Modern shampoo packaging demands more than manual accuracy. It needs automation that works fast without errors. King Pack’s liquid filling lines do exactly that.

Built for high-viscosity and foamy products, they fill, cap, and label bottles with precision. Each system keeps production smooth, reduces labor, and meets hygiene standards in the cosmetic filling equipment industry.

In this article, we’ll explain how King Pack’s shampoo filling systems support large and small manufacturers in building efficient, hygienic packaging lines.

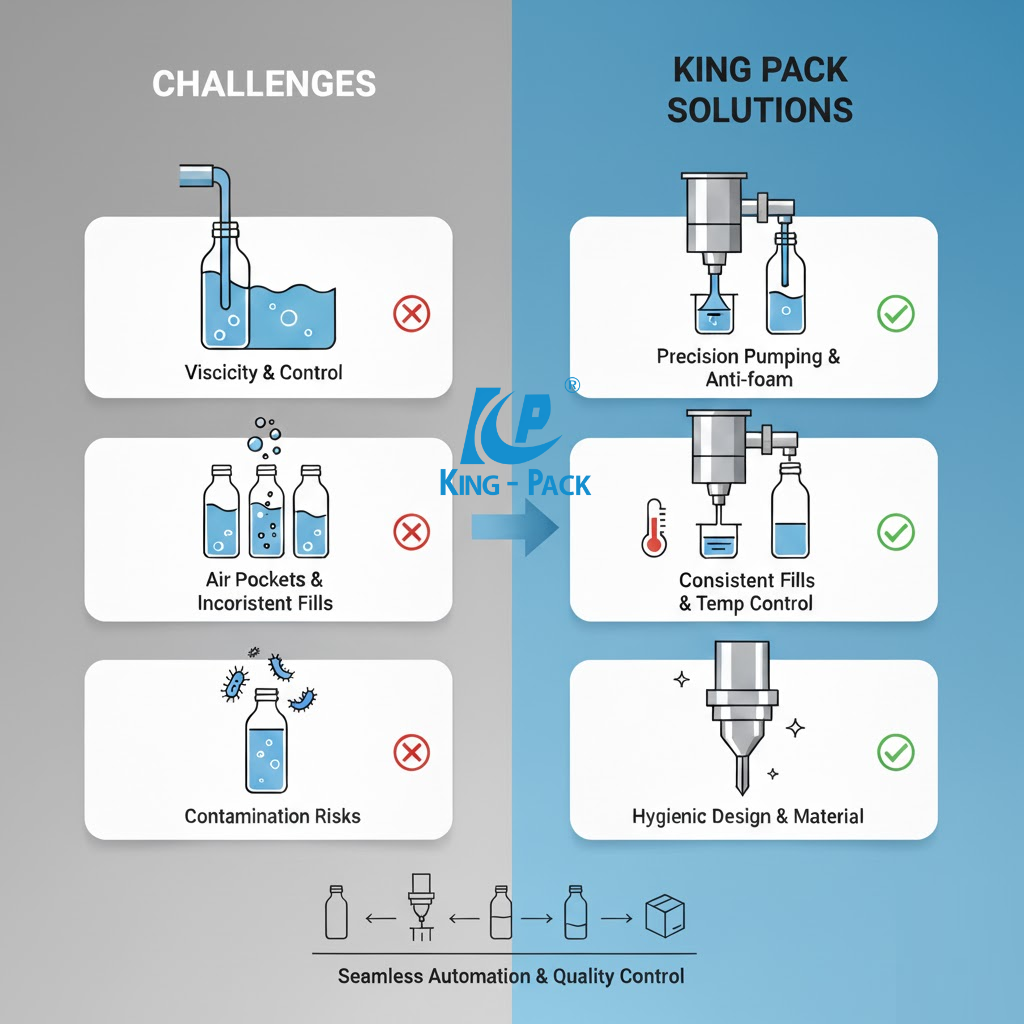

Challenges & Objectives in Shampoo Filling

Shampoo is thick and foamy, which makes it hard to fill accurately. Regular fillers struggle to move viscous liquids through the system, often creating air pockets and uneven fills.

King Pack’s shampoo filling machines solve this with anti-foam technology and smooth flow control. Piston and peristaltic pumps handle the heavy texture with precision, keeping fill levels consistent. The system also manages temperature to maintain the right viscosity, preventing flow issues during production.

Hygiene is another key factor in shampoo filling. Contaminated equipment can affect product safety and shorten shelf life. That’s why, King Pack builds all contact parts from pharmaceutical-grade stainless steel, which prevents residue buildup and simplifies cleaning.

Each filling nozzle seals tightly and fills from the bottom up, minimizing splashes and air exposure. The system also integrates automatic capping and sealing units that secure every bottle, protecting product quality during transport and storage.

