Automatic sauce packaging is moving from a hidden background task to a strategic advantage for brands that rely on clean, accurate, single‑serve portions. King Pack Automatic Sauce Packaging Solutions points to a new generation of systems built to deliver consistent dosing, neat seals, and shelf‑ready presentation with minimal operator input. This article aims to explore every technical detail, while also discussing why such precision sachet solutions matter for modern sauce producers and how they can support efficiency, quality, and brand reliability.

Overview of Automatic Sauce Packaging Machines

What is a VFFS/HFFS Sauce Packaging Machine for Viscous Liquids?

A VFFS sauce machine pulls roll stock film downward, forms it into a tube or sachet shape, doses viscous products through a filling nozzle, then, after heat sealing, cuts the finished packs vertically. HFFS ketchup packing machine designs instead move film horizontally, forming pouches that are filled from the top or side before transverse and longitudinal sealing, which is advantageous for larger volumes or shaped sachets. Both VFFS and HFFS viscous liquid packers use volumetric piston fillers or servo‑piston systems sized for typical sauce ranges such as 5–100 ml per sachet on stick packs and 100–1000 ml for larger pouches.

Why Automated Sachet Packaging is Essential for Sauces and Condiments?

Automated sachet packaging is essential for sauces and condiments because it standardizes portion control, strengthens hygiene, and delivers a uniform, premium brand appearance that manual or semi-automatic filling machines cannot match. Typical liquid and paste fillers, like ketchup or mayonnaise, run around 20–60 bags per minute per lane, while modern multi-lane packaging systems can reach roughly 240-300 sachets per minute in total, best suited for large production plants. This enables high‑throughput foodservice and QSR supply.

Advanced piston- and servo-driven technology fillers routinely achieve dosing accuracy of ±0.5–1%, sharply cutting overfill and product giveaway. The sauce packing machinery market is growing fast. These machines will grow from about USD 1.2 billion in 2024 to about USD 1.9 billion by 2035. Vertical Form-fill-seal packaging systems, which are key for sauce sachets, will grow from around USD 4.2 billion in 2025 to about USD 6.8 billion by 2035. This shows that automation will be very important for future sauce and condiment operations.

Typical Industries & Applications

| Category | Typical Industries | Example Products |

| Food processing | Food manufacturers, sauce plants | Ketchup, chili sauce, barbecue sauce, salad dressing, jam, honey, soy sauce, tomato paste |

| Beverage & liquid food add‑ins | Beverage, hospitality, catering | Syrups, concentrates, flavor shots, smoothie bases |

| Daily chemicals & related liquids | Home & personal care, agrochemical | Shampoo, lotion, hair conditioner, shower gel, detergents, selected agrochemicals and pesticides (where packaging materials are compatible) |

Machine Capabilities & Technical Specifications

Packing Range, Speed, and Bag Dimensions

Entry‑level automatic sauce sachet filling machine models often support filling ranges such as 5–100 ml per bag, with packing speed around 20–60 bags per minute on a single‑lane vertical stickpack machine. Multi‑lane stickpack or sachet packers suitable for sauces can multiply throughput by running 8–10 lanes in parallel, achieving total outputs of up to about 320–400 sachets per minute.

Typical bag size envelopes for sauce sachet packing include:

- Width: 20–150 mm (stick packs at the lower end, pillow or flat sachets wider).

- Length: 30–150 mm for individual condiments, with some HFFS designs going up to 300 mm for larger pouches.

Power & Build

Automatic sauce packing machine systems generally operate on AC 220 V or 380 V, 50/60 Hz power supplies, with rated power consumption in the 2–5 kW range for mid‑size equipment. A food-grade stainless steel enclosure uses S/S 304 for frames and guards, with S/S 316 or 316L for product-contact parts when handling acidic sauces like ketchup or vinegar‑based dressings. It improves corrosion resistance and GMP compliance.

