King Pack delivers a complete portfolio of automated packaging machines. It covers powders, liquids, sauces, granules, premade pouches, blisters, and cartoning machines. These features help manufacturers increase throughput and improve dose accuracy. They also keep strict hygiene and regulatory standards in food, pharmaceutical, cosmetic, and chemical lines. So, this guide serves as an essential guide for different Packaging Machine Solutions. In this article, we will discuss all the machines offered by King Pack, their features and how they benefit various businesses. Let’s dive in and get started.

Overview of Packaging Machine Capabilities

King Pack’s equipment portfolio spans primary and secondary packing. Let’s understand their expertise and packaging equipment capabilities.

King Pack’s Expertise and Engineering Strength

The company builds complete packaging lines for pharma, nutraceutical, personal care, and food manufacturers. These lines balance output speed with compliance and product protection. King Pack focuses on packaging and pharmaceutical machinery for the long term. They use mature servo motion control, precise dosing hardware, and modular mechanical structures. These parts are strong enough for continuous multi-shift operation. Standard designs are typically customized by changing dosing modules, forming sets, sealing jaws, or control recipes to match different SKUs without redesigning the entire line.

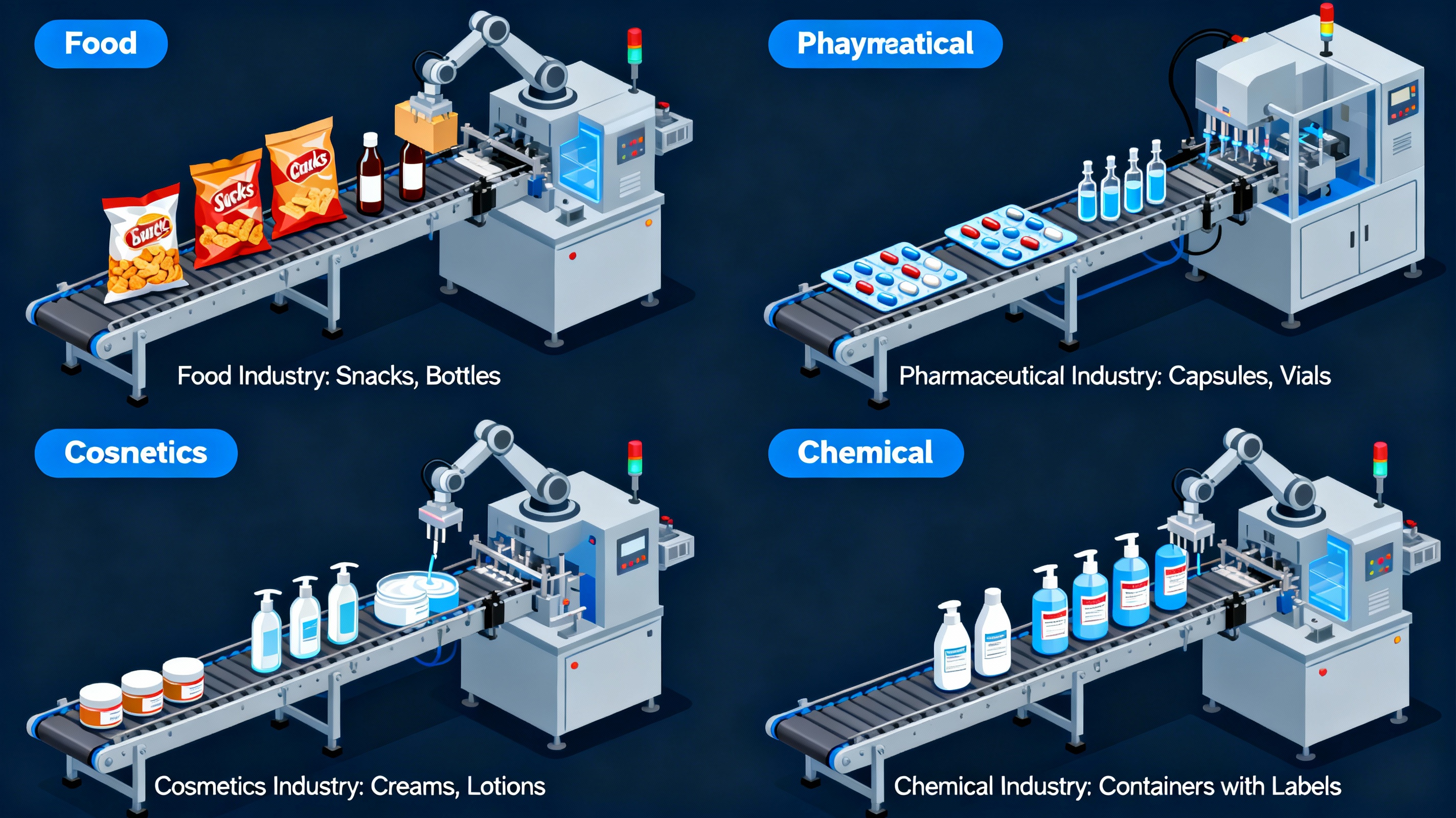

Applications Across Food, Pharmaceutical, Cosmetics, and Chemicals

- In food industry, powder, and granule packaging machines are available. These are used for packaging food products such as coffee, spices, instant beverages, seasonings, nuts, snacks, sugar, and staple grains. While liquid-filling and sauce systems pack edible oils, beverages, condiments, and ready‑to‑eat components with an airtight seal. This keeps the product Shelf Life intact.

- Pharmaceutical and nutraceutical producers use blister and cartoning machines for tablets, capsules, syringes, and medical consumables, ensuring unit‑dose integrity and tamper evidence.

- Cosmetics and household chemical manufacturers rely on liquid and paste fillers for shampoos, lotions, detergents, gels, and creams, where viscosity variation and foaming behaviour demand carefully selected pumps and piston systems.

Automation, Hygiene, and Data Tracking Features

Core lines integrate PLC‑based control with touch‑screen HMIs, recipe management, automatic fault detection, and I/O for upstream and downstream equipment, enabling synchronized, end‑to‑end automation. Hygienic design is supported by stainless steel frames, smooth product‑contact surfaces, and enclosed product paths that minimize contamination and simplify wash‑down. Advanced models can log production counts, alarms, and basic process data such as batch numbers and timestamped output totals for traceability and quality audits.

