In today’s fast-paced manufacturing environment, production lines are more efficient than ever. Advanced filling, processing, and primary packaging machines operate at incredible speeds, pushing product throughput to new heights. Yet, for many companies, a critical bottleneck emerges just before the finish line: end-of-line packaging.

While the front end of the line hums with high-speed automation, the final stage of case packing often relies on manual labor, creating a costly and inefficient choke point. This disconnect prevents businesses from realizing their full production potential. The solution lies in bridging this gap with intelligent automation. Here, an automatic case packaging machine stands as an important part of the system. It unlocks smooth, end-to-end efficiency. It changes the final, important step of your production process from a problem into a strategic advantage.

1. Production Line Capacity Peaks, but End-of-Line “Stalls”?

The scenario is all too common: a company invests heavily in upgrading its core production and filling capabilities, achieving impressive output rates. Products fly off the primary line, only to accumulate in a queue, waiting for human hands to manually erect boxes, collate items, and seal cartons. This “stall” at the end of the line negates the upstream efficiency gains and introduces a host of problems that ripple through the entire supply chain.

Why End-of-Line Packaging Becomes the New Bottleneck

Manual case packing is inherently limited by human speed, stamina, and consistency. Unlike machines, human operators are prone to fatigue, repetitive strain injuries, and variability in performance. This leads to several critical issues.

- Firstly, throughput is capped by the number of workers and their physical limitations, creating a hard ceiling on how many finished goods can be shipped.

- Secondly, inconsistency in packing patterns and sealing quality can lead to product damage during transit, resulting in financial losses and diminished customer satisfaction.

- Finally, relying on manual labor for this physically demanding task often leads to high employee turnover and increased operational costs, making it difficult to scale operations or adapt to sudden spikes in demand.

This reliance on manual processes in an otherwise automated environment makes the end-of-line solution the weakest link in the modern production chain.

2. Automatic Case Packaging Machine: Eliminating the Last-Mile Bottleneck

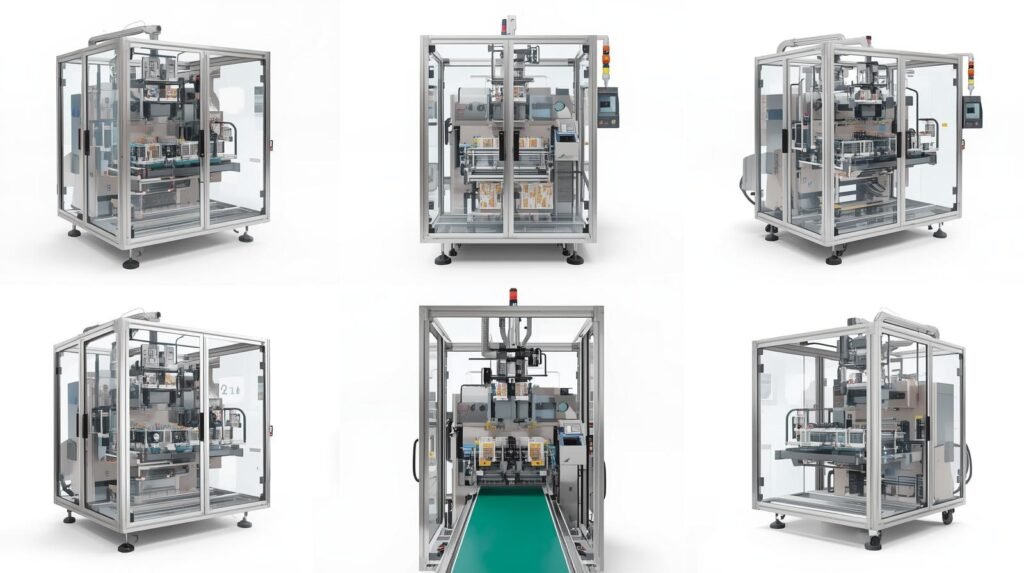

An automatic case packaging machine, often called a case packer, is a sophisticated piece of equipment designed to automate the entire process of secondary packaging. This automated solution is designed specifically to replace the manual case-packing operation and synchronize with upstream production in a closed-loop manner. These machines seamlessly execute a sequence of tasks:

- Selecting a flat case blank, erecting it into a box,

- Collating the incoming product,

- Carefully placing it into the case according to a precise pattern, and

- Finally, closing and sealing the carton.

