Hot sauce production has evolved from a niche specialty to a global commercial sector driven by a consumer appetite for bold, diverse, and ethnic flavors. The packaging operation for this condiment is not merely a final step; it is a critical process that ensures product integrity, extended shelf life, and compliance with rigorous food safety standards. The choice of bottling equipment must therefore be highly specialized.

At King Pack, we provide advanced filling and packaging systems engineered specifically to handle the unique characteristics of hot sauce: varying viscosities, high particulate content, and corrosive acidity.

This guide examines every essential component of a successful hot sauce bottling line, from container selection to high-speed line integration, helping producers secure both efficiency and lasting product quality.

How to Choose the Right Bottle for Hot Sauce

The container selection directly impacts the hot sauce’s preservation, transportation safety, and brand aesthetics. While new packaging formats like sachets and pouches are rising (with sachets and pouches expanding at an 8.11% CAGR through 2030), bottles still retain a substantial market share, accounting for over 85% of revenue in the packaging segment.

Considerations for Material Type

Choosing the right bottle material is critical for maintaining hot sauce quality and shelf life. The material affects durability, chemical compatibility, and consumer perception. Here are main material options:

- Glass: Offers the highest barrier protection, is non-porous, and conveys a premium aesthetic. It is ideal for long-term storage and high-acidity recipes.

- PET Plastic: Provides excellent shatter resistance and is lightweight, significantly reducing shipping costs. It is generally suitable for low-acidity sauces or quick-turnaround products.

- HDPE Plastic: Occasionally used for high-volume, cost-sensitive products, but provides a lower barrier and less aesthetic appeal than glass or PET.

Ultimately, the investment in high-quality packaging material, particularly food-grade glass or specialized high-barrier PET, protects the flavor profile of the hot sauce and assures consumers of product integrity until consumption.

Recommended Reading: Automatic Case Packaging Machine — Intelligent Transformation of End-of-Line Packaging – King Pack Machinery