Types of Packaging Machines Offered

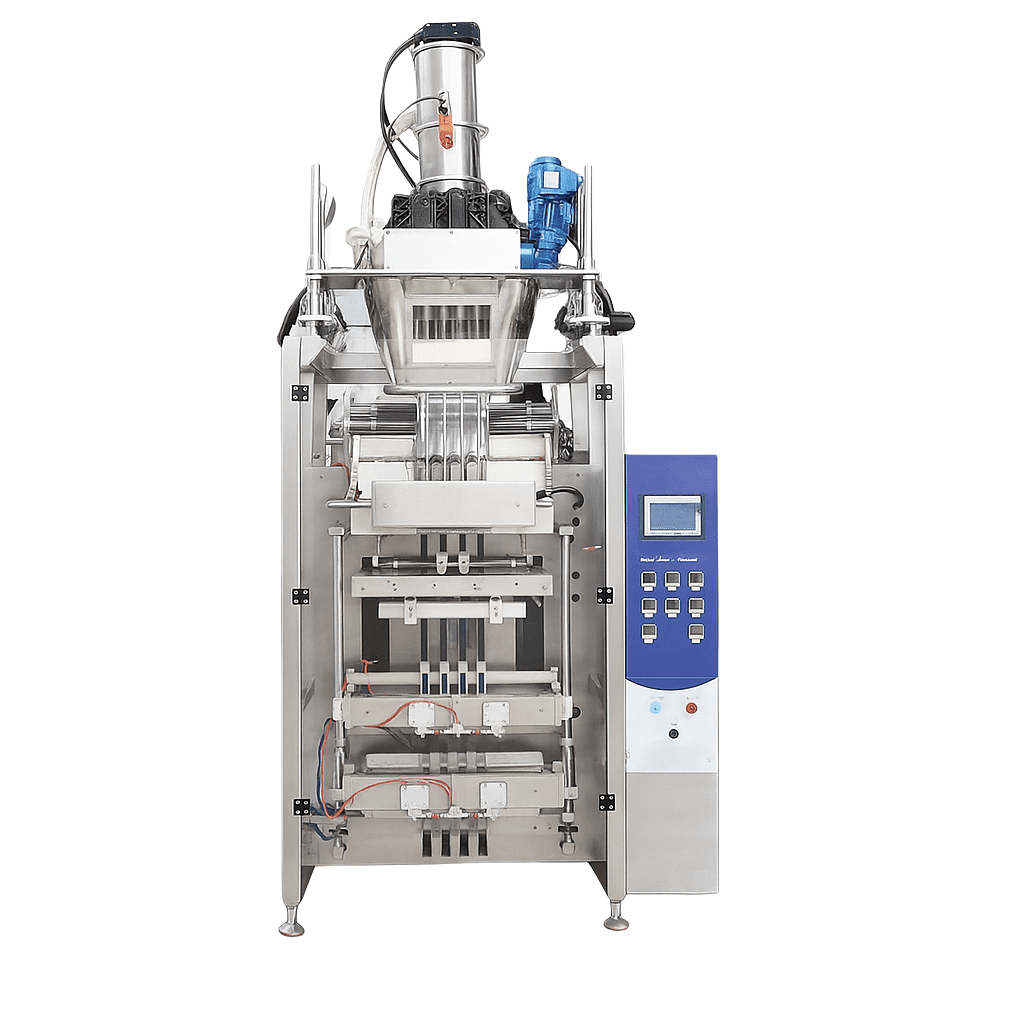

Powder Packing Machines

King Pack powder packing solutions combine powder filling, auger dosing with vertical form-fill-seal (VFFS) machines or multi‑lane sachet technology, providing high repeatability for low‑density and dusty products. Single‑lane systems pack 2–80 g into back‑seal or 3/4‑side‑seal sachets at around 30–60 bags per minute with accuracy typically within ±1%, which is critical for pharmaceuticals, nutraceuticals, and high‑value ingredients. Multi‑lane sachet machines add multiple parallel forming tubes and augers, multiplying lane count to deliver high‑volume stick packs or 4‑side‑sealed sachets for instant beverages, food powders, oral powders, sugar, and other single-portion products.

Liquid Packing Machines

Liquid packing equipment includes single‑lane and multi‑lane sachet machines for low‑viscosity liquids like water, juice concentrates, and pharmaceutical syrups, as well as thicker products such as honey or shampoo. Product is typically metered via different types of systems, including volumetric pumps, servo‑driven piston systems, and gear pumps. These maintain filling accuracy over a wide viscosity range and temperature window. For multi‑lane applications, each lane has independently controlled dosing so that 4–10 lanes can pack consistent stick‑packs or 4‑side sealed sachets in parallel, dramatically raising output per square meter of floor space.

Sauce Packaging Machines

High speed continuous packing machine for sauce – King Pack Machinery

Sauce packaging systems use piston filling machines to fill and pack stick packs and sachets. lobe pumps and auger fillers handle viscous applications like thick pastes and those containing particulates, such as ketchup with pulp, chili sauces with seeds, and ready‑to‑eat gravies with vegetable pieces. The piston filler’s controlled suction and discharge cycle enables accurate dosing even when the product exhibits shear‑thinning behaviour or non‑uniform particle distribution. These systems are typically combined with robust vaccum sealers, adjustable dwell times, and high sealing pressures to guarantee hermetic seals through any contamination from oil or particulates at the seal area. They are compatible with different composite plastic films.

Granule Packaging Machines

Granule packaging machines rely on combination (multi‑head) weighers or volumetric cup systems integrated above VFFS or premade pouch lines. Multihead weighers rapidly combine discrete weight values from several heads to achieve the target weight with minimal giveaway, ideal for nuts, snacks, candies, seeds, and pet foods. For uniform materials like rice, fertilizer prills, or plastic pellets, cup fillers provide high-speed volumetric dosing. They have simple mechanical adjustments. This balances cost and accuracy for industrial uses.

