The biotech and pharmaceutical industries process billions of syringes yearly, driven by the demand for precise drug delivery, sterility, and high-speed production. Prefilled syringe filling machines automate filling syringes with exact drug amounts, eliminating human dosing errors and ensuring sterility. These machines ease the filling process with high-speed filling lines for businesses of all sizes, speeding up production and boosting efficiency. Let’s explore these important machines in detail.

Definition & Industrial Relevance

A prefilled syringe filling machine is advanced pharmaceutical equipment. It automates filling accuracy and drug packaging into ready-to-use injection devices. They integrated various mechanical systems that handle multiple production stages simultaneously, from automated aseptic loading, filling systems, to stoppering, and sealing systems.

The pre-filled syringe filling machinery possesses precision dosing pumps, computer-controlled servo systems, stoppering units, and vision inspection systems. These various systems in a single machine ensure the precision, accuracy, and consistency across the production of bulk syringe batches. Production speeds range from hundreds to thousands of units per hour, depending on system configuration. High-speed filling lines can process over 18,000 syringes hourly while maintaining pharmaceutical quality standards. Mid-scale systems are best for batch filling operations, processing between 6,001 and 18,000 units per hour.

Industry Relevance and Market Impact

Based on market research insights, the global prefilled syringe industry represents a substantial pharmaceutical sector valued at $9.59 billion in 2025. This market demonstrates strong growth momentum, expanding from $8.70 billion in 2024 to the current valuation. Industry projections indicate continued expansion, with the sector expected to reach $20.62 billion by 2032.

The market size reflects widespread adoption of prefilled syringe technology across multiple therapeutic areas. Data shows the industry maintaining an annual growth rate of 10.8% through the forecast period. This growth trajectory positions prefilled syringes as one of the fastest-expanding segments within pharmaceutical packaging and drug delivery systems.

Core Components & Technical Features

Prefilled syringe filling machines use several key systems. Each component performs specific tasks. These machines can accommodate both glass syringes and plastic syringes. They can process nested syringes, vials, and bulk syringes easily. Let’s analyze all the core components and technical features of pre-filled syringe Filling Machinery.

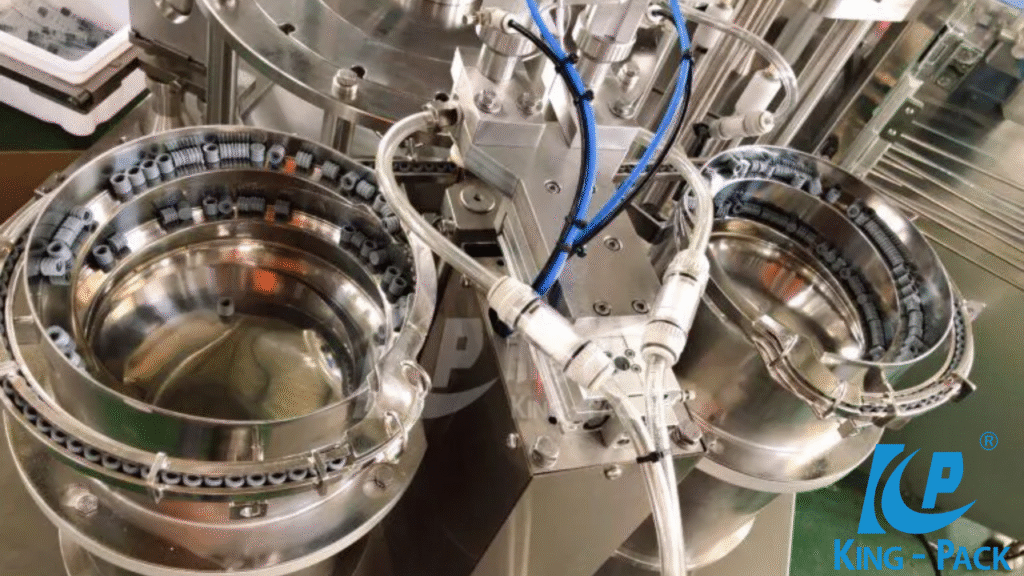

- Feeding and De-nesting Systems: The pre-filled syringe filling machinery uses a rotary mechanism to move syringes from storage into filling areas. Tray systems handle syringes in honeycomb arrangements. Robotic arms offer flexibility for different syringe types. These systems work automatically. They maintain sterile conditions throughout the filling and stoppering operation.

