The demand for portion-controlled, single-serve packaging is expanding across global consumer markets. For liquids and viscous products—from sauces and beverages to creams and pharmaceuticals—the sachet format offers unparalleled convenience and cost efficiency. Meeting this high-volume demand requires a production system capable of extraordinary throughput without compromising accuracy.

At King Pack, we offer multi-lane sachet packing machines engineered as a strategic solution for scaled production. In this article, we will explore the core technology, operational advantages, and critical selection factors that make King Pack’s multi-lane sachet packers the definitive choice for high-volume liquid and paste packaging.

What Is a Multi-Lane Sachet Packing Machine

A multi-lane sachet packing machine is an automated, Vertical Form-Fill-Seal (VFFS) system designed to produce multiple sealed sachets simultaneously from a single, wide roll of packaging film.

These machines are characterized by their parallel operation, where the roll film is slit into multiple strips (lanes), and each strip is formed, filled, and sealed independently, yet in perfect synchronization.

High speed continuous packing machine – King Pack Machinery

Unlike traditional single-lane machines, which process one package per cycle, a multi-lane system multiplies the output within a compact footprint. This design is paramount for businesses aiming for mass production of small-format packets, significantly boosting total output capacity per unit of factory floor space.

Why Use Multi-Lane for Liquids and Semi-Liquids

For liquid and semi-liquid products—which are often sold in high-volume, low-margin categories like condiments and personal care samples—speed, film economy, and filling accuracy are critical for profitability.

Multi-lane systems provide distinct operational and economic advantages:

- Capacity Multiplication: An 8-lane machine operating at 35 cycles per minute can achieve an output of 280 sachets per minute (sachets/min), which is economically impossible to match with single-lane units in the same area.

- Cost Efficiency: By utilizing a single, large roll of film and sharing the primary drive and control mechanisms (PLC, HMI, main servo motors) across all lanes, the unit cost of production is substantially reduced.

- Market Growth Alignment: The global sachet packaging market was valued at USD 8.75 billion in 2023 and is projected to reach USD 14.19 billion by 2032, exhibiting a robust CAGR of 5.54%.

Typical Industries & Products (Sauces, Cosmetics, Pharma, Personal Care)

The multi-lane sachet format is a foundational element in several high-demand industries, particularly those requiring precise dosing of liquid or viscous materials.

| Industry | Typical Sachet Products | Key Feature Utilized |

| Personal Care & Cosmetics | Shampoo, conditioner, liquid soap, sun cream, lotions | High-speed production of trial-size and travel packets |

| Food & Beverage | Ketchup, honey, liquid seasoning, sauces, syrups, condensed milk | Portion control, on-the-go convenience, and airtight, tamper-evident seals |

| Pharmaceuticals | Oral liquid doses, cough syrup, over-the-counter liquid medications | Precise dosing accuracy (often 1–10 ml segment dominant) and adherence to strict regulatory requirements |

Core Technology & Mechanisms

The ability of a multi-lane machine to deliver speed with precision stems from the sophisticated electronic and mechanical synchronization of its core components, primarily utilizing advanced servo technology.