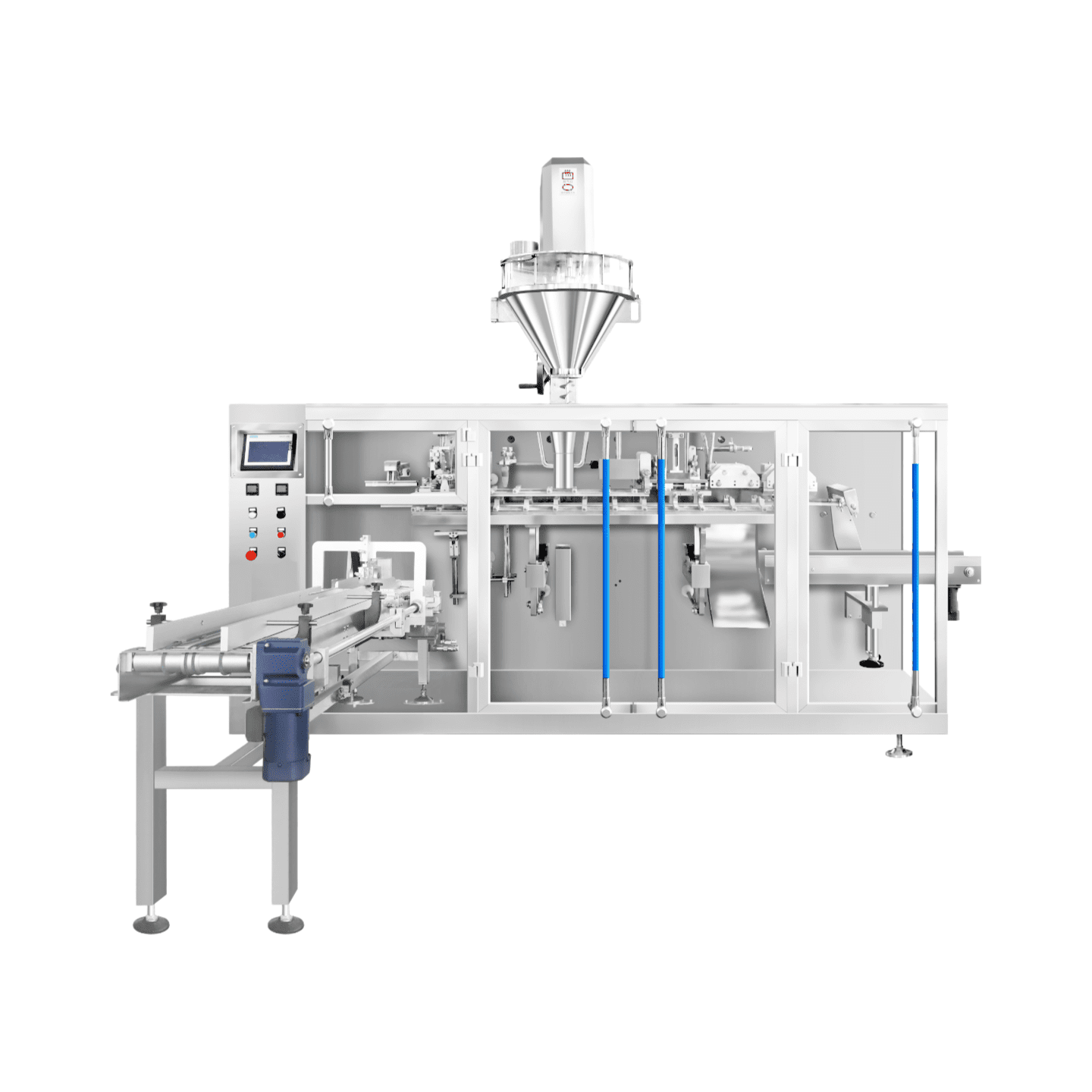

Premade Pouch Filling Machines

Pre-Made Pouch Bagging Machines handle stand‑up pouches, zipper pouches, corner‑spout bags, and shaped pouches that are formed off‑line, then picked, opened, filled, and sealed in an indexed rotary or linear system. These machines can be equipped with augers, piston fillers, pumps, or multi‑head weighers, allowing a single platform to run powders, liquids, sauces, and granules by changing only the dosing module and product recipe. Advanced pouch lines include automatic pouch presence detection, zipper opening devices, gas flushing if required, and reject stations for under‑weight, poorly opened, or unsealed pouches, improving line‑level quality control.