- Filling Station Technology: Multi-needle heads fill several syringes at once. Piston pumps provide high filling accuracy with quantitative filling. Peristaltic pumps handle sensitive products without contact. Therefore, liquid filling stays precise. Additionally, speeds reach thousands per hour.

- Stoppering and Sealing Units: Vacuum systems include a vacuum pump and a vacuum stopper. After the syringes are filled, they are sealed with the stoppers. The vacuum pump prevents air bubbles during stopper insertion. Force controls ensure proper vacuum stopper placement. Sealing stations complete syringe assembly automatically. Consequently, each syringe gets proper closure while the sterility remains intact.

- Sterility Maintenance: Clean rooms meet ISO 5 standards for particle control. CIP systems clean equipment between batches. SIP processes are sterilized using steam. So, contamination risks stay minimal. The machines improve regulatory compliance.

- Handling and Orientation Systems: Grippers hold syringes securely without damage during the entire syringe filling process. Aligners position components correctly. Vision systems check orientation and quality. As a result, handling stays gentle. The machines keep positioning accurately.

- Control and Recipe Management: PLC controls coordinate all machine functions. Recipe software enables quick product changes. Monitoring systems track performance continuously. Hence, operations stay consistent. Changeovers become faster.

- In-line Inspection Systems: Weight checks verify fill volumes accurately. In-process control (IPC) improves filling quality at weight checking and inline inspection of syringes. Camera systems detect defects and particles. Rejection units automatically remove faulty syringes. Therefore, quality stays high. Furthermore, manual checking decreases significantly.

Applications in Pharma & Biotech

In the biotech and pharmaceutical industry, these filling and closing machines are of keen importance. They work with liquid medicine filling and many other drug types.

Prefilled syringe filling machines have many uses. Their application includes:

- Vaccines – Machines fill flu shots, COVID vaccines, and childhood immunizations quickly. Sterile conditions keep vaccines safe during production.

- Biologics – Insulin, antibodies, and hormone drugs need gentle handling. Precise dosing prevents waste of expensive medicines.

- Emergency drugs – Epinephrine auto-injectors and overdose treatments require exact amounts. Life-saving accuracy matters most.

- Injectable medications – Pain drugs, antibiotics, and hospital preparations benefit from automated filling.

These machines offer high efficiency, processing up to 36,000 units per hour with full automation that fills and stopper syringes with ±1% accuracy. This reduces waste from 20-25% overfill to under 2%, greatly improving liquid filling efficiency and lowering defects compared to manual vial filling.

Advantages of Prefilled Syringe Filling Machines

Modern filling machines offer many benefits in pharmaceutical manufacturing. These systems improve operations while ensuring patient safety and product quality.

Improved Patient Safety and Dosing Accuracy

Precise dosing eliminates measurement errors during drug administration. Automated systems deliver exact medication volumes within ±1% accuracy. Furthermore, pre-measured doses prevent dangerous overdosing or underdosing situations. Additionally, consistent fill volumes ensure reliable therapeutic outcomes for patients.

Reduced Contamination and Operator Risk

Sterile processing occurs within enclosed systems using ISO 5 clean environments. Aseptic filling stops microbial contamination during production. Moreover, automated handling eliminates human contact with drug products. Consequently, infection risks decrease while product integrity improves.

Lower Drug Overfill and Waste

With these machines, the syringe filling process is improved as the filling range can be defined. This results in Minimal overfill requirements dropping from 20-25% to under 2% compared to vials. Precise filling reduces medication waste significantly. Furthermore, exact dosing prevents valuable drug loss during production. Improved efficiency also lowers manufacturing costs a lot.

