The cosmetics, pharmaceutical, food, and other industries have grown. Consumers want quality products. So, manufacturers have added advanced technology machines. Now, manufacturing processes like mixing, emulsifying, filling and sealing of products are done by machines. In short, the whole process is automatic with minimal human input. For products like lotions, creams, and ointments, special equipment called emulsifying machines is used in their manufacturing processes. They serve well for tasks such as mixing, dispersing, emulsifying, and homogenizing.

Currently, the Vacuum Emulsifying mixers market is on the rise. These machines offer advanced features and settings, automating the process. So, they are applicable in various fields, especially food, cosmetics, pharma, and chemical industries. This article is backed up with all the information about Vacuum Emulsifying mixers from their basics to core types, working principle and applications. So, let’s dive in and read till the end.

What Is a Vacuum Emulsifying Mixer?

Definition and Core Functions

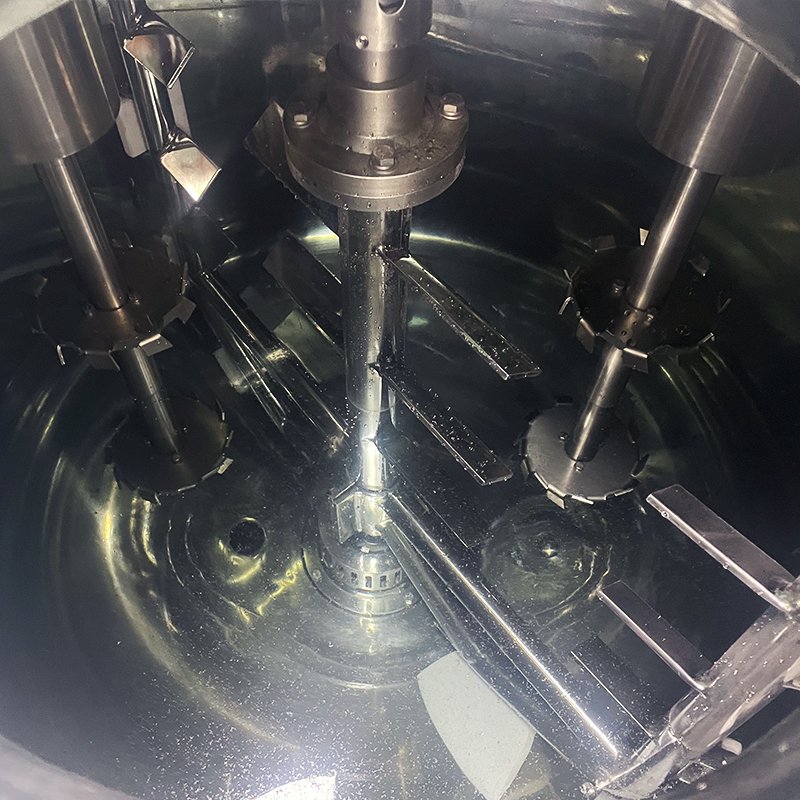

A vacuum emulsifying mixer, or vacuum emulsifier, is special equipment. It emulsifies, disperses, mixes, homogenizes, and aspirates thick materials. The core function of the vacuum emulsifier is to emulsify the product in a vacuum environment. This improves the shelf life of the product as they prevent air bubbles from forming in the mixture, maintaining its uniformity, while decreasing the droplet size to approximately 1 micron. They consist of a vacuum system, a high shear mixer and a homogenizer, integrated into a machine. They work together to make a uniform mixture. This prevents dead corners inside the machine. T

hey are used in large manufacturing industries and small setups, and are in high demand in the market. They provide excellent product quality. They work best for medicinal pharmaceutical ointments, cosmetic creams, and various products in the biotech industry.

Design Features of Vacuum emulsifying mixer

Scraper: There is a specially angled interior spherical blade called a scraper that rotates automatically. It moves against the mixer walls during operation, preventing material buildup and ensuring complete evacuation of the mixing chamber.

