Introduction

You can find single-serve ketchup packets in a lot of places, like fast food restaurants, airlines, and school cafeterias. They are easy to serve and help with portion control, hygiene, and simplicity. In this article, we’ll show you how to make these packets step by step, from getting the ketchup ready to sealing them.

The process relies on technologies like form-fill-seal machines, automated filling systems, and strict quality control. At King-Pack Machinery, we supply such advanced equipment that keeps ketchup packet manufacturing efficient, consistent, and ready to meet growing demand.

Our solutions make it possible to handle ketchup’s viscosity while maintaining consistent portion sizes and shelf life. Let’s get into more details about how these systems work and why choosing the right machinery makes a big difference in production quality.

Market Overview and Statistics

The ketchup packaging industry represents a significant segment of the global condiment market. Current market data shows the tomato ketchup market was valued at approximately USD 20.18 billion in 2024 and is projected to reach USD 25.98 billion by 2033, with growth rates ranging from 2.8% to 4.6% CAGR across different market analyses.

Here are the key market drivers of Ketchup Packets production:

- Consumer Convenience: Growing demand for portable, mess-free condiment dispensing

- Food Service Growth: Expansion of quick-service restaurants and delivery services

- Portion Control: Cost management and waste reduction in commercial operations

- Hygiene Standards: Increased focus on contactless food service post-pandemic

As more brands and foodservice operators turn to single-serve ketchup packets, demand for automated pouch packing machines, customizable sachet systems, and sustainable packaging options continues to climb. And manufacturers who invest in modern filling technology can stay competitive while meeting both consumer expectations and regulatory standards.

Step-by-Step Process of Ketchup Packet Manufacturing

1. Ketchup Preparation and Processing

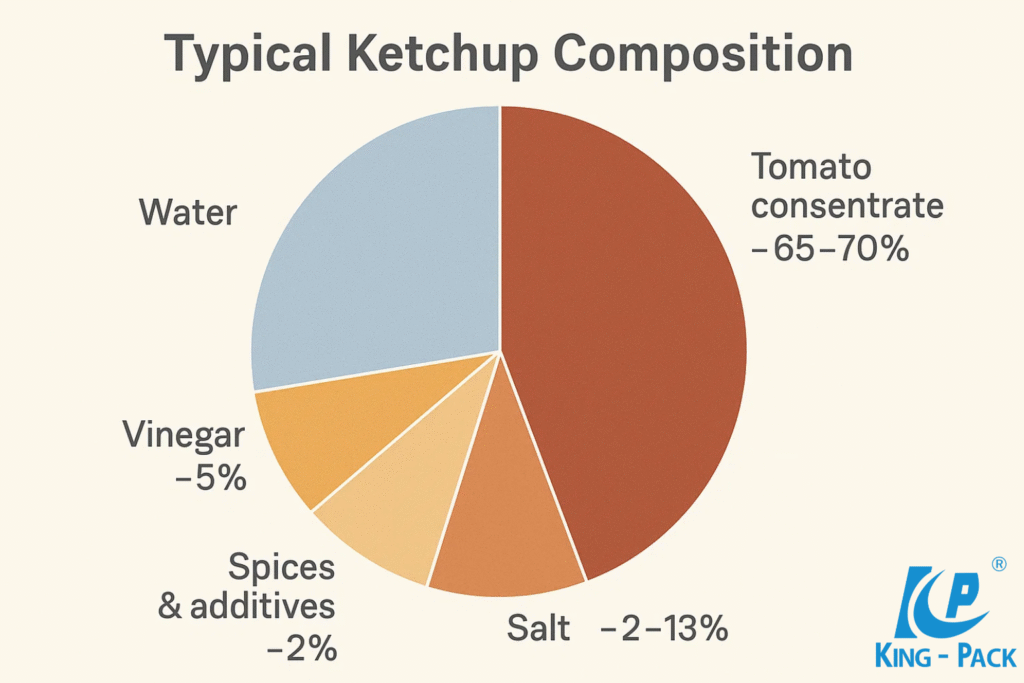

Packet production starts with a standardized ketchup recipe. Tomato concentrate (28–32% solids), vinegar (4–6% acetic acid), sugar, salt, and spices are blended to meet consistency targets of 25–33° Brix, pH 3.7–4.2, and viscosity of 50,000–150,000 cP at 20 °C.