Film Compatibility

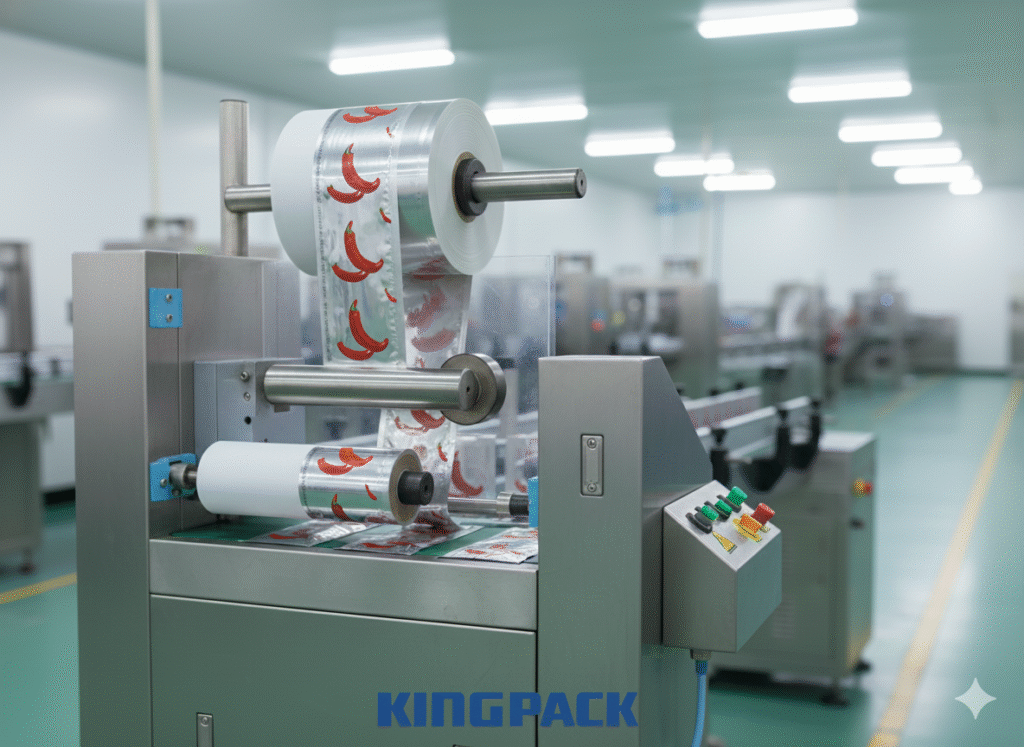

Most automatic sauce packaging machines are designed to run multi‑layer laminated films with good heat‑sealing and barrier properties. Composite film materials include PET/PE, OPP/PE, PET/AL/PE, BOPP/CPP, or similar composites. For specific formats, roll film thickness ranges typically fall around 40–80 microns for flexible sachet materials, with easy‑snap or rigid blister‑like films for speciality designs up to about 0.45–0.46 mm hard film thickness. All of these are food-grade films.

Core Functions & Workflow

Film Feeding & Bag Forming

VFFS sauce machines unwind roll stock film, guide it through tension control and tracking sensors, and form it into either a vertical tube or multiple parallel lanes for sauces. Vertical and horizontal sealing jaws then create three‑ or four-sided seals, stick packs, or back‑sealed pillow sachets according to the forming set and sealing pattern selected. Photoelectric sensors track registration marks so that printed logos, tear notches, or easy‑tear slits line up correctly with the sealing and cutting operations.

Precise Filling & Metering

For viscous sauces and condiments, volumetric piston pumps or servo piston systems are the dominant dosing technologies, because they can meter thick, non‑free‑flowing products without relying on gravity alone. Specifications from piston filling equipment suppliers show typical filling accuracies of around ±0.5% of target volume for paste‑like products, provided the machine is correctly calibrated and supplied at a stable pressure. Anti‑drip or anti‑foaming nozzle designs help prevent stringing, splashing, and trapped air, improving seal integrity and pack cleanliness.

Sealing, Cutting, Date Printing & Discharge

PID‑controlled bag sealing maintains consistent jaw temperatures in the appropriate window for the laminate used, supporting strong, leak‑proof seals without film scorch. After filling and sealing, cutting knives separate sachets, and optional batch coding or inkjet units print production dates, expiry dates, or traceability codes. Finished sachets or stick packs exit onto conveyors or collection bins, ready to be cartoned or packed into secondary packaging as part of a complete food sauce packaging line.

Hygiene, Material Handling & Design Features

Food-Grade Stainless Steel and CIP

Automatic sauce packaging lines for human consumption use food‑grade surfaces and, in higher‑end systems, Clean‑in‑Place (CIP) or at least clean‑out‑of‑place designs. Contact parts in S/S 316 or 316L, polished welds, and drainable product paths reduce microbial harborage and support HACCP or GMP plans. Many piston filling sauce equipment designs now integrate CIP connections or removable pumps and hoses for fast sanitization between product changeovers.

PLC Touchscreen, Servo Motors, and Auto-Lubrication

Modern sauce packaging machine platforms use PLC control with touchscreens and multilingual user interfaces, allowing operators to select recipes, adjust bag lengths, bag width, and monitor alarms. Servo motors on film pull belts, horizontal sealing jaws, and piston drives improve repeatability and allow on‑the‑fly speed changes to balance filling time and seal quality. Centralized or auto‑lubrication points on bearings and chains support 24/7 operation in high‑duty environments by reducing manual maintenance tasks.

Quick Changeover and Foaming/Overfill Prevention

Quick‑release forming sets, adjustable sealing heads, and stored parameter recipes make it feasible to change between different sachet sizes or products in a relatively short time, often under 30–45 minutes for experienced crews. Overfill and foaming often happen with thick liquids. Advanced machines use level sensors, back-pressure control, and nozzle designs to reduce foam. Reject systems can automatically remove packs that are too light or too heavy, as detected by checkweighers.