Food Packaging Machines For Containers

In addition to bag and pouch systems, King Pack offers packaging machinery systems that handles bottles, jars, and rigid containers within beverage and food filling lines. These systems can integrate filling, capping, labeling machines, and sometimes shrink wrapping, providing a continuous path from empty container infeed to finished retail‑ready pack discharge. Container systems are well-suited for oils, sauces, ready‑to‑drink beverages, spreads, and dry foods that require reclosable packaging for consumer convenience and extended shelf life.

Blister Packaging Machines

Blister packaging machines thermoform or cold‑form cavities and then seal them with lidding material such as aluminum foil or PVC‑based laminates. In pharmaceutical applications, these systems protect tablets and capsules from moisture, oxygen, and mechanical damage while delivering unit‑dose convenience and tamper evidence. For medical devices and consumer goods, custom‑shaped cavities and card sealing options allow visually appealing yet secure packs for syringes, medical consumables, and small hardware components.

Automated Horizontal and Vertical Cartoning Machines

Horizontal and vertical cartoning machines automatically form cartons from flat blanks, load primary packs such as blisters, bottles, or sachet bundles, and then close and code the cartons. Sometimes these systems include fully automatic packaging equipment, such as pick-and-place machines, which can be integrated with VFFS machines in the production lines. Horizontal cartoners are typically used for blisters, tubes, and small bottles, loading product from the side at high speeds, while vertical cartoners suit bags, sachets, and loose components dropped in from above. King Pack integrates printing, inspection, and rejection modules. This ensures each carton has the correct product and batch code. It also adds serialization marks when needed for pharmaceutical traceability rules.

Technical Advantages & Machine Features

Full process automation

Across machine types, automation extends from product feeding and dosing to bag or carton forming, sealing, cutting, coding, counting, and discharge, minimizing manual intervention. For example, a multi‑lane sachet system can unwind film, form multiple lanes, dose product, seal, cut, print batch codes, and accumulate sachets for cartoning in one continuous process. Premade pouch systems similarly perform pouch pick, open, fill, seal, and outfeed with synchronized stations controlled by a central PLC, reducing coordination issues that arise in piecemeal semi‑automatic setups.

Flexible Modular Structure & Fast Changeover

Mechanical and control modularity means dosing systems, forming sets, sealing jaws, and even infeed and outfeed options can be swapped or adjusted to accommodate different product SKUs and packaging formats. Recipe‑based control lets operators change parameters such as fill volume, sealing temperature, and cutting position from the HMI without manual re‑tuning, cutting changeover time. This production efficiency and flexibility allow producers with diverse product portfolios—like co‑packers and contract manufacturers—to run short batches economically and respond rapidly to market demands.

Hygienic Stainless Steel Construction

Most product‑contact parts and frames are fabricated from corrosion‑resistant stainless steel, typically grades similar to 304 or better, chosen for food and pharma compatibility. Smooth welds, minimal crevices, and accessible contact surfaces support effective dry cleaning and wet wash‑down while reducing microbial harborage points.

Smart PLC Control, Touch Screen Interface, Data Recording

Machines are driven by industrial PLCs linked to color touch‑screen interfaces that provide real‑time status, alarm diagnostics, and guided set‑up steps for operators. Parameter sets can be stored as recipes, and basic production data such as bag counts, shift totals, and reject statistics can be viewed or exported to supervisory systems. When integrated with upstream scales or downstream inspection and cartoning equipment, the control system coordinates machine start/stop, jam handling, and product tracking to stabilize the entire line.

Energy Efficient, High Throughput, Low Downtime

Servo‑driven axes, optimized sealing profiles, and efficient heating systems help reduce energy consumption per packed unit compared with older pneumatic or relay‑based machines. High‑speed multi‑lane and multi‑head systems raise production efficiency with effective throughput without proportionally increasing footprint or energy draw, which is critical in space‑constrained plants. Robust mechanical design and standard, easy-to-find parts lower unplanned downtime. They also make maintenance easier. This improves overall equipment effectiveness.