Considerations for Bottle Size & Shape

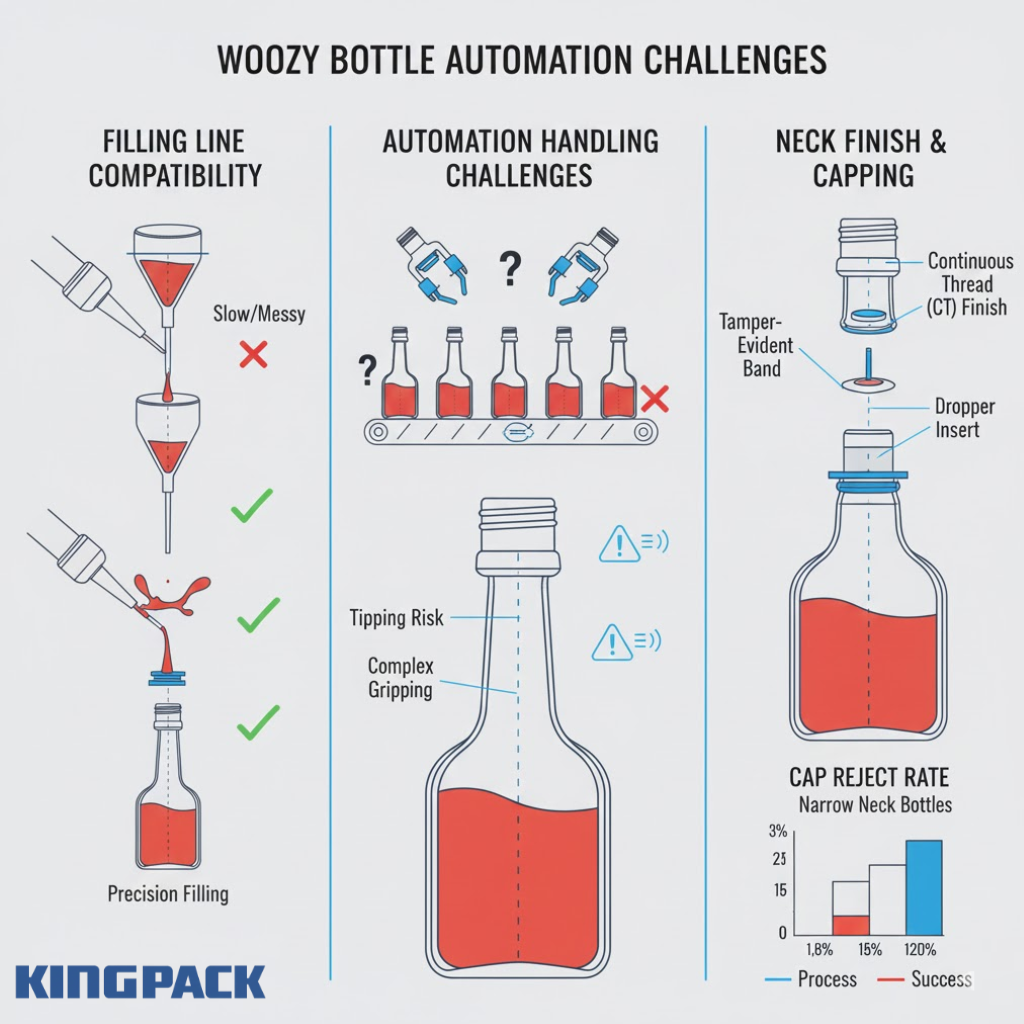

The physical dimensions of the bottle affect consumer perception, line efficiency, and handling logistics. The distinct “woozy” bottle shape is iconic in the hot sauce industry, suggesting tradition and artisanal quality.

But it presents unique challenges for high-speed automated lines that require stable, consistent surfaces for gripping and capping. Furthermore, the size must reflect market segmentation, with small single-serving bottles targeting travel or samples, and larger bottles serving retail or bulk use.

- Standard Sizes: The most common sizes are 5 oz (150 ml), 10 oz (300 ml), and 12 oz (355 ml), providing instant consumer familiarity.

- Neck Finish: A narrow bottle neck is often used to restrict the flow of liquid, which requires specialized neck handling systems on the filling machine to maintain stability during high-speed operation.

- Aesthetics/Shelf Appeal: Custom shapes differentiate the brand but may necessitate custom tooling (star wheels, guides) on the bottling line, increasing initial capital expenditure for the machinery.

Choosing a bottle size and shape should be a measured decision that balances brand visibility with the operational complexity it introduces to the bottling line, prioritizing a shape that can be efficiently handled by automatic filling, capping, and labeling equipment.

Filling Technologies for Hot Sauce

The texture and consistency of hot sauce can vary dramatically—from thin, vinegar-based sauces to thick, chunky varieties laden with pepper seeds, fruit pulp, or garlic. Selecting the correct filling technology is the most important mechanical decision in designing the production line. King Pack specializes in offering filling solutions tailored to this complexity.

Volumetric Filling: For Light, Free-Flowing Sauces

Volumetric fillers are ideal for thin, smooth sauces like vinegar-based hot sauces or pureed pepper liquids. They measure and dispense a fixed volume into each container, ensuring consistent portioning at high speeds without damaging the product. These systems are reliable, cost-efficient, and designed for continuous production in retail or bulk packaging lines.

| Filler Type | Key Advantage | Best Applications | Typical Throughput |

| Gravity Filler | Uses gravity and timed dispensing | Low-viscosity sauces without particulates | High-speed bottling up to 500 bottles/hour |

| Overflow Filler | Ensures uniform visible fill | Clear bottles or premium presentation | Medium to high-speed lines |

Volumetric fillers maintain consistent fill levels, which is critical for brand aesthetics and packaging uniformity. By matching the filler type to your sauce’s viscosity and bottle size, you reduce product waste and improve line efficiency.