Recommended Reading: Liquid Shampoo Sachet Packaging Machines Guide: Working, Types, and Buying Tips – King Pack Machinery

Core Modules of the Shampoo Filling Line

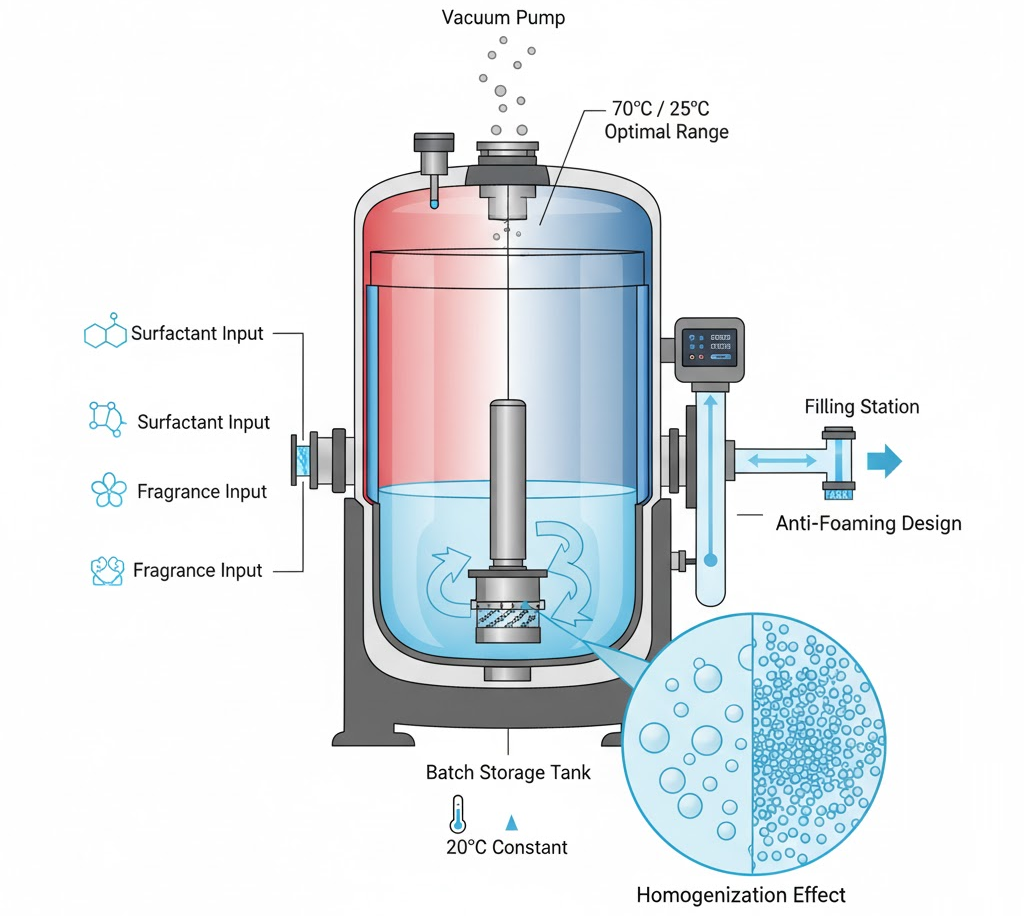

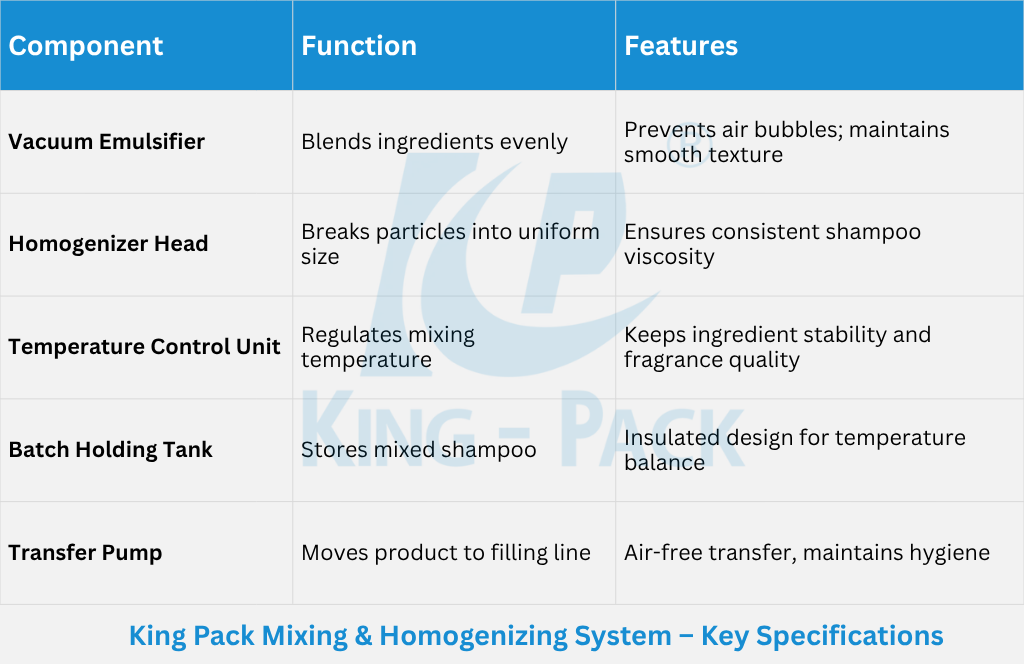

Mixing & Homogenizing (Product Preparation)

Product preparation is the foundation of a stable and high-quality shampoo filling process. Each batch must be uniform, free from bubbles, and maintain the right texture and viscosity.

