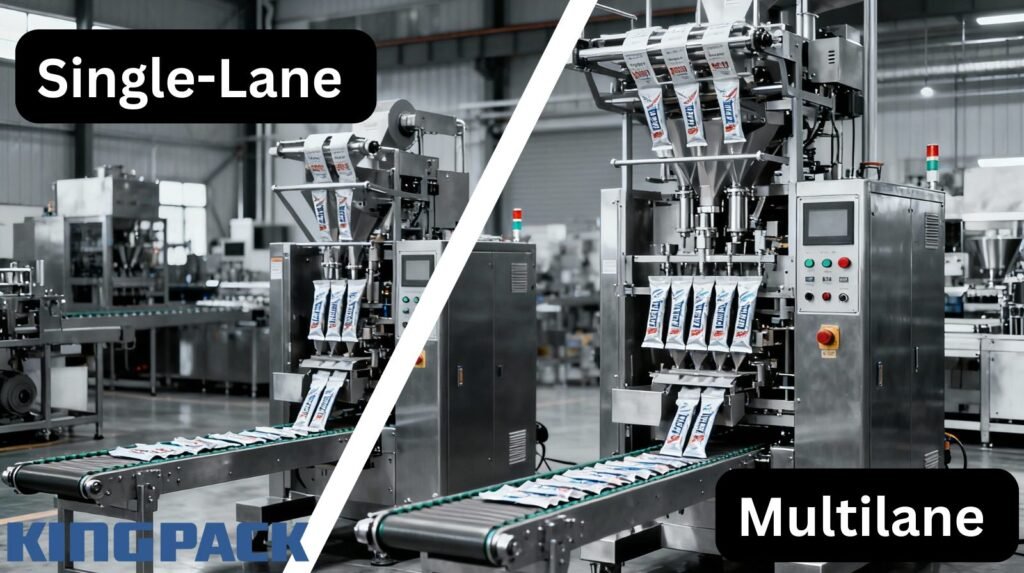

The core importance of multilane sachet machines lies in their ability to scale production capacity exponentially. In a market where speed-to-market and volume are paramount, a single-lane machine can quickly become a limiting factor. By processing anywhere from two to over ten lanes at once, a multilane system can achieve outputs that are simply unattainable with traditional equipment. This high throughput is essential for large-scale manufacturers, co-packers, and businesses experiencing rapid growth. It enables them to meet large orders, reduce lead times, and maintain a competitive edge in demanding sectors like the food, pharmaceutical, and cosmetic industries. According to market reports, these machines are widely used, and the market is experiencing staggering global growth.

Key Advantages Over Single-Lane Packing Machines

| Aspect | Multilane packing machine | Single-lane packing machine |

| Production capacity | Packs multiple sachets or sticks in each cycle across several lanes, delivering very high total output on a single frame. | Forms only one pack per stroke, so matching high volumes usually requires several machines in parallel. |

| Line speed vs stability | Reaches high throughput by adding lanes, allowing moderate film speed and more stable sealing and registration. | Must run the web faster to increase output, which can make sealing, cutting, and print alignment less stable. |

| Floor space utilization | Concentrates many lanes in one compact frame, giving high packs‑per‑square‑meter. | Each unit needs its own footprint, so capacity increases expand the line length and occupied area. |

| Packaging quality and consistency | Central control keeps temperatures, pressures, and timings synchronized across lanes, improving seal and print uniformity. | Each machine is tuned separately, so quality can vary between units and is harder to keep aligned. |

| Integration with downstream equipment | Provides a single, high‑density product discharge that is straightforward to feed into counters, cartoners, or case packers. | Multiple discharges must be merged or handled separately, complicating conveyors and secondary packaging. |

| Investment vs unit cost | Higher initial price than one small machine, but can replace several units, reducing cost per pack at medium and high volumes. | Lower entry cost per machine, yet total capital, labor, and utility costs rise quickly as more units are added. |

| Suitability by plant size | Best fit for large or fast‑growing plants that need high throughput with limited floor space. | Suits smaller operations or low‑volume SKUs where extreme speed and density are not critical. |

Core Components & Technology

PLC and HMI Control Systems for Smart Operation

Two main systems work in a modern multilane Filling machine, controlling all smart operations. they are:

- Programmable Logic Controller (PLC): It acts as the central brain. It synchronizes every mechanical action across all lanes with microsecond precision. These functions include film transport, lane sealing, dosing, registration, and cutting using high‑speed digital and analog I/O. Advanced machines integrate a servo driver under PLC control with a touch screw so that sealing jaw motion, film pulling system, and piston fillers are electronically synchronized rather than cam‑driven, improving flexibility and reducing changeover time. Most industrial equipment uses the Siemens PLC system.