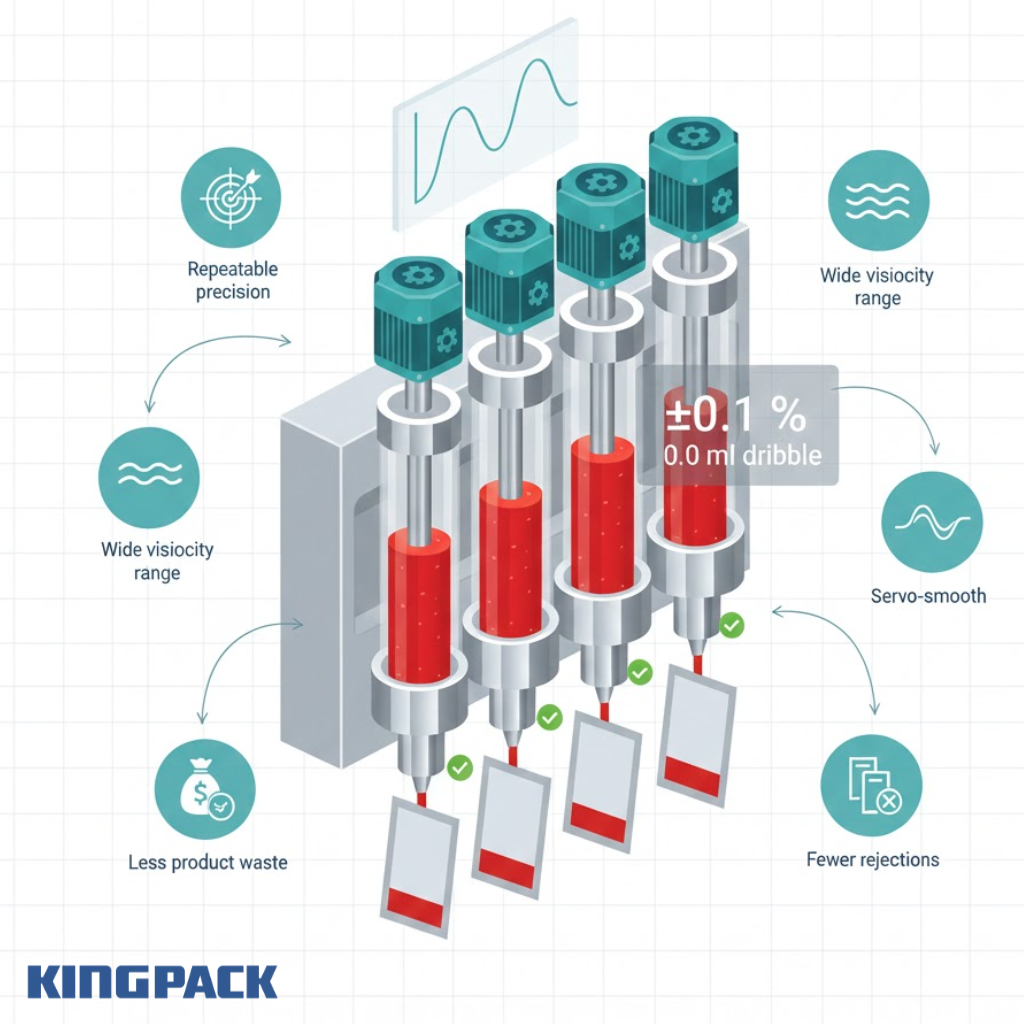

Servo‑Driven Piston Pump for Precise Filling

A stable filling system is at the heart of every multi-lane sachet machine, and King Pack builds this stage with high-precision servo-driven piston pumps. These pumps give operators steady control over how each dose is delivered, even when running several lanes at high speed. The servo motion keeps the piston stroke smooth, which helps maintain accuracy across long production cycles.

These pumps:

- Provide accurate, repeatable fill volumes.

- Shut off cleanly to avoid dribbling or leaking.

- Handle a wide range of viscosities — from low-viscosity sauces to thicker creams.

This design lowers the risk of weight variations and keeps every sachet consistent. With cleaner cut-off points and predictable dosing, producers save product, reduce rejections, and maintain a polished final package that reflects well on the brand.