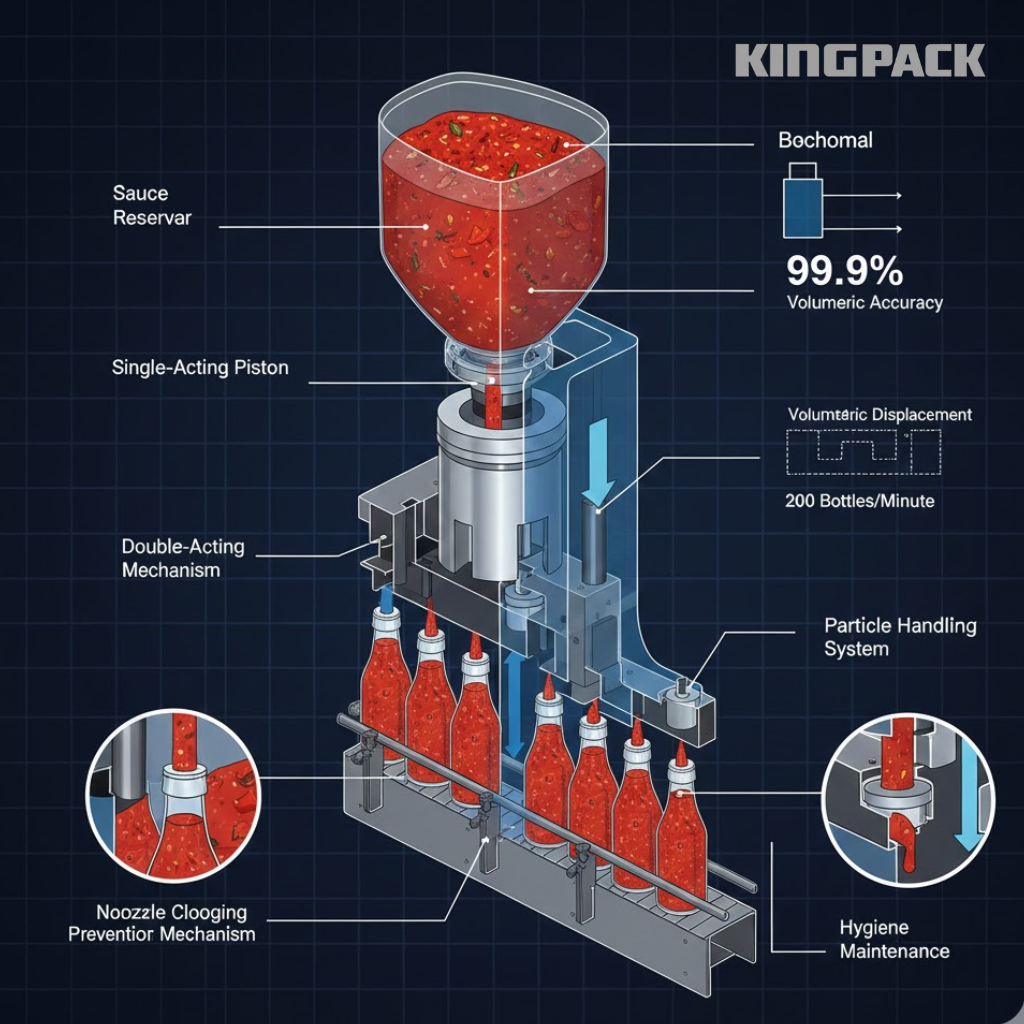

Piston Filling: For Thick Sauces, Chunks & High Viscosity

Piston fillers are built to handle high-viscosity sauces, purees, or chunky condiments containing seeds, pulp, or solids. They work by mechanically pushing a set volume of product into the container, providing precise, repeatable fills regardless of thickness. This ensures even portion control and prevents nozzle clogging or inconsistent fills.

| Filler Type | Key Advantage | Best Applications | Typical Throughput |

| Single-Acting Piston | Accurate volumetric dosing | Thick sauces, pastes, or pepper-based hot sauces | Medium-speed lines, 150–300 bottles/hour |

| Multi-Acting Piston | Handles larger volumes per stroke | Chunky or semi-solid sauces | Medium to high-speed lines |

Piston filling guarantees uniformity for high-viscosity sauces that are challenging for gravity-based systems. Proper calibration and nozzle selection further reduce product splashing, minimize foam, and maintain hygiene throughout the production run.

Sealing, Capping & Labeling in the Bottling Line

Once the hot sauce is precisely filled, the integrity of the packaging rests on the sealing, capping, and final labeling processes.

Sealing That Protects & Preserves

King Pack integrates induction sealing into their lines. When a cap is applied, an induction coil bonds a foil liner to the bottle rim, creating a hermetic seal.

This seal is critical for:

- Preventing oxygen loss

- Avoiding leakage or contamination

- Giving your product a professional, tamper-evident finish

Capping Options: Screw, Chuck, Spindle

Your choice of cap drives the capping tech. King Pack supports:

- Spindle cappers — ideal for threaded caps with high-speed lines

- Chuck cappers — precise pneumatic or servo heads grip and rotate

- Snap cappers — for press-on caps or specialty lids

Torque control is built in, so every bottle is closed tightly enough to prevent leaks — but not so tight that customers struggle.

