An automatic honey sachet packing machine is an important machine for modern food and beverage manufacturers. They need reliable, hygienic, and efficient packaging for thick liquids like honey, jams, sauces, and fruit purees. King Pack’s automatic honey sachet packing machine combines forming, automatic filling, sealing, and cutting into one compact system. It provides efficient liquid sachet solutions that are fast, accurate, and safe for the product. This article explains how a honey packing machine using VFFS honey packaging technology works. It describes the main parameters of the machine. It also explains why a fully automatic sachet filling machine is a good long-term investment for producers focused on quality and cost control.

Overview of Automatic Honey Sachet Packing Machines

What is a VFFS Sachet Packing Machine for Honey and Viscous Liquids?

Vertical Honey Sachet Packing Machines for honey and viscous liquids are Vertical Packing Machines in which the film travels downward, is formed into a bag around a forming tube, and then filled and sealed in sequential steps. The King Pack sachet machine uses a piston pump or similar metering device that can handle the high viscosity of honey without air entrapment or pulsation. This VFFS honey packaging concept allows for a very compact footprint, as all major operations—film feeding, sealing, filling, and cutting—occur on a vertical axis. The automatic paste packer design also accommodates other viscous products such as ketchup, fruit puree, and creams, so producers can use the same PLC sachet filler platform for multiple recipes.

Why Automated Sachet Packaging is Essential for Food and Beverage Producers

Automated sachet packaging is now essential for food and beverage producers to stay competitive. It ensures repeatable dosing, consistent bag quality, and full traceability. It also works at production speeds that manual honey sachet packing machines cannot match. A modern honey bag sealing machine with a PLC system minimizes direct human contact with the product, which is critical for meeting food safety standards and certification requirements. By using these automatic packaging machines, manufacturers can reduce labor costs, prevent operator fatigue, and maintain consistent performance over long shifts. Automation improves yield by reducing product spillage and rejected sachets. This directly increases profitability.

Typical Industries & Applications

| Industry / Segment | Typical Products Packaged in Sachets |

| Food processing | Honey, jam, sauces, fruit purees, dessert toppings |

| Bakeries | Single‑serve honey sachets, portion‑packed jams and spreads, and small condiment sachets for bakery use |

| Condiment & flavor manufacturers | Ketchup, mayonnaise, mustard, dressings, flavored butters, and seasoning sauces |

| Non‑food | Shampoos, hair oils, creams, lotions, lubricants, household and personal care liquids |

Machine Capabilities & Technical Specifications

The technical parameters of King Pack’s automatic honey sachet packing machine are engineered to match the most common portion sizes and throughput needs in the market. Understanding these specifications helps buyers align the machine with their specific production targets and packaging formats.

Packing Range, Speed, and Bag Dimensions

The honey packing machine typically fills 0–50 ml per sachet, which is ideal for single‑serve and small multipack formats. Within this range, a piston filling system delivers precise viscous liquid dosing, with setpoints easily adjusted on the touchscreen to suit different product densities and target weights. In normal operation, the liquid sachet packer reaches about 30–60 bags per minute, depending on film quality, bag size, and product viscosity. Standard bag dimensions span 15–120 mm in width and 30–100 mm in length, allowing anything from slim stick packs to larger pillow‑style sachets, so producers can serve retail, food-service, or promotional needs on the same machine.

Power & Build

The automatic honey sachet packing machine runs at roughly 1.3 KW on an AC 220V supply, fitting easily into most small and medium industrial facilities. Its compact 650×600×1900 mm footprint simplifies integration into existing production areas or pilot lines with limited floor space. The frame and product‑contact parts are made from food‑grade stainless steel S/S304, giving strong resistance to corrosion, heat, and cleaning chemicals, while the vertical layout improves ergonomics for film roll change, adjustment, and routine inspection.