This technology acts as the smart link between primary production and final palletizing. It removes the manual “last-mile” bottleneck effectively.

The machine typically includes several core modules. A case erector that forms flat blanks into open cases, and a product grouping and collation section with vision-guided robotics. A picking/placing system (such as a servo-driven gantry robot or robotic arm with vacuum or mechanical grippers). Additionally, A case top-closing and sealing box unit that uses tape, hot-melt glue, or both, depending on the specification

This intelligent transformation moves beyond simple mechanization to create a responsive, efficient, and reliable packaging operation that supports overall business growth.

Types of Automatic Case Packers: Matching Technology to Your Application

The versatility of automatic case packers stems from the variety of designs available, each tailored to specific product types, packaging formats, and production needs. Selecting the right machine is crucial for optimizing the packaging process. The most common configurations include:

- Top Load Case Packers: Ideal for applications involving bottles, jars, tubs, and flexible pouches, these machines gently pick and place products vertically into an open-top case. They often utilize robotics or advanced collation systems to arrange items in precise patterns, making them highly flexible for products that are best handled from above.

- Side Load Case Packers: Best suited for stable, rigid items like cartons, boxes, and reams of paper, side load packers accumulate a full case pattern and then gently push the collation horizontally into an erected case. This method is efficient for products that can be easily grouped and handled as a single unit.

- Bottom Load Case Packers: This configuration is designed for heavy products or applications where multiple layers need to be stacked precisely. The case is lowered over the collated product, which is supported from below, ensuring stability and minimizing the risk of damage during the loading process.

- Wraparound Case Packers: For businesses seeking material savings and a tighter, more secure pack, wraparound packers form a flat corrugated blank around the product collation. This creates a snug fit that enhances product protection and often uses less cardboard than a traditional Regular Slotted Container (RSC).

- Robotic Case Packers: Leveraging the ultimate flexibility of industrial robots, these systems can handle irregularly shaped products, perform complex collation tasks, and manage multiple product lines simultaneously. Robotics is the solution for the most demanding and varied case packing applications.

Each type offers distinct advantages, allowing businesses to select a case packing solution that perfectly aligns with their product characteristics, speed requirements, and operational goals.

3. Core Advantages — Efficiency, Stability, and Cost Reduction

Investing in an automatic case packaging machine delivers a powerful trio of benefits that directly impact the bottom line: enhanced efficiency, improved packaging stability, and significant cost reductions. These advantages work in concert to streamline operations and create a more resilient and profitable production environment.

3.1 Perfect Efficiency Matching High-Speed Production Lines

The primary advantage of automatic case packers is their ability to operate at high, consistent speeds, 24/7. While manual packing struggles to keep up, these machines are engineered to match or exceed the output of the fastest upstream filling and primary packaging equipment. This synchronization eliminates product accumulation and ensures a continuous, uninterrupted flow through the entire production line. Companies can automate case packing to use their manufacturing assets fully. This increases overall throughput and helps meet production targets consistently. The final packaging step no longer limits production.

3.2 Packaging Consistency and Logistic Safety

Automation brings a level of precision and consistency that manual labor simply cannot replicate. Every case is erected squarely, packed with the exact product count in the correct orientation, and sealed securely. This uniformity is critical for logistic safety. Properly packed cartons are more stable, stack better on pallets, and are less prone to collapse or damage during shipping and handling. This reduces the risk of costly returns and protects brand reputation by ensuring the customer receives their products in perfect condition. Consistent sealing also provides better protection against environmental factors like dust and moisture, further safeguarding product integrity throughout the supply chain.

