Introduction

Choosing the right tube filling machine brand is a decision that impacts your product quality, regulatory compliance, and long-term profitability. If you manufacture cosmetics, food pastes, ointments, or pharmaceuticals, a small mistake in selecting the brand can lead to downtime, maintenance costs, or worse—product recalls.

Key parameters include efficiency, precision, cost, support, and certification. These will guide your investment decision. This article compares tube filling machine manufacturers from four major regions—USA, Europe, Japan, and China—highlighting strengths, trade-offs, and what to look for. By the end, you’ll understand what matters most for your scale, product type, and business goals.

Recommended Reading: What Differentiates Tube Filling and Sealing Machine from Ultrasonic Tube Sealing Machine? – King Pack Machinery

US Manufactured Tube Filling Machines

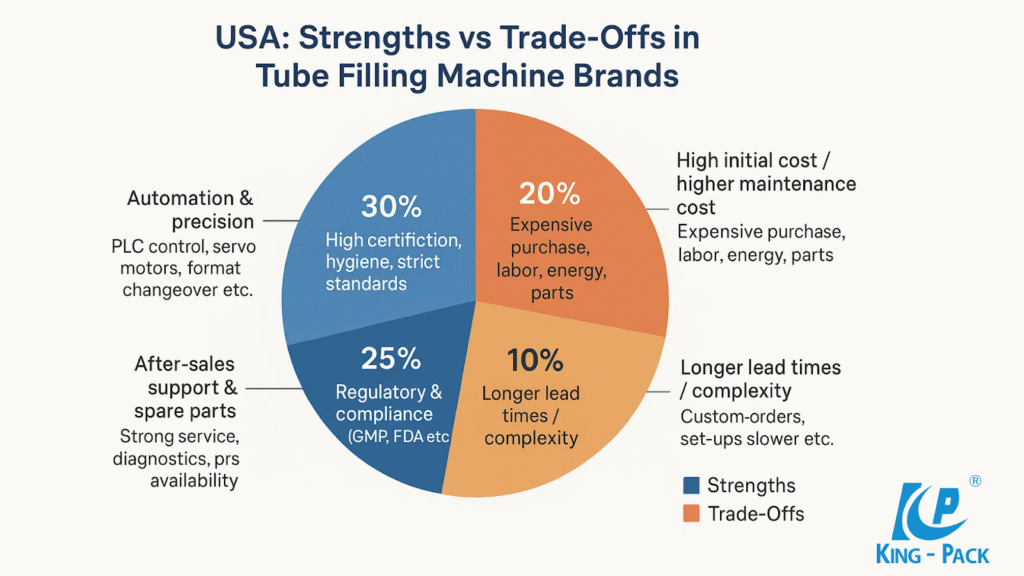

Technological strengths and advanced automation

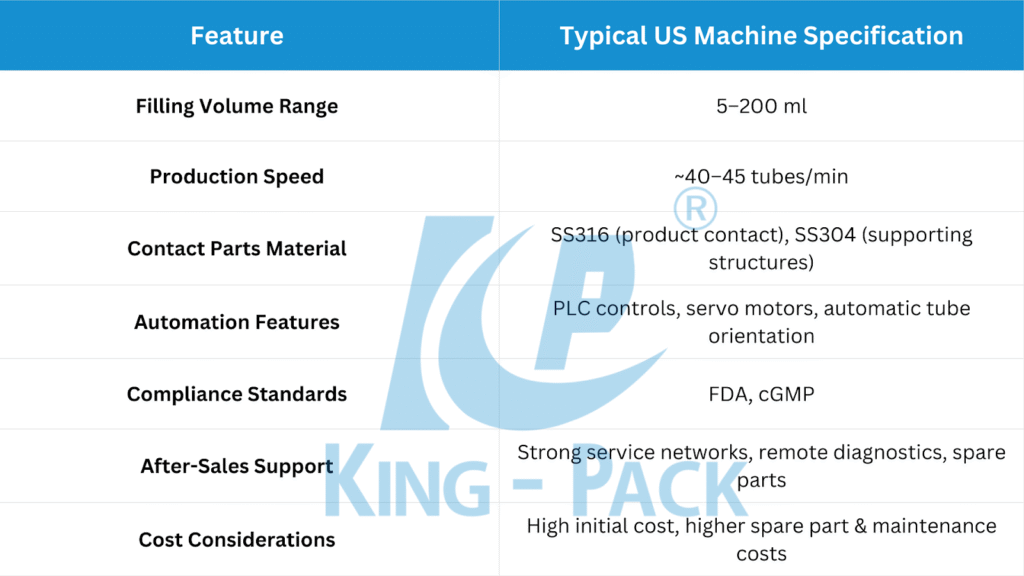

In the USA, many brands emphasize high automation, tight tolerances, and robust design. American tube fillers often include PLC controls, servo motors, automatic tube feeding, orientation, sealing, and tool-less format changeovers.

One example: Shree Bhagwati (though headquartered in India with some US distribution) offers fully automatic tube filling & sealing machines with volumetric filling, auto tube feed, and servo drives. Their models handle filling volumes 5-200 ml, run speeds of ~40–45 tubes/min, use SS316 contact parts, and comply with cGMP standards.

Another advantage among US manufacturers is strong after-sales infrastructure: spare parts, field service, remote diagnostics. These help minimize downtime. However, high automation comes with higher initial cost and more complex maintenance, particularly for high-speed or multi-format machines.

High cost and long-term maintenance considerations

While US-made machines often excel in robustness and compliance (for example FDA and cGMP), their total cost of ownership (TCO) can be high. Labor, spare parts, and energy consumption are usually more expensive in the US market. Replacement nozzles, sensors, and sealing jaws may also be costly, particularly for specialized or custom models.

Key considerations include:

- Higher operating costs – Labor and parts are priced higher compared to other regions.

- Expensive spares – Specialized nozzles, sealing jaws, and sensors increase recurring costs.

- Energy consumption – High-powered automation systems may lead to higher utility bills.

- Longer lead times – Custom orders and modifications can take months to deliver.

- Format change flexibility – Frequent tube size changes require modular components and tool-less systems.

- Service dependency – Maintenance of precision parts like rotor-stator seals requires expert technicians and stocked parts.

This balance of high reliability with high cost makes US tube filling machines best suited for companies that value compliance, automation, and long-term operational stability over initial cost savings.