Film Compatibility

King Pack’s honey sachet machine works with a wide range of heat‑sealable composite films and laminated film pouches. Film material includes PET/PE, Paper/PE, PET/AL/PE, and OPP/PE. These structures combine good printability, barrier performance, and sealing strength, which is crucial for long‑lasting, attractive sachets. High‑barrier films such as PET/AL/PE help protect honey flavor and color by limiting oxygen and moisture ingress, while Paper/PE offers a more natural, eco‑oriented look. The machine’s temperature‑controlled sealing jaws and adjustable film path allow reliable seals across different film thicknesses and laminations.

Core Functions & Workflow

The core functions of the automatic honey sachet packing machine follow a continuous workflow that starts with roll-fed film and ends with finished sachets discharged onto a conveyor or collection tray. Every stage is synchronized by the PLC-based control panel.

Film Feeding & Bag Forming

- Roll Stock Unwinding: The process starts with a roll of packaging film, unwound and pulled via servo-driven belts.

- Tube Forming: Film passes around a forming collar and tube, where back (vertical) sealing bonds the film edge.

- Custom Sachet Sizes and Shapes: Machines can be configured for flat, stick, round-corner, or even shaped sachets to enhance visual appeal and utility.

Precise Filling & Metering

- Piston Pump Filler: Specialized piston or peristaltic pumps dose viscous honeys with high accuracy, preventing blockage and ensuring clean fill, even with sticky products.

- Photoelectric Tracking: Sensors read eye-marks or registration marks on the film, aligning every cut and fill cycle for minimal waste and high accuracy.

Sealing, Cutting, Date Printing & Discharge

- Digital Temperature Control: Both horizontal and vertical thermal sealing jaws are digitally regulated for robust, leak-proof seals, crucial for sticky liquids.

- Date Coding: An integrated printer can stamp batch numbers and expiry dates directly on each sachet.

- Cutting: Sachets are cut with sharp blades or rotary knives, resulting in uniform bags.

- Discharge: Finished sachets are counted and delivered via conveyor—ready for secondary packaging.

Hygiene, Material Handling & Design Features

Hygiene and cleanability are core concerns in any honey or condiment packaging environment, and the King Pack sachet packaging machine addresses these through thoughtful material and design choices.

Food-Grade Stainless Steel Construction for Rust/Heat Resistance & Easy Cleaning

The frame, hopper, and contact components are made of stainless steel S/S 304 or higher, with smooth welds and minimal crevices where residue could accumulate. This material choice ensures excellent resistance to rust, acidic ingredients, and the heat of CIP or manual washdowns. Surfaces are often polished to reduce adhesion of sticky products like honey, which simplifies cleaning and reduces downtime between product changeovers. Drainage and access panel design also support compliance with food hygiene regulations.

PLC Control with Touchscreen Interface, Servo Motors & No-Leak Filling System

A modern PLC sachet filler uses a touchscreen HMI to allow operators to set bag length, filling volume, speed, temperature, and other key parameters. Recipes can be stored and recalled to switch quickly between different products or pack sizes. Servo electronic control motors operate the film pull belts and filling system. They provide smooth and repeatable motion. They also allow fine control over acceleration and deceleration. This reduces stress on the film and mechanical parts. The no-leak filling system uses precisely machined pistons and valves. It prevents honey or other thick products from dripping on the sealing area. This improves seal quality and reduces the need for manual cleaning during production.

Low Noise Operation, Quick Changeover & Minimal Floor Space for Easy Maintenance

The compact VFFS honey packaging layout, combined with modern drives and sound-dampened enclosures, results in relatively low noise levels compared with older mechanical machines. Changeover from one sachet size to another generally involves adjusting forming parts, changing settings on the HMI, and possibly switching nozzles or filling cylinders, which can be done quickly with minimal tools. The small footprint simplifies installation and maintenance access, making the automatic honey sachet packing machine suitable for both large industrial plants and smaller workshops.

Advantages of the King Pack Honey Sachet Packing Machine

King Pack’s automatic honey sachet packing machine offers economic, technical, and quality benefits. These advantages support stable production over the long term.