King Pack’s vacuum emulsifier machines handle this step with precision. The vacuum chamber prevents unwanted air from mixing into the product, which helps maintain a smooth and creamy consistency.

During homogenization, the machine reduces particle sizes to create a fine and even mixture. This process enhances product stability and gives shampoo its premium texture. Temperature regulation throughout mixing ensures that ingredients like surfactants and fragrances remain balanced and effective.

Once the mixture is ready, batch tanks store it at the optimal temperature before transfer. Specially designed pumps move the shampoo to the filling station without introducing air or causing foaming. Every contact point in the system meets hygienic design standards, keeping the entire line clean and contamination-free.

King Pack’s integrated mixing and homogenizing system prepares shampoo efficiently for the next stage, ensuring every bottle starts with a perfectly blended formula.

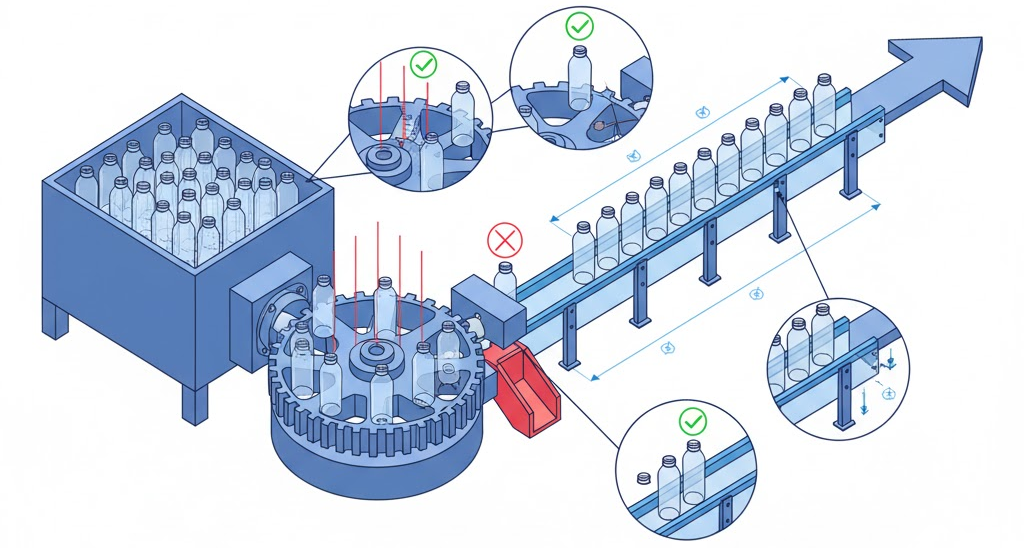

Bottle Sorting and Feeding

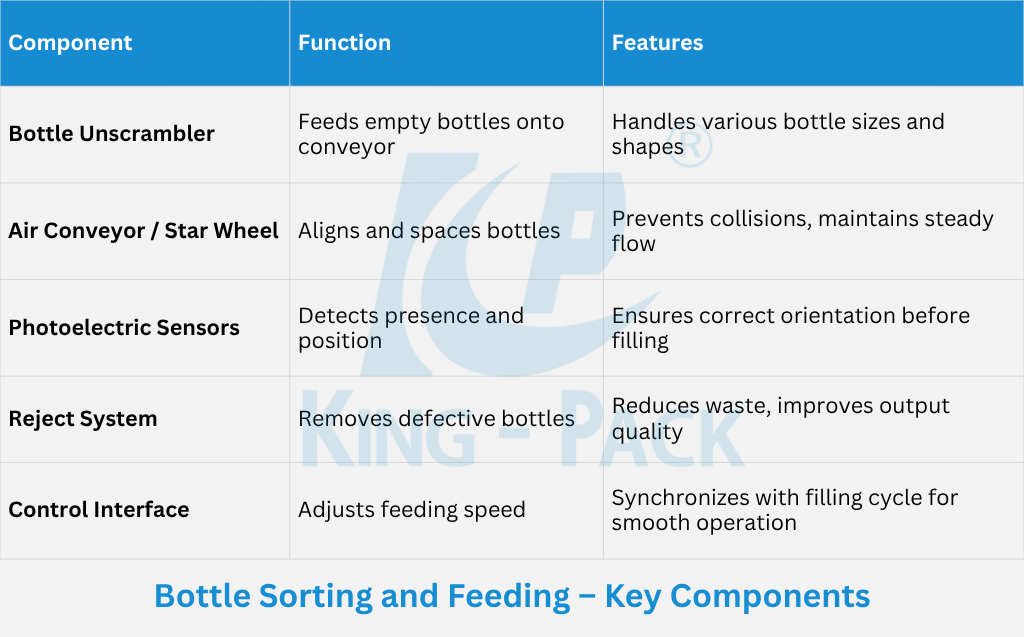

A smooth filling process starts with efficient bottle handling. King Pack’s automatic bottle sorting and feeding systems align empty bottles accurately before filling. Each bottle passes through detection sensors that check its position, size, and orientation. This prevents jams and ensures the system only handles bottles ready for filling.