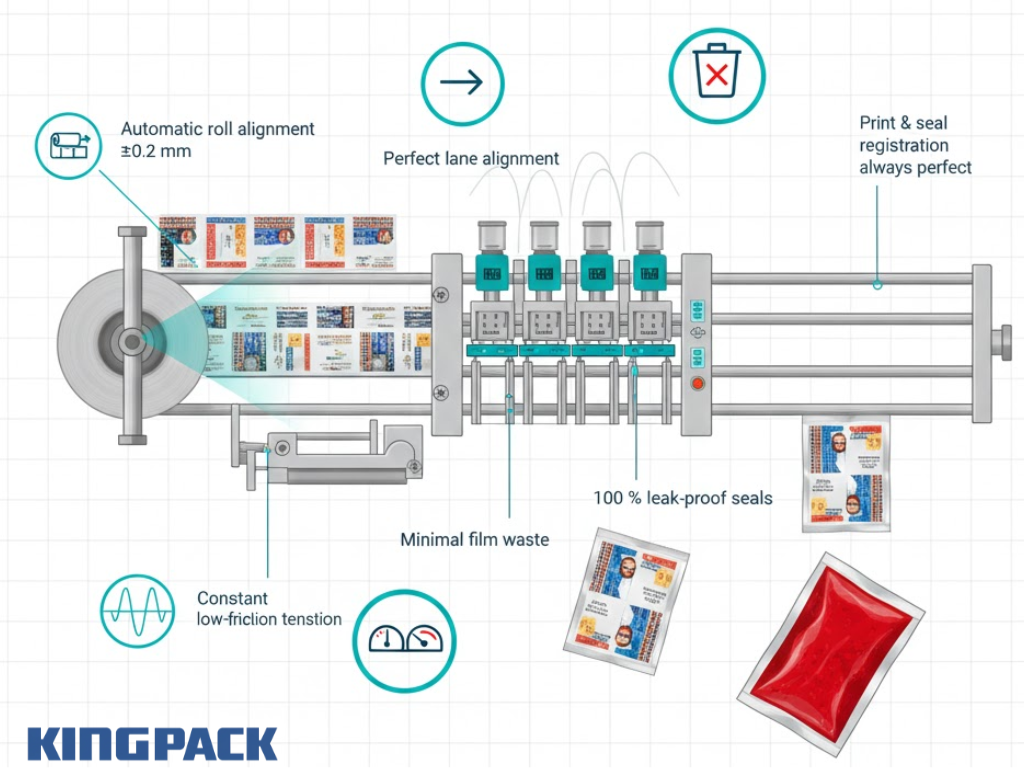

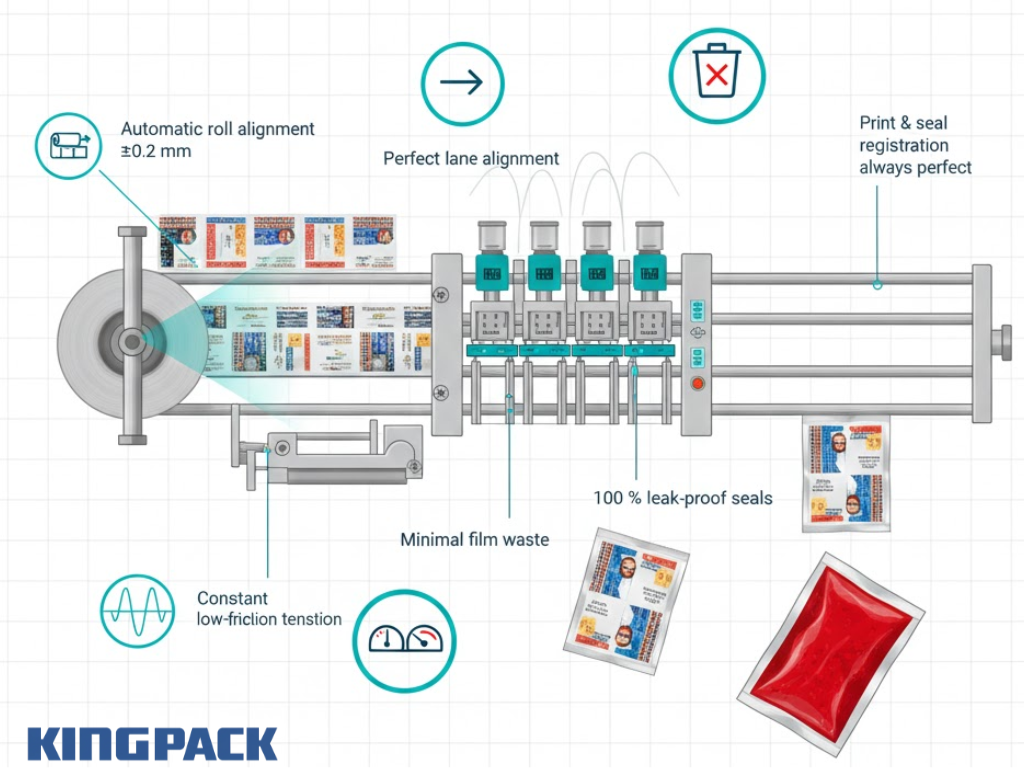

Film Handling: Automatic Roll Alignment & Servo Sealing

Reliable film movement is essential in a multi-lane setup, especially when the machine is running liquids or pastes. King Pack systems manage film with tight mechanical control so lanes stay aligned and continuous production runs stay smooth. The film moves through the machine with minimal friction, which protects print quality and keeps registration marks accurate.

Key mechanisms include:

- Automatic roll alignment, which ensures the film is fed reliably and evenly across all lanes.

- Servo-controlled sealing, where each lane’s sealing bar is managed independently (or semi-independently) to optimize timing, pressure, and temperature.

These systems keep film waste low and help maintain seal strength, even when the product inside has higher moisture or viscosity. Strong seals protect the liquid inside and reduce the chances of leaks during shipping, which is vital for food, cosmetics, and pharma products.

PLC Control & HMI Operation for Easy Parameter Setting

Modern packaging lines need clear visibility and simplified adjustment. King Pack uses a PLC paired with a friendly HMI screen, giving operators direct access to important settings without relying on manual tuning. The interface keeps everything organized, helping teams move quickly during setup or production checks.

The control system allows operators to:

- Set parameters like fill volume, sealing temperature, and lane speed.

- Switch “recipes” quickly between products or batch runs.

- Monitor real-time status, alarms, and diagnostics.

Efficient software support cuts downtime and limits human error. Each batch runs with consistent parameters, and operators can track performance or troubleshoot issues without halting the line. This creates a more controlled environment where product quality stays steady from the first sachet to the last.

Machine Configuration & Lane Options

The modular nature of King Pack’s multi-lane design allows manufacturers to specify a machine configuration tailored precisely to their output goals and available factory space.