Labor Savings: Fully Automated – No Manual Intervention, Reduces Costs by Up to 70%

By automating film forming, filling, sealing, and cutting, the machine drastically reduces the number of operators required per production line. Instead of a team doing manual filling and sealing, one trained operator can run the automatic honey sachet packing machine. The operator watches the settings and manages supplies. This shift can reduce labor-related costs by up to 70% in high-throughput operations, especially where labor is scarce or expensive.

Precision & Efficiency: Exact Dosing (±0.5% Accuracy), Low Waste with Empty Bag Detection

The piston dosing system and PLC control logic are designed to achieve high accuracy, often in the range of ±0.5% of target fill volume. This level of precision means fewer product giveaways and more consistent net content declaration on every sachet. Many King Pack sachet machines have empty bag detection and alarms. These stop the machine if the film breaks or feeds incorrectly. This prevents long runs of empty or faulty sachets and saves film and product.

Product Quality Preservation: Clean Seals Extend Shelf Life, No Contamination

Honey is a relatively stable product, but it is still susceptible to environmental moisture and contaminants if packaging is compromised. Strong, clean seals created under sanitized conditions preserve color, flavor, and nutritional value for longer periods. The closed, stainless steel design of the honey bag sealing machine minimizes contamination from external sources, supporting compliance with HACCP or similar quality programs.

Flexibility: Customizable for Liquids, Pastes, Granules; Scalable from Small to High-Volume Runs

A key selling point of the King Pack sachet machine is its ability to package different kinds of materials on the same base platform, including liquids, pastes, and even granules when fitted with appropriate dosing systems. This versatility allows producers to start with lower-volume, niche products and scale up to high-speed, multi-shift operations without changing the entire food sachet packaging line. Options such as multi-lane configurations, additional printers, or gas flushing can be added as business grows.

Suitable Products & Use Cases

The automatic honey sachet packing machine is not limited to honey; it is a general-purpose viscous liquid filling and packaging system with broad application.

Honey, Jam, Ketchup, Fruit Purees, Sauces & Butters – Viscous Food Liquids

Typical food applications include mono-floral and blended honey, flavored honeys, strawberry or apricot jam, tomato ketchup, barbecue sauces, salad dressings, chocolate sauces, and nut or seed butters. Each product can be configured with dedicated filling parameters and sealing temperatures to ensure correct flow, accurate dose, and visually appealing sachet finish.

Non-Food: Shampoo, Creams, Oils, Lubricants & Chemicals in Sachet Format

In the personal care and household sector, the same automatic paste packer concept handles shampoo, hair conditioner, lotions, cosmetics, sample creams, engine oils, and small volumes of industrial lubricants. These products benefit from the same high-precision metering and robust seals, especially when sold as samples or travel packs.

Granules & Pastes: Spices, Jelly, Bath Foam – Multi-Material Versatility

By changing the dosing system from piston to auger or volumetric cup, the VFFS honey packaging platform can also adapt to fine granules such as spices, instant coffee, or powdered drink mixes. Gel-type and foaming products, such as bath jellies or bath foam concentrates, can also be handled when the correct contact parts and cleaning procedures are used. This multi-material versatility maximizes return on investment in the sachet filling machine.

How to Choose the Right Automatic Honey Sachet Packing Machine

Choosing the right model and setup requires a careful review of product properties, performance needs, production capacity, and after-sales support.