Star wheels or air conveyors guide bottles into single-file order, keeping the flow consistent with the filling cycle rate. Proper spacing reduces contact between bottles and prevents spills or scratches.

Damaged or misaligned bottles are automatically rejected to maintain high-quality standards. This early inspection step minimizes waste and protects downstream equipment.

The entire bottle feeding section connects seamlessly with other modules like capping and labeling. Operators can easily monitor bottle flow and adjust speeds using the control panel, keeping production stable and continuous.

Precision Filling System (Piston / Peristaltic Type)

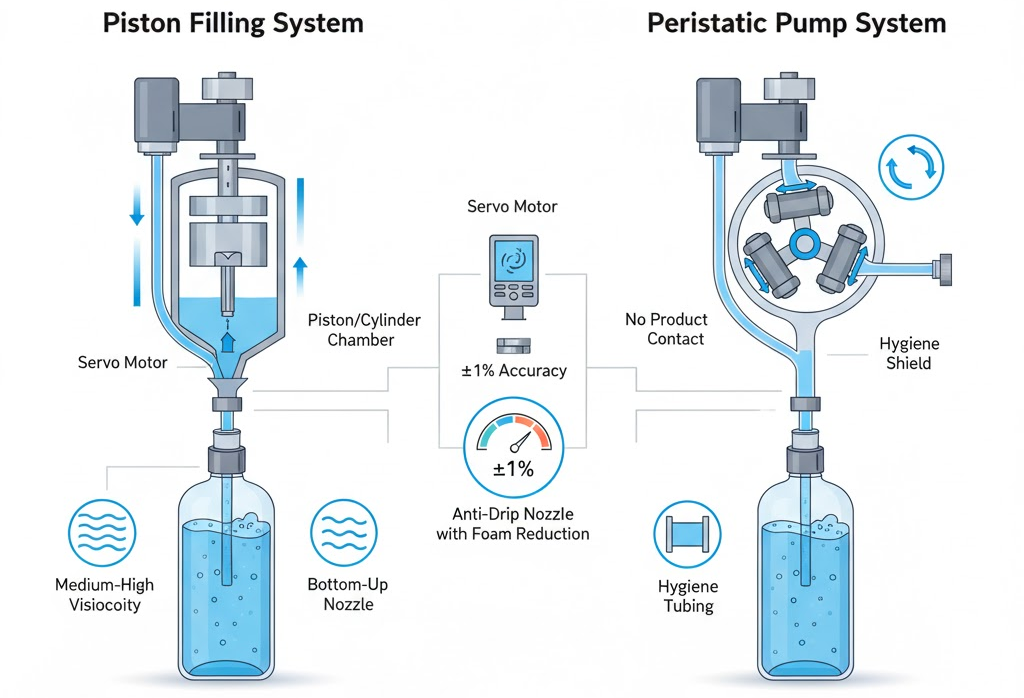

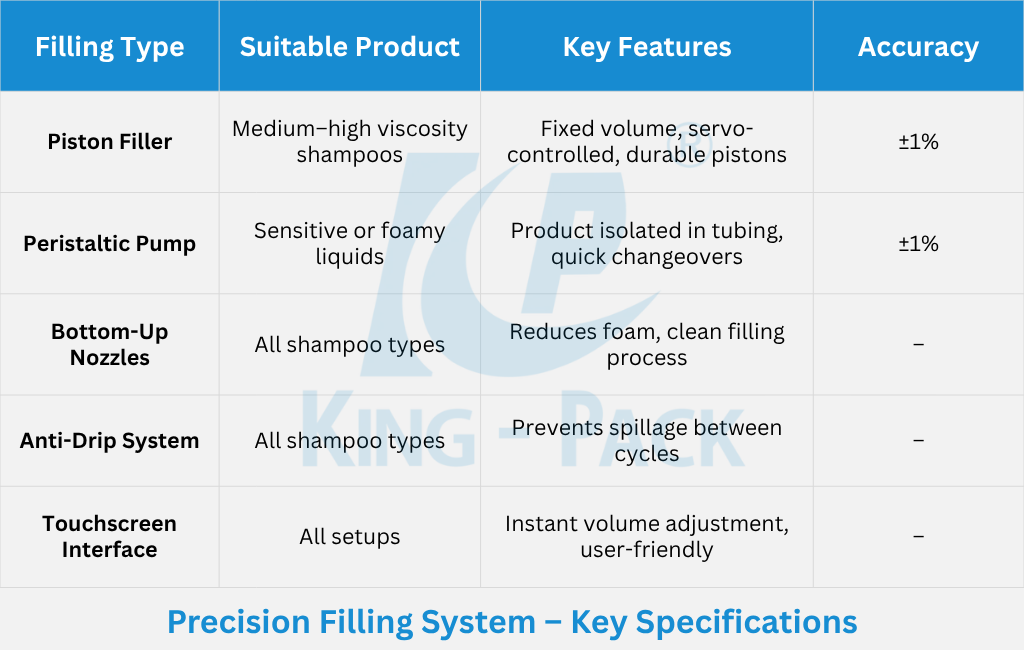

King Pack’s filling systems are designed for precision and adaptability. The piston filler handles medium to high viscosity products like shampoo, conditioner, and body wash. Each piston stroke dispenses a fixed amount of liquid, providing stable fill volumes even at high speeds.