Recommended Reading: How Does a Tube Filling Machine Work? – King Pack Machinery

European Tube Filling Brands

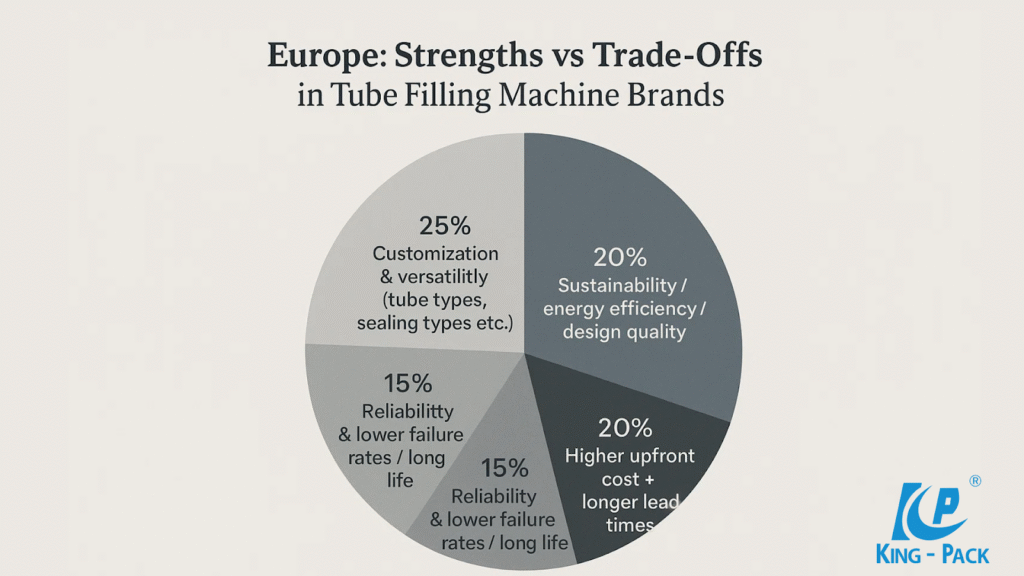

Focus on craftsmanship, sustainability, and customization

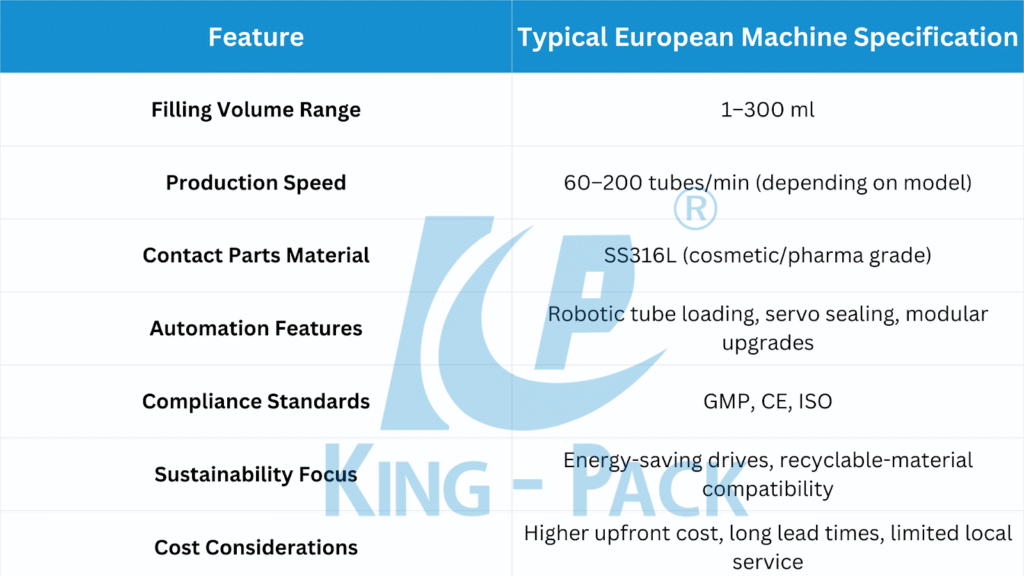

Europe has long been a strong center for tube filling innovation. Brands here (for example Norden Machinery in Sweden) focus not only on precision but also sustainability (e.g., energy use, materials), design quality, and flexibility. Norden offers high-speed tube filling, cartoning, and box/tray packaging lines with robust stainless steel build.

European makers tend to emphasize customization: machines that can handle metal, plastic, laminate tubes; different sealing types (hot-air, saddle fold, roller crimp), and user interfaces that meet the strict safety and usability norms of EU, UK, etc.

Lead times, service network, and energy efficiency

European machines may have longer engineering lead times due to certification, regulation, and often lower production volumes. But their service network—for many brands—spans many countries, making spare parts, inspections, and support more accessible. Energy efficiency is also often an engineering priority.

Key points to consider:

- Extended lead times – Custom builds and strict compliance testing can slow delivery.

- Wide service coverage – Strong networks across Europe make maintenance and parts easier to access.

- Energy-saving designs – Many machines focus on reducing power usage without compromising output.

- Higher upfront cost – Initial purchase price is often steeper than Asian alternatives.

- Strong compliance standards – EU/GMP/CE certifications support global export readiness.

- Lower failure rates – Reliability reduces long-term downtime and unexpected costs.

For companies in pharmaceuticals, personal care, or cosmetics, these factors often outweigh the higher upfront investment. A European tube filling machine may take longer to arrive and cost more initially, but the combination of reliability, global compliance, and lower energy consumption can deliver stronger value over its lifetime. This makes European brands particularly appealing to businesses that prioritize long-term efficiency and regulatory security.