Mixing Tank: The main stainless steel mixing vessel or tank is designed with a curved bottom. This shape of the pot eliminates dead zones during processing. They come in different capacities of up to 1000 litres and can be filled to 90% of their tank.

Hydraulic Lifting: The hydraulic system provides smooth vertical movement of the mixing head assembly. It offers precise positioning control and consistent lifting force throughout the operational range. The system includes safety locks to prevent accidental lowering during maintenance or cleaning procedures.

Vacuum Pump: The vacuum pump has two connections: one connects to the water tank. It seals when the pump is operating. The other is connected to the emulsifier pot through a gas-liquid separator. The gas-liquid separator removes moisture from the vacuum system. Steam gets pulled into the pump during operation and passes through this separator. Part of the steam condenses into water and drains from the separator bottom. This prevents liquid contamination of the vacuum pump while maintaining system efficiency.

Heating/Cooling System: The temperature control system circulates thermal fluid through jacket channels surrounding the mixing vessel. It provides uniform heat distribution across all contact surfaces for consistent product temperature. The system can rapidly switch between heating and cooling modes as required by the process recipe.

Electric Control System: The control panel houses transformers, circuit breakers, and protective devices for safe electrical operation. The system has programmable logic controllers: These controllers manage automated sequences and monitor parameters. The system allows manual override. It also has emergency shutdown functions to keep operators safe.

SS316L Parts: Stainless steel 316L offers superior corrosion resistance and meets food-grade manufacturing standards. The low carbon content stops carbide from forming. It keeps the fabricated parts easy to weld. All product contact surfaces use this material to ensure chemical compatibility and easy cleaning validation.

Types of Vacuum Emulsifying Mixers

Vacuum Homogenizer

Vacuum homogenizers are specialized mixing machines that work under reduced pressure conditions. They use traditional mixing. They also use high-speed homogenization. This breaks down particles well. They consist of a water and oil pot, and bottom-entry or top-entry homogenizing heads for different applications. The homogenizing rotor spins at high speeds to create high shear energy. This breaks down ingredients into particles as small as 2 micrometres. The vacuum system removes trapped air bubbles from the mixture. This results in smoother textures and improved product stability. Industries use these vacuum mixers for cosmetics, pharmaceuticals, and food products. They can also be used as laboratory-scale mixers for small testing batch sizes. These vacuum mixers can handle both water-based and oil-based formulations but are not applicable for high-viscosity materials. various types of vacuum homogenizers are available in the market including inline emulsifiers and batch vacuum emulsifier mixer.

Vacuum Planetary Mixer

Planetary mixers use a unique dual-axis rotation system during operation. The mixing bowl remains stationary while a sharp knife-like scrapper moves in planetary motion. The blade mixer rotates around its own axis while orbiting the bowl center. This creates thorough mixing without dead spots in the container. The vacuum feature eliminates air bubbles during the mixing process. Temperature control systems keep the best conditions during mixing cycles. They are double-column and operate through hydraulics. Multi-section speed settings allow operators to adjust mixing intensity for different phases. These mixers handle thick pastes, creams, and viscous materials effectively. The sealed vacuum chamber prevents contamination and oxidation. Laboratory and cosmetic industry production places use these mixers for research. They also use them in the medical field for medicinal ointment manufacturing purposes.

Vacuum Stainless Steel Mixing Pot

These types of pots provide excellent corrosion resistance for various applications. The material meets food-grade standards. The system follows pharmaceutical manufacturing rules. These vessels feature pre-treatment boiler, high sidewalls mixing tank and wide base designs for efficient mixing. The vacuum-sealed lids preserve product freshness during processing and storage. Multiple inlet ports allow ingredient addition without breaking the vacuum seal. Outlet valves enable easy product discharge after mixing completion.

The smooth interior surfaces facilitate thorough cleaning and sanitization. These pots work well with both manual and automated mixing systems. Temperature control jackets maintain precise thermal conditions when required. Industries use these vessels for batch size mixing operations in clean environments.