The mixture is processed in large tanks with high-shear mixers, then homogenized at 2000–3000 psi for smooth texture. It undergoes HTST pasteurization at 85–95 °C for 15–30 seconds, followed by filtration to remove particles over 1 mm.

2. Formation of Pouches

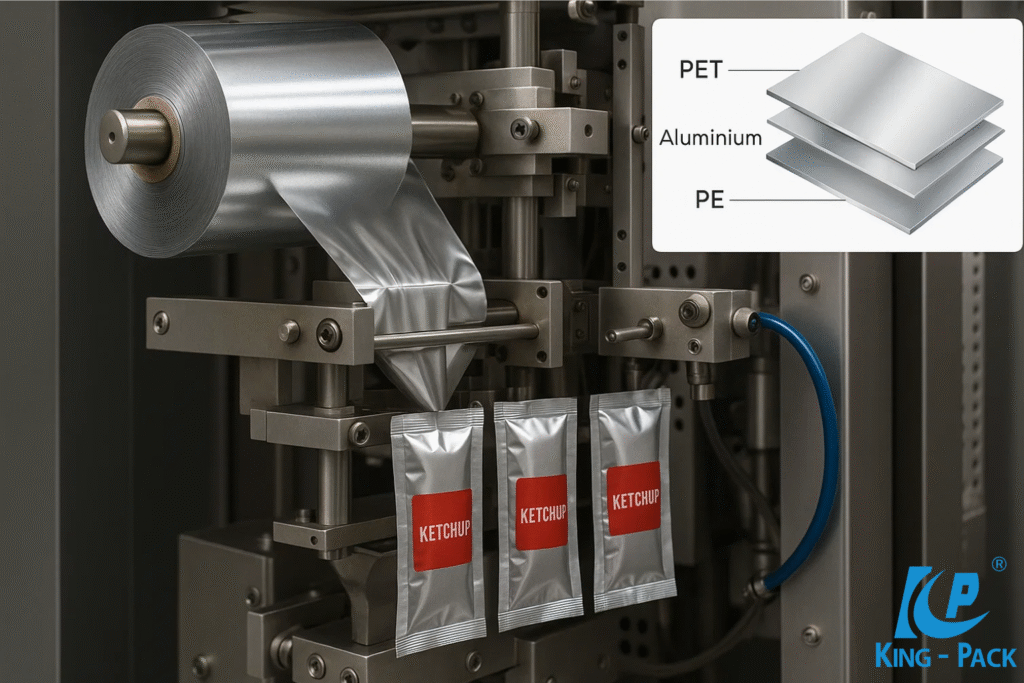

Modern ketchup packet production relies on form-fill-seal machines that create pouches from rolls of flexible packaging material. These machines unwind plastic film, then the film passes through forming stations where heat and pressure create the characteristic pouch shape.

To keep ketchup fresh and packets durable, films must meet specific technical standards:

- Tensile strength: minimum 40 N/15 mm

- Seal strength: 15–25 N/15 mm

- Oxygen transmission rate: below 1 cm³/m²/day

- Water vapor transmission: below 1 g/m²/day

3. Filling the Pouches

The next step is filling the Ketchup Pouches. The filling stage represents the heart of the ketchup packet production process. For filling process form-fill-seal (FFS) machines are used.

These machines typically run at 50–100 packets per minute, with high-performance models reaching up to 150 packets per minute.

