A jam filling machine is an essential piece of equipment for businesses producing fruit jams, marmalades, and preserves. They serve both large commercial factories and small artisanal producers. Market research shows the global jam filling machine market is about USD 5.2 billion in 2025. It should reach around USD 7.2 billion by 2033. This means a yearly growth rate of over 6%. This rise is primarily driven by the food industry’s push for efficient, automated processes that reduce labor and waste while boosting throughput.

Filled jars are then moved to automatic capping, where lids are tightly secured.

Filled jars are then moved to automatic capping, where lids are tightly secured.

What is a Jam Filling Machine?

Definition and Purpose

At its most fundamental, a jam filling machine is a specialized filling equipment. It is used to fill and package viscous products. These include fruit jams, jellies, marmalades, or chili sauce in glass jars, bottles, or containers. These machines utilize automated technology to do all the tasks, such as filling, capping, and sealing. The main goal is to make portioning and packaging jams easier. The machine ensures exact filling amounts, reduces waste, and improves hygiene during the process.

Modern designs prioritize easy cleaning, stainless steel food contact surfaces, and modular construction for flexibility. These machines automate portioning. They keep product quality and consistency, which is important in the food industry.

Importance for Food Factories and Small-Scale Producers

In commercial jam factories, the machines fill many bottles quickly. They make thousands of jars each day. This meets market demand and lowers labor costs. For small or medium-sized producers, a jam filling machine makes batch production affordable, improving workflow and product reliability even at lower scales of output. This enables local producers to meet higher quality and hygiene standards, opening access to retail and export opportunities.

Automated Filling Boosts Efficiency and Consistency

Jam-filling machines control flow rate, filling volume, container movement, and hygienic handling. Automation is very important for this. Automated operation stops uneven fills and reduces spillage. They also reduce microbial contamination. The system places caps evenly. This is important for shelf stability and customer satisfaction. These features collectively improve efficiency and ensure that the final product meets commercial standards for appearance, weight, sealing, and labeling.

How Do Jam Filling Machines Work?

Knowing how a jam filling machine works helps you understand its benefits and uses in food production.

Step-by-Step Workflow of a Jam Filling Line

A jam filling line uses automation technology with a conveyor belt to streamline production. Clean jars or plastic bottles are loaded and transported along the bottling line. An intelligent control system operates the pump or piston for precise jam filling, preventing overfill and air pockets. Filled jars are then moved to automatic capping, where lids are tightly secured. Next, the labeling and packing table applies labels for branding and compliance. This seamless integration of feeding, filling, capping, labeling, and packaging ensures speed, accuracy, and hygiene throughout the process.

Each stage is carefully controlled to minimize human contact, maintain speed and accuracy, and optimize hygiene. Advanced models track weight, thickness, and temperature. They adjust settings automatically for the best output. The system works fast, filling up to 60 jars or bottles per minute in advanced setups. It is very accurate, controlling weight down to single grams. It keeps jars clean by sealing them quickly and reducing worker handling.

Semi-Automatic vs Fully Automatic Machines

Commercial jam filling machines fall into two main categories:

- Semi-Automatic Machines: These semi-automatic jam-filling machines require manual loading of jars and often manual operation of some steps (like capping).

- Fully Automatic Machines: These systems handle everything from feeding to labeling, forming continuous production lines capable of tens of thousands of jars daily. They suit large jam factories or export-focused businesses, providing high throughput, minimal labor, and reduced error rates.

The choice between these types depends on the desired production scale, available budget, and product variety.

Types of Jam Filling Machines

Jam filling technology has evolved to meet the diverse operational needs and container types. Key formats include:

- Semi-Automatic Fillers: Manual or pedal-activated; best for small batch production or highly variable products.

- Fully Automatic Fillers: PLC systems in these machines serve large-scale, fast, and consistent filling.

- Piston Fillers: Use mechanical pistons for accurate portioning, especially with thicker or chunkier jams.

- Volumetric Fillers: Rely on volumetric mechanical piston-action dosing. It includes calibrated chambers or pumps to measure product volumes, offering speed and adaptability for different container sizes.

- Linear Machines: Move jars in a straight line through filling, capping, and labeling stations; preferred for scalable production or varied container dimensions.

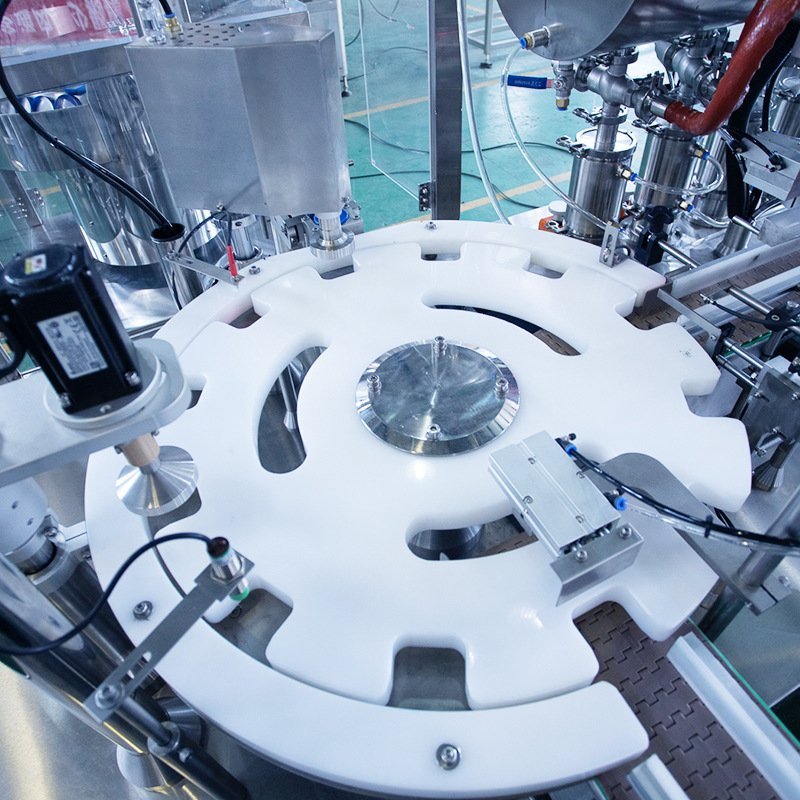

- Rotary Machines: Containers move in a circular pattern for higher speed and efficiency, ideal for uniform product runs at an industrial scale.