Labeling & Coding: Brand Meets Compliance

Labeling is your moment to shine — and King Pack’s systems support a variety of styles:

- Wrap-around labels for standard cylindrical bottles

- Front/back panels for nutrition or brand messaging

- Tamper-evident or shrink-band labels for security

They also offer vision inspection to catch misaligned or missing labels, ensuring quality before your products leave the line.

Automation Levels & Line Integration

Selecting the appropriate level of automation ensures a packaging line meets current production demands while allowing for future growth.

Manual / Benchtop Solutions

Manual or benchtop hot sauce bottling solutions are ideal for small-scale producers, craft brands, or startups entering the market. Operators perform the filling, capping, and labeling tasks by hand, giving full control over each batch while requiring minimal investment in machinery.

These systems are best suited for low-volume production, typically handling under 500 bottles per hour. Despite the lower speed, manual lines offer flexibility, allowing small brands to experiment with recipes and package sizes without committing to large-scale automation.

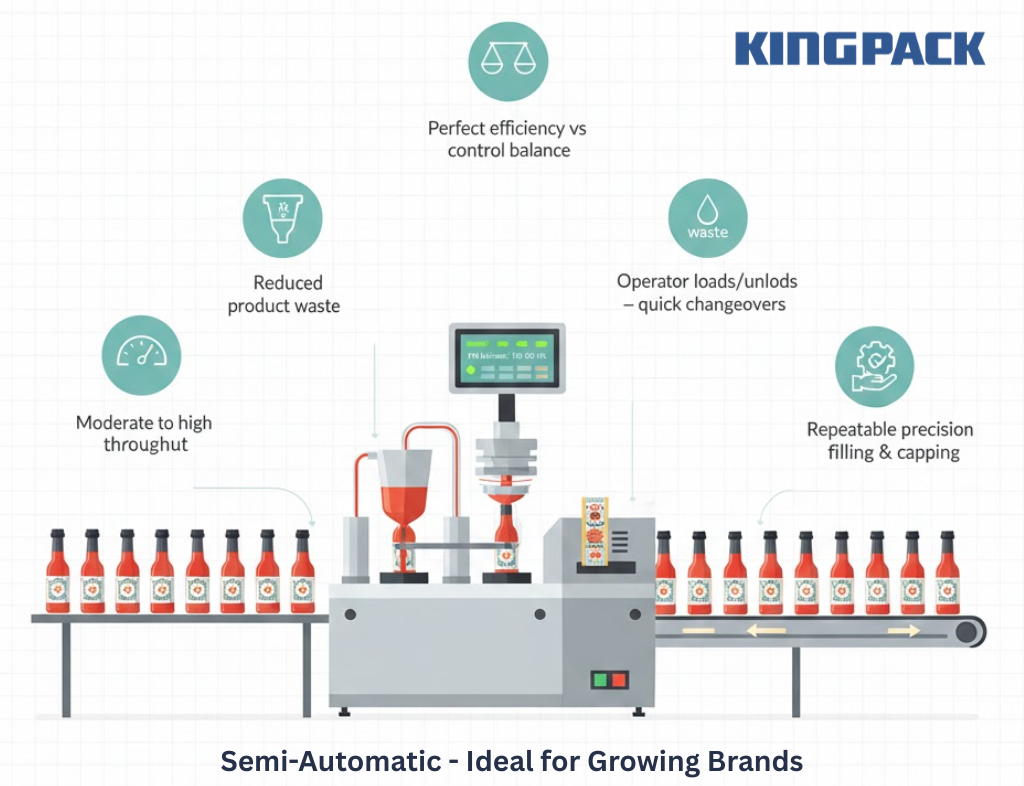

Semi-Automatic Lines

Semi-automatic lines strike a balance between efficiency and operator control. Machines perform the precise filling, sealing, and capping functions, while an operator handles bottle loading, unloading, and occasional adjustments.

This setup works well for growing businesses that need higher throughput than manual lines can provide. Semi-automatic systems improve consistency, reduce product waste, and support moderate production volumes without the full investment of a fully automatic line.

Fully Automatic Lines

Fully automatic hot sauce lines are engineered for high-volume, commercial production. These turnkey systems manage the entire process autonomously, from unscrambling and feeding bottles to filling, capping, labeling, and final case packing.