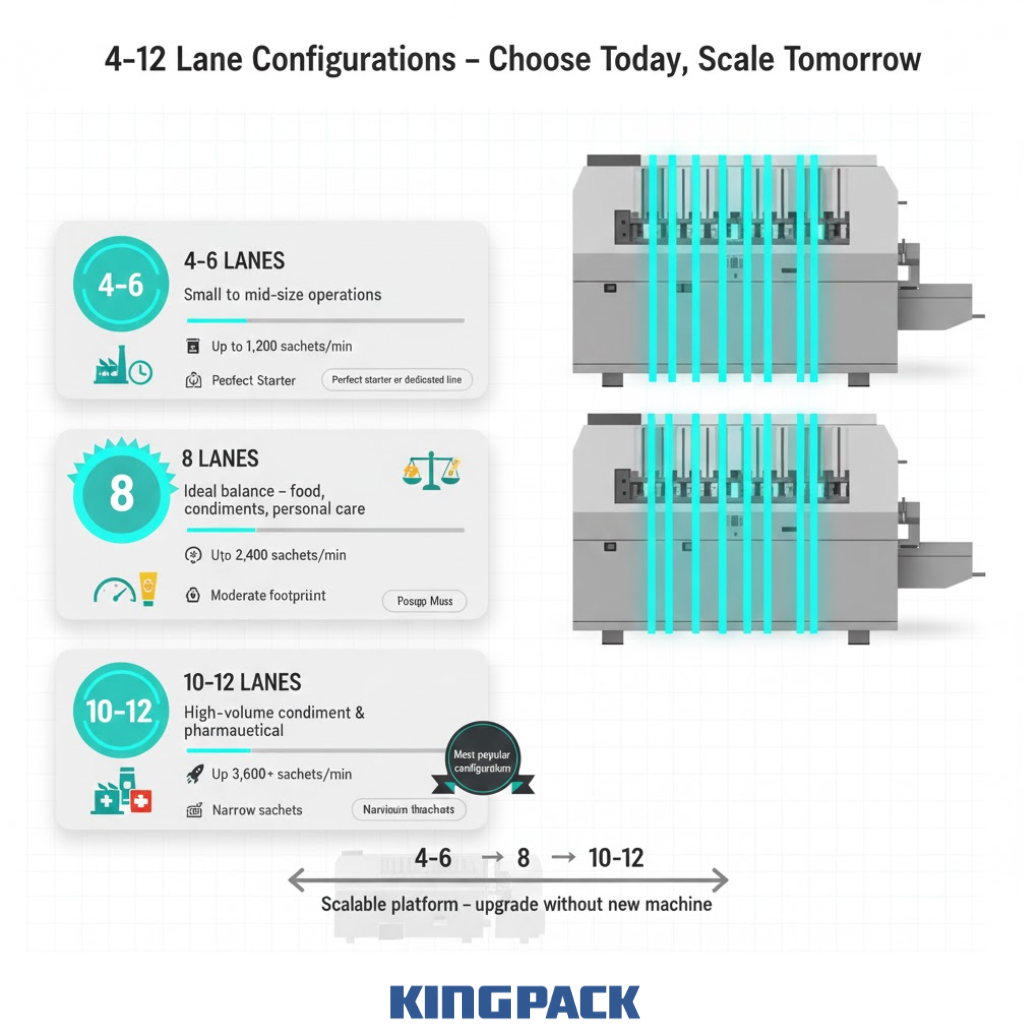

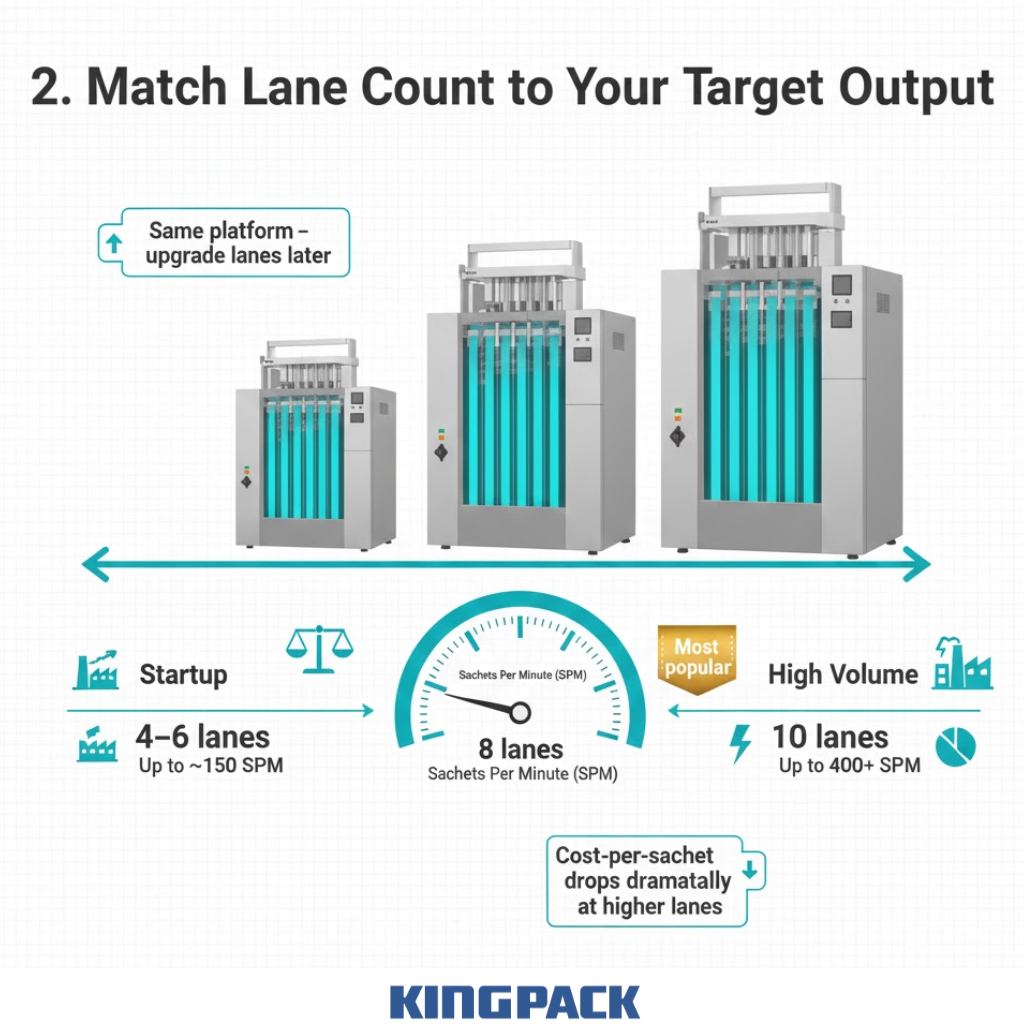

4 to 12 Lane Configurations Supported

A wide range of lane counts is available, from compact four-lane units to high-capacity twelve-lane systems. The final configuration depends on sachet width, film width, and desired throughput. This range gives manufacturers a predictable path for growth, since the machine purchased today can be scaled or re-configured to meet future demand.

| Lane Count | Typical Use Case | Production Advantage |

| 4–6 lanes | Small to mid-size operations | Lower footprint with stable daily output |

| 8 lanes | Balanced capacity for food and personal care | Strong speed with moderate space needs |

| 10–12 lanes | High-volume pharmaceutical or condiment production | Maximum sachets per minute on narrow formats |

Selecting the right lane count helps maintain efficiency without overloading the line. Each configuration is designed to keep the film movement and sealing cycle steady, even during long production shifts.