Other than these types, there are Tracking Type Jam Jar Filling Machine, MIC Jam Packing Machine, 2 Head Pump Filling Machine that can handle variable product viscosity and material characteristics. All these machines work much better than manual filling. They lower the variation and contamination risks. They also improve product uniformity and shelf life.

Jam Filling Machine Construction and Components

A good jam filling machine must have precise engineering and use food-safe materials. It should also offer options to fit specific production needs.

Key Components

A jam filling machine consists of essential components designed for smooth, accurate operation across a wide product range. The filling pump or piston, driven by an electric motor, moves jam from the main tank or stainless steel container into jars with precision dosing. Filling heads/nozzles dispense the jam with minimal dripping or clogging, supported by anti-leak features and easy cleaning. The conveyor system, often paired with a bottle loading turntable, transports containers through the bottling line, adjustable for batch size and jar dimensions.

the

the

The capping system automatically places and tightens lids for airtight seals, while programmable controls on the control panel enable operators to set fill volumes, speed, and other parameters with ease. Additional features like the mixing & heating function maintain jam consistency, and the labeling/packing table completes the process by applying labels efficiently. Multi-filling heads enhance speed, making the machine versatile and highly efficient for jam production.

Materials For Food Safety and Durability

Industry standards require food contact parts to be made from stainless steel (usually 304 or 316 grade) due to its corrosion resistance, durability, and ease of cleaning. Non-contact surfaces may use food-grade plastics for housing and guides. All materials must follow international food safety rules. This prevents leaching or contamination.

Optional Features

- Inline Labeling Units: Enable quick, consistent labeling for traceability and branding.

- Automated Capping: Varies the torque and seal types for different lid designs.

- Heating Systems: Slightly heat viscous or chunky jams, improving flow without compromising texture or flavor.

These features boost customization and efficiency for diverse jam recipes and packaging standards.

Benefits of Using a Jam Filling Machine

Investing in a jam filling machine offers transformative advantages for food producers.

- Improved Accuracy and Consistency: Automated controls guarantee each jar receives the exact intended fill.

- Reduced Labor Cost and Human Error: Minimizing manual handling lowers staffing needs and eliminates costly mistakes.

- Enhanced Hygiene and Compliance: Machines are built for regular cleaning, sterilization, and compliance with HACCP, FDA, and other food safety standards.

- Versatility: Designs accommodate various jam viscosities, fruit chunks, and jar sizes, making them suitable for both traditional and specialty products.

Modern machines save product and prevent waste. This increases profits and meets customer demands for consistent quality.

What to Consider Before Buying a Jam Filling Machine

Choosing the right jam filling machine means balancing operational requirements, financial planning, and technical constraints.

- Production Capacity and Batch Size: Machines range from low-output (100 jars/hour) for artisanal producers to high-output (6,000+ jars/hour) for industrial plants.

- Compatibility With Jam Viscosity: Select a pump or piston-based system matched to your product consistency and any added inclusions.

- Budget and ROI: Assess both upfront investment and long-term savings from labor reduction and waste minimization.

- After-Sales Support and Maintenance: Reliable suppliers offer technical support, replacement parts, and service contracts for ongoing performance.

- Compliance: Ensure the machine meets local and international standards (FDA, HACCP, ISO), particularly important for export businesses.

- Energy Efficiency and Safety: Opt for energy-saving motors, low-power control systems, and guards to prevent injury during operation.

Careful comparison and checking of suppliers help you pick a machine that works well and saves money for many years.

Maintenance and Troubleshooting Tips

Routine care is pivotal for long-term performance and product safety.

- Regular Cleaning and Sanitization: Daily or batch-end cleaning prevents buildup, spoilage, and contamination. Design features like quick-release nozzles and clean-in-place (CIP) circuits simplify this process.

- Pump and Nozzle Calibration: Periodic calibration maintains consistent fill volumes as viscosity or fill temperature changes.

- Common Issues: Watch for uneven filling (caused by viscosity changes or air entrainment), leakage (damaged seals or misalignment), and jams sticking to machinery (due to poor heating or cleaning). Swift troubleshooting and maintenance minimize downtime.

Keeping detailed maintenance logs and following manufacturer instructions helps the machine run smoothly. It ensures reliable performance every day.

Conclusion

A jam filling machine is indispensable for any jam producer seeking to maximize efficiency, consistency, and hygiene. There are small semi-automatic units for artisans and large fully automated lines for industry. These machines help businesses compete in tough food markets. Producers can select technology that meets their production goals and requirements by understanding the workflow. They should check machine types and focus on food-safe construction. Regular maintenance and smart investment choices protect that value, ensuring consistent quality and growth for businesses of any size.

If you need a trustworthy production partner, King Pack Filling Machine serves as a one-stop solution — Elevate your jam production with precision, speed, and smart automation. Experience unmatched efficiency and quality; get yours today and transform your bottling line! Contact us now to learn more and get expert support.