Automatic Vacuum Emulsifying Mixer

Fully automatic systems combine an automatic vacuum homogenizer mixer and a high-speed shear head. That’s why they operate at very high speeds and are suitable for thick material.

There are two types of stirring heads that can be chosen according to the business needs. PLC control systems with touch screen interfaces manage all operations automatically.

The equipment handles viscosities up to 50,000 centipoise without manual intervention. Integrated vacuum pumps maintain consistent negative pressure throughout processing. Heating and cooling systems control temperature according to programmed recipes. Automatic ingredient feeding systems add materials at predetermined times. Safety interlocks prevent operation when covers are open or systems malfunction.

These mixers suit high-volume processing capacity, requiring consistent quality. They are highly demanded in the market. Automated machines are used in large-scale manufacturing. These machines reduce labor costs. They also lower the chance of human error.

Semi-Automatic Vacuum Emulsifying Mixer

These mixers balance manual control with automated processing capabilities. Operators manually load raw materials into the mixing tank and unload finished products from the system. They have an oil pot, a water pot and a disperser emulsifier. The mixing cycle runs automatically once started by the operator. Touch screen controls allow operators to adjust parameters during processing. Operators add ingredients by hand. This helps with complex formulas that need ingredients added in stages. The vacuum system operates automatically during mixing cycles. Operators must watch the temperature control. These mixers work well for research laboratories and pilot plant operations. Small to medium-scale manufacturers prefer this type for speciality products. Manual features and automatic features give operators flexibility. They also help keep quality control.

Working Principle & Core Benefits

The homogenizer uses a special rotor/stator design to create strong shearing forces. The rotor spins at high speeds inside a fixed stator housing. This breaks down large particles into very small ones. The shearing reduces droplet sizes to 200 nanometers to 2 micrometres. Vacuum prevents air bubbles from forming during mixing. Materials get pulled into the gap between rotor and stator blades. High-speed rotation of the blade mixer creates forces that tear apart particles. This happens repeatedly as materials move through the system. The vacuum removes gases that could make foam. The result is very fine particles spread evenly in the mixture.

Benefits of Vacuum Emulsifying Mixers

Vacuum mixers offer multiple benefits:

- The high-speed and continuous shearing and homogenizing create fine emulsions with smooth textures. Small particles give better looks and feel. Even mixing makes products stable and prevents separation.

- Vacuum mixing uses less energy than normal methods. The closed design keeps out dirt and bacteria. This is important for medicine and cosmetics.

- The sealed system stops oxygen damage to ingredients. No air gets in to cause bubbles or foam.

- Heat control works better with improved flow. These machines work faster and make higher-quality products.

- Some machines may use an aluminium metal outer case and anti-slip mats for mechanical accuracy.

Applications Across Industries

- Food industry: They produce mayonnaise, sauces, jams, dairy products, and baby food with smooth textures and extended shelf life.

- Cosmetic industry: These mixers create creams, lotions, shampoos, and sunscreens with fine particle distribution for superior skin feel and product stability.

- Pharmaceuticals: They manufacture medical ointments, syrups, and emulsions under sterile conditions to meet strict quality and safety standards.

- Chemicals, Paints, Latex, Resins, Pesticides, etc.: They process these products for uniform consistency and optimal performance characteristics.

- Biotech industry: These vacuum mixers develop cell culture media, protein solutions, vaccine preparations, and specialized biological formulations.

Summary

After studying Vacuum emulsifying mixers, you have seen they provide advanced ways to make high-quality emulsions. These mixers work in many industries. These machines produce fine, stable products through vacuum technology and precise mixing controls. They work in food processing and pharmaceuticals. They give consistent results. They also reduce the risk of contamination. The different types suit various production scales and requirements effectively.

If you are in search of high-quality emulsifying machines, King Pack Filling Machinery serves as an all-in-one solution for your business needs. Contact us today and see your business grow fast!