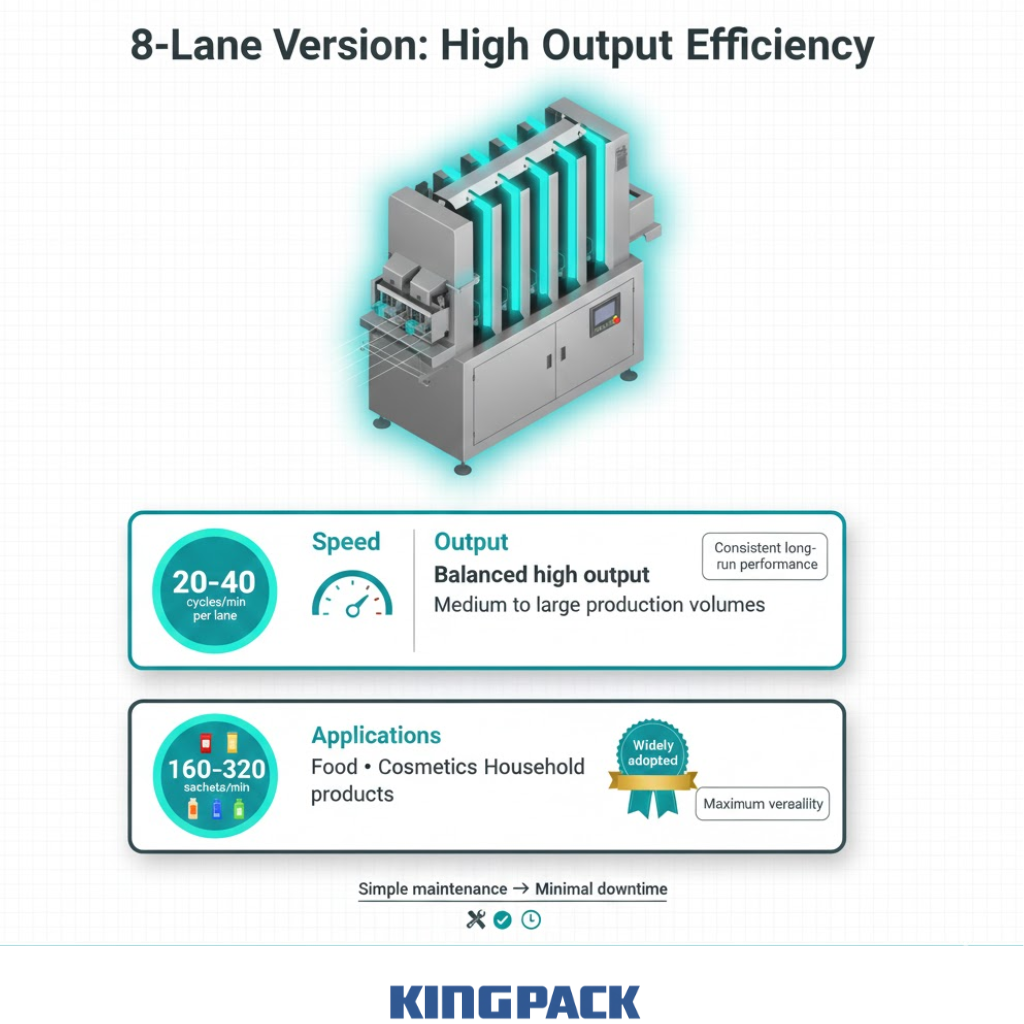

8-Lane Version: High Output Efficiency

The 8-lane system offers a strong balance between speed and floor space. It suits brands that need continuous output without the complexity or cost of very high-density systems. This configuration works well in food, cosmetic, and household product manufacturing, where medium and large production volumes are common.

| Spec | 8-Lane Details |

| Typical speed range | 20–40 cycles per minute per lane |

| Estimated output | 160–320 sachets per minute |

| Best suited for | Ketchup, honey, sauces, cosmetic liquids, personal care |

This version is widely adopted across many plants because it keeps maintenance simple while still delivering high throughput. It is also known for steady long-run performance, making it a reliable choice for operations that cannot risk downtime during peak output periods.