Japanese Tube Filling Manufacturers

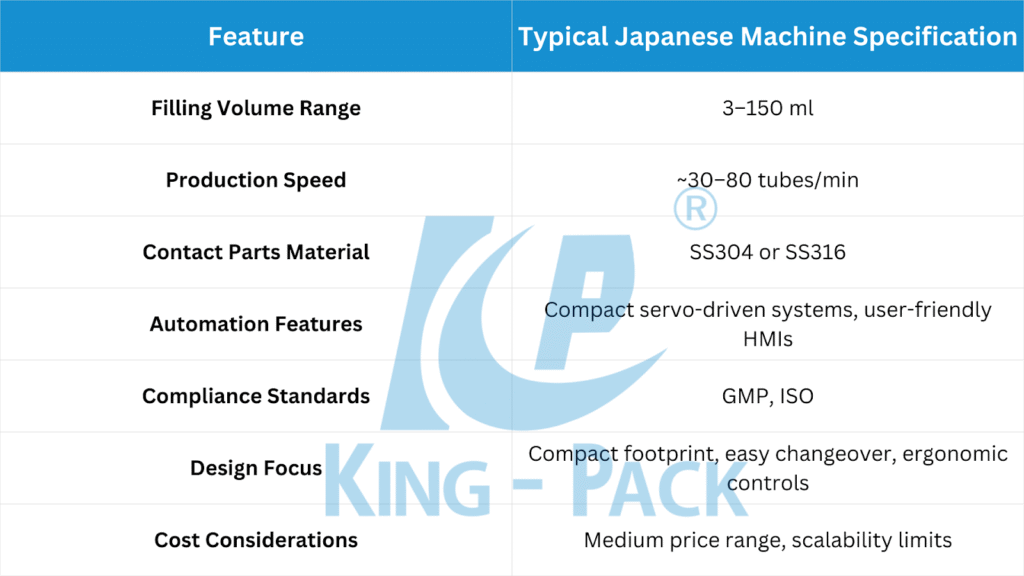

Compact designs and operator usability

Japan’s strengths include compact machine designs, excellent UI/UX, and reputation for cleanliness and reliability. Japanese brands often engineer their tube fillers to take up less floor space, be more ergonomic, and require less frequent maintenance. These machines are well suited for small to medium batch cosmetics, ointments, and paste products where operator usability matters as much as speed.

Often, Japanese machines deliver high precision even at lower volumes. The design often includes easy cleaning (important for cosmetic blends, perfumes, creams), quieter operation, and durability. They may have slightly lower maximum throughput compared to large European or Chinese lines, but excel in consistent performance, low drift, and product quality.