Advantages of the King Pack Sauce Packaging Machine

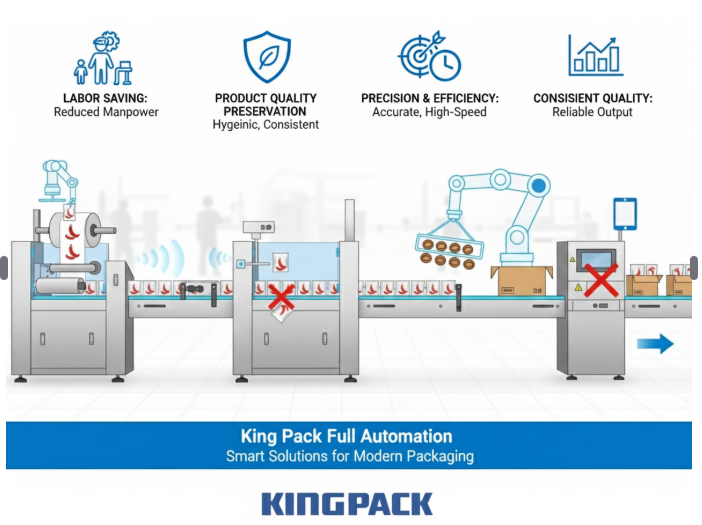

Labor Savings

Replacing manual sachet filling with a fully automated single‑ or multi‑lane sauce sachet filling machine can dramatically reduce operator headcount per output. Industry examples show speeds of 20–60 bags per minute on single lanes and up to 400 bags per minute on 10‑lane systems; even assuming conservative staffing, this can cut labor needs by more than half compared to manual or semi‑manual approaches. For many plants, that translates to overall sauce packing labor cost reductions on the order of tens of per cent over the first years of operation, depending on baseline practices.

Precision & Efficiency

High‑precision servo piston systems with advertised filling accuracy at or below ±0.5% help control giveaway and ensure compliance with labeled volumes. Stable film tracking and reduces rework, vibration-free operation, rejects, and product waste. This helps improve overall equipment effectiveness (OEE) in packaging thick liquids.

Product Quality Preservation

Good sealing and choosing the right laminate keep sauces fresh. They protect flavor, color, and stop microbes by limiting oxygen and moisture from entering. Oxygen and moisture cause quality loss and shorter shelf life in condiments. Hygienic contact surfaces and well-designed cleaning protocols help keep food safe during repeated production. This is important for sauces with high water content, as they can support the growth of microbes more easily.

Flexibility

Automatic sauce packaging machines can handle sauces of varying thicknesses. They can package both thin sauces, like soy sauce or vinegar, and thick ones, like mayonnaise or tomato paste. They do this by selecting the appropriate piston, nozzle, and temperature settings. Multi-lane sachet packers, stick pack systems, and single-lane VFFS or HFFS machines can be configured for different markets and regulatory requirements. CE or ISO-certified designs allow use in many regions.

Suitable Products & Use Cases

- Sauces & condiments: ketchup, tomato sauce, chili sauce, barbecue sauce, soy sauce, jam, honey, syrup.

- Viscous foods: butter, margarine, salad dressing, cheese sauce, meat sauce, fruit purees with small particulates (within nozzle clearance limits).

- Non‑food: shampoo, cosmetic creams, lotions, detergents, some edible oils and agrochemicals, provided materials and seals are compatible with product chemistry.

How to Choose the Right Automatic Sauce Packaging Machine

Assess Viscosity, Solids Content & Foaming

High‑viscosity, particulate, or foaming sauces tend to favor piston filling systems with large‑bore valves and anti‑drip nozzles over simple gravity or peristaltic pumps. Users should consider maximum particle size versus nozzle diameter, desired filling temperature for hot‑fill products, and whether the product tends to entrap air when agitated.

Define Output Needs and Bag Types

Required throughput (bags per minute) and target sachet style— three-side or back side sealing type, four-side sealingsauces of varying thicknesses, or stick pack. Determine whether a single‑lane VFFS machine or a multi-line functionality is appropriate. For example, fast‑moving ketchup sachet programs for foodservice often justify 8–10-lane systems capable of about 400 sachets per minute, while slower, more flexible single‑lane systems may better serve niche premium sauces.

Evaluate Support, Certification, and Features

Prospective buyers should confirm that the sauce packaging machine meets applicable food‑grade or GMP requirements, with documentation and materials such as SUS316 contact surfaces and certified electrical components. You should evaluate spare parts availability, service networks, customer support, customization for specific bag sizes or local codes, and features like checkweigher integration or anti-overfill logic as part of the total cost of ownership. Do not focus only on the purchase price.

Conclusion & Call to Action

Automatic sauce packaging machines built on VFFS, HFFS, and multi‑lane sachet packer platforms provide food brands and co‑packers with a precise, hygienic, and scalable way to pack viscous liquids and condiments in sachets, stick packs, and pouches. These machines combine servo-driven piston fillers, PID-controlled sealing, and food-grade stainless steel parts. This reduces waste, improves uniformity, protects product quality, and helps distribute products like ketchup sachets and thick pastes efficiently worldwide.

Simplify your sauce packaging today! Contact us at King Pack for a free customized quote and demo video. Also, you can chat now for an engineering consultation—respond within 4 hours. Get Your Free Sauce Packaging Quote Now → Email: sales@kingpack-cn.com