- Human-Machine Interface (HMI): It is typically a user-friendly touchscreen. It allows operators to set bag length, heat sealing temperature, sealing pressure, filling volume, and target output, often with password‑protected recipe storage for multiple products and formats. Diagnostic pages display alarm histories, sensor status, and production counters, helping maintenance teams quickly locate causes of film jams, seal failures, or dosing faults.

Filling Mechanisms: Liquid Pumps, Auger, Volumetric Systems

Multilane machines are versatile because they can work with different filling technologies. Each technology suits specific product features.

- For powders and fine granules, Auger Fillers are the industry standard. These systems use a precisely controlled rotating screw to dispense a consistent volume of product into each sachet.

- For free-flowing granular products like sugar or salt, Volumetric Fillers offer a simple, fast, and reliable dosing method.

- When packaging liquids, gels, or pastes, piston or rotary pumps are employed to ensure accurate and drip-free filling.

Each lane is equipped with its own filling nozzle, ensuring that all products have the right dose accuracy. This makes the machine a highly effective Powder Packaging Machine for a variety of applications.

Sensor Systems and Dead-Film Protection for Accuracy

To maintain high accuracy and minimize waste at high speeds, Sachet Packing Machines are equipped with an array of sophisticated sensors.

- Photo-eye sensors track registration marks on the film, ensuring that each cut and seal is perfectly aligned with the printed artwork.

- Other sensors monitor film tension, detect the end of a film roll, and verify that the product has been dispensed correctly.

An essential feature is dead-film protection, where sensors detect if the film has stopped advancing. This immediately halts the sealing and cutting processes to prevent wasted product and film, as well as damage to the sealing jaws—a critical safeguard in a continuous, high-speed environment.

Design & Build Features

Stainless Steel Construction for Hygiene and Durability

In industries like food, pharmaceuticals, and cosmetics, hygiene is non-negotiable. King Pack multilane sachet machines are constructed primarily from high-grade SUS304 stainless steel. This material is chosen for its exceptional corrosion resistance, durability, and non-porous surface, which prevents bacterial growth and is easy to clean and sterilize. The sachet machine has a strong frame and parts made from SUS304 stainless steel. This lets it handle 24/7 production. It also meets strict rules like Good Manufacturing Practices (GMP) used in the Pharmaceutical Industry.

Compact Multi-Lane Layout for Space Efficiency

Despite their massive output capabilities, multilane filling machines are designed with a remarkably compact footprint. By arranging the packaging channels vertically, these machines maximize production capacity per unit of floor space. This vertical VFFS design saves space. It lets manufacturers increase packaging speed a lot without making their facilities bigger. This intelligent layout is a key consideration for factories where floor space is at a premium.

Tool-Free Changeover and Modular Design

Modern multilane stickpack machines are designed to reduce downtime. They also increase operational flexibility by allowing quick changeovers. Many key components, such as forming tubes and dosing nozzles, are designed for tool-free removal and installation. This allows operators to quickly switch between different shaped sachet sizes or product types with minimal interruption. The modular design further enhances this flexibility, enabling easier maintenance, upgrades, and integration of different filling systems. This focus on user-centric engineering ensures that the machine spends more time running and less time idle.

Operational Advantages

High-Speed Output with Minimal Downtime

The main benefit of multilane technology is that it produces very high output rates. By multiplying the packaging process across several lanes, these machines can produce hundreds or even thousands of finished sachets per minute. This speed is complemented by robust design and intelligent automation features that minimize unplanned downtime. Servo-driven motors are reliable. PLC Control is precise. Protective systems like film-end detection work together to keep the machine running without stopping. This maximizes overall equipment effectiveness (OEE).

Consistent Product Quality Across All Lanes

High speed is meaningless without consistency. Multilane stickpack machines are engineered to deliver uniform quality across every single sachet produced. The centralized control system ensures that parameters like fill weight, seal temperature, and package length are identical for each lane. This precision guarantees that the last sachet of a production run is identical in quality to the first. This consistency is very important for brand reputation, customer satisfaction, and following industry rules. It is especially important for pharmaceutical powder products that need precise doses. The Vertical Sealing mechanism ensures each seal is strong and reliable.