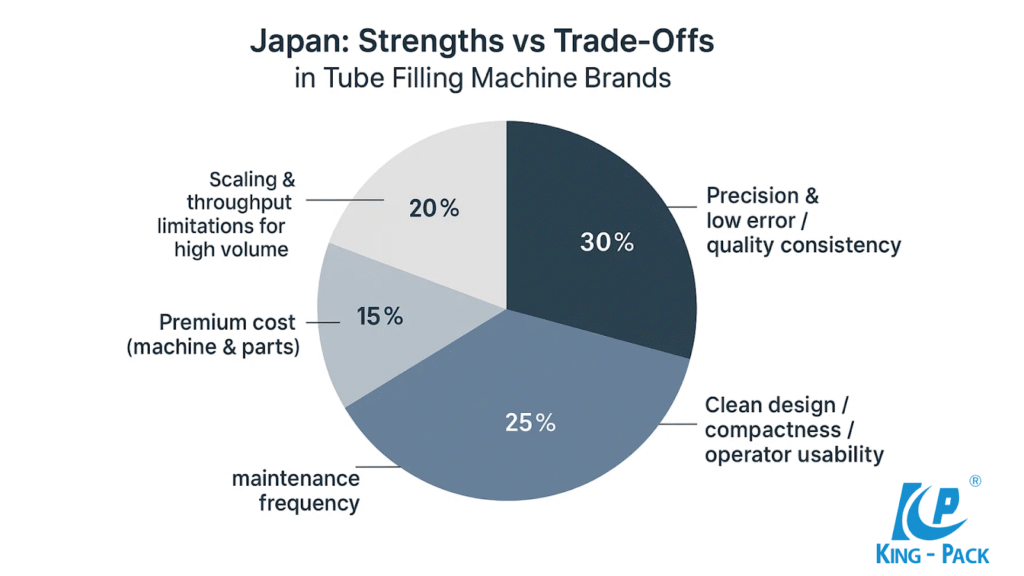

Precision and reliability vs scalability limitations

With Japanese tube fillers, you often gain excellent precision (low fill error, good sealing accuracy), reliability (long MTBF — mean time between failures) and high build quality. However, cost per unit (both machine and maintenance) tends to be higher. Scaling to very large production volumes may be less economical with Japanese brands—it may require multiple units or higher capital investment. Parts and labor costs in Japan are also higher, which impacts total cost of ownership.

Key considerations include:

- High precision filling and sealing accuracy for sensitive or premium products

- Exceptional reliability with long machine life cycles

- Strong compliance with GMP and cleanroom-ready designs

- Higher upfront and maintenance costs due to premium engineering

- Limited scalability for very high-volume production without multiple lines

For companies making premium cosmetic creams, serums, or niche products, Japanese tube filling machines often offer excellent value: high precision, clean design, and strong support. But for mass-volume commodities, businesses need to assess carefully if the throughput and cost structure align with their long-term growth targets.

Recommended Reading: Top 10 Tube Filling Machine Manufacturers Today – Global Leaders in Tube Packaging Technology – King Pack Machinery

Chinese Tube Filling Machine Brands

Cost-effectiveness and faster customization

China has become a major force in tube filling machine manufacturing. Brands often offer similar basic features—PLC control, stainless steel contact parts, multiple sealing types, varying filler technologies—at lower price points than many Western competitors.

For example, King-Pack Machinery offers an “Automatic Filling and Sealing Tail Machine” with measuring accuracy ±1%, production capacity 20-50 pcs/min, filling ranges from 3-30, 5-75, 30-260 ml depending on configuration.

Also, many Chinese makers offer faster customization: you can get machines in different configurations for tube size, sealing method, or power supply more quickly. Spare part availability is often more local and cheaper, which reduces downtime and maintenance costs.

Local spare parts support and growing technical capability

One challenge historically for Chinese brands was consistency, precision, and long-term support. But things are changing. Product listings show Chinese machines with filling accuracy ≤ ±1%, capacities in thousands of tubes/hour for some models, and designs using stainless steel, touchscreens, and safety interlocks. For example, an automatic tube filler & sealer from China offers capacity of 1800–2400 tubes/h, filling range of 5–250 ml, and tube diameter support of ф10–50 mm.

Key strengths of modern Chinese tube fillers include:

- Improved filling accuracy and repeatability, often ≤ ±1%

- Higher throughput models supporting thousands of tubes per hour

- Integration of stainless steel 304/316 for contact parts and hygienic design

- User-friendly HMI touchscreens with programmable settings

- Local spare parts supply chains and growing after-sales support

- Competitive pricing compared to US, European, and Japanese counterparts

King-Pack Machinery is a notable example, presenting itself as GMP-compliant and offering tube filling and sealing solutions as part of its wider cosmetics and pharmaceutical equipment line. With its portfolio that includes emulsifying, filling, and packaging machines, King-Pack addresses both cost-effectiveness and regulatory compliance, making it a strong option for businesses seeking reliable yet affordable tube filling solutions.

Strategic Selection Criteria

Matching machine scale to production volume

When selecting a brand, first decide your target output: are you producing a few hundred, a few thousand, or tens of thousands of tubes per minute? Brands from the USA or Europe may offer very high throughput machines with low downtime for large production outputs, while Chinese brands often give better value for small-to-medium volumes with faster ROI.

Options range from semi-automatic tube filling machines to fully automated lines like the Automatic Tube Filling and Sealing Machine or even advanced models such as the Nordenmatic 702.

Evaluating total cost of ownership

Don’t just look at initial purchase cost. Consider power consumption, maintenance, spare parts cost, consumables (seals, Filling Nozzle, Pneumatic Cylinders), cleaning requirements, format changes, and downtime. Factor in certification costs (GMP, CE, etc.), shipping, tariffs, and expected lifetime.