3.3 Significant Labor Savings & Safety Enhancement

Automating the case packing process yields substantial financial and human resource benefits. It dramatically reduces the reliance on manual labor, allowing employees to be reassigned to more value-added, less physically demanding roles. This leads to direct cost savings in wages, benefits, and recruitment. Automating repetitive lifting, bending, and twisting tasks improves worker safety. It reduces the risk of musculoskeletal injuries. A safer workplace not only improves employee morale but also reduces costs associated with workers’ compensation claims and lost productivity due to absenteeism.

4. Technical Features & Multi-Format Compatibility

Modern automatic case packers are defined by their advanced technical features and remarkable flexibility. These machines are engineered not only for speed and reliability but also for adaptability. This allows them to handle a diverse range of products and packaging formats with minimal downtime.

High Flexibility for Different Product Types

Modern automatic case packaging machines are designed to handle multiple product formats on a single platform, such as pillow bags, doy-packs, bottles, jars, cartons, or pouches. Advanced product handling technologies achieve this multi-format compatibility. These include sophisticated collation systems, servo motor-driven mechanisms, and integrated robotics.

Quick-changeover designs with pre-set parameters allow operators to switch between different product SKUs, pack patterns, or case sizes in minutes, not hours. This agility is essential for manufacturers with diverse product portfolios and the need to respond quickly to changing customer demands, such as the growing popularity of variety packs.