Easy Integration into End-of-Line Packaging Systems

A multilane packing machine is rarely a standalone unit; it is typically the core of a larger, integrated packaging line. These machines are designed for seamless integration with downstream equipment. The high-volume output of sachets can be synchronized with conveyors, check weighers, cartoning machines, and case packers to create a fully automated Repackaging Line. This end-to-end automation reduces manual handling, improves traceability, and further streamlines the entire production process from primary packaging to final shipment.

Applications Across Industries

Food – Sauces, Powders, Granules, Beverages

In the food industry, multilane machines are invaluable for packaging a wide range of products. They handle everything from single-serve ketchup and mayonnaise sachets to stick-packs of instant coffee, drink mixes, and spices. For Powders and granules, the Granule Stick Pack Machine is equipped with servo Auger Fillers and Volumetric Fillers, which provide the necessary accuracy. The speed and efficiency of these machines are ideal for the high-volume, liquid, pasty, powdery and granular products

Pharmaceuticals – Oral Powders, Sachets, Granules

The pharmaceutical Industry relies heavily on multilane Sachet & Stick Pack Machinery for its precision, hygiene, and reliability. These systems are perfect for packaging single-dose pharmaceutical powder, effervescent granules, and oral rehydration salts. The use of SUS304 stainless steel and adherence to GMP standards ensure product safety and integrity. Giving a precise dose in every sachet is about quality and patient safety. The accuracy of the weigher and filling systems is very important.

Cosmetics & Personal Care – Creams, Gels, Serums

The cosmetic industry uses a multilane Vertical Packaging Machine to package single-use samples and travel-size products like shampoos, lotions, face creams, and serums. These formats are popular for product trials and on-the-go convenience. The machines must handle viscous liquids, pasty products, and delicate emulsions without compromising the product’s quality as they are equipped with auger pumps offering smooth and plus-free flow. A perfect, clean seal is essential not only for product integrity but also for the aesthetic appeal of the final package, reflecting the high standards of the cosmetic industry.

Choosing the Right Multilane Machine

Lane Count Selection Based on Production Volume

The first consideration when selecting a multilane machine is the required production volume. The number of lanes directly correlates to the machine’s maximum output. A wise consideration would be :

- 2- or 4-lane model of a small sachet packaging machine for a small but growing business

- 10- or 12-lane system may be needed for a large-scale manufacturer

It is essential to analyze current production needs and forecast future growth to select a machine with the appropriate lane count to serve as a long-term investment.

Matching Filling Technology to Product Characteristics

The nature of the products being packaged will dictate the necessary filling technology. It is crucial to match the filler to the product’s characteristics—its viscosity, flowability, and density.

- Auger Fillers with micro-dosing systems are ideal for non-free-flowing powders.

- Volumetric cup fillers are better for granular products.

- Piston pumps are necessary for thick liquids and pastes.

Choosing a supplier like King Pack, which can offer and integrate the correct filling system for your specific products, is key to achieving optimal performance and accuracy. while these sachet packing machines can be customized for different sealing patterns and filling mechanisms to meet customer needs.

Evaluating Support, Maintenance, and After-Sales Service

A high-performance machine is only as good as the support behind it. When investing in a multilane packing system, it is vital to evaluate the manufacturer’s after-sales service. This includes the availability of technical support, spare parts, and maintenance programs. A strong partnership with your equipment provider ensures that any potential issues are resolved quickly, minimizing downtime and protecting your investment for years to come. King Pack supports its customers with ultimate after-sales service.

Conclusion

Multilane sachet and stick-pack machines greatly improve packaging efficiency. They provide unmatched speed, accuracy, and versatility. These systems process multiple packages at the same time. They help manufacturers in the pharmaceutical and cosmetic sectors meet high-volume demands. They also reduce operational costs and keep product quality consistent.

Ready to invest and grow your business?

Investing in the right multilane machine is a strategic decision that can redefine your production capabilities. It streamlines your packaging line, enhances throughput, and delivers a rapid return on investment. If you are ready to elevate your production speed and efficiency, the next step is to explore a solution tailored to your specific needs. Contact King Pack today to discuss your product and production requirements, and let our experts help you configure the perfect high-speed multichannel solution to drive your business forward.