For products that need higher hygiene levels or frequent formula changes, the peristaltic pump is ideal. It moves shampoo through flexible tubing that never comes into contact with pump components. This design reduces contamination risk and simplifies cleaning during product changeovers.

Servo motors control every filling head, and operators can fine-tune fill volumes through a touchscreen interface. Bottom-up filling helps minimize foam, while anti-drip nozzles keep the workspace clean. Fill accuracy remains consistent at ±1%, even during long production runs.

Together, these systems form the core of King Pack’s automatic bottle filling machine, ensuring every shampoo bottle is filled cleanly, accurately, and efficiently.

Capping and Sealing (Pump / Screw / Flip Cap)

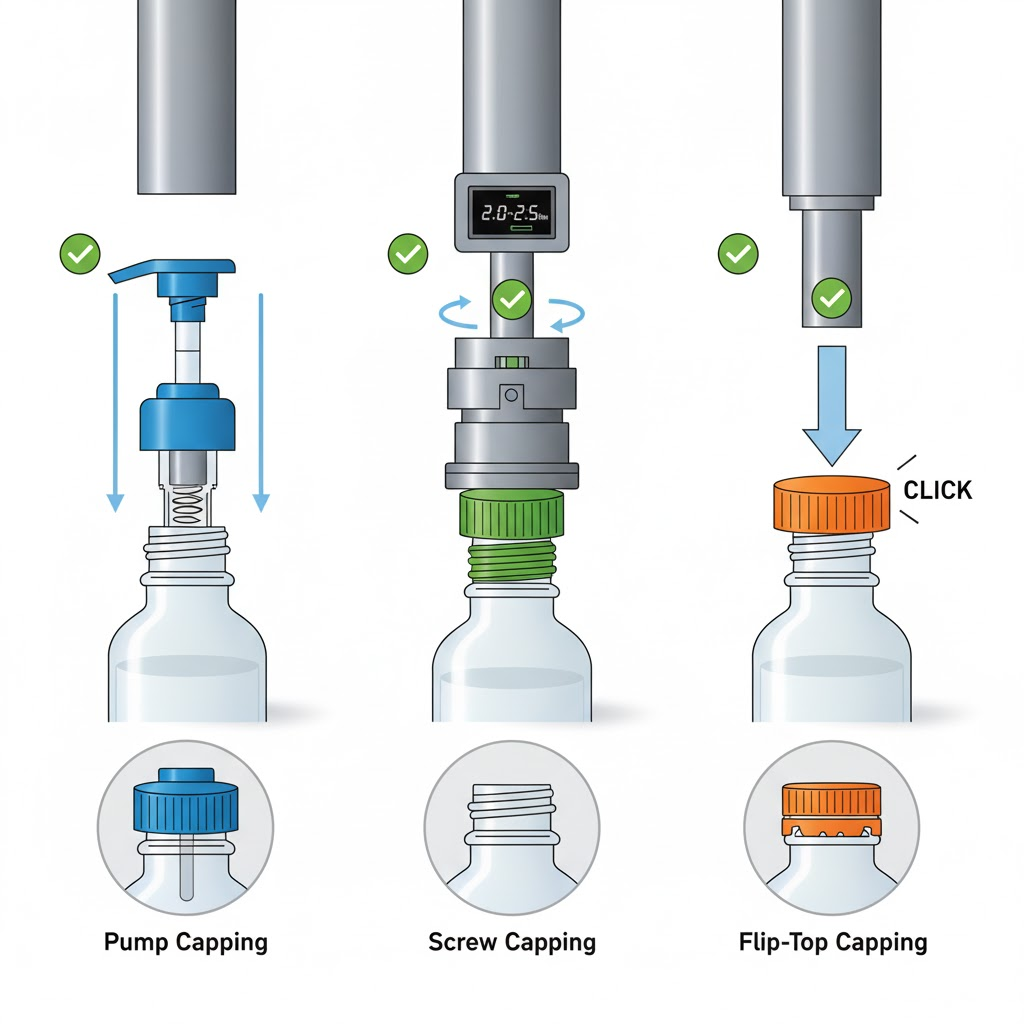

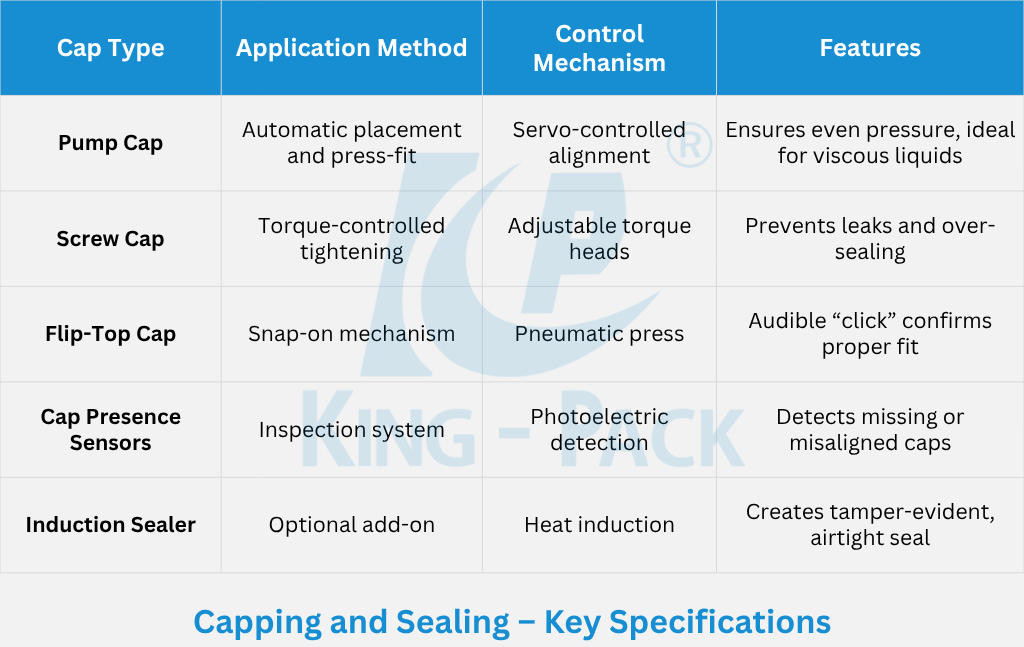

Capping is the final step in sealing product integrity before labeling. King Pack’s bottle filling and capping line integrates capping immediately after the filling stage, reducing product exposure to the environment. The system accommodates multiple closure types — from pump and screw caps to flip-top designs — all on one flexible platform.

Each cap type requires specific handling precision. Pump caps demand alignment with the bottle neck and controlled insertion pressure. Screw caps are tightened with adjustable torque control to prevent leaks or over-tightening. Flip-top caps are pressed into place until a secure “click” confirms proper sealing.

Advanced sensors verify that every bottle is capped correctly. Bottles missing caps or with tilted closures are automatically removed from the line. For enhanced product protection, induction sealers can be added to apply tamper-evident foil seals. These features protect product freshness during transport and storage.

This integrated system combines speed, accuracy, and hygiene. It helps cosmetic and personal care producers maintain consistent quality across large-scale shampoo packaging lines.

Recommended Reading: Fragrance Filling Machine Handbook: How it Works, Types, and Buying Guides – King Pack Machinery

Labelling and Coding (Traceability and Branding)