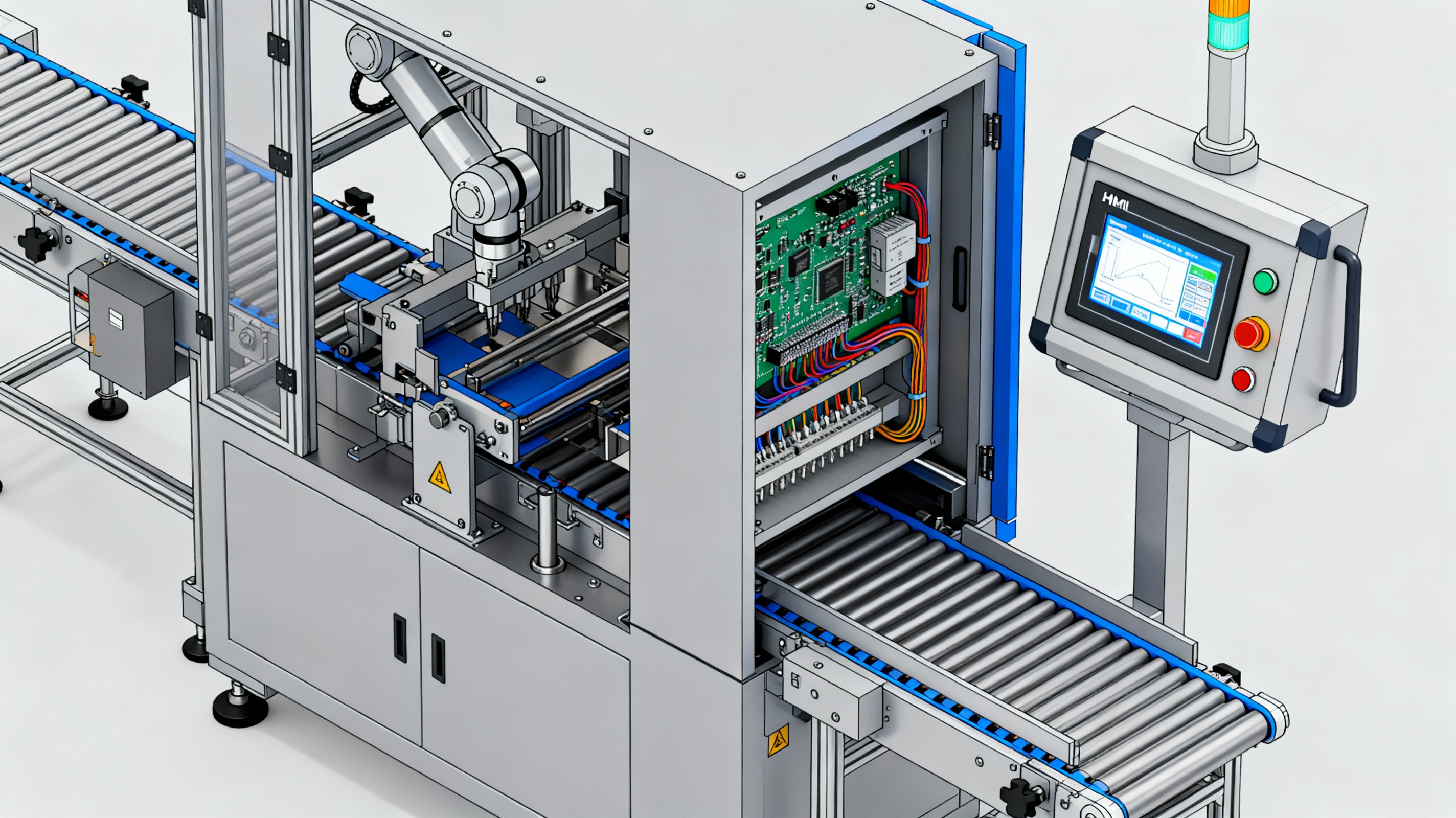

Smart Control System (PLC + HMI)

At the heart of every automatic case packer is a smart control system, typically comprising a Programmable Logic Controller (PLC) and a Human-Machine Interface (HMI).

The PLC is connected to servo drives, sensors, and actuators over fieldbus networks such as EtherCAT or Profinet. This architecture provides deterministic control of motion profiles, ensuring that picking, case opening, loading, and sealing are perfectly synchronized.

The HMI gives operators a clear overview of machine status, alarms, and performance indicators such as OEE (Overall Equipment Effectiveness), instantaneous speed, and shift output. Operators can easily select recipes, monitor machine status in real-time, and access on-screen diagnostics to quickly resolve any issues.

This level of intelligent control maximizes uptime and ensures the machine runs at peak performance.

Modular Structure for System Integration

Automatic case packers are rarely standalone machines; they are a vital component of a complete end-of-line packaging system. Their modular design facilitates seamless integration with both upstream and downstream equipment.

The case packer systems can be linked directly to upstream filling and cartoning machines and downstream systems for automatic sealing, coding, labeling, and palletizing. This modularity allows companies to build a fully automated, cohesive packaging line that optimizes workflow, minimizes factory floor space, and creates a single, streamlined process from product to pallet.

5. Why Companies Must Upgrade End-of-Line Packaging Today

Manufacturers must upgrade end-of-line packaging because manual case packing has become the main bottleneck, inflating labor costs and capping line throughput.

The global end-of-line automation market is forecast to grow from about 5.1 to 7.5 billion USD by 2029, reflecting the rapid adoption of automated case packing and palletizing.

Automation typically cuts packaging labor 25–40%, improves consistency, and integrates in-line quality checks, reducing product damage and compliance risks.

Case studies report up to 80% capacity gains and payback in roughly 1–3 years, making end-of-line automation one of the fastest-return investments on a modern line.

Delaying upgrades risks structural cost and competitiveness disadvantages.

6. Get Your Customized Case Packing Solution

Recognizing the need for automation is the first step. The next step is finding the right solution. Because no two production environments are identical, a one-size-fits-all approach to case packing is rarely effective. The optimal solution depends on a multitude of factors, including product type, required speed, available floor space, existing packaging systems, and long-term business goals. A successful implementation requires a partner who can analyze these unique variables and engineer a customized case packer that integrates perfectly into your specific operation.

Are you ready to eliminate your end-of-line bottleneck and unlock your production line’s true potential?

It’s time to explore how a tailored automatic case packing solution can transform your operations. Contact the King Pack team of packaging automation experts today for a comprehensive assessment of your needs. We will help you select a robust, flexible, and intelligent automatic case packaging system—from initial concept to full integration with sealing, labeling, and palletizing—that drives efficiency, ensures quality, and delivers a rapid return on investment.

Contact us today!

Phone: (+86)18851568556

Email: info@kingpack-cn.com