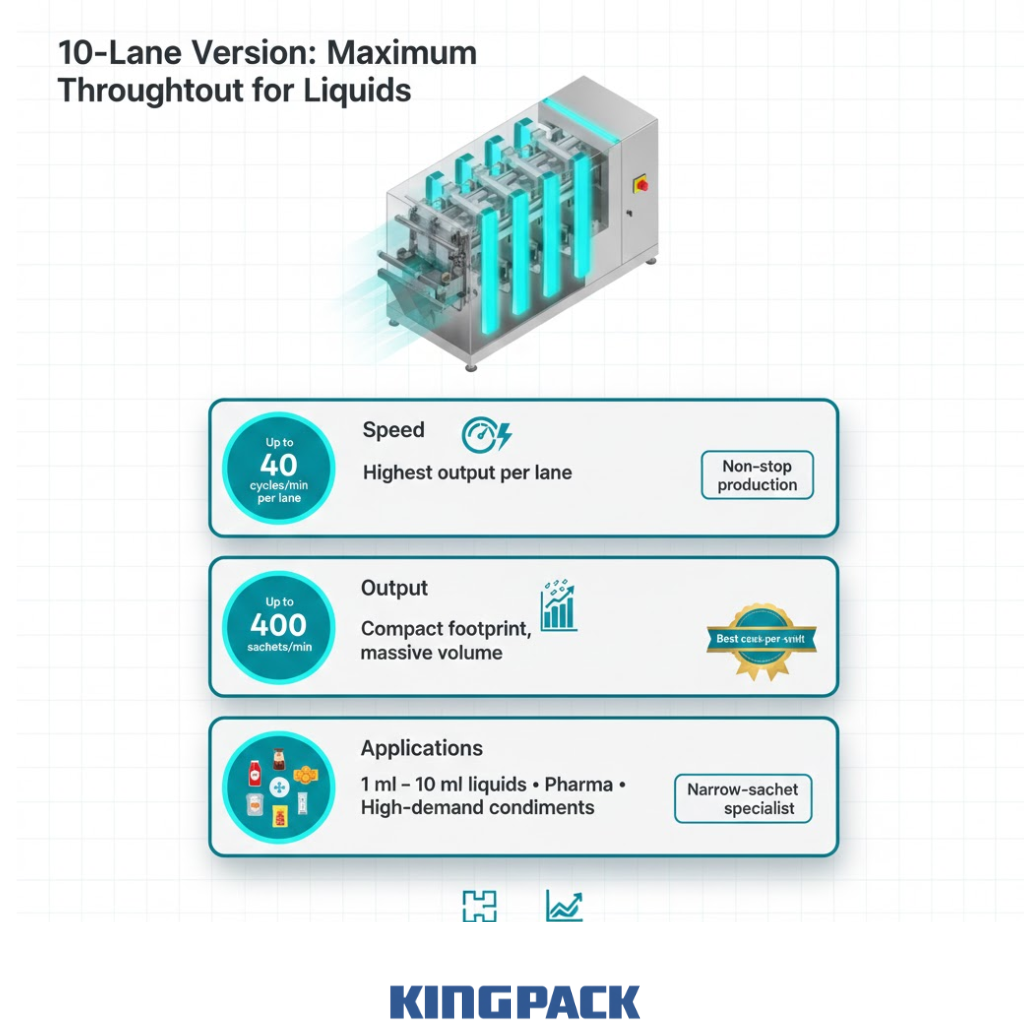

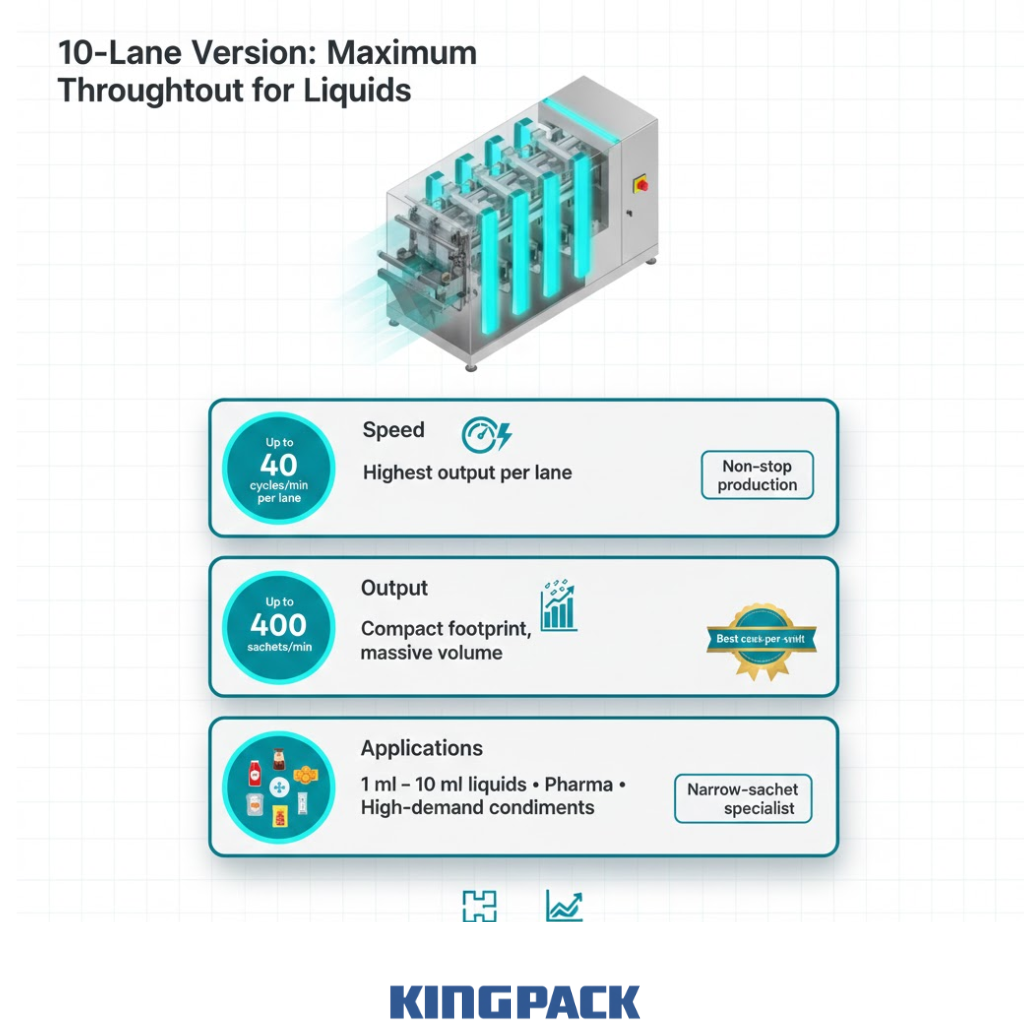

10-Lane Version: Maximum Throughput for Liquids

The 10-lane format is designed for producers who need the highest number of sachets per minute within a compact footprint. It is ideal for small-dose liquids, pharmaceuticals, and fast-moving condiments packaged in narrow sachet sizes. Its higher lane density creates strong cost efficiency per unit produced.

| Spec | 10-Lane Details |

| Typical speed range | Up to 40 cycles per minute per lane |

| Estimated output | Up to 400 sachets per minute |

| Best suited for | 1 ml–10 ml liquid sachets, medical liquids, high-demand condiments |

This configuration supports heavy-duty production schedules and helps manufacturers meet market demand without adding parallel lines. Its strong output per square meter makes it a valuable option for facilities with limited space but high production targets.

Design & Operational Advantages

Precision Filling with Leakage Prevention

Thanks to servo piston pumps, King Pack’s multi-lane machines deliver precise filling with minimal leakage. The pump stops sharply, reducing drips, and the system can be tuned to the viscosity of the product to avoid overfill or underfill.

Stable Film Running & Cursor Correction

Servo-driven film pullers and alignment ensure each lane’s film is accurately registered. This prevents pouch misalignment and minimizes film waste. Such control also helps keep seals even, reducing risk of weak or faulty seals.