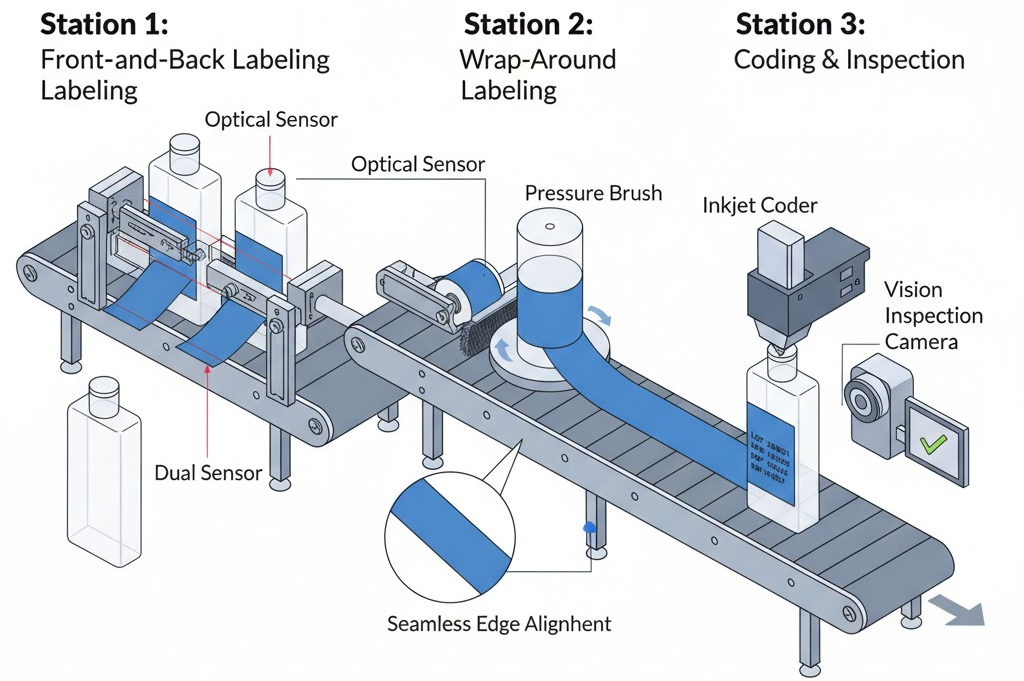

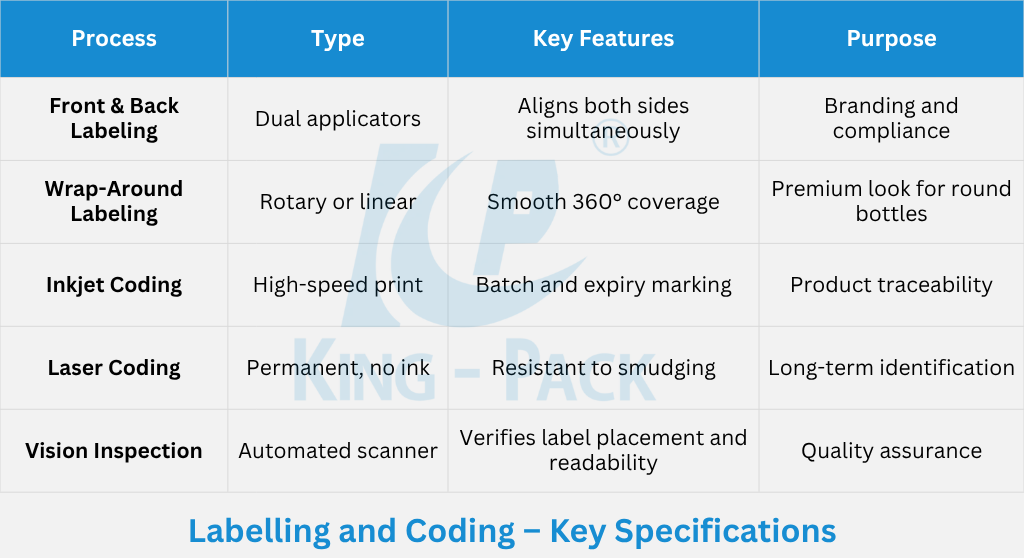

Once bottles are sealed, they move to the labeling and coding section — a critical stage for both branding and compliance. King Pack’s personal care packaging solutions feature high-speed labeling systems that apply front, back, or wrap-around labels with precision. The machines can handle flat, round, or irregular bottle shapes without adjustment delays.

Front-and-back labelers align stickers accurately using optical sensors. Wrap-around systems fully encase cylindrical bottles, producing a seamless, professional look. Each label adheres smoothly, with mechanisms designed to eliminate wrinkles and air bubbles.

For identification and tracking, inkjet or laser coders print batch numbers, manufacturing dates, and expiration details. These systems provide complete traceability throughout production and distribution. Automated vision inspection verifies label position and code clarity before bottles leave the conveyor, ensuring that every product meets regulatory and brand standards.

By combining accurate labeling and reliable coding, King Pack’s systems deliver clean presentation and full traceability — essential for high-volume shampoo and cosmetic filling lines.

Recommended Reading: What Is a Planetary Mixer? – King Pack Machinery

Advanced Line & System Solutions

Integrated Turnkey Shampoo Filling Lines

King Pack specializes in complete solutions. Our shampoo production line includes everything from mixing to palletizing. Each component integrates seamlessly with others.

Turnkey systems arrive pre-configured and tested. Installation time drops dramatically compared to assembling separate machines. Manufacturers start production faster.

Single-source responsibility simplifies support. One supplier handles all equipment questions and service needs. This eliminates finger-pointing between multiple vendors.

Flexible Configurations for Various Bottle Sizes

Modern hair care filling machines handle multiple container formats. Quick-change parts let operators switch between sizes in minutes. No tools required for basic adjustments.

King Pack systems accommodate bottles from 30ml to 1000ml. Height, diameter, and shape variations pose no problems. The same line produces travel sizes and salon bulk containers.

Recipe storage remembers settings for each product. Operators select the desired SKU from a menu. The machine automatically adjusts fill volumes, speeds, and cap torque specifications.

Automation, Servo Control, and Smart Operation

Servo motors control every critical function. Fill volumes stay precise regardless of product viscosity changes. Speed adjustments maintain smooth operation across production rates.

Smart sensors monitor line performance continuously. Data collection tracks output rates, reject counts, and downtime causes. Manufacturers gain insights for continuous improvement.

Remote monitoring allows off-site troubleshooting. King Pack’s support team can diagnose issues without site visits. This minimizes disruption to production schedules.

Supporting Systems & Material Handling

Conveying and Buffering Systems

Conveyors move bottles between processing stations. King Pack’s King Pack filling systems include properly sized conveying. Speed matching prevents bottlenecks.

Buffer zones accumulate product between machines. If one station slows briefly, buffers prevent line-wide stoppages. This maximizes overall equipment effectiveness.