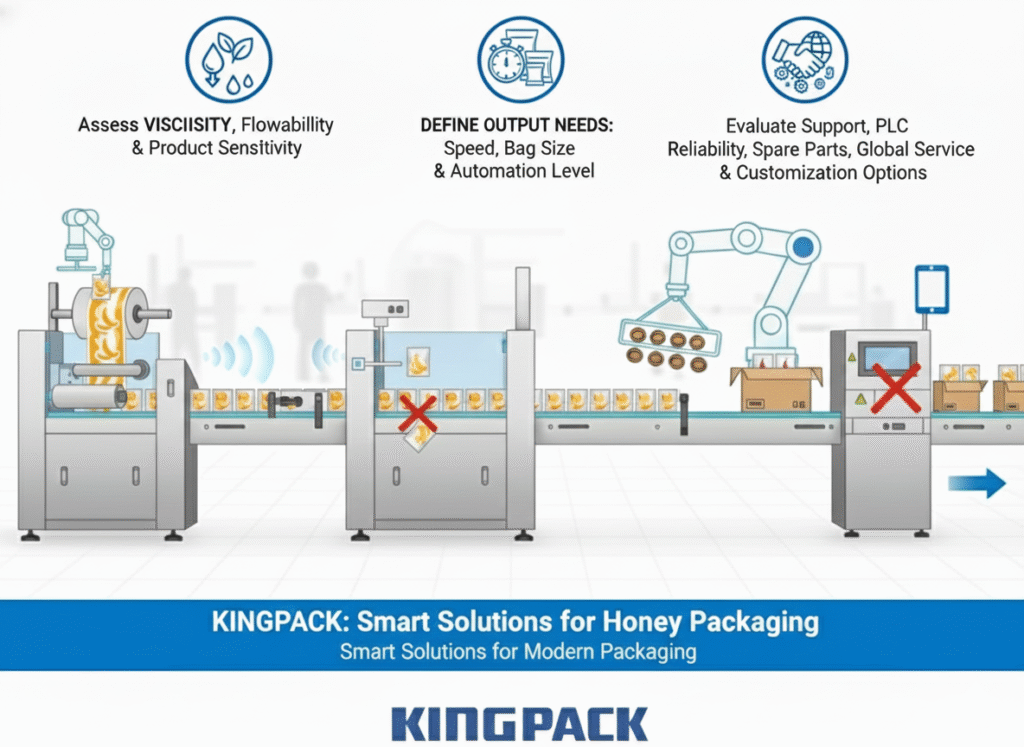

Assess Viscosity, Flowability & Product Sensitivity

The viscosity and flow behavior of the product determine which filling system and nozzle design are most suitable. Sticky, high-viscosity honey demands high-torque pistons, carefully sized valves, and possibly jacketed tanks to maintain consistent temperature. More fluid products, such as thin juices or flavored syrups, may use lighter-duty pumps but require attention to foaming or splashing. Product sensitivity to heat or shear also guides the selection of film and sealing settings.

Define Output Needs: Speed, Bag Size & Automation Level

Before investing in a King Pack sachet machine, producers should define target output in bags per minute, total daily volume, and required bag sizes. Small operations may start with a single-lane machine at moderate speeds, while larger plants may need higher throughputs or multi-lane configurations. Choosing between semi-automatic and fully automatic machines depends on available labor and budget. It also depends on the need to connect with upstream mixing and downstream cartoning or case packing.

Evaluate Support, PLC Reliability, Spare Parts, Global Service & Customization Options

Finally, it is crucial to evaluate the reliability of the PLC platform, the availability of spare parts, and the responsiveness of technical service. A strong automatic honey sachet packing machine is valuable only if it has quick support and clear instructions. It should also allow custom features like bag shape, coding, or connection to data systems. King Pack’s experience in supplying machines to multiple countries and industries offers a strong foundation for long-term cooperation and tailored solutions.

Conclusion & Call to Action

King Pack’s automatic honey sachet packing machine is a complete solution for packaging thick liquids. It combines precise dosing, hygienic stainless-steel parts, and a space-saving VFFS design in one strong machine. This honey packing machine reduces product waste and labor needs. It also ensures strong seals. These features help producers maintain quality and produce at high speeds for many food and non-food uses. King Pack’s PLC sachet filler has CE certification and works well in over 50 countries. It is a reliable and scalable choice for factories that want to improve or start a high-performance food sachet packaging line.

Elevate your honey and sauce packaging today by choosing an automatic honey sachet packing machine that is engineered for precision, hygiene, and flexibility. Contact us at King Pack for a free customized quote and demo, with a typical response time within four hours.

Get Your Free Sachet Packing Quote Now → Email: info@kingpack-cn.com