In this step, several components work together to achieve precise and efficient operation:

- Film handling systems with tension control and web tracking to keep films aligned

- Forming tubes that shape packets with ±0.1 mm accuracy

- Filling pumps (piston, gear, or peristaltic) to deliver 7–14 ml per packet

- Sealing systems including heat, ultrasonic, or cold sealing, with 5–10 mm seal widths for durability

Fill accuracy is kept within ±1–2%, and sealing is controlled at 120–180 °C for reliable closure. At King-Pack Machinery, our piston-based filling systems are built to handle ketchup’s thick viscosity while keeping every portion uniform. With advanced automation, our solutions also cut product waste and lower contamination risks, giving manufacturers efficiency and peace of mind in every run.

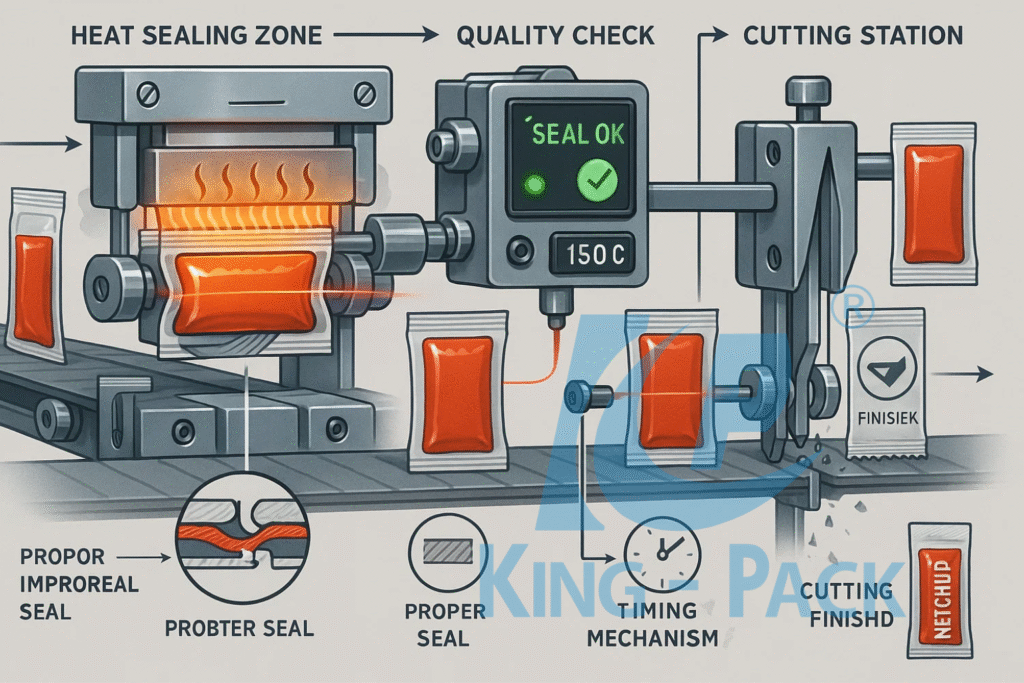

4. Sealing and Cutting

Once filled, the pouches move through sealing stations where heat and pressure create airtight seals. The sealing process must be precise to prevent leakage while allowing easy opening by consumers. After sealing, cutting mechanisms separate individual packets from the continuous film. Modern food packaging machinery incorporates sensors and controls to verify proper sealing before cutting occurs.

5. Quality Control and Packaging

The final stage involves comprehensive quality control measures, including leak detection, weight verification, and visual inspection. Packets that pass quality standards are collected and packaged into bulk containers for distribution. Advanced ketchup packaging technology includes automated sorting and packaging systems that prepare products for shipping to food service customers.

Technologies Used in Ketchup Packet Production

Form-Fill-Seal (FFS) Machines

Form-fill-seal systems are at the core of ketchup packet manufacturing. They shape the film into pouches, fill them with ketchup, and seal them in one continuous cycle. A well-engineered FFS line delivers both speed and precision, keeping fill accuracy within strict margins. Standard units run at 50–100 packets per minute, while high-performance models can reach 150 packets per minute with seal temperatures maintained at 120–180 °C.