King Pack specializes in designing these integrated, high-speed systems, capable of producing thousands of bottles per hour. Automation maximizes efficiency, ensures precise portioning, and maintains consistent quality across every batch, making them ideal for large-scale manufacturers with demanding production targets.

Recommended Reading: Hot Sauce Bottling Machine Complete Guide – King Pack Filling & Packaging Systems – King Pack Machinery

Key Considerations When Buying a Hot Sauce Bottling Machine

Purchasing a bottling machine is a substantial investment that requires careful evaluation against five key criteria to ensure long-term value and operational fit.

Viscosity & Consistency of Your Sauce

Matching the machine technology to the product rheology is paramount.

- Thin, runnier sauces (low-viscosity) require volumetric or overflow filling for speed and visual consistency.

- Thick, chunky sauces (high-viscosity) require the power and precision of piston or pump fillers. Failure to select the correct technology will result in either inconsistent fills or damage to the product particulates.

Container Size, Material and Compatibility

A machine must offer flexibility to handle your current and prospective product portfolio. If you package your signature sauce in a 5 oz glass woozy bottle and your commercial bulk product in a 64 oz PET jug, the machine should be designed with the format flexibility to switch between these specifications quickly and easily. King Pack specializes in highly adaptable platforms to mitigate future compatibility issues.

Budget & Return on Investment

While automated systems require a higher initial investment, the long-term ROI is realized through significant operational savings.

- Reduced Product Giveaway: High-precision fillers cut product loss, which is critical for expensive, high-quality ingredients.

- Increased Throughput: Automation allows higher bottles per minute (BPM) output, facilitating market expansion and meeting large order fulfillment demands.

- Labor Savings: Moving from semi-automatic to fully automatic drastically reduces manual labor costs and error rates.

Future Expansion & Scalability

A wise investment is protected by the ability to scale. Look for machines built on modular designs that permit additional components—like extra filling nozzles, secondary cappers, or inspection systems—to be integrated later. This ensures your line can grow organically with your business, without needing a complete overhaul as production demands increase.

Recommended Reading: Multilane Packing Machines – High‑Speed Multichannel Sachet & Stick‑Pack Solutions | King Pack – King Pack Machinery

Real-World Use Cases & Industry Relevance

King Pack’s sauce bottling equipment is designed to serve diverse market segments with tailored configurations.

Food & Condiment Manufacturers

Large-scale food producers need uninterrupted, high-speed performance. King Pack delivers automatic sauce filling machines and rotary bottle filling machines that operate continuously, achieving peak production capacity.

These filling lines feature robust construction, stainless hopper components, and automated conveyors for smooth operation. Advanced sensors and servo drive technology maintain precise control, ensuring consistent throughput for sauces, condiments, and other liquid fillers across 24/7 operations.

Craft Hot Sauce Producers

Artisanal and small-batch producers prioritize accuracy over speed. King Pack offers semi-automatic sauce fillers and piston filler machines that handle high-viscosity products with precision.

Linear fillers and volumetric piston fillers provide accurate dosing, while quick-change designs support multiple product lines. This setup works well for hot fill applications, chunky salsas, or specialty condiments.

Other Applications: Sauces, Condiments, Non-Food Fillers

King Pack’s filling lines and packaging machinery handle viscous, corrosive, and high-particulate products beyond hot sauce.

- Thick Condiments: Piston filler machines and semi-automatic sauce fillers work with BBQ sauces, ketchups, and chunky salsas, using gravity feed and stainless hopper systems for precise filling.

- High-Value Liquids: Volumetric piston fillers and rotor lobe pump fillers deliver accurate dosing for pharmaceutical syrups, cosmetic creams, and other liquids with food-grade construction and advanced sensors.

Bottling packaging production lines, CIP cleaning stations, and aseptic packaging solutions meet cGMP standards, ensuring product quality, microbial control, and sustainable operations.

Conclusion & Call to Action

The journey of hot sauce, from the chili pepper to the consumer’s table, demands machinery that offers precision, durability, and versatility. King Pack’s hot sauce bottling solutions provide flexible, high-precision, and scalable machinery tailored for food-grade, high-acidity environments. Investing in the right bottling line, equipped with the correct filling technology and integrated capping and labeling, enables both brand growth and lasting product quality assurance.

Our expertise is built on engineering systems that minimize waste, maximize uptime, and ensure your unique product is packaged perfectly, every time. Contact King Pack to design your custom hot sauce bottling line and get a tailored quote.