Packaging Machine Benefits for Businesses

Productivity Boost & Labor Reduction

Automated feeding, weighing, filling, and sealing dramatically cut manual handling, allowing one operator to supervise a machine that replaces several manual packing stations. Higher speeds and continuous operation speed up the production process, enabling manufacturers to meet volume targets or absorb seasonal demand peaks without proportionate increases in labour cost. Lower handling also improves ergonomic conditions, reducing repetitive tasks such as hand‑filling, manual sealing, and labeling.

Consistency & Accuracy in Packaging Output

Precision dosing technologies—augers, piston fillers, pumps, and multi‑head weighers—are designed to maintain fill volume or weight within tight tolerances across long production runs. Forming shoulders, sealing jaws, and cutting systems generate uniform pouch and carton dimensions, improving shelf presentation and palletization efficiency. Consistent seals and accurate cutting also reduce rework and scrap, directly impacting material yield and packaging cost per unit.

Traceability & Real-Time Monitoring

Integrated printers and code markers apply batch numbers, manufacturing dates, and, where required, serialized identifiers directly on pouches, blisters, or cartons. Reject mechanisms linked to sensors and vision systems allow out‑of‑spec packs to be removed automatically, supporting quality management and regulatory compliance. Real‑time display of counts, shifts, and alarm history provides a data trail that quality and maintenance teams can analyze to optimize performance and document production history.

Compliance with GMP, Food-Grade, and Pharma Standards

Stainless steel construction, cleanable designs, and controlled product paths help machines meet cGMP and food safety standards—FDA-compliant packaging solutions for hygiene and cross‑contamination control. For pharmaceutical use, blister and cartoning systems are designed to support validation, documentation, and the use of compliant materials and inspection devices. In food and cosmetics, adherence to food‑grade contact material standards and support for tamper‑evident structures align output with retailer and regulatory industry standards.

How to Choose the Right Packaging Machine

Match Machine Type with Product Forms & Characteristics

Selecting the correct machine begins with defining product state (powder, liquid, granule, paste), flow behavior, particle size, and required dose accuracy.

- Free‑flowing powders and granules pair well with augers or volumetric cups,

- Sticky powders and cohesive products may require specific auger geometries and agitation to prevent bridging.

- High‑viscosity liquids and sauces typically need piston or lobe‑pump systems

- Water-like liquids can be handled by gravity or gear pumps at higher speeds.

Evaluate Speed, Packaging Format, and Automation Needs

Target output per hour, packaging style (sachet, stick‑pack, premade pouch, bottle, blister, carton), and desired level of human intervention define whether a single‑lane, multi‑lane, or rotary system is appropriate.

- For high‑volume commodity products, multi‑lane or multi‑head‑weigher VFFS configurations generally deliver the best balance of output and footprint,

- Lower-volume, premium products may favour flexible premade pouch or cartoning solutions.

- Required integration with upstream mixing, feeding, or downstream case‑packing and palletizing also influences whether a standalone machine or fully integrated line is optimal.

Decide Between Standalone Units or Turn-Key Solutions

There are two types of systems; you may need to decide which one will be best for your business:

- Standalone machines are suitable when existing manual or semi‑automatic operations only need to automate one step, such as filling or primary sealing, without full line redesign.

- Turnkey solutions combine feeding, weighing, primary packaging, secondary packaging, and sometimes palletizing into a unified project, reducing interface risks and simplifying commissioning. For greenfield plants or large upgrades, turnkey lines from a single supplier streamline validation, operator training, and long‑term service coordination.

Assess After-Sales Service, Maintenance, and Training

When choosing equipment, attention should be given to the availability of spare parts, the responsiveness of technical support, and the clarity of maintenance documentation. Machines built from standard industrial components allow local sourcing of wear parts like belts, bearings, and sensors, shortening downtime in the event of failures. Structured operator and maintenance training, combined with clear HMIs and diagnostic functions, helps plants reach design speeds quickly and maintain stable long‑term performance.

Conclusion

King Pack offers a wide, modular packaging portfolio. It helps manufacturers in the food, pharmaceutical, cosmetic, and chemical sectors build scalable lines. These lines improve efficiency, protect products, and meet regulations from sachet to carton. By aligning machine type, speed, and automation level with specific product and business requirements, plants can realize higher throughput, tighter quality control, and lower per‑unit cost.

Contact King Pack today to get your customized packaging machine solution and quotation.