At King-Pack Machinery, we design FFS machines specifically for sauces and condiments. Our Automatic Ketchup Pouch Packing Machine comes equipped with PLC controls, stainless steel contact parts, and adjustable filling ranges. Built for thick, viscous products like ketchup, it minimizes waste while preventing clogging, ensuring smooth production at every stage.

Click here to check our products

Automation in Packaging Lines

Automation has reshaped ketchup packet production, making it faster, safer, and more reliable. With PLCs and touchscreen HMIs, operators can set precise recipes for fill volumes, seal strength, and packet sizes, then fine-tune them in real time. Automated film tracking, tension control, and rejection systems further reduce errors and material loss.

KP-310L Pouch Packing Machine – King Pack Machinery

Our Packaging Machines bring this automation to life. Featuring servo-driven filling heads, automatic temperature control, and real-time error detection, they let production lines run efficiently with less manual input. Whether you’re scaling up or streamlining operations, King-Pack’s automated solutions deliver consistency batch after batch.

Recommended Reading: How an Automatic Tube Filling and Sealing Machine Works – King Pack Machinery

Customization Options for Packaging

Ketchup packets are more than just functional — they also carry branding and compliance information. Modern machines can switch between sizes, shapes, and seal types quickly, while digital printers add logos, batch codes, or expiration dates directly onto the film. This flexibility helps brands stand out and meet traceability requirements at the same time.

Here are the best examples of customization-ready machines you can try from King-Pack Machinery:

- Multi-Lane Sachet Packing Machine – Ideal for producing large quantities of single-serve packets with customizable widths and volumes.

- Liquid & Paste Filling Machines – Built for thicker products like ketchup and tomato paste, with adjustable fill ranges (5–100 ml).

- Premade Pouch Packing Systems – Allow for unique pouch designs such as spout pouches, three-side seals, or four-side seals, with integrated date coding.

These options give manufacturers the flexibility to match packet design with brand identity while still meeting food safety standards.

Challenges in Ketchup Packet Manufacturing

Maintaining Freshness and Quality

Preserving ketchup quality throughout the packaging process requires careful attention to temperature control, oxygen exposure, and contamination prevention. The packaging materials must provide appropriate barrier properties while maintaining flexibility for consumer use. Automated filling systems must handle the product gently to prevent degradation of texture and flavor compounds.

Recommended Reading: How Long Do Sealed Sauce Packets Really Last? Shelf Life, Storage & Safety Tips – King Pack Machinery

Steady Consistent Portion Sizes

Achieving consistent portion sizes across millions of packets requires precise control of filling mechanisms. Variations in ketchup viscosity, temperature, and flow rates can affect portion accuracy. Advanced ketchup pouch packing machines incorporate feedback systems that continuously monitor and adjust filling parameters to maintain uniformity.

Addressing Environmental Concerns

The packaging industry faces increasing pressure to reduce environmental impact through sustainable materials and manufacturing processes. Manufacturers are developing biodegradable packaging materials and optimizing production processes to minimize waste generation. At King-Pack Machinery, we design our equipment with energy efficiency in mind, helping partners reduce resource use while maintaining the high standards their customers expect.

Innovations in Ketchup Packaging

Sustainable Materials and Eco-Friendly Practices

Recent innovations in ketchup packet manufacturing focus on sustainable packaging solutions driven by environmental concerns and regulatory pressures. According to industry data, 22% of food brands tested smart packaging solutions with QR codes or freshness indicators in 2023 to enhance traceability and consumer engagement.