Accumulation tables provide space for line operators. Manual inspection or minor adjustments happen without disrupting flow. Pressure-less accumulation prevents bottle damage.

Bottle Feeding and Outfeed Integration

Bottle unscrambling systems orient containers from bulk. Vibratory bowls or centrifugal feeders sort and align empties. Output matches filling line speed requirements.

Outfeed conveyors carry finished products to secondary packaging. Height and speed match downstream equipment. Smooth transitions prevent product damage.

Collection tables accumulate bottles for batch processing. Manual packing or automated case loading happens efficiently. King Pack designs these interfaces carefully.

Compatibility with Cartoning and End-of-Line Systems

Complete packaging requires multiple stages. King Pack’s automatic bottle filling machine connects with cartoning equipment. Filled bottles flow directly to carton loading.

Case packers bundle multiple units for distribution. Palletizers stack cases for warehouse storage. The entire system operates as one coordinated process.

Control system integration allows centralized monitoring. One operator oversees filling through palletizing. Alarm systems identify issues immediately.

Hygienic Design & Quality Control

Stainless-Steel Construction and Sanitary Design

All surfaces that touch the product are made with 316L stainless steel contact parts. This material handles corrosive ingredients found in shampoos, hair care products, and other viscous pastes without wearing down. Polished finishes help prevent bacteria from sticking, keeping your facility clean and safe. By design, there are no hidden corners or dead spaces where product could build up, which makes cleaning easier and prevents contamination.

Sloped surfaces and integrated liquid recovery trays allow every drop to drain completely. Using FDA-compliant, food-grade materials means your products meet international industry standards. Documentation for material grades and certifications makes audits simple. For manufacturers in the personal care industries, this helps maintain a hygienic environment while minimizing product waste.

CIP/SIP Cleaning and Maintenance Accessibility

Clean-in-place systems handle the sanitation automatically. Solutions circulate through all filling nozzles and dosing systems, so you don’t have to take machines apart between runs. Sterilize-in-place features use steam to give a deeper clean, meeting pharmaceutical-level standards when required.

Quick-disconnect fittings and user-friendly controls make maintenance faster. Technicians can reach critical parts easily, and preventive maintenance takes less time. Even with automatic filling machines running multiple products, downtime is minimal, keeping your operations smooth and efficient.

Inspection, Leak Detection, and Quality Assurance

Digital control systems with Touch Screens make monitoring the process straightforward. Vision systems inspect every bottle for fill volume, cap placement, and labeling stickers. Any defects are flagged immediately, preventing mistakes from reaching customers.

Leak tests use vacuum or pressurized tanks, catching even tiny seal failures. Filling volume control and check-weighing ensure precise and consistent fills. Statistical process control keeps an eye on trends, so operators can fix issues before they affect production. Overall, these systems maintain high filling efficiency and precision, keeping your packaging processes reliable.

Choosing King Pack for Your Shampoo Line

High Accuracy for Viscous and Foamy Liquids

King Pack’s expertise with difficult products shows in every detail. Our high viscosity filling technology handles thick shampoos effortlessly. Foam control features maintain accuracy despite challenging formulations.

Years of experience with personal care products inform design decisions. Engineers understand the specific challenges manufacturers face. Solutions work reliably in real production environments.

Our testing facilities also allow trials with your actual products. See performance before committing to purchase. Make informed decisions based on demonstrated results.

GMP-Compliant Design and Global Certifications

Good Manufacturing Practice compliance comes standard. King Pack equipment meets pharmaceutical industry requirements. This opens doors to regulated markets worldwide.

CE certification proves European safety standards. ISO quality management demonstrates consistent processes. Documentation packages satisfy import requirements globally.

Validation support helps customers qualify equipment. Installation qualification and operational qualification protocols come standard. Performance qualification assistance accelerates production startup.

Recommended Reading: World Top 10 Vial Filling Machine Manufacturers – King Pack Global Pharma Solutions – King Pack Machinery

Customization, Service, and Long-Term Support

Every production line has unique requirements. King Pack customizes solutions to match specific needs. Bottle sizes, production speeds, and floor space all factor into designs.

Installation and commissioning services get lines running quickly. Experienced technicians handle setup and operator training. Production starts on schedule.

Long-term parts availability keeps lines operating. King Pack maintains spare parts inventory for discontinued models. Customers avoid costly production interruptions.

Technical support responds within 24 hours. English-speaking teams understand customer challenges. Remote assistance resolves many issues immediately.

Conclusion

King Pack delivers complete shampoo filling and packaging solutions. Our equipment supports a wide range of viscosities and container types, ensuring smooth handling for everything from thin formulations to thick, creamy shampoos. Each line is designed to maintain consistent fill accuracy, reduce waste, and optimize throughput.

If you’re ready to improve your shampoo production line or build a new one from scratch, our team can guide you through machine selection, setup, and integration.

Contact King Pack today to explore our shampoo filling and packaging solutions that boost productivity, protect quality, and strengthen your brand’s efficiency.