Brands like King-Pack Machinery offer machines with CE/ISO/GMP style compliance which can cut regulatory costs. Their lines often feature touch Screen PLC, Control Panel interfaces, and rotary indexing with oval chain transport for smoother operation and maximum productivity.

Meeting regulatory and certification standards

Particularly for Pharma & Healthcare, cosmetics, and food products—certifications like GMP, ISO 9001, CE marking, and safety standards are vital. The machine must have proper material grade (SS304, SS316), finish (mirror or electropolished), hygiene design (no dead corners, easy cleaning), and safety interlocks.

Machines designed for chemical industries, Skin & Sun Care, and Hair Care often integrate heat sealing, ultrasonic sealing, or hot air sealing options with batch number or stamping date coding for compliance and traceability.

Considering flexibility, modular design, and upgrade options

A brand that offers modularity—adjustable fill ranges, interchangeable sealing heads, tool-less changeover—will help you adapt to new products. Flexible systems like the Plastic Tube Filling and Sealing Machine, Universal Tube Filling and Sealing Machine, and aluminum tube filling models can handle plastic tubes or aluminum tubes with ease.

Also, consider whether the brand provides training, spare parts, and local technical support. Add-ons like labeling machine, cartoning machine, Tray packer, and Tray and Case packing with infeed systems improve operational efficiencies. King-Pack’s lines also support cutting excess plastic, Automatic Cassette Tube Feeding, and oval tube transport system integration, all of which enhance packaging quality standards.

Industry-Specific Recommendations

Cosmetics Manufacturing

For cosmetic manufacturers, precision, clean design, and compliance matter deeply. Key considerations include:

- Material compatibility: Stainless steel contact parts required

- Cleaning validation: Easy disassembly and sanitization

- Batch tracking: Integration with quality management systems

- Viscosity handling: Capability for creams, lotions, and gels

Recommended approach: Start with medium-speed Chinese machines like KP Filling Machine for initial production, upgrade to European high-speed systems as volumes grow.

Pharmaceutical Applications

Pharmaceutical tube filling requires the highest standards:

- GMP compliance: Mandatory for regulated markets

- Validation documentation: Complete IQ/OQ/PQ protocols

- Material traceability: Full component documentation

- Change control: Validated modification procedures

Recommended approach: European or US manufacturers for critical applications, with proper validation support.

Food and Personal Care

Food grade applications need specific certifications:

- FDA compliance: For US market entry

- HACCP compatibility: Food safety management integration

- Allergen handling: Cross-contamination prevention

- Sanitary design: 3-A sanitary standards compliance

Real Examples of Tube Filling Machines (King-Pack & Others)

Here are some real machines as examples to help compare specs and see what to expect:

- King-Pack Automatic Filling and Sealing Tail Machine: Filling ranges (3-30, 5-75, 30-260 ml), accuracy ±1%, production capacity 20-50 tubes/min. Good option for medium-volume operations.

- Chinese Automatic Tube Filler & Sealer (Made in China) version: capacity ~1800-2400 tubes/hour, tube diameter ф10-50 mm, filling volume 5-250 ml, accuracy ≤±1%. Higher speed, good for large scale.

- Pack Leader FL-300 Fully Automatic Tube Filler & Sealer: handles aluminum, plastic, laminate tubes; semi-viscous to viscous products such as creams and ointments; PLC & touchscreen control.

Comparing these machines shows trade-offs: speed vs cost, complexity vs maintainability, accuracy vs ease of cleaning.

Conclusion

Choosing a tube filling machine brand is about aligning the machine’s capabilities with your production goals, product types, and regulatory obligations. If your priority is high speed and high output, US or European brands may offer stronger throughput and longer lifetimes. If cost, faster customizations, or more flexible configurations matter, Chinese brands like King-Pack Machinery are compelling.

For cosmetic manufacturers, especially, precision, clean design, and compliance matter deeply. Assess brands on not just pricing, but total cost of ownership, spare parts support, and real performance (not just lab specs).

If you’re considering investing in a tube filling line, reach out to King-Pack Machinery to see how their customizable and compliant tube filling machines might balance cost, precision, and efficiency for your business.