Continuous Vacuum Feeding to Hopper

Many multi-lane sachet machines employ a vacuum feeding system for the product hopper, ensuring a steady supply of liquid or paste. This prevents air entrainment in the filling pump and helps maintain consistent pressure and volume across lanes, which is especially important for high-speed operation.

Hygiene, Maintenance & Cleaning

Removable Filling Device for Easy Cleaning

King Pack designs its filling components (such as pistons, nozzles) to be easily removed and reassembled. This allows for fast, thorough cleaning — a must in food, cosmetics, and pharmaceutical production, where hygiene is non-negotiable.

All Product Contact Parts in Stainless Steel

Components that come in contact with product are typically made from food-grade stainless steel to resist corrosion, ensure durability, and comply with hygiene standards. King Pack is known for building machines that meet GMP (Good Manufacturing Practices).

Low Maintenance Design with Minimal Wear Parts

By relying on servo motors and linear guides (rather than heavy mechanical linkages), multi-lane sachet machines can reduce wear parts. This design choice leads to lower downtime, less maintenance, and a longer lifecycle for critical components.

Application Examples

Here are some real-world applications where King Pack’s sachet and stick pack machinery delivers strong results:

Food – Sauces, Ketchup, Honey, Syrup

Large sauce producers often need to handle heavy daily volumes. Small sachet packaging machines and multi-lane VFFS form fill and seal setups help meet this demand. An 8- or 10-lane high-speed four-side seal vertical packaging line produces thousands of ketchup or chili sauce sachets per hour for fast-food chains, meal kits, and retail distributors. Monoblock sealing and vertical continuous-motion machines ensure uniform sachets, reducing product waste and improving line efficiency.

For thick or sticky products like honey or syrup, auger fillers, rotary valve pumps, piston filler machines, or auger dosing systems deliver controlled flow. These systems prevent trapped air, uneven weights, or messy seals, maintaining consistency for viscous pastes and high-viscosity liquids.

Cosmetics – Shampoos, Conditioners, Creams

Travel-size cosmetic products benefit from Sachet & Stick Pack Machinery and vertical packaging machines with intermittent working principle. Multi-lane setups provide consistent runs with minimal manual intervention.

Operators can remove filling heads or peristaltic pumps for cleaning, reducing downtime while maintaining product purity. Auger fillers and volumetric fillers support precise dosing for creams, preventing thin spots, hollow areas, or overflow.

Pharmaceutical & Personal Care Liquids

Pharmaceutical sachets and personal care liquids like hand sanitizers require precise, sanitary handling. King Pack machines with servo rotary lobe pumps, stainless-steel construction, and well-defined cleaning points meet strict hygiene standards.

Gravity pumps, diaphragm pumps, and gear pumps ensure consistent filling for liquid, pasty, powdery, and granular products. Steady production, uniform sachets, and reliable sealing help manufacturers maintain dosage accuracy, compliance, and consumer safety.

How to Choose the Right Multi-Lane Sachet Machine

Selecting the appropriate machine is a strategic decision that depends on current product specifications and future production scalability.

Consider Your Product Viscosity & Filling Range

The physical characteristics of your product are the primary factors determining the filler type.

- For thick pastes (e.g., peanut butter, certain topical creams), the robust power and volumetric control of a piston pump are necessary.

- For free-flowing liquids (e.g., mouthwash, light syrups), a peristaltic or lobe pump or a mass flow meter may be more appropriate to maximize speed and precision.

- Additionally, ensure the machine’s filling range (e.g., 1 ml to 50 ml) aligns with both your smallest and largest target sachet volume.

Decide on Lane Number Based on Your Target Output

Establish your required sachet per minute (SPM) or daily output goal. The lane count is the most direct factor in determining machine capacity.

- A lower lane count (4-6) may suffice for a startup or for packaging very large sachet formats.

- For established high-demand products, a high lane count (8-lane or 10-lane) offers the most cost-effective path to achieving high output targets (e.g., 300+ SPM).

Evaluate Support & Spare Parts Availability

An advanced machine is only as valuable as its uptime. Before making a final selection, scrutinize the vendor’s after-sales service structure. Confirm the ease of obtaining common wear parts, the response time for technical support, and the availability of on-site service to protect your investment and maintain production continuity.

Conclusion & Call to Action

King Pack’s multi-lane sachet packing machines deliver a powerful mix of speed, accuracy, and hygienic design. Whether you’re packaging food sauces, cosmetic shampoos, or pharmaceutical liquids, these systems can scale with your output demands while maintaining product quality.

Because King Pack emphasizes modular, engineering‑driven solutions, you can tailor a line to your needs — choosing lane count, pump type, and automation level. Their GMP- and ISO-certified machines further ensure that you’re investing in equipment built to global standards.

Ready to scale your sachet production? Contact King Pack to get a quote and design your custom multi‑lane sachet packing line.