High Throughput and Consistent Quality Control

Fast production reaches up to 36,000 syringes per hour with multi-needle systems. Automated operations maintain consistent quality across extended runs. Moreover, in-line inspection verifies every unit before packaging. Therefore, defect rates drop while production speeds increase dramatically.

Key Considerations for Design & Procurement

Now that you have the idea of the Pre-Filled Syringe Filling & Stoppering Machine in detail, there are some considerations you must consider. So, when you are in the market for a new machine for your business, you must assess your needs and your customer demand. At the same time, it’s also good to consider your future plans and the growth of your business.

Here are some important yet effective considerations to choose the right filling systems to make an informed decision.

Cleanroom integration:

Isolator systems provide complete environmental separation with built-in HEPA filtration. These enclosed units maintain ISO 5 air quality while protecting products from contamination. RABS technology offers restricted access with glove operation capabilities. Furthermore, double-bag transfer systems enable sterile material entry using H₂O₂ decontamination. No-touch transfer chambers eliminate human contact during syringe handling. Additionally, proper cleanroom zoning requires A-grade areas for filling operations. Moreover, personnel flow patterns must minimize contamination risks throughout production areas.

Cleanability & Sterilization

Smooth surface finishes with polished welds eliminate bacterial harboring sites. All product-contact surfaces use 316L stainless steel for chemical compatibility. CIP systems circulate cleaning solutions through all fluid pathways automatically. Similarly, SIP processes employ superheated steam for terminal sterilization between batches. Furthermore, drainable designs prevent liquid retention in dead spaces. Compatible elastomers and gaskets withstand repeated sterilization cycles. Modular construction lets you take apart equipment completely for thorough cleaning checks.

Format Flexibility

Quick changeover features enable rapid switching between different syringe sizes. Adjustable guide rails accommodate various container formats without extensive retooling. Modular designs let you change the setup for different production needs. Interchangeable filling heads can handle many needle types efficiently. Recipe-driven controls save settings for different products automatically. Tool-free adjustments reduce changeover times a lot. Consequently, standardized components simplify spare parts management across production lines.

Advanced Control Systems With Recipe Memory and Compliance

Recipe memory stores filling parameters for different products automatically. Electronic systems maintain audit trails documenting all production activities. MES connectivity links with manufacturing execution systems. This allows real-time monitoring. Furthermore, 21 CFR Part 11 compliance ensures electronic record integrity. Moreover, user access controls restrict system modifications to authorized personnel. Electronic batch records remove the need for paper documents. Data backup systems protect critical production information all the time.

Containment for Potent Drugs

Closed isolator systems provide complete operator protection during potent compound handling. Negative-pressure environments keep hazardous materials inside processing areas. OEB classification determines appropriate containment levels based on drug toxicity. Filtered exhaust systems stop pollution from spreading. Moreover, emergency procedures ensure safe shutdown during containment breaches. Decontamination protocols keep the work area safe. Consequently, personnel monitoring verifies that exposure limits remain within acceptable ranges.

Maintenance & Vendor Support

Preventive maintenance programs ensure consistent equipment performance. A comprehensive spare parts inventory minimizes production downtime. Remote diagnostics enable proactive troubleshooting before equipment failures occur. Furthermore, technical support provides a rapid response to operational issues. Moreover, training programs maintain operator competency on complex systems. Service contracts ensure the equipment stays reliable for a long time. Therefore, performance monitoring tracks equipment efficiency trends over time.

Conclusion

To conclude, you must have understood these syringe filling machines in detail. In many industries, especially the pharmaceutical and biotech industries, they are very useful in various filling applications. These automated syringe filling machines deliver precision, safety, and efficiency across drug production. They enable manufacturers to meet growing global demand for ready-to-use injectable medications. The technology transforms traditional vial-based processes and reduces medication errors compared to manual methods.

Partner with KING PACK for Advanced Solutions

Transform your pharmaceutical production with KING PACK’s pre-filled syringe filling machines. Our systems combine German engineering with innovative automation technology. We provide validated solutions that meet international standards. These solutions also maximize operational efficiency. Contact our specialists today to discover how KING PACK can elevate your manufacturing capabilities.