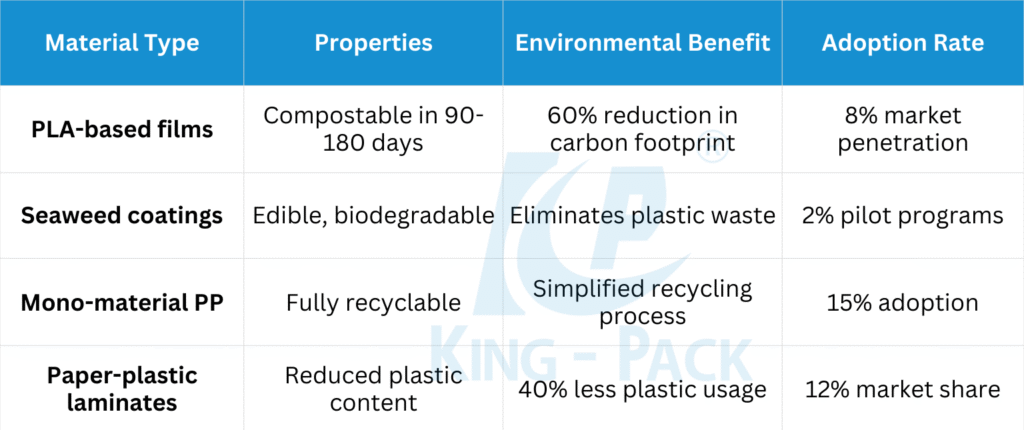

Emerging sustainable packaging technologies include:

Modern ketchup packet production is moving toward smarter, cleaner operations. Heat recovery systems, variable speed drives, and advanced insulation are helping manufacturers cut energy use by as much as 30%.

At King-Pack Machinery, we take this further with servo-motor driven systems that lower power consumption by up to 25% compared to traditional pneumatic designs.

Water efficiency is another key focus—our equipment supports closed-loop recirculation and optimized CIP cycles, reducing cleaning water usage by nearly 35% without compromising hygiene.

Recommended Reading: The Importance of Tube Filling Machine and Tube Sealing – King Pack Machinery

Smart Packaging Solutions

Emerging smart packaging technologies incorporate sensors and indicators that provide information about product freshness and storage conditions. These innovations may include temperature indicators, freshness sensors, and tamper-evident features that enhance consumer confidence and product safety.

Beyond safety and freshness, smart packaging is also being used to support supply chain transparency. Features like embedded RFID chips or scannable data codes help retailers and distributors track products in real time, reducing spoilage and streamlining logistics. For ketchup manufacturers, this means greater efficiency, fewer returns, and more consistent quality on store shelves.

Consumer Convenience Features

Modern ketchup packet designs prioritize ease of opening and controlled dispensing. Features like tear-away corners, squeeze-to-dispense mechanisms, and improved grip surfaces make packets more user-friendly. These design improvements rely on advanced ketchup manufacturing lines and specialized packaging material to maintain consistency at high-speed production.

Portion control is another key focus. Adjustable flow designs and dual-compartment packets allow consumers to dispense the right amount of ketchup, reducing waste. This approach also accommodates ingredients like high fructose corn syrup and hot sauce, ensuring even distribution and maintaining product quality in every packet.

Packet Contract Packaging and careful use of external manufacturing data help foodservice operators and quick-service restaurants maintain cleaner serving areas while minimizing product loss. By integrating these practices, brands can deliver a better user experience while improving efficiency across their production and packaging processes.

Conclusion: The Future of Ketchup Packet Manufacturing

The ketchup packet manufacturing industry continues to evolve through technological advancement and changing consumer preferences. Future developments will likely focus on sustainable packaging materials, improved production efficiency, and enhanced consumer convenience features.

At King-Pack Machinery, we are investing in equipment that supports eco-friendly films, higher automation, and smarter filling systems. Our goal is to help manufacturers cut down on waste, lower energy use, and meet global sustainability standards while keeping production reliable. With these innovations, ketchup packets will remain a vital part of modern food service, but with solutions that align with both market growth and environmental responsibility.

If you’re looking to upgrade your ketchup packet production line, contact King-Pack Machinery today and discover the right